Repairing a heating system is an expensive, complex, but necessary procedure. It must be carried out regularly, with a certain frequency, both in a city apartment and in private real estate. If you do not pay attention to this design, over time it will begin to fail until it falls into disrepair. The drop in pressure and temperature is just the beginning. The most tragic consequences are manifested in leaks and breaks in the main line. This is dangerous to health and is fraught with large material costs. The scope of repair of the heating system is determined by its age, degree of wear and existing damage. Based on the diagnosis, a decision is made on local or major intervention.

Rules for choosing a material to solve a problem

When the cause of the pipe damage has been established, it is necessary to look for acceptable repair methods. There are several of them. Only most are suitable for low water pressure in the water supply circuit or heating system.

If you don’t have such a device at hand, then any piece of rubber (for example, from a bicycle inner tube) and wire or something similar will do .

But other methods of eliminating leaks when it comes to heating or hot water supply systems are unlikely to work. Thus, often used cold welding and special sealants are not relevant for wet surfaces.

Other instantly hardening composites (epoxy resin, dichloroethane) are also excluded, since they can be used on dry and disconnected water supply routes.

A minor leak in the pipeline can be repaired on your own . But this will only be a temporary measure. At the end of the heating season, it is recommended to carry out major repairs so that the system no longer fails.

Incorrectly installed heating radiators

The absence of heating problems depends on the correct installation of radiators.

The issue of correct installation of batteries is most relevant for private homeowners, since they themselves have to regulate the heating in their home. Replacing radiators yourself should be treated with responsibility, because installing them without preliminary calculations can add unnecessary problems to the heating system.

For example, the installation was done according to the instructions, but some of the radiators are working at half capacity. It turns out that it is skewed and the coolant cannot fill it entirely. And the reason is that the heavy multi-section radiator was hung on only two brackets, although it would have been more reliable to use four. As a result, the metal structures bent and the internal tubes were deformed.

The reliability of the radiator also depends on its location. The bottom edge of the battery should be raised above the floor by 10 cm, and there should be 2-3 cm of free space between the radiator and the wall.

Each radiator must hang on reliable brackets without sagging, play or distortion.

Hot and cold H2O - is there a difference in the way the gap is sealed?

It's all about the difference in coolant temperature. It is this factor that is decisive when choosing a material.

With hot pressure, minor damage can heal without outside intervention . Larger gaps can be easily repaired with regular salt and a bandage.

But when the water cools, the flow will resume. It will not be possible to fix a leak in a cold water pipe with salt and a bandage. It is easier to repair a failed hot water pipe in the summer when it is turned off. Then you don’t have to control the temperature in the room while fixing the leak.

Construction of an installation without a project

Repairing a heating system is often more difficult than building a new home from the very beginning. Therefore, if you decide to make changes, it is worth making a project. Moreover, the house and the need for heat could have changed significantly over the years - the walls were insulated, the windows were replaced, and so on. Carrying out calculations and re-adjusting the boiler and radiators can bring significant savings - at the investment stage, if we do not buy an unreasonably large boiler and radiators, and during operation, since an incorrectly selected boiler will operate with less efficiency.

In addition, there are many elements in the system, the parameters of which must be selected by a specialist based on calculations; sometimes it turns out that switching two radiators in the same room helps to balance them hydraulically, without significant damping of flows using valves.

And such intensive damping means, for example, a higher load on the circulation pump, higher energy consumption and unpleasant squeaks and noise from the system.

How does the pipeline material affect the solution to the problem?

Metal pipes are distinguished by their enviable resistance and durability. Almost their only drawback is their susceptibility to corrosion. This is often what causes a leak in the circuit.

Less commonly, other pipelines also fail: plastic, polypropylene (mainly in places of threaded or fitting connections).

It is enough to compress the plastic pipe in the problem area, and all manipulations can be carried out under water pressure. The main thing is not to overdo it with the screed, otherwise the plastic will crack, and then you will have to replace the entire pipe.

A polypropylene pipeline can be easily repaired by soldering a separate fragment; a metal-plastic pipeline requires inserts . In the latter case, if the damage is not extensive, wrapping with electrical tape or treating with an adhesive (polyurethane, epoxy) will be sufficient.

Appliances operating on liquefied gas are placed indoors below ground level

Liquid gas, i.e. Liquefied gas has a higher density than air, so in case of a leak it accumulates on the floor of the room. This is contrary to natural gas, which, lighter than air, rises to the ceiling, where it is removed by ventilation (exhaust grilles are installed at a distance of at least 15 cm from the ceiling).

Due to this property of liquefied gas, the equipment supplied with it should not be installed in rooms whose floor is below ground level - in the event of a leak, liquid may accumulate in them.

How to solve a problem?

When water circulates under pressure in the pipes, most major repairs cannot be done. Therefore, you have to act in other available ways in order to at least temporarily stop the leak and wait for emergency services.

Using a self-tapping screw

This option is applicable only for minor holes with a diameter of no more than 3-4 mm .

To plug the hole, you need a galvanized self-tapping screw, which is additionally equipped with a press washer.

It is simply screwed into the hole and secured . As a result, the water is blocked. After such repairs, the pipe can last up to 3 years, but it is better to replace the burst fragment as soon as possible. In addition, a self-tapping screw inside the pipeline leads to clogging of the system.

Cementing

Cast iron or steel pipes can be easily patched using cementation.

The sequence of actions is as follows:

- Using a special hard metal brush, carefully remove the layer of rust in the area of the fistula. The metal that is being painted is also removed, even if this leads to an enlargement of the hole.

- Cut the bandage to a certain length and dip it in the cement solution.

- They wrap it around the crack in several passes to form a kind of cocoon.

- The top is coated with cement to secure the result.

Clamp

A clamp is a fairly simple design consisting of a metal ring, a rubber gasket and a tightening bolt.

This device is sold in stores, but in emergency situations you can quickly make it yourself. You will need a piece of plastic rubber, scissors and a metal clamp corresponding to the diameter of the pipe.

Further actions:

- clean the damaged area from rust;

- put on a clamp, and slip a rubber gasket under it;

- The coupling is pressed tightly.

If the pipe is very rusty, a clamp will be almost the only way to disguise the leak. This is because welding cannot be used here.

Bandage and table salt

Salt is ideal for sealing leaks in hot water pipes under pressure. Step-by-step instruction:

- Distribute digestive salt over the bandage in as large a layer as possible.

- Wrap it around the hole, preferably more tightly.

Sealant

Using sealant (also called “cold welding”) to eliminate leaks in existing pipelines is not productive, since there is no guarantee that the problem will be solved 100%.

This is due to the fact that such compositions are designed to work with dry surfaces , and condensate is present on pressure pipes.

But if there is a small crack, you can try to seal it with a heat-resistant sealant. Outwardly, it is similar to plasticine.

Break off a small piece, carefully crumple it with your fingers and insert it into the hole, followed by smearing it to the sides . Large holes cannot be masked this way; first you will need to insert a wooden chip.

Here you will need fiberglass fabric and BF-2 glue.

Step by step steps:

- the problem area is thoroughly cleaned of rusty particles and degreased with aviation gasoline (acetone is an alternative);

- wait 15 minutes until the surface dries;

- cut a tape from the fiberglass of such a width that it completely covers the area of the leak;

- an adhesive composition is applied along the edges, and epoxy resin is applied to the center;

- apply to the crack, press with your hand and wrap;

- fixed with copper wire.

Wire or harness

A method somewhat reminiscent of the one with a clamp . Only instead of it they take a medical tourniquet and any metal wire. Rubber is tightly wrapped around the damaged pipe fragment and tightened with wire.

Wooden chop

It is necessary to quickly plan a wedge-shaped peg of a suitable diameter from any piece of wood. Then they hammer it into the hole with a hammer.

Chimney, ventilation system and boiler room

Every year, boiler room equipment requires maintenance. It includes an internal inspection of the shut-off valves. Ventilation is checked and filters are cleaned. If faulty elements are found that cannot be repaired, they are replaced.

Checking the draft in the chimney is carried out using an open flame. You can light a piece of newspaper and hold it near the vent. If the fire tends to it, then everything is in order with the draft.

As for the connections of gas pipes, they are checked for leaks using a soap solution. This solution is applied to seams and joints, and if it starts to bubble, it means gas is escaping and there are holes.

Boiler and ventilation maintenance typically includes the following:

- Removing rust from metal components with an iron brush;

- Disassembling the circulation pump for cleaning;

- Checking pressure gauges and other sensors;

- Gas equipment is carefully checked for leaks;

- Inspection of the chimney and, if necessary, cleaning it;

- Removing scale from heating elements.

How to stop a leak in a hidden pipe?

You won’t be particularly happy when a pipe hidden under a building structure starts leaking. Especially if the renovation has only recently been done. Since it is not always possible to quickly reach the source, you need to know how to temporarily stop the flow.

Here are a few techniques that are suitable for a water supply system in a private home:

In just a couple of hours, mustard will seal microcracks from inside the pipeline. When the leak is fixed, the circuit should be flushed.

- The heating system is temporarily filled with industrial sealant. It will settle on the internal surfaces of the pipeline and thereby stop water from seeping through microscopic gaps. After a major overhaul, the coolant is replaced with a new one.

Large holes cannot be sealed this way. Then they turn off the system, drain the water from the riser and begin straightening. Namely, it will be necessary to dismantle the structure and replace problematic spans. If you live in an apartment building, neighbors are warned about the upcoming event.

Features of equipment repair

Repairing heating equipment requires a responsible approach.

Gas boiler repair

The gas boiler is the main and most complex element in the entire heating system of a private home. Automation of this equipment is proceeding at such a pace that even specialists do not have time to keep track of all the innovations. Nevertheless, primary diagnostics and elimination of minor faults can actually be done with your own hands.

Photo 2. The process of repairing a gas heating boiler. Work must only be carried out by a qualified specialist.

Most boiler problems that you can fix yourself are described in the equipment data sheet.

Boiler breakdowns that can be repaired independently:

- Malfunctions of the boiler caused by voltage fluctuations in the electrical network. To eliminate this, connect the boiler through a stabilizer or uninterruptible power supply.

- The pressure has dropped, the boiler has stopped and will not turn on. The pressure in the system is raised to normal by opening the water supply tap.

- Boiler shutdown due to overheating. The heat exchanger is clogged on the outside. It will help to completely de-energize the heating device and clean the heat exchanger with a brush and vacuum cleaner.

- The AGV turns off after 2-3 minutes of operation and does not turn on until it cools down completely. The chimney is clogged. It is recommended to clean the ventilation duct.

- Water is leaking from the gas water heater. To solve the problem, all pipes and clamps inside the boiler are inspected and the leak is eliminated.

Correction of pumping equipment

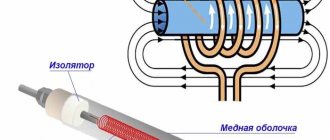

Home heating systems use circulation pumps. These devices are divided into two types: monoblock and collapsible.

If you use a model consisting of separate blocks, then sometimes it is possible to repair it yourself.

Malfunctions of pumping equipment that can be eliminated independently:

- The pump hums, the impeller does not rotate. It is advisable to disassemble the pump, rotate the rotor and, if possible, clean accessible parts from oxidation. Sometimes the cause of such a problem lies in a foreign object that has gotten inside.

- The pump does not hum, nothing rotates. It is recommended to look for the fuse. If it is not there, then it is time to change the pump.

- The pump makes a lot of noise when turned on. There is a large amount of air in the pipes. To troubleshoot problems, open the water make-up valve and bleed air from the boiler.

- The pump stops a few minutes after starting and does not produce enough pressure. Scale or other obstructions have formed on the pump cover, interfering with normal operation. The solution to the problem is to remove and clean the cover.

Pipe replacement

Repair work to replace pipes is carried out during the process of major re-equipment of the heating system. When installing new pipes, the following rules are observed:

- Before starting work, it is advisable to turn off the water in the house.

- The water from the heating system is completely drained before dismantling the old equipment.

- Taps are provided for each battery. The necessary fittings are calculated and prepared in advance.

- The pipes are placed at some distance from the floor and walls to make working with them convenient.

Photo 3. Installation of heating pipes made of polypropylene. A special laser is used for marking.

Preventing the problem from recurring

It is easier to prevent problems in the heating circuit than to suddenly look for ways to eliminate them. So before the start of the heating season, communications are checked by testing, especially focusing on dangerous areas.

These include:

- level spans;

- threaded connections and welds;

- zone of joining sections at radiators;

- places of implantation of heating equipment;

- near fittings;

- hard-to-reach areas.

First, everything is checked by eye, then with the circuit running.