The heating system of a private house is a complex pipe layout, the heart of which is the heating boiler. It heats up the coolant, which, under the influence of the laws of physics or with the help of a circulation pump, moves through the pipes, enters the radiators, where it gives off its heat, and cools down again into the boiler. And this process is repeated ad infinitum.

The modern market of boiler and heating equipment today offers a huge range of heating devices. Unfortunately, the price of many models is not affordable for everyone. Therefore, some consumers are faced with the question of whether it is possible to make a heating boiler with their own hands, will this home-made device work as efficiently as factory-made analogues? You can make a boiler if you are a good welder and it will work just as well.

Types of heating boilers

First of all, you need to decide which boiler is needed for your home. This will depend on the fuel that will be used for kindling. Hence the classification:

- gas;

- electrical;

- solid fuel;

- liquid fuel.

Electrical

Any of these boilers can be made with your own hands. The simplest of them is electric. Essentially, this is a tank in which a heating element is mounted. There are also two pipes coming out of the tank, connected to the supply and return circuits. There is no chimney, no combustion chamber, everything is simple.

Electric boilers are good for everyone, but they have two drawbacks. First: electricity is the most expensive fuel. Second: when the voltage in the network drops (and this happens with enviable regularity), the boiler stops working correctly. Its power decreases and the coolant temperature drops.

Gas

The designs of other types are more complex. And they are all practically similar to each other with some differences. As for the gas boiler, its installation will require permission from the gas service.

Representatives of this organization may not accept such a heating unit for installation. First of all, they will require that it be tested in their laboratory.

The presence of the act is a guarantee that you will still be given permission.

Liquid fuel boilers

The operation of this option is associated with great difficulties. Firstly, you will have to build a separate warehouse near the house where the fuel will be stored. Everything in it must comply with fire safety requirements.

Secondly, a pipeline will have to be drawn from the warehouse to the boiler room. It must be insulated. Thirdly, a special burner is installed in this type of boiler, which must be adjusted. This is not so easy to do in terms of setup.

Solid fuel

It is this type of boiler that home craftsmen most often produce with their own hands today. For small dachas and cottages this is the best option. Moreover, firewood is by far the cheapest type of fuel.

We will talk about how to make a boiler that runs on solid fuels for heating a house below.

How does the combustion duration of solid fuel increase?

The dream of many homeowners is to install a solid fuel boiler, to which they do not have to run with firewood every 4-6 hours. Taking advantage of this, manufacturers and sellers of heating equipment apply the prefix “burning duration” to all heat generators, including pellet ones, which operate independently for up to 7 days.

Varieties of classic boilers with an enlarged fuel chamber

The duration of the combustion process is usually justified by using the smoldering mode with a limited air supply. But burning wood and coal in this way is ineffective, and here’s why:

- Wood and coal boilers reach their efficiency of 70-75% during maximum combustion. When smoldering, the efficiency of the unit decreases to 40-50% (like a conventional potbelly stove).

- Smoldering firewood produces little heat energy. Who needs a “long-lasting” heat generator that does not fully heat the house?

- Freshly cut wood of certain species (for example, poplar, willow) and low-calorie fuel cannot be burned normally in smoldering mode.

Factory boiler with an enlarged firebox, where wood burns from top to bottom

In fact, long-burning solid fuel boilers are those that have an enlarged fuel chamber, only its size affects the duration of the process, all other things being equal. The principle is simple: the more wood in the firebox, the longer it burns and produces heat.

Household boilers that can operate for 8-12 hours on wood and up to 24 hours on coal from one start are of the following types:

- classic, with forced air supply;

- operating on the principle of top combustion (such as the Baltic “Stropuva”).

It is quite possible to make these designs of TT boilers at home if you have the necessary tools and practice in welding. You can also find drawings of mine boilers using solid fuel and sawdust on the Internet, but such heaters are quite bulky and difficult to manufacture, and therefore deserve a separate topic.

What will you need?

As mentioned above, in order to weld a heating unit, you must be a good welder. Amateur level work will not work here.

Tools

What is required to carry out this work. Tools you will need:

- electric welding machine;

- cutting torch;

- Bulgarian;

- hammer;

- roulette;

- marker or chalk.

Materials

From materials:

- seamless pipe with a diameter of 425 mm;

- pipe with a diameter of 100 mm;

- pipe with a diameter of 25 mm;

- metal sheet 4 mm thick;

- two bends with a diameter of 25 mm;

- small loops;

- corner 25 mm;

- fittings with a diameter of 8 mm.

Project

Many beginners look for boiler drawings on the Internet or special technical literature and already work on them. In principle, this is the right way.

The most important thing is to find drawings that indicate the dimensions of the heating device.

Where can I buy

You can purchase a water heater as quickly as possible at your nearest specialty store. A good option in terms of price-quality ratio is purchasing from the AliExpress online store. Mandatory long waits for parcels from China are a thing of the past, because now many goods are in intermediate warehouses in destination countries: for example, when ordering, you can select the “Delivery from the Russian Federation” option:

| HYUNDAI Instant Electric Water Heater | Electric water heater TINTON LIFE with temperature display | Stainless steel liquefied water heater |

| 2500W floating electric water heater, for bath, swimming pool | RX-21.3500W instantaneous electric water heater | Kitchen electric water heater HYUNDAI |

Case manufacturing

So, first of all, the details of the future unit are prepared. The body of the heating device will be made from a 425 mm pipe. For a small heating boiler, a height of 1.0-1.2 m, taking into account the small diameter, is the best option.

We cut the pipe to these dimensions using a gas cutter. We process the edges with a grinder.

Openings for firebox and ash pan

Now you need to cut two holes in the body: for the firebox and for the blower. They should be rectangular. A size of 20x10 cm is suitable for the firebox, 20x3 cm for the blower. They are located one above the other, the firebox hole is higher.

The distance from the edge of the pipe to the blower is within 5-7 cm. The distance between the holes is 5 cm. The edges of the hole are processed with a grinder. A cut piece of the firebox pipe wall will be used as a door. Its edges are also cleaned.

Holes for pipes

Using a cutter, two more holes are cut for the supply and return pipes with a diameter of 25 mm. The holes are located opposite each other. In this case, the return hole is cut out on the side of the boiler above the firebox: from the firebox hole at a distance of 15 cm.

At a distance of 5 cm only from the upper edge of the housing, a hole is cut to supply coolant. Two bends can be welded to these holes right there.

What parts does a solid fuel boiler consist of?

Before you start working on the boiler, you need to understand its operating principle. Main elements of the boiler design:

- The combustion chamber is a chamber into which fuel is placed and where the combustion process occurs.

- The heat exchanger is the main structure of the boiler through which the coolant passes and, after heating, enters the heating system.

- The body is a structure that contains all the components of the boiler.

Independent creation of heating boilers for the home is usually limited to a simple design, but nevertheless has two design options: brick and metal.

Let's consider each option in detail.

Internal details

Three pancakes are cut from a metal sheet: two with a diameter of 425 mm, one with a diameter of 412 mm. The latter will be installed inside the housing, and since the thickness of the pipe wall is 6 mm, then 12 mm falls on the diameter, plus 1 mm for free entry.

In one of the pancakes with a diameter of 425 mm and in a circle of 412 mm, a hole with a diameter of slightly more than 100 mm is cut in the center. A chimney is being prepared from a 100 mm pipe. To do this, a section of 120-130 mm is cut. Pieces 50 mm long are cut from a 25 mm pipe for the legs of the boiler. A grate for the ash pan is made from fittings; the size of the internal diameter of the body is taken as a basis.

Assembling the heating unit

First of all, the chimney is welded to the 412 mm pancake. Then, temporary stops must be welded inside the housing at a height of 30-35 cm from the combustion hole. It can be wire or fittings. A pancake with a chimney is lowered on top of them.

Main joints

And now the most important point - you need to weld the pancake and the boiler body together. It is necessary to weld the seam on both sides and it must be done efficiently. This joint is the connection between the firebox and the water tank.

Next, a 425 mm pancake is placed on the chimney protruding from the boiler. Here it is necessary to thoroughly weld two joints: between the outer edges of the pancake and the boiler body, between the chimney and the metal circle.

Combustion compartment

The next stage concerns the combustion chamber. On the back side of the chimney, a ready-made grille made of reinforcement is inserted into the housing.

Then, several pieces are cut out from a 25 mm angle using a grinder, which are welded inside the boiler between the combustion hole and the ash pan. These will be the stops on which the grille will rest.

Lower body

And one last thing. It is necessary to weld a 425 mm pancake to the lower edge of the body, weld four legs from a 25 mm pipe with a height of 5 cm to it. Next, weld the hinges on which the firebox door is hung.

Blower valve design

The design can be different: in the form of a regular door, in the form of a gate (this is a damper that moves in the plane of the hole), in the form of a rotary damper with holes in the body. Finished products are sold that are simply welded in place.

You can weld a solid structure with your own hands and attach it to the boiler. Of all the proposed options, the simplest is either a door or a gate.

What does the design depend on?

The design of the heating boiler is influenced by several conditions:

- cost and availability of materials;

- Type of fuel;

- coolant circulation method.

Heat-resistant stainless steel demonstrates the greatest durability. However, it is this that has the highest price on the market, and its processing is a rather complex task that cannot be handled without special equipment. The same applies to cast iron, which, however, costs much less than stainless steel. Traditionally, for the manufacture of heating boilers, sheet steel with a thickness of 4 mm is used - this option is relatively easy to process and, most importantly, is quite reliable and durable.

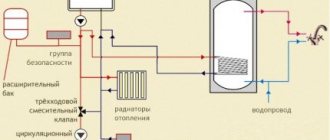

To ensure natural circulation of the coolant, it is necessary to use heating circuits and connecting fittings of large diameter, and place the storage tank at a height. If this is not possible, you will have to use a circulation pump - it will reduce the diameter of the pipes. However, the heating boiler pumping system is energy-dependent, which must be taken into account when choosing the design and functionality of the unit.

Testing and connecting to the system

The solid fuel boiler for heating the house is ready. Now you need to check it. To do this, a plug is screwed onto one of the outlets, and water is poured into the second. If water does not pass through the welds, then the welding was carried out at a high level.

There is no need to fear that the heating unit will leak during operation. The finished unit is connected to the heating system of a country house. That is, the flows are connected to the coolant supply and return pipes.

Chimney installation

The chimney is being installed. Please note that this element of the device must extend vertically upward. If it is not possible to arrange it in this way, then there should be a minimum number of bends.

In an unheated attic it will have to be insulated.

First kindling

It is very important to conduct the first fire correctly. In this case, large amounts of fuel cannot be used. A small fill should heat the unit itself, especially the chimney. With a sharp increase in temperature, condensation may form on its walls, which will turn into tar, narrowing the diameter. And this is a decrease in draft, which is responsible for the correct operation of the heating device.

Gap adjustment

During the combustion process, the gap in the ash pan is adjusted. It is necessary to find the optimal size that will provide the combustion chamber with the required amount of fresh air (oxygen).

Be sure to pay attention to the height of the bookmark. Its upper edge should be located at a distance of 20 cm from the inner pancake. This distance will ensure optimal combustion of wood or coal. In this case, smoke and carbon monoxide will be freely discharged through the chimney pipe.

Varieties

Any electric boiler can be divided according to different criteria:

- Principle of operation;

- Type of instalation;

- Power adjustment.

According to the operating principle

It is quite possible to make a homemade electric boiler for heating of the following types:

- Induction - water is heated using eddy currents in the core of an electromagnetic circuit.

- Electrode - the liquid between two electrodes is heated due to the current passing between them.

- Heating elements - closed-type heating elements, under the influence of current, heat up and transfer heat to the surrounding coolant.

type of instalation

- Wall mounting is a more compact option for placing a heating boiler and, accordingly, low power.

- Floor installation is more voluminous, but, in principle, the dimensions do not matter much, since in this option it is possible to increase the power of the heating equipment.

Power adjustment

Strictly speaking, this concerns the additional capabilities of the equipment that will be used in conjunction with heating boilers. These are various types of automation that are capable of equalizing the temperature of the coolant in the heating circuit. It can be of different designs:

- relay;

- seven-sided;

- on a magnetic starter.

Principle of operation

In essence, a traditional solid fuel boiler works like a regular stove. There is also a firebox in which wood (coal, pellets and other types of solid fuel) burns. The released energy heats the coolant located in a container above the combustion chamber.

The coolant in this design is heated both from the internal pancake and from the chimney, which penetrates through the container with water. At the same time, the boiler body also heats up, which creates an accumulating effect that inhibits rapid cooling when the unit is turned off.

The heated coolant rises up and exits through the upper pipe into the supply circuit of the heating system. The cooled coolant enters the boiler through the lower pipe connected to the return circuit.

Pros and cons of wood-burning home heating

The use of solid fuel units is a common way of arranging autonomous heating for private buildings, cottages, garages, as well as industrial facilities.

It is quite possible to construct a wood-burning boiler with your own hands if you understand the operating principles of this equipment, follow the manufacturing technology and at the same time take into account fire safety requirements.

Wood-burning units have the following advantages compared to boilers operating on other types of fuel:

- Wood used for heating is affordable and does not require large energy costs.

- Firewood is an environmentally friendly material that does not cause allergies or other diseases.

- The device is easy to use.

- The room warms up very quickly - after starting the boiler, heat begins to flow into the room immediately.

- Wood-burning equipment is energy independent.

- The appliances can provide hot water at no additional cost. The boiler heats a boiler with liquid, which acts as a water heating radiator.

Wood-burning units have fewer disadvantages:

- The metal body is susceptible to corrosion.

- The equipment requires regular cleaning of ash collected during fuel combustion.

- A single load of fuel is enough for a short time.