Rock wool (aka basalt fiber) is a gift from Mother Nature from the Hawaiian Islands! What a strange name the insulation got! Can cotton wool be stone?

Maybe something is confused here and the usual modern insulating material is not called at all? Well, let's find out...

After the volcanic eruption, when the lava cooled, people found strong long threads and gave them a beautiful name - “Pele’s Hair”. By the way, the famous football player himself has nothing to do with this.

Pele is the name given to the goddess of fire and volcanoes in Hawaiian mythology. Volcanologists did not come up with a new name for the beautiful golden strands.

This is how the fragile volcanic fiber received such an unusual name.

If nature was able to create such a miracle on its own, then man can do it too.

Stone wool production technology

And in 1897, a new, modern mineral fiber insulation made of stone was first produced in the United States!

The rock (gabbro-basalt) is crushed and melted in smelting furnaces. The melting point of the stone is very high. When the rock becomes viscous, fiery liquid, it is wound on special drums and cooled by an air flow. As a result of this simple process, the finest fibers are drawn, the thickness of which is determined in microns.

To give the fiber strength and elasticity, special compounds are added. Phenols and formaldehydes are added to bind the fiber together. Then they are heated again and put through the press.

Basalt fiber is a natural material, and it is 95% stone. Agree, the name stone wool is well deserved for this material.

Areas of use

Among the materials that are created on the basis of rocks, the most common is basalt wool. It differs in that it repels moisture. That is why it is often used to insulate baths and saunas. It is also used for thermal insulation of pipelines and other utilities.

As already mentioned, the described material has high strength, so it is used for floor insulation. It is worth noting that cotton wool can have varying degrees of elasticity. A material with a soft structure is used in areas of building structures that are not subject to heavy loads. Cotton wool can also be used when laying wells and ventilated facades. If installation occurs on the floor, it is necessary to protect the insulation with a vapor barrier.

Rockwool semi-rigid stone wool is used in ventilated facade systems with unlimited air flow. Often this type of insulation is installed in air duct structures. It is often used for insulating multi-storey buildings. In this case, the material is secured from the outside.

The material has high rigidity and is suitable for structures subject to heavy loads.

This material is used in many situations:

- When insulating building structures. Since this material consists of environmentally friendly components, there is no harm to health from it.

- During the installation of fire protection systems. The use of the described material allows you to increase the level of fire safety of the entire building.

- For thermal insulation of ships and their parts.

- During insulation of ventilation systems. Stone wool is also often used to insulate smoke exhaust systems.

When purchasing TechnoNIKOL stone wool, it is worth considering its technical characteristics, since the instructions indicate the scope of application. If you make the wrong choice, the insulation will be used for a shorter period.

Types of mineral fiber insulation

In general, there are three types of mineral fiber insulation: glass wool, slag wool and basalt wool (stone wool).

The principle of operation of these insulating materials is the same - between the layers of fibers there is air, which plays the most important insulating role. Air comes first in preventing heat loss and stone wool is no exception...

The task of any thermal insulation is to retain heat in the room. It is desirable that when performing this function the insulation remains dry and static.

If the insulation absorbs moisture, its protective properties are very low.

What are the characteristics of stone wool?

What is thermal conductivity and thermal resistance

When choosing building materials for construction, you need to pay attention to the characteristics of the materials. One of the key positions is thermal conductivity

It is represented by the thermal conductivity coefficient. This is the amount of heat that a particular material can conduct per unit time. That is, the lower this coefficient, the worse the material conducts heat. And vice versa, the higher the number, the better the heat is removed.

Materials with low thermal conductivity are used for insulation, and materials with high thermal conductivity are used to transfer or remove heat. For example, radiators are made of aluminum, copper or steel, as they transfer heat well, that is, they have a high thermal conductivity coefficient. For insulation, materials with a low thermal conductivity coefficient are used - they retain heat better. If an object consists of several layers of material, its thermal conductivity is determined as the sum of the coefficients of all materials. During calculations, the thermal conductivity of each of the components of the “pie” is calculated, and the found values are summed up. In general, we obtain the thermal insulation capacity of the enclosing structure (walls, floor, ceiling).

There is also such a thing as thermal resistance. It reflects the ability of a material to prevent heat from passing through it. That is, it is the reciprocal of thermal conductivity. And, if you see a material with high thermal resistance, it can be used for thermal insulation. An example of thermal insulation materials is the popular mineral or basalt wool, polystyrene foam, etc. Materials with low thermal resistance are needed to remove or transfer heat. For example, aluminum or steel radiators are used for heating, as they give off heat well.

Characteristics of stone wool

The characteristics and properties of any product are ensured by the material from which it is made.

Thermal conductivity of basalt insulation

The basis of stone wool is chaotic thin fibers of molten rock. They have no sequence in arrangement, the space between them is filled with air, so the structure of the material is airy. And air, as mentioned above, is an excellent heat insulator. For this reason, stone wool has very low thermal conductivity.

Ability to absorb moisture

Even molten rock that has undergone additional processing is not able to absorb moisture. Water cannot get inside the basalt fiber, so the hydrophobicity of stone wool is about 2%. Therefore, it is an excellent material for insulating and insulating the dampest rooms.

Materials of the previous generation (for example, glass wool), unlike basalt fiber, absorb moisture well. Therefore, their thermal conductivity indicators are low; wet insulation does not retain heat, it loses it.

Ability to pass steam

Regardless of the hardness index (we’ll talk about this a little later), stone wool is stable to humidity.

Passing through numerous fibers, the moisture contained in the air does not form condensation inside the insulation. That is, the fibers do not get wet and the room is guaranteed to maintain optimal humidity and temperature.

Soundproofing

Stone wool fiber absorbs sound waves and dampens vibration.

In addition to excellent thermal insulation properties, good noise insulation can be added to the usefulness of this material. If the walls of a room are insulated with stone wool, then not only this room, but also others are protected from noise.

Strength of stone wool

Basalt fiber can withstand heavy loads due to the random arrangement of the fiber. Regardless of the density of the material, stone wool does not change size and shape when deformed. This is a guarantee that the material will last for a long time.

Fire resistance

Basalt fiber is a completely non-flammable material (how can a stone burn). For this reason, stone wool is used for insulation in work involving high temperatures.

Stone wool cannot burn, but at high temperatures (600-700 degrees) the fiber disintegrates into hot dust. The maximum temperature that stone wool fiber can hold without melting is over 800 degrees Celsius.

Chemical and biological activity of stone wool

This insulation does not interact with metal surfaces or aggressive environments. By insulating metal structures with basalt fiber, you can say with 100% accuracy that rust will not appear. This material is not susceptible to rotting, fungi and mold. Rodents, ants and other pests will not cause any harm to stone wool. This is an excellent barrier to any invasion.

Classification of expanded polystyrene

Regular foam

Thermal insulation material obtained by foaming polystyrene. As mentioned above, its volume is 98% air, which is sealed into granules. This speaks not only of its excellent thermal insulation qualities, but also of its sound insulation properties.

The main advantage of the material is the lack of ability to absorb moisture. In addition, it does not rot or biodegrade. Durable material, light weight and easy to use. It can be glued to any building material.

Expanded polystyrene is easy to burn, but it contains a substance called a fire retardant. This is what gives the foam the ability to self-extinguish. In addition, expanded polystyrene cannot be used to insulate facades. This is due to its low vapor permeability. And in order to carry out work with foam plastic under the roof, you should carefully consider the ventilation system.

Use depending on the brand of material

- PSB-S 15. The marking of polystyrene foam indicates that it can be used to insulate structures that are not subject to mechanical stress. For example, insulation of the roof, the space between the slings and the ceiling.

- PSB-S 25 and 25F. Common markings for polystyrene foam. It says that any surface can be insulated. Walls, facades, ceilings or flooring, roofing.

- PSB-S 35 and 50. This material can be used to insulate objects that are under constant high load.

Hardness index

The insulation is produced in three levels of rigidity:

- Soft stone wool is made from the finest fibers. It has a huge number of cavities that hold air. Soft stone wool is used to insulate building facades, frame walls, and roofs. That is, in places where there will not be much mechanical impact

- Medium hardness wool is made from medium fibers, they are stiffer. This type of insulation is used to insulate ventilation ducts, that is, where there is a strong air flow

- Thick and durable fibers of rigid stone wool. This insulation is used for heavy loads. It can be used to insulate walls at an intermediate stage of construction, before reinforcement, concrete screed, etc.

Video description

Video comparison of the heat-saving properties of mineral wool with other popular insulation materials:

In addition, before purchasing a material, it is useful to know the values of its technical characteristics:

- Dynamic rigidity, shape stability at a given temperature.

- Degree of compressibility and mobility.

- Load during deformation.

- Moisture saturation level when immersed in water.

- Sound absorption coefficients and air permeability.

Knowledge of these parameters will allow you to determine for what specific conditions the insulation is suitable - on the roof, in ceilings without load, in the floor or under a screed.

Important! When purchasing mineral wool from any manufacturer, it is advisable to look at the material in advance and make sure of its quality. So, if the cotton wool pricks when touched, small fragments fall out of it, this will not only negatively affect the installation procedure, but will also lead to a further deterioration in comfort in the home, since individual fibers of such insulation can penetrate into the atmosphere of the room.

Application

Basalt fiber has quite a lot of advantages; the open porosity of the material provides it with heat and sound insulation properties. Unlike glass wool, basalt fiber does not prick and does not cause allergic reactions.

For this reason, stone wool is used very widely. It is used to insulate and insulate facades, walls, partitions, and rooms with high humidity (saunas, baths).

Basalt fiber is used to insulate floor slabs, floors, and roofs.

It is used to insulate pipelines of various types.

Stone wool is used to insulate ship structures and cabins on ships. It is widely used as fire protection for beams and load-bearing structures, air ducts, and cable passages.

Why is thermal insulation needed?

The relevance of thermal insulation is as follows:

- Keeps you warm in winter and cool in summer.

Heat loss through the walls of a typical multi-storey residential building is 30-40% . To reduce heat loss, special thermal insulation materials are needed. The use of electric heaters in winter contributes to additional energy costs. It is more profitable to compensate for these costs by using high-quality thermal insulation material, which ensures heat retention in winter and coolness in the summer heat. At the same time, the cost of cooling the room with air conditioning will also be minimized.

- Increasing the durability of building structures.

In the case of industrial buildings using a metal frame, insulation helps protect the metal surface from corrosion, which is the most detrimental defect for this type of structure. And the service life of a brick building is determined by the number of freeze/thaw cycles. The impact of these cycles is perceived by the insulation, because the dew point is located in the thermal insulation material, and not in the wall material.

Such insulation allows you to increase the service life of the building many times.

Protection against increasing noise levels is achieved by using such noise-absorbing materials (thick mattresses, sound-reflecting wall panels).

- Increasing the usable area of buildings.

The use of a thermal insulation system makes it possible to reduce the thickness of external walls, while increasing the internal area of the building.

Disadvantages of stone wool

Despite all the undeniable advantages, stone wool still has disadvantages. There are not many of them, but still:

- High price

- If the technology was violated during production, then the insulation loses a good half of its quality. When installing insulation, tiny stone pieces may break off from the fiber, and stone dust may form. Breathing stone dust is far from good for our lungs. For this reason, construction work with basalt insulation is carried out wearing respirator masks

- The seams at the joints of the insulation cannot create a 100% tightness

Glass wool

One of the most common types of insulation nowadays is glass wool. This is insulation produced, as the name suggests, from glass production waste. Glass wool consists of long and wide glass fibers, the length of which can reach up to five centimeters.

Advantages of glass wool

It is quite actively used due to the fact that it has a number of undeniable advantages, among which it is important to note, for example: - High elasticity. During transportation, glass wool is compressed up to 4 times, and when transportation is completed, it is straightened out without any problems. — Very high resistance to vibration. - Extremely high moisture resistance - such an excellent material almost never gets wet! - Exceptional non-toxicity and purity - No less good sound insulation and thermal insulation. — Complete fire safety. Glass wool generally does not ignite at all! — Glass wool does not rot or mold. - Glass wool is not at all edible for mice, rats and any other rodents who like to feast on building materials. This is especially important for those who live on the ground floor of a high-rise building or arrange their summer cottage with glass wool.

Disadvantages of glass wool

But it would be unfair not to note certain disadvantages of the glass wool material: - Short service life when compared with insulation materials consisting of other materials; - Low level of thermal performance for products consisting of glass wool (again, compared to other insulation materials); — Some types of glass wool contain formaldehyde; — When working with glass wool, special, enhanced precautions must be taken to avoid problems. The fact is that glass microfibers, when they come into contact with mucous membranes and skin, can cause persistent severe itching, redness, and burning. These microfibers will be extremely difficult to wash off, because they get into microcracks and pores of human skin. In addition, when small particles of glass enter the respiratory tract, serious health problems often arise, often irreversible. An unambiguous conclusion follows from the last drawback - if you still decide to use such an ambiguous type of insulation, then you will need devices that can ensure safe work with glass wool. A respirator or special one is good. gloves, professional glasses. You should definitely dress with the expectation that your special suit will be thrown out because... it will be more than permeated with fine glass dust and fiberglass.

In what form is it produced?

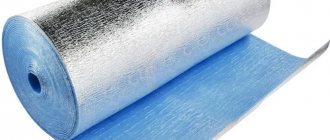

Basalt wool is produced in rolls, slabs and cylindrical shapes. The softest material is contained in rolls, in slabs of medium and high hardness. And the cylindrical shape is intended for insulating pipelines.

Double insulation of stone wool - foiling. Stone wool covered with foil is universal; it not only does not release precious heat, but also reflects it and directs it back into the room.

What affects the ability to retain heat?

One of the main indicators of the thermal conductivity coefficient, including for insulation materials based on mineral wool, is composition. In addition, parameters such as:

- density (aka porosity);

- humidity;

- temperature of the structure.

For example, if we talk about a metal body, then as it warms up it will conduct heat more and more slowly. Wet materials conduct heat faster than dry materials, and in gaseous bodies heat is transferred mainly by convection.

In the case of insulation with mineral wool as a base - porous multilayer materials, it is worth talking about the minimum thermal conductivity, which mainly depends on the composition and brand of the insulator. The coefficient indicators will be noticeably better for those brands whose structure is looser. This is due primarily to the arrangement of mineral fibers. In mineral insulation they occupy random positions, thus increasing the air capacity, and with it the ability to retain heat.

Analyzing a lightweight insulator based on mineral wool, they talk about a thermal conductivity coefficient of 0.045 W/m*K, while brands of insulator with a more noticeable weight may have slightly different indicators - 0.055 W/m*K. Cotton wool has approximately the same coefficient.

conclusions

Stone wool is a universal material; it is resistant to any chemical attack. He is not afraid of paints, solvents, alkalis, or acids.

The material will not lose its thermal insulation properties for quite a long time; it can serve faithfully for more than fifty years. The insulation lends itself well to installation, as it has a low specific gravity and at the same time large size.

There is a lot of controversy surrounding the environmental safety of this material, since the binders of stone wool are phenol-formaldehyde resins.

Studies have shown that toxic substances in stone wool are contained in very small quantities. During installation and operation, they are not released from the fibers, so basalt insulation stone wool can be confidently called harmless to humans.

Foam brands

If you are interested in the question of what is the best brand to buy polystyrene foam, and what is its thermal conductivity, then we will answer it for you. Below are the most popular product brands, as well as the density values and thermal conductivity of the foam.

- PSB-C15. With a thermal conductivity of 0.042 W/mK and a density of 11-15 kg/m3

- PSB-S25. With a thermal conductivity of 0.039 W/mK and a density of 15-25 kg/m3

- PSB-S35. With a thermal conductivity of 0.037 W/mK, and a density of 25-35 kg/m3

Our list is completed by polystyrene foam PSB-S5, whose thermal conductivity is 0.04 W/mK and density is 35-50 kg/m3. Having analyzed the density and thermal conductivity, we can say with confidence that density does not significantly affect the main quality of the foam, heat saving.