Siberia gas boilers are among the TOP 3 most popular and competitive lines of heating equipment among domestic manufacturers. All models have an excellent efficiency of 90%, do not have a record, but rather low gas consumption, and have a simple, reliable and trouble-free design. There are both models with steel and cast iron heat exchangers, universal floor-mounted and compact wall-mounted.

All boilers are characterized by an average market price in the budget price segment - from 19 thousand rubles for the simplest models.

In the article we will look at the best models of wall-mounted and floor-standing gas boilers Siberia, how they behave in practice, what advantages and, most importantly, disadvantages are noted by the owners, as well as what malfunctions may arise during the operation of boiler units in real conditions.

Characteristics of Siberia gas boilers

Siberia boilers have excellent technical characteristics. They appeared on world markets quite recently, but due to their original manufacturing technology they have already managed to outperform most of their competitors.

Siberia boilers have high performance and excellent characteristics. In addition, one of their main advantages is complete independence from the availability of electricity.

Technical characteristics of Siberia boilers:

- The heat exchange tanks of such boilers are of very high quality and durable, thanks to the automatic welding of their parts. They can be cast iron or steel. The former have an impressive service life, the latter quickly heat up the coolant.

- Siberia boilers have two circuits. Coolant flows through one, and the other is responsible for heating water for domestic needs.

- Such devices have a thermal insulation layer, making their use safer. This material is used in the rocket industry.

- The Italian Eurosit system is responsible for controlling the temperature in such boilers.

- The system of such boilers is fully automated. It has electric piezo ignition.

- Also in Siberia boilers there is draft and flame control;

- The burner function is selected by the automatic system itself. Thanks to this, the device consumes gas at an optimal level.

- Due to the fact that the boilers of this manufacturer are made of steel, they do not burn out even at maximum temperatures.

- All elements of the product are made of high-quality and safe materials. Therefore, when gas burns, environmentally harmful impurities are not released into the atmosphere.

- The burner is easy to use. You can clean and replace system elements even without special skills.

- The system can operate on liquid fuel. This ability will be useful to you when replacing the igniter and the main part of the boiler.

As you can see, the technological characteristics of such boilers are at their best. The manufacturer has made sure that its products not only meet, but also exceed all international standards.

What functions does it have?

The main function of the unit is to heat the coolant for the heating circuit of a private house or other premises.

Additional functions of the boiler are:

- Thermometer providing visual control of coolant temperature.

- Piezo ignition system.

- The presence of a two-stage burner, pilot (pilot) and main.

- Availability of gas, flame and draft control.

All components and blocks of the boiler are conveniently located and allow for easy maintenance or repair.

IMPORTANT!

It is not recommended to do independent work or repair the unit, especially if the warranty period has not yet expired. You should use the services of technicians from service workshops.

The best and most famous models: characteristics and prices

Classic floor-standing boilers Siberia

Classic, inexpensive and most popular boilers with a steel heat exchanger. They are distinguished by their compact size, heat exchanger steel thickness of 4 mm, reliability and reasonable price. Efficiency is 90%, gas consumption of the 11.6 kW model is only 1.18 m3/hour. Available in 11, 17, 23, 29 and 35 kW versions. There are also double-circuit models; they come with the prefix “K” (for example, Siberia 11K) and cost only 5-15% more than single-circuit ones.

Otherwise, after more than 12 years of operating experience, there are practically no serious service complaints; the model is considered the most successful and most reliable of domestic gas boilers. It has almost all the previously described disadvantages - sensitivity to clogging, noisy ignition

Please note that the maximum permissible operating pressure is only 1 bar, so it is not recommended to use the model in closed systems, where the operating pressure is usually 1.5-2 bar

Cost: 19,800-26,000 rubles.

KCHGO series

One of the best Siberia gas boilers for heating a private home. This is a larger and heavier model with a durable cast iron heat exchanger. Cast iron is practically not subject to corrosion, so such heat exchangers last 30 years or more, although they are much more expensive. Unlike the previous model, the permissible operating pressure is now 3 bar, which allows the boiler to be used in any domestic closed heating systems with forced circulation of coolant. Available in 16, 25, 40, 50 kW versions.

The burner and automation of the boiler are still the same - the famous Italian EuroSit and Polidoro, so the gas consumption remained at the same level - 1.7 m3/hour for the 16 kW model. Otherwise, everything is the same as with classic steel floorplates. A significant drawback is the lack of dual-circuit versions. Prices for cast iron models, although quite high, are much lower than foreign analogues and are among the lowest among domestic ones

Cost: 33,900 – 62,000 rubles.

Top Line Series

A mounted model, the body of which already contains all the necessary modules of the heating system (expansion tank, circulation pump, safety group, etc.). It is distinguished by the presence of a smoothly modulated burner, which is reflected in the maximum gas consumption - 2.65 m3/hour with a power of 24 kW. The copper heat exchanger is more resistant to corrosion than steel and more thermally conductive. But in dual-circuit models it is bithermic (double), which means almost zero results when washing it and vulnerability to scale accumulation. Therefore, it is imperative to use soft purified water as a coolant and change it as rarely as possible.

Cost: 21,500-26,000 rubles.

Which boiler model is ultimately better to choose?

Siberia 23 in the interior of a private house.

The choice is quite simple: if you have a limited budget, these are definitely classic floor-standing boilers with a steel heat exchanger (Siberia 11, 17 and 23K are in greatest demand). If your budget allows, it is better to choose a floor-standing unit with a cast-iron heat exchanger (KChGO series), it practically does not differ in characteristics, but is much more reliable (due to corrosion resistance) and stronger, and can be installed in a closed type CO.

We recommend choosing a wall-mounted Top Line only if you have very limited space or if you want to organize control through a programmable thermostat, which, with proper operation, allows you to greatly save gas consumption.

The main thing is to determine the required boiler power. For an average house in the climatic zone of the Moscow region, with a masonry of 2 bricks and a ceiling height of 2.7 m, the minimum required power of heating equipment is calculated from a simple rule: 1 kW for every 10 m2 of area. We also recommend setting aside a reserve of 15-20%.

For example, for the house described above with an area of 130 m2, the minimum required power is 130/10 * 1.2 (20% reserve) = 15.6 kW. That is, a version with a heating capacity of 16 or 17.4 kW is required.

When choosing a dual-circuit option, it is recommended to add another 5-10% margin to the obtained value. This calculation method is relevant for more than 90% of cases. If the house is well insulated (for example, polystyrene foam 10 cm thick) or is located in the extreme southern point of a country with a warm climate, the result can be adjusted downward by 5-30%.

How to accurately calculate the required boiler power Individual calculation, formula and correction factors

Equipment installation

Equipment installation must be carried out by a specialist. To do this, you will additionally need to obtain permission to install:

- Registration of permission;

- The gap between the wall and the equipment must be at least 3 cm;

- For a floor-standing unit, you will need to prepare a foundation;

- To prevent gas leakage, all connections must be carefully insulated;

- The boiler should be started up for the first time by a specialist;

- The company representative must provide the equipment with a warranty upon first start-up;

- If you connect an electric boiler, you will need to install the electrical network and water supply;

- When connecting heaters that are not volatile, additional equipment will need to be installed separately;

- If you connect it to the network using the “cascade” principle, you can increase the power several times. Thus, it is possible to connect all types of boilers;

- A piezoelectric element is used for ignition;

- Initially, the igniter lights, and then the main burner.

If condensation appears on the heat exchanger during the first start-up, this is not a problem. When the unit heats up, it will disappear.

Model overview

The manufacturer produces products in three series: premium, comfort and economy:

- The first series of gas boilers are Premium Topline-24 models, designed for use in small buildings, and the presence of a second circuit in them makes it possible to heat water. The main feature of such models is the presence of electronic ignition of the burner. Moreover, ionization control of the flame and exhaust gases is carried out, and a function provides protection against scale. The boilers have high efficiency (90%).

- The second comfort series includes several models: Comfort Serbia 50, 40, 35, 29, 23. Their collection includes devices with both two and one circuit and heat large areas of premises. The first model has the ability to heat up to 8 liters of liquid in one minute. This series produces floor-standing boilers; their designs have a circular pump that prevents the heat exchangers from overheating.

- The third series of Econom Siberia boilers. It appeared on market shelves in 2005 and includes 4 models. The difference between these samples lies in the contours and power (17.6 and 11.6 kW). If the letter “K” appears in a line of this type, there are two contours. High-quality atmospheric burner made of high-alloy steel from an Italian manufacturer. Automatic protection can be American (Honeywell) or Italian (Eurosite). If the equipment is reconfigured, it can use liquefied gas, which makes this series an indispensable unit during an emergency in gas pipeline systems. The body of the units is painted with special enamel, which gives the structure a modern look and protects it from chips and scratches.

- All models from Rostovgazoopparat are combined by installation method - on the floor and have standard height (85 cm) and depth (65 cm), width can be different.

Technical characteristics of Siberia boilers

Each Siberia gas boiler has fairly high performance characteristics, which are on par with those of the most famous foreign products.

If we talk about the advantages and disadvantages of the device of the brand in question compared to analogues, then we can highlight the following qualities:

- High strength and reliability of the heat exchanger tank, which is achieved through the use of high-quality materials and automatic welding. Choosing a boiler equipped with a steel heat exchanger will allow you to achieve the highest possible efficiency. Heat exchangers made of cast iron are not as efficient, but they can last more than 25 years.

- The Siberia double-circuit gas boiler provides not only heating of the room, but also supplying residents with hot water. Boilers of this brand use flow-through copper circuits.

- Heating equipment of the brand in question is suitable for use in systems with forced and natural circulation of coolant.

- The design of Siberia boilers includes high-quality thermal insulation materials, due to which high fire safety is achieved and users are protected from burns.

- Each Siberia gas heating boiler is very easy to install, easy to maintain and does not create the slightest problem during operation.

It is also worth considering the features of EUROSIT automation, which you should know about before purchasing a boiler:

- Possibility of precise temperature adjustment and stable support of a given mode;

- Availability of piezoelectric ignition;

- Quite convenient arrangement of automation units, which provides simple control of the system;

- Availability of a draft sensor and combustion intensity control;

- The presence of several burner operating modes, which are selected automatically and allow you to optimize gas consumption;

- The combination valve operates in fully automatic mode;

- Automation does not require a connection to electricity, so the Siberia gas boiler will work even in any case.

It is also worth saying a few words about the burners used in the construction of boilers:

- For the boilers in question, Siberia Worgas burners are used, which are manufactured in Italy;

- For the manufacture of burners, stainless steel is used, which does not burn out even if the gas pressure is at a minimum level;

- The burners are environmentally friendly, so they do not pose any danger to the environment or human health;

- Operation of Siberia burners is simple, and replacing or cleaning them requires a minimum of knowledge and skills;

- When replacing the igniter and the working element of the burner, the boiler can operate using liquefied gas from a cylinder as fuel.

Owner reviews

Siberia wall-mounted and floor-mounted gas boilers are well represented in the retail network; they are quite in demand among Russians and have proven themselves to be excellent in practice, about which there are quite a lot of responses on the Internet. They reflect how devices behave in practice, their advantages and disadvantages.

Some user reviews on the operation of Siberia boiler units:

- A good quality, simple and reliable device. Almost nothing superfluous, everything you need, does not need to be connected to electrical networks. An excellent competitor to imported boilers, it provides excellent service, heating and comfort at a low cost.

- Siberia gas boilers are a device for those who have a good understanding of their design and operating principle. Many users choose imported units loaded with sophisticated electronics, not realizing that they are paying exorbitant prices for features they will never need.

- Need for constant cleaning. It is advisable to clean the boiler, burner device and piezo igniter every year. If there are blockages in the boiler modules, difficulties arise with ignition and the functioning of the automatic protection system.

- Noisy operation of the piezo igniter of the burner device; clicks are excessively loud during ignition. Many users believe that the device must be placed in a separate room.

Installation rules

Important! Creating an autonomous heating system and installing equipment requires a project and permits signed by the gas company. At the request of the manufacturer, installation of the Siberia floor heat generator must be carried out in accordance with SNiP standards and the requirements of GOST and SanPiN, only by certified specialists authorized for this type of work

- After obtaining permission and purchasing a boiler installation, additional equipment should be purchased: an expansion tank and a circulation pump that ensures forced movement of the coolant through the heating circuit. This equipment is not included in the delivery package.

- Prepare the boiler room. Floor-standing boiler units of this brand can be installed in the kitchen or in a specially designated non-residential separate room, which is equipped with a supply and exhaust ventilation system and an exhaust gas removal system. Utilities must be connected to the furnace room.

- Installation location. Installation of equipment on a foundation near fireproof walls is allowed. The gap between the device and the wall should not be less than 3 cm. For ease of maintenance and operation, it is necessary to provide at least 1 meter of free space in front of the boiler.

You can do the work on connecting the water supply and heating circuit yourself. The connection of the installation to the gas main must be carried out by representatives of the gas industry. And lastly, in order to correctly connect the Siberia floor-standing gas boiler, the manufacturer’s instructions must be followed in full.

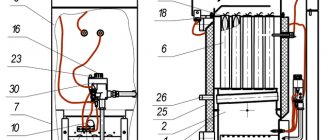

AOGV Siberia inclusion

“EMK”, an electromagnetic valve of Rostovgazoapparat’s own design, is participating in the launch of the device. The following manipulations will be required:

- Make sure that the heating system circuit and the unit itself are completely filled with coolant;

- Don't forget to check your traction. A good vacuum draws in the flame, just place a match under the umbrella, position 5 in the figure;

- Make sure that the water tap is closed;

- Set the gas valve on the gas pipeline to the open position;

- Set the gas valve of the main burner to the closed position, figure position 9;

- Press the round key of the magnetic valve until it stops, bleed the air for two minutes, and then light the pilot burner. Hold the key pressed for about 1 minute to warm up the thermal cylinder;

- After one minute, begin to smoothly release the magnetic valve button. If you did everything correctly, the AOGV Siberia pilot burner will remain burning without going out. In order for the thermocouple to be constantly hot and not give a signal to stop the gas supply, the direction of the flame from the igniter must fall on the thermal cylinder. If the flame misses, you should adjust the tube in the right direction;

- Gradually, without sudden movements, open the gas valve of the main burner to half the full stroke (counterclockwise by 45°). As soon as the flame spreads across the entire plane of the burner, set the required flame value while continuing to manipulate the gas valve handle.

- In the case when the actions taken did not lead to the main burner burning, and the pilot went out, re-ignition is performed no earlier than 5 minutes later. This requirement must be met in order to completely ventilate the firebox;

- Set the size of the main burner fire to at least 2–3 cm, otherwise there is a possibility of self-extinguishing. The maximum flame height can be set to 7cm. If you set the flame higher, the flame will jump into the mixer and the process of soot formation in the burner and heat exchanger will start. In the absence of draft, the flame may jump out of the firebox; it is prohibited to operate the AOGV Siberia boiler in this condition. The combustion flame height values are set using the gas tap of the main burner on the automation unit.

- Stopping the boiler operation is quite simple; to do this, you need to close the gas valve of the main burner and the gas valve on the supply line.

Advantages of AOGV Siberia and customer reviews

- Long service life;

- Due to the simple design, judging by the reviews, good reliability is noted;

- Low price. AOGV Siberia boiler for 17 kW can be found for 22 thousand rubles;

- You can save two times: on the cost of purchase and operation;

- Modern design and oversized dimensions allow you to install the boiler even in the kitchen space;

- An automatic unit that controls the entire system.

- Safe operation.

- Easy controls.

- Low noise characteristics.

- Developed service network.

- A well-known brand, one of the leaders in its class.

- Wide range of power units.

- Unpretentiousness to the “quality” of the supplied gas.

According to reviews from customers and owners, AOGV Zhukovsky is often compared with the AOGV Siberia boiler. AOGVs

of the Zhukovsky

Machine-Building Plant are more expensive, but they have Italian automation installed. The same applies to Lemax boilers, with which AOGV Siberia is also often compared.

Boilers have the same purpose, and in the end it all depends on your wallet. Perhaps a better decision would be to purchase a boiler from a manufacturer that has a specialized service center in your area. This way you will be under reliable protection.

Specifications ↑

Features of this brand at the moment

The manufacturer itself positions itself as a competitor to Slovenian gas units “Proterm”. This can be seen in some design and technological solutions, as well as in the adopted standard outlet openings for various purposes. Siberia, of course, generally loses to Proterm in power, build quality and efficiency, but very seriously all the “disadvantages” are covered by an affordable and more than acceptable price.

Due to the desire to comply with foreign analogues and the best domestic representatives of gas boiler equipment, the implementation of technical and design innovations has led to very great difficulty in setting up the boiler. That is, if previously any user could adjust the equipment to suit himself, now only a specialist can do this. True, we must pay tribute that after high-quality tuning, the boiler noticeably reduces energy consumption, while leaving thermal indicators unchanged. It should also be noted that another, to a certain extent, weak point of the Siberia boilers is the automation, or rather, some of the sensors included in its composition. This applies to:

- draft sensor (this is a problem with all domestic boilers);

- flame cutoff sensor (an unconfigured pilot burner often cuts off the pilot flame when the wind is strong enough, but the sensor does not manifest itself in any way and gas continues to flow to the burner.

In Fig. samples of Rostov heating equipment products are presented below, you can familiarize yourself with the technical characteristics of its basic model:

The Siberia boiler is presented below, compare the technical characteristics

Main faults of Siberia

The simple design of these boilers does not cause serious malfunctions, especially when users carry out systematic maintenance of the main modules. For this reason, there is practically no interest in spare parts for Siberia gas floor equipment.

The most common operational failures are:

- The piezo igniter or the main burner device does not light well. The most common cause of this failure is poor traction. A possible reason for the lack of combustion is a clogged wick or base burner.

- The pilot burner goes out after 5-15 seconds. This failure indicates reverse draft in the chimney. The reason for this is often an incorrectly designed gas duct: it is too short or too long and there is no deflector.

- The boiler unit does not raise the temperature of the heating water above 60 C. Most often, this occurs due to a clogged gas valve.

- Software failure E01, it indicates the absence of a torch. This can happen when the gas tap is turned off, there is a significant pressure drop in the gas network or surges in the electrical network.

- Failure E04 - pressure drop in the water system is less than 0.7 bar. As a rule, this is due to air locks, leaks, breakage of the expansion tank or safety relief valve.

How to choose a gas boiler

First you need to decide on its power. The larger the room, the more power the speaker will need.

For every 10 sq. m. needs 1 kW of energy. In order for the device to work longer, you should not purchase it one-on-one with the calculated power

It is better to take with a reserve of 1/3.

It is important to take into account climatic conditions, as well as the decoration of the house. If the house is insulated, then heat loss will be less

Accordingly, a less powerful boiler will do.

You also need to take into account what it is needed for. Only for heating or for the availability of hot water.

If the equipment will be installed in an apartment, it is recommended to use a wall-mounted speaker, and if in a house, then it is better to use a floor-standing speaker. But it still depends on preferences, and, of course, on the size of the heated area.

For long-term operation, the type of heat exchanger is important. If it is cast iron, then this is only a guarantee of durability.

Types of devices

The Siberia gas boiler, the characteristics of which we have already reviewed, is manufactured in different modifications. For example, all manufacturer’s products can be divided into 3 types:

- Floor-standing single-circuit. Their feature is a cast iron heat exchanger, which is characterized by increased power. This device is most often used for large houses or buildings consisting of several floors.

- Floor-standing dual-circuit devices. They are equipped with a heat exchanger made of high-quality and durable steel. Such devices are intended not only for heating the room, but also for producing hot water.

- Wall-mounted. These devices are lightweight, compact in size and have high performance.

About Siberia boilers

These boilers are manufactured by NMK, one of the largest manufacturing companies in the field of heating devices in Russia. “Siberia” is considered one of the most popular devices among all manufactured analogues.

“Novosibirsk Metalworking Company” - this is how the well-known abbreviation “NMK” stands for. The company began its existence in 1995. The years of successful development were not in vain. Thanks to the correct approach to all stages of the production process, the company has managed to establish itself from the best side. The brand's products are distinguished by first-class quality, due to excellent materials, modern technologies and careful control of all stages of model creation.

A huge assortment allows us to please clients with any income. There are products on sale in different colors, sizes and purposes. There are stoves and high-quality greenhouses here. Boilers deserve special attention. These devices belong to boilers from the “solid fuel” section. They are represented by two series: “Hephaestus” and “KVO”.

There are five standard sizes of Siberia units: KVO 10,12,15,20 and 25 kW. The main material from which these devices are made is steel, which has good resistance to elevated temperatures. Cast iron is also sometimes used. As for Hephaestus, it is available in three versions: 15, 20 and 30 kW.

Design

Looking at the Siberia units, you can see that they are simple classic boilers. The design includes a water jacket and, in fact, the boiler itself. “Siberian” boilers are quite compact, which allows them to be located in absolutely any part of the house.

If we consider the design in more detail, then we need to say a few words about the grate, transversely located beams, and the lid.

- A grate is needed to achieve maximum effect. It helps to make the heat removal area larger.

- The beams are installed on the paths of flue gases. They direct heat into the heating system.

- The lid has holes where charcoal is usually placed.

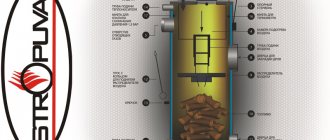

Design and principle of operation

The main idea used by the creators of Siberia is to develop a completely energy-independent floor-standing gas boiler Siberia. It can work in difficult situations without requiring electricity. This approach became correct, and the low cost of the units created great consumer demand.

The structure of Siberia. Photo source: mtbwn.us

The Siberia gas boiler is made with an open-type atmospheric burner, which places increased demands on air exchange in the room where it is located.

Smoke removal is carried out in a natural way; for this reason, drafts or a sudden change in air movement are dangerous, since they contribute to an emergency situation due to the separation of the gas flame from the burner or smoke in the room.

An internal highly efficient heat exchanger, made of steel or cast iron, makes it possible to heat water with an efficiency of 90%, which corresponds to the performance of many popular Western analogues.

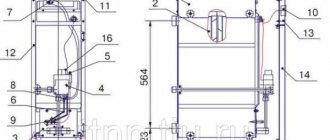

Design of floor-standing gas boilers Siberia:

- Internal heat exchanger of the heating circuit, for single-circuit devices.

- Secondary heat exchanger for heating DHW, for dual-circuit devices.

- Multifunctional three-way valve for adjusting coolant flows.

- Set of gas elements: shut-off valve, torch combustion stabilizer, fine filter.

- Automatic piezo ignition.

- Gas burner device in the form of two burners - main and ignition.

- Automatic regulation and protection system.

The basic functions of the Siberia gas boiler are performed by the burner device and heat exchangers, where the water coolant is heated. The heated water directly enters the three-way valve for single-circuit modifications or flows through the secondary boiler, heating the water for domestic hot water.

In the mixing unit, the coolant acquires the specified temperature and enters the heating circuit. The movement of streams occurs by gravity, under the influence of natural circulation of layers of water.

Similarly, using the natural circulation of air layers, smoke combustion products are discharged into the atmosphere.

Device Features

So, Siberia gas boilers have the following operational features:

- The size of the flame is adjusted automatically, and this is done very smoothly.

- The device has a very high level of efficiency - up to 90%.

- The device is capable of heating rooms whose area ranges from 100 to 500 square meters. m.

- The heat exchanger can be open or closed, it all depends on the model of the device.

- The temperature of water and heating is regulated separately, which allows you to use the Siberia gas heating boiler as a boiler in the summer. The heating system remains switched off.

- Availability of additional functions: anti-blocking of the circulation pump, resistance to contamination and freezing.

Advantages of Siberia boilers

The Siberia boiler is a product of an Italian manufacturer, which in terms of quality can easily compete with most European companies. It is thanks to the impressive list of advantages that Siberia is the best-selling Russian brand of gas boilers.

Siberia boilers have gained great popularity in the domestic consumer market due to their excellent performance and high quality. Therefore, we invite you to familiarize yourself with the main advantages of such equipment.

The advantages of the Siberia gas floor-standing boiler:

- Quite long service life. Siberia boilers are made exclusively from high-quality materials that wear out slowly and rarely fail.

- The cost of such boilers is lower than that of European models of similar quality. It is also worth noting the cost-effectiveness of servicing Siberia boilers.

- Such a device is controlled exclusively using automation. Thanks to this, gas boilers from this company are safe and easy to use.

- Such boilers are quite easy to install. In addition, they have relatively compact dimensions for floor-standing equipment.

- The burner of such boilers is made of heat-resistant steel. At the same time, the choice of Siberia boiler models is truly huge.

The advantages of these devices explain their popularity. Most of their owners like these boilers and, judging by the reviews, they do not have any obvious drawbacks.

Advantages

Siberia boiler logo

According to the manufacturer, the Siberia gas floor-standing boiler is a new generation heating device that is used not only to heat a house, but also to supply it with hot water. If we compare these devices with foreign-made analogues, we can note the following advantages:

- a wide range of models, each user will be able to choose the best option based on the required functionality and funds;

- fully automated control system that ensures simple and safe operation;

- the units are highly economical;

- ensures uninterrupted operation of the device even in harsh operating conditions;

- availability of service support;

- acceptable price.

Technical characteristics of Siberia brand boilers

If you are interested in Siberia boilers, you should take a closer look at their technical characteristics. In terms of quality of work and design, the products are not inferior to foreign analogues. And if we compare with competitors, these units have many advantages. For example, the heat exchanger tank is quite durable. It is reliable due to the use of high-quality materials in the manufacturing process. During the production of the equipment, an automatic welding process is used. The units are equipped with a steel heat exchanger, which is able to guarantee efficient heating of the coolant.

On sale you can find models that are equipped with a cast iron heat exchanger. It ensures the service life of the device up to 25 years or more. Siberia double-circuit boilers supply hot coolant to the heating system due to the fact that a copper circuit is installed inside. If necessary, you can use the equipment in a water supply system with forced and natural circulation. The described units are manufactured using a layer of thermal insulation. It eliminates injury and burns. The devices are manufactured using high-quality materials and are easy to maintain during operation.

The lineup

The Siberia line of floor-standing boilers includes nine models, of which five are designed only for heating, and four are designed for heating and domestic hot water supply.

Attention! The letter “K” in the designation indicates that the boiler has the ability to extract water for household needs. In other words, it is intended for heating and hot water supply at home

The power of the boilers varies from 11.6 kW to 35 kW, which is enough to heat rooms ranging from 100 to 350 m2. Below are the main technical characteristics of the lines of floor-standing gas boilers, AKGV and AOGV.

A feature of the boilers of this model range is the presence of a steel heat exchanger, which has high strength and reliability, and also ensures efficient heat transfer to the coolant.

Important! Steel is susceptible to corrosion. It is this fact that casts doubt on the long service life of a gas boiler with a steel heat exchanger

For heating large rooms, the manufacturer has provided a line of boilers with a cast iron heat exchanger KCHGO. The model range includes floor-standing boilers with a power from 16 to 50 kW. For clarity, we present a list of technical characteristics of this line of Siberia gas boilers.

Cast iron heat exchangers are not subject to corrosion and practically do not react to low quality coolant

However, the “innate” fragility of this material requires careful operation from the owner, which is to prevent sudden changes in coolant temperatures

Based on the foregoing, we can conclude that the range of Siberia floor-standing gas boilers is indeed quite large and capable of satisfying the demand of domestic consumers.

The most reliable models

All Siberia gas boilers have a good trouble-free operation period of more than 10 years.

The most popular model lines:

- Single-circuit floor heating with power from 11 to 35 kW: Siberia 11, Siberia 17.

- Double-circuit gas boilers with simultaneous heat supply for heating and hot water supply: Siberia 17K, Siberia 23K.

- Models with increased power and cast iron heat exchanger: Siberia KCHGO-40, Siberia KCHGO-16.

Siberia or Lemax: which is better

Floor-standing gas boilers have a similar, slightly more complex design, but similar automation and burners. The efficiency of almost the entire Lemax model range is also 90%, but gas consumption is on average 10% higher. For example, Lemax Premium-16 kW has a maximum gas consumption of 1.9 m3/hour. Lemax boilers are quieter, and even steel models are designed to operate in a circuit with a pressure of up to 3 bar. However, their cost is 10-20% more expensive.

Siberia is more reliable, more economical, simpler and cheaper. But it is deprived of the above-described advantages inherent in the Lemax model range. In general, both manufacturers are worthy of attention and it is not for nothing that they are sales leaders among domestic manufacturers of gas boilers.

Review of Lemax gas boilersThe most famous and widespread among domestic models

Manufacturer of universal boilers

The Siberia representative office in Rostov-on-Don is Russia's largest manufacturer of the RGA and AOGV model ranges. The

well-known Siberia trade representative office, located in the city of Rostov-on-Don, is the largest Russian manufacturer of the RGA and AOGV model ranges. The company was registered in 2002, but the date of its birth is unofficially considered to be the beginning of factory production, opened in the middle of the last century. Already in 1959, the AOGV-80 model, which later became legendary, was released.

The history of the Sibir trademark indicates that this enterprise has extensive experience in the manufacture of gas equipment. This is confirmed by the ever-expanding demand for budget models, which differ from Western models in their simplicity of design and low fuel consumption. In this they differ significantly from more expensive products of the Russian brand Lemax, for example, or similar heating units from Ukraine.

Known faults of Siberia boilers

As mentioned earlier, the common simple design of floor-standing boilers does not imply serious damage, especially if regular maintenance of the main modules is carried out. Therefore, there is practically no demand for spare parts for Siberia boilers. Only occasionally there are cases of replacing the igniter or thermocouple (often the reason for its replacement is oxidized contacts, which can simply be cleaned with sandpaper).

Unlike service complaints, operating difficulties are more common. Most often, owners encounter the following phenomena:

+ The igniter or main burner does not light

Make sure that you light the boiler according to the algorithm described earlier. If you follow the instructions exactly, the most common cause is reverse thrust or no thrust at all. To check the presence of draft, hold a lit match to the window at the bottom of the boiler, on the burner module block: if the fire goes in the direction of the combustion chamber of the boiler, then everything is in order with the draft; if it remains unchanged or moves away from the boiler/goes out, it means there is not enough draft or the boiler is being blown by the wind. What to do if the gas boiler blows out in a strong wind

Another common cause is a clogged pilot or main burner. It is necessary to disassemble the boiler by removing the burner module and carefully clean the igniter first and then the burner. Be careful not to allow even the slightest scratches or deformations.

+ The igniter (wick) goes out

If the pilot burner lights up, but goes out after 5, 10 or 15 seconds, the problem is almost guaranteed to be backdraft. Check its presence with a lit match, as described in the previous case. The cause of backdraft in most cases is an incorrectly designed chimney: insufficient or excessive length, lack of a protective deflector, etc.

+ The boiler does not reach temperature (usually more than 60 degrees)

The most common cause is a clogged gas valve (on the gas supply line). Unscrew the gas pipeline nut in front of the boiler automation and carefully blow through the tube, as well as the mesh in it. If the temperature has not returned to normal, make sure that the boiler’s heating output is sufficient to replenish the heat loss in the house and that it is not operating at its maximum. For example, measure the gas consumption per hour of operation at maximum power and compare it with the factory indicators: if your consumption indicator is equal to or greater than the factory one, the boiler really does not have enough power.

+ Errors E01 and E04 for mounted boilers

Error E01 indicates the absence of flame. This can happen if the gas supply valve is closed, there is a pressure drop in the gas line or a short-term power outage (even for 1 second). Error E04 indicates a drop in pressure in the system below a critical point (0.7 bar). Most often this happens due to air locks, leaks, a malfunction of the expansion tank or relief valve. We have already described all possible causes of pressure drop in one of the previous articles.

Compliance with operating rules

The heater, like any other equipment, will last longer and be of better quality if you follow the established rules during use:

- Do not turn on if the burner is faulty;

- Do not use if the chimney is dirty;

- The case must be grounded;

- It is necessary to ensure that the water in the system does not reach a boil;

- The boiler must be installed in a safe place to prevent the surrounding materials from catching fire;

- Before turning it on, you should make sure that the system is full;

- Maintenance should be carried out once a year:

- Chimney cleaning;

- Filter cleaning;

- Burner flushing;

- Checking the tightness of connections.

Read with this

- Types and principle of operation of a gas boiler for heating a private house

- Turbocharged or atmospheric gas boiler? which one should I take?

- The operating principle of a double-circuit gas boiler. classification and advantages

- Why does a gas boiler go out: what could be the reasons and what to do if it turns off

- Ariston double-circuit gas heating boilers

- Wall-mounted, non-volatile gas boilers

- How to choose a wood-electricity combi boiler

- Design and application of a mini gas burner

- How to reduce the power of a gas boiler: the best options to reduce gas consumption by the boiler

- Lemax boilers