Home / Gas boilers

Back

Published: March 25, 2020

Reading time: 8 min

0

1794

The Bear boiler is produced by the Slovak company Protherm. There are about 100 different gas boilers of this modification on the Russian market.

The most popular is the Proterm Medved floor-standing gas boiler, operating in the “Winter-Summer” mode. A unique feature of the brand is the developed Protherm service network - more than one and a half thousand service centers located not only in the Czech Republic and Slovakia, but also in Russia and many CIS countries

- 1 Who is the manufacturer

- 2 Varieties of Bear boiler models

- 3 Distinctive features

- 4 Technical characteristics Bear 40 KLOM

- 5 Installation features

- 6 Reviews of Protherm Bear

- 7 Error and fault codes

- 8 Maintenance of the Proterm Medved boiler

Who is the manufacturer

The international company Protherm was founded in 1991 in the Czech Republic. The initial production line was located at a plant in Prague and specialized in the production of electric boilers.

Proterm produce quite a few modifications of boilers

The high popularity of the products forced the company's management to increase production, so the company moved its workshops to the Slovak city of Skalica.

The rapid growth of production led to the fact that by 1993 the Medved concern occupied 65% of the market for electric heating boilers in Eastern Europe.

A year later, Proterm begins production of boiler units operating on liquid fuel and using two types of gas: liquefied and main gas. In 1997, the company acquired the European quality certificate ISO 9001 and began exporting boiler equipment to England and Germany.

At the same time, the company is launching a production line for the production of solid fuel and condensing boilers, as well as boilers for heating and storing hot water. In 2013, Protherm began manufacturing solar collectors.

Since 2010, the Protherm brand has been part of the group of red brands of the trading company Vaillant Group, which has thoroughly redesigned the corporate identity of the boilers.

Varieties of Bear boiler models

The Proterm company has a unique assembly technology. Based on the type of product being manufactured, the assembly line operates on the principle of a conveyor, for floor-standing units, and for mounted ones using the “one boiler - one master” or “one piece flow” technology.

Installed boiler with boiler

In the latter case, each unit is assembled entirely by one master, who is responsible for the result and quality of the assembly. The company produces Comfort boilers with the function of high-speed heating of hot water, in no more than 5 seconds. Quality control is organized on all production lines, with all components and elements of the Protherm Medved boiler checked.

Floor models exist in 6 modifications:

- Grizzly KLO, cast iron heat exchanger, step control, natural draft, efficiency - 91%.

- Bear TLO, floor-standing gas boiler, non-volatile, single-stage, natural draft, efficiency - 91%.

- Bison NO, two-way smoke exhaust system, energy-dependent, forced draft, efficiency - 92%.

- Bear KLOM, cast iron heat exchanger, smooth modulation, natural draft, hot water supply, boiler efficiency - 92%.

- Bear PLO, piezo ignition, step control, natural draft, DHW, efficiency -91%, with comfort function.

- Bear KLZ, built-in accumulator tank 90 l, smooth modulation, hot water supply, efficiency - 91%, air supply method - forced.

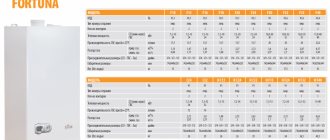

Technical characteristics of gas floor boilers:

- Bear 20 PLO, 200 m2 of heated area, efficiency - 91%, price - 41,710 rubles.

- Bear 30 KLOM, 300 m2 of heated area, efficiency - 92%, price - 79,939 rubles.

- Bear 30 PLO, 280 m2 of heated area, efficiency - 92%, price - 58,850 rubles.

- Bear 20 TLO, 180 m2 of heated area, efficiency - 91%, price - 57,313 rubles.

- Boiler Protherm Bear 30 TLO, 300 m2 of heated area, efficiency - 91%, price - 54,300 rubles.

Insulate your house

If the building has already been completed, you need to inspect it for zones of maximum heat loss. The house loses heat:

- through the roof (up to 25-30%);

- through ventilation (up to 25-30%);

- through walls (up to 25-30%);

- through windows (10-20%) and doors (10-20%);

- through the floor and basement (up to 5-15%).

These are averages and may vary in specific cases.

Then you should select insulation (penoplex, mineral wool, polyurethane foam, etc.) and decide whether the walls will be insulated from the inside or outside (facade thermal insulation is considered more preferable, but the choice depends on many factors and is always individual). It may be necessary to insulate the roof, replace double-glazed windows and entrance doors.

After a comprehensive thermal modernization, less heat will escape from the house. Thanks to this, gas consumption will decrease.

Distinctive features

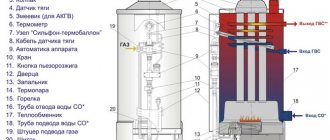

The Bear floor heating boiler runs on gas fuel, depending on the modification: TLO, KLOM, PLO and KLZ, and has different design solutions for organizing the operation of the burner device, the smoke exhaust system and the movement of the coolant in the circuit.

The main differences between Protherm Bear floor-standing gas boilers:

- Modulation of thermal power, with adjustment of gas consumption and energy savings during transitional heating periods.

- Electric ignition of the boiler, with a closed combustion chamber, ensures 100% automation of the combustion process.

- Cast iron heat exchangers for the heating circuit increase the service life of the boiler by 5-8 years, compared to the steel and copper version

- High efficiency, up to the maximum achieved level of 92%, reduces the cost of generated thermal energy and the payback period of boiler equipment to 3-4 years.

- Affordable gas boiler repair due to a developed service network.

Advantages

- A wide range of models, differing in parameters and design, can be selected for any area.

- Affordable price - in comparison with German analogues.

- High efficiency.

- Availability of built-in boilers.

- Adaptation to domestic conditions. Detailed Russian-language instructions.

- Environmental friendliness - Protherm is installed even in children's and medical institutions.

- Universal - can be used for heating residential and industrial premises.

- Automation and self-diagnosis are the basis for comfortable use.

Technical characteristics Bear 40 KLOM

This is a stationary floor-standing model of a gas heating boiler unit, in which the thermal power is regulated by a modulating burner. The heat exchanger is made of cast iron elements. There is an electronic ignition system and control of the torch combustion processes.

The control system ensures operating efficiency with an efficiency of 92%. There are outlet pipes for installing an external DHW heating boiler. The injection burner is capable of operating at the command of a weather-dependent control system and allows the use of both main and liquefied gas.

Technical characteristics of Bear 40 KLOM:

- Electronic ignition.

- Thermal power is 24/35 kW on main gas and 23/33 kW on liquefied gas.

- Efficiency is 92% on main gas and 91% on liquefied gas.

- Noise level 55 dB.

- The maximum coolant temperature in the heating circuit is 90 C.

- Maximum flue gas temperature, 131 C.

- Exhaust gas volume, 26.6 g/sec.

- Trunk gas consumption volume 2.9-4.1 m3/hour

- Protection class IP 45

- Dimensions: 505x600x880 mm

- Weight, 130 kg.

- Price - 49,500 rubles.

Installation features

Bear boilers are installed in a room protected from sub-zero temperatures, not far from the chimney. The permissible temperature of the internal air in the combustion chamber is from +5 C to +40 C.

The boiler is placed on a reinforced concrete foundation or on a concrete floor, which must support the full weight of the boiler filled with water and auxiliary equipment and not be slippery.

To remove boiler gases, it is allowed to install a fan and a smoke exhauster, which will ensure their forced movement. The size of the outlet pipe for connection to the chimney varies depending on the heating capacity of the model, for example, for KLZ 30 - 133 mm, and for KLZ 40 - 152 mm.

Before starting Proterm Bear for the first time, thoroughly wash the internal surfaces of the heating system. A safety relief valve is installed on the cold water supply line to the indirect heating boiler to protect against high pressure. It is prohibited to install any shut-off valves between it and the housing.

The unit must be equipped with a drainage line to drain water from the heating circuit during repair of the Proterm Medved boiler. Installation of the expansion tank is carried out by the safety group.

All main and auxiliary boiler equipment is tied according to the diagrams indicated by the boiler design and technical documentation of the manufacturer.

Wall series

The most popular option among apartment owners. They are economical and compact, they can be installed directly in the kitchen. The Protherm wall-mounted boiler has the following features:

- Frost protection.

- The power is smoothly adjustable - 3,500-11,000 kW and 9,500-23,000 kW.

- The circulation pump is protected from jamming.

- The control unit has a display that displays current information about the operation. There is a microprocessor.

- Self-diagnosis function.

- Overheat protection.

- Separate power control for heating and domestic hot water.

- Built-in boiler for 25 l.

- SPIN electronic system – for monitoring the temperature and speed of water heating.

Reviews of Protherm Bear

Protherm Bear is a very well-known brand of gas boilers in Russia; buyers who are planning to purchase these DHW heating sources, first of all, expect reliability, efficiency in providing thermal conditions and durability from the model.

Over the course of several years of use, many have not been disappointed with their choice and are happy to share reviews on the Internet, while not forgetting to highlight the negative aspects of the device.

Before purchasing any boiler, the user needs to read such reviews in order to take into account all aspects of the unit when purchasing.

The most typical user reviews for Protherm Bear:

- The Protherm “Bear” KLZ model was purchased before the last heating season. Very convenient design with an additional 90 liter tank. The boiler is supplied assembled by the manufacturer; virtually no special assembly processes are required during installation; it is simply delivered, unpacked and connected. The installation of the heating system along with radiators and piping took about 2 days. A disadvantage is the lack of a water purification system to remove scale and suspended solids, so it is better to install an effective water treatment system.

- Protherm Bear 40 klom is a good choice in terms of the “functionality-quality-price” balance. The powerful unit reliably and fully provides hot water to the entire family through an external boiler. The boiler control is very accessible - a number of keys and a large LCD display. For two years of use in different temperature conditions - not a single complaint, although the boiler is still under warranty and is being serviced by service specialists.

Regular heating system maintenance helps save money

Owners often think that their heating boiler does not need maintenance. They install it and forget about it until failures and breakdowns occur.

Even such reliable boilers as Protherm Bear need:

- be sure to remove soot every year;

- check for proper air supply and smoke exhaust.

Also, as part of annual maintenance, the integrity of the system, the tightness of joints and seams are checked, minor faults and calibration problems, if any, are identified.

Proterm Bear is a high-quality heating equipment, but it must be monitored as part of scheduled periodic maintenance.

Error and fault codes

Proterm boilers are very reliable equipment, which is confirmed by more than ten years of experience in using units in Russia and the CIS countries. Almost the majority of failures are caused by disturbances from the outside, in external utility networks: water, electricity and gas.

Errors on Bear boilers can be easily removed

Failures occur in the control unit due to violations in the grounding system of the boiler equipment. The boiler software package has a good diagnostic system, which will not only identify malfunctions in the operation of components and mechanisms and report them to the user so that corrective measures can be taken

Basic fault codes for Proterm boilers:

- F00 - the line of the primary sensor NTC2 is open, the temperature of the supply pipeline.

- F01 - NTC5 primary sensor line is open, return pipe temperature.

- F10 - short circuit in the line of the primary sensor NTC2.

- F11 - short circuit in the line of the primary sensor NTC5.

- F20 - high coolant temperature in the supply circuit above 90 C.

- F22 - low pressure in the heating circuit.

- F23 - high temperature difference between forward and return.

- F24 - low circulation in the heating circuit.

- F25 - flue gas leak in the room.

- F27 - separation of the torch from the burner.

- F28 - low gas fuel pressure.

- F33 - low air supply to the firebox.

- F49 - low voltage in the mains and at the Ebus terminal, less than 15 V.

“My neighbor pays less for gas than I do. What to do?"

This question comes up quite often, but it is not entirely correct. Think for yourself: most likely, your homes are not identical, and neither are your ideas about a comfortable temperature.

Different thickness and type of insulation, the presence of a room thermostat, the number of windows and doors, the thickness of double-glazed windows and insulation of door panels, the type of foundation and roof, the operating time of the gas stove and oven in the kitchen, the frequency of cleaning the boiler... all these and many other factors affect gas consumption .

Only in rare cases can replacing a boiler lead to significant savings. To truly improve your home's energy efficiency and spend less on gas, there's a lot of work that needs to be done. Below we will give some tips for reducing fuel consumption.