For those who are interested in what it is - a coaxial chimney for a gas boiler, the material in this article about self-installation and construction of such a design will be useful. The modern choice on the market of heating devices from various manufacturers is striking in its diversity; more and more users are choosing water heating devices of various designs for autonomous heating systems.

Difference from conventional pipes: what's new

First of all, it stands out for its greater efficiency and safety. Designed to remove hot flue gases containing harmful substances formed during the combustion process. Its advanced design is suitable for models with a closed combustion chamber.

The cost is much higher than a simple steel product, but the performance qualities fully justify such an investment. It is much easier to buy it than to make it yourself, although this method is also possible. The fundamental difference between such a gas outlet and a conventional one is that clean air enters it from the street, and is not taken from inside the boiler room.

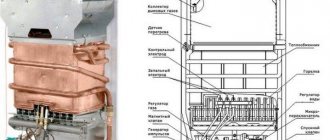

Design and operating principle

The name itself means “double channel”. This refers to two pipes of different diameters, with one being inserted inside the second. At its core, the device of a coaxial chimney for a gas boiler is a set of a pair of pipes nested one inside the other - a narrow one inside a wide one. In order for their central axes to coincide with each other, their surfaces are connected by jumpers that hold them in the desired position.

The internal circuit with a diameter of 60 mm is designed to remove combustion products. Through the outer one, with a diameter of 100 mm, an air supply is provided, called the “inlet”. The supply of oxygen is necessary for maximum fuel combustion, which significantly increases the efficiency of the boiler and reduces harmful emissions into the atmosphere.

The installation of a chimney can be considered using the example of a double-circuit design

The installation of chimneys for a gas boiler is carried out in the direction of the structure from the bottom up, that is, from the heating objects of the room towards the chimney. With this installation, the inner pipe is put on the previous one, and the outer pipe is inserted onto the previous one.

All pipes are fastened to each other with clamps, and along the entire laying line, every 1.5–2 meters, brackets are installed to secure the pipe to a wall or other building element. A clamp is a special fastening element that not only connects parts to each other, but also ensures the tightness of the joints.

The laid sections of the structure in the horizontal direction up to 1 meter should not come into contact with elements that run close to communications. Working chimney ducts are located along the walls of buildings.

Be sure to install a bracket on the wall every 2 meters of the chimney, and the tee is attached using a support bracket. If it is necessary to attach the channel to a wooden wall, then the pipe is lined with non-flammable material, for example, asbestos.

When mounting on a concrete or brick wall, special aprons are used. Then we bring the end of the horizontal pipe through the wall and there we mount the tee required for the vertical pipe. The brackets must be installed on the wall every 2.5 m.

The next step is to secure, lift the vertical pipe and lead it through the roof. The pipe is usually assembled on the ground and the mounting brackets are prepared. A fully assembled volumetric pipe is difficult to install on an elbow.

To simplify, use a hinge, which is made by welding pieces of sheet iron or cutting a pin. Typically, the vertical pipe is inserted into the tee pipe and secured with a pipe clamp. Attaching the hinge to the knee occurs in a similar way.

After lifting the pipe in a vertical position, the pipe joints should be bolted together where possible. Then you should unscrew the nuts of the bolts on which the hinge was fastened. Then we cut or knock out the bolts themselves.

Having selected the hinge, attach the remaining bolts to the joint. After this we tighten the remaining brackets. We first adjust the tension manually, then secure the cable and adjust it with screws.

Required distances to be observed when placing the chimney outside

The installation is completed by checking the chimney draft. To do this, bring a burning piece of paper to the fireplace or stove. Draft is present when the flame deviates towards the chimney.

The figure below shows the distances that must be observed in various options for placing the chimney outside:

- when installed on a flat roof, the distance should not be less than 500 mm;

- if the pipe is removed from the roof ridge at a distance that is less than 1.5 meters, the height of the pipe must be at least 500 mm in relation to the ridge;

- if the chimney outlet installation is located at a distance of more than 3 meters from the roof ridge, then the height should not be greater than the expected straight line.

The installation depends on the type of channel directions required for fuel combustion. In the interior of the room, there are several types of directions for the chimney duct:

Chimney support bracket

- direction with a rotation of 90 or 45 degrees;

- vertical direction;

- horizontal direction;

- direction with a slope (at an angle).

It is necessary to install support brackets to secure the tees every 2 meters of the smoke duct; additional wall mounting must be provided. Under no circumstances should horizontal sections higher than 1 meter be created when installing a chimney.

When installing chimneys, consider:

- the distance from metal and reinforced concrete beams to the inner surface of the chimney walls, which should not exceed 130 mm;

- the distance to many flammable structures is at least 380 mm;

- cuttings for non-combustible metals are made to allow smoke ducts to pass through ceilings to the roof or through a wall;

- the distance from combustible structures to an uninsulated metal chimney must be at least 1 meter.

Connecting the chimney of a gas boiler is carried out on the basis of building codes and the manufacturer’s instructions. The chimney requires cleaning up to four times a year (see How to clean a chimney).

To optimally calculate the height of the chimney, it is necessary to take into account the type of roof and the height of the building:

- the elevation of the chimney pipe must be at least 1 meter when installed on a flat roof and at least 0.5 meter above a non-flat one;

- the location of the chimney on the roof must be done at a distance of 1.5 meters from the ridge;

- The height of an ideal chimney is at least 5 meters high.

How the design works

Air masses from the street enter inside through a larger diameter pipe. Passing through the external channel, they absorb heat from the internal channel, which serves to remove exhaust gases. The movement of air of different quality and temperature occurs in different directions. It enters the combustion chamber already hot, no additional energy is wasted on heating it, which significantly increases efficiency. At the same time, gas consumption per unit time decreases, making heating equipment much more economical.

Heating from the inside, the air from the outer channel simultaneously cools it, preventing overheating. This feature, firstly, ensures a long service life, and secondly, makes it possible to install it even in a wooden house without any additional protection: in good condition it is not at all fire hazardous. But nevertheless, it is often additionally thermally insulated with basalt insulation, as this significantly improves traction and efficiency.

Fire safety technology

It is allowed to install a chimney in accordance with the requirements:

SNiP 2.04.05–91U.

DBN B 2.5-20–200.

NAPB A.01.001–2004.

Installation should only be carried out by professionals. The cross-section of the chimney must correspond to the value specified by the manufacturer in the instructions supplied with the boiler.

The required chimney height is usually recommended by the manufacturer, or it must exceed 5 meters.

If there is a horizontal section, its length should not exceed one meter.

The design must provide for the possibility of draining condensate, as well as cleaning the smoke exhaust channel.

How to connect a chimney

All connections of parts to the nozzle of a solid fuel boiler are made with a heat-resistant sealant that can withstand temperatures in the range of 1250-1500 degrees.

When the diameter of the chimney does not match the size of the chimney outlet, an adapter is installed to create a tight joint.

How the parts are assembled

Any single-walled, as well as sandwich, with insulation, are assembled in only one option: “pipe is inserted into pipe.” The connection points of the chimney parts do not require the installation of additional clamps.

If the structure is made of special stainless steel, assembly is carried out only using condensate. In this case, condensate, as well as the resulting tar deposits, will never get out; they will flow along the walls of the pipe directly into the condensate drain.

If a revision is used in the chimney and tees are installed, all parts are assembled “according to the smoke.” The assembly of vertical parts extending from the tee is carried out “using condensate”.

If it is necessary to line the channel, the gap formed between the pipe and the channel must be more than 4 cm. It is necessary when the metal expands when heated.

To ensure that the chimney sandwich parts have a more rigid fastening, rivets are installed or screws are screwed in.

Fixing the chimney

The pipe is attached to the wall only with special materials.

The single-wall structure must be fastened with a fastening step of 1.5 meters on all vertical sections of the pipe.

If the sandwich chimney does not have a supporting structure, it is necessary to secure each element.

If the system uses a 45–87 degree tee or a 45–90 degree elbow, installation is carried out in such a way that the load on the rotating parts of these parts is completely eliminated.

If installation requires additional support, use a floor stand installed under the inspection.

When the chimney pipe is raised above the roof by more than 1.5 meters, a bracket must be installed under the brace.

Passage through floors

To make a passage through the wall of a house or its ceiling, it is necessary to use the building codes that are in force in Ukraine today.

If a sandwich chimney with insulation passes through wooden walls, a liner must be installed and another layer of thermal insulation is applied.

When a chimney pipe is installed through the roof, builders must install a special additional pipe part, the so-called “roof”. Another additional layer is created, consisting of fireproof insulating materials.

The final stage of construction

When a brick chimney is lined, its upper part is covered with an additional part - the end.

Usually the top of the pipe is covered with a baffle or a beautiful fungus.

If the building's roof covering is made of a fire-hazardous material, such as bitumen shingles, a special spark arrestor is mounted on the top of the chimney.

If a gas boiler is installed in the house, installing a deflector is strictly prohibited. According to current regulations, the upper part of the gas device pipe is always kept open.

What's included as standard

The main component is a coaxial pipe that runs from the heat generator and goes outside. It consists of three parts:

- adapter;

- bend at 90°, 30° and 45°;

- the pipe itself.

If a resident of an apartment building wants to have a gas boiler with a closed combustion chamber, the implementation of this idea will only be possible if there is apartment heating, and then the pipe will go into the shaft.

The approximate kit looks like this:

- coaxial pipe 1.0 m and compensator 0.5 m;

- “elbow” – angled adapter, 45° or 90°, for connection;

- tee for connection;

- transition coupling;

- draft regulator;

- unit for preventive cleaning of the device;

- condensate drain;

- protective screen of the outer part;

- securing clamps;

- support platform;

- cone;

- flange for attaching to the wall of the house;

- O-rings to provide tightness and tightness at joints.

The range and prices of Ferrum store parts can be found in the price list on the website.

Placement of coaxial chimney systems

- Experts recommend determining the location of the chimney system only after installing the gas combustion boiler itself.

- Place the pipes from window and door openings at a distance of at least 50 cm. To ensure the best traction, the first component pipe must be at least 1 meter in length. It is secured at the boiler outlet on the pipe with a metal clamp.

- If the boiler is equipped with a natural exhaust, then the chimney elbow must be installed above this structure. If a fan is installed, installation can be carried out at any height.

- Then you need to arrange a hole for the pipes to exit to the street; if the house is made of wood, then you will need to install a thermal insulation layer: this will prevent a possible fire in the wood.

- So that the resulting condensate can go through the drainage system to the street, the pipes are installed with a downward slope.

Coaxial chimney for a gas boiler: materials for manufacturing

There are various options available on the heating market.

Plastic

Pipes made of polymer material with high heat resistance can withstand heating up to 205°C and are suitable for condensation-type devices. Their advantages include ease of installation, light weight, and affordable price. However, the cost is justified: such products are short-lived, they have to be changed often, and besides, they are not suitable for other types of gas boilers, since they have restrictions on connecting to them.

Their service life is no more than 5 years. Plastic parts can only be used to remove gases in low-temperature mode: the maximum temperature must not be exceeded, as this will lead to malfunction of the device.

Stainless steel

Steel parts are much more in demand in the harsh Russian climatic conditions, especially in the northern regions, where heating must be used most of the year. For example, the chimneys of the Craft LAS series are made of austenitic stainless steel AISI 316. This allows them to be used with condensing boilers with low temperatures of combustion products.

The fuel in such heat generators is saturated with hydrogen and, as a result, is characterized by high dew point temperatures. Under these conditions, there is a high risk of condensation and an aggressive acidic environment. This steel is suitable for use over a wide temperature range and is resistant to a large number of concentrated acids, so it is ideal for servicing apartment heating systems.

Stainless steel is resistant to aggressive substances, its heat resistance is much higher than the most durable plastic - up to 550°C. Stainless steel products are divided into 2 types:

- Non-insulated (double-circuit) - have a more primitive design, the internal part is acid-resistant. It is durable and can be used for residential and industrial premises. Limitations include its mandatory thermal insulation to reduce the release of condensate during the cold period.

- Insulated (three-circuit: sandwich-double-circuit pipe) - suitable for placement on the street or in an uninsulated shaft. They are most often used for vertical smoke exhaust in multi-storey buildings from several boilers at once. It has the ability to connect to a device with both natural and forced flue gas exhaust systems. This design has better aerodynamic characteristics and a long service life - up to 30 years. The disadvantages include the need for preliminary complex calculations, which have to be ordered from the design organization. This is a mandatory requirement, since a chimney with a vertical outlet and external air intake is installed during the construction phase of the building, which means it must be included in the project.

Our production

Single wall chimneys

Double wall chimneys

Mounting elements

Chimney device for a turbo boiler

The coaxial flue duct is a double-walled “pipe-in-pipe” structure that simultaneously performs 2 functions: removing smoke to the outside and taking in combustion air from the street. Hot gases move along the internal channel, the air flow goes towards the outer channel (between two walls).

Important point. The forced movement of combustion products and air is provided by the gas boiler fan; natural draft does not work here. At the same time, the coaxial chimney cannot be connected to turbocharged units using other types of fuel - wood, pellet or diesel.

The diagram shows a vertical version of the chimney, but more often it is installed horizontally

The 2 in 1 chimney system “air/combustion products” provides the following advantages:

- Hot gases give off some of the heat to the air flow, the combustion process improves, and the efficiency of the heat generator increases.

- The coaxial pipe is led out horizontally, using the shortest route through a hole in the outer wall. In some cases, vertical installation is possible.

- Thanks to the double-walled design of the flue, the turbo boiler or column can be installed in almost any room without a traditional smoke duct - the kitchen of a country cottage, garage, basement and even in a bathhouse. The room must meet the requirements for gas boiler rooms.

- The owner does not need to worry about the additional flow of air needed for combustion. Although general ventilation will still have to be done.

Clarification. In apartment buildings, it is prohibited to lead a horizontal smoke duct to the street through a wall.

The disadvantage of the chimney system is the freezing of the tip in severe frost. The sucked air comes into contact with the hot wall of the inner pipe and releases condensation, forming an icicle. The problem is solved by installing a special stainless steel extension cord.

Main elements of a coaxial chimney:

- straight section with a head at the end;

- the same double-walled bend at 90° or 45°;

- adapter – adapter for the coaxial output of the boiler;

- connecting clamps, flanges;

- elastic cuffs, aprons;

- inspection section with condensate drain (for vertical installation);

- fastener

Note. Different adapters can be used to connect to different heaters. For example, Viessmann Vitopend wall-mounted boilers are already equipped with a flange and pipe, while for the Vaillant Turbo heat generator these parts are supplied separately.

Installation kit for the STOUT coaxial system for horizontal installation. The adapter is suitable for gas heat generators Bosch, Buderus.

We will tell you how to install coaxial elements correctly below. But first we suggest you study...

Advantages and disadvantages of use

Let's look at the positive and negative characteristics.

Pros:

- Drawing in air masses from outside, which allows you to keep the composition of the air in the boiler room unchanged. There is no foreign smell in the room, no burning. This significantly reduces ventilation and space requirements and therefore reduces costs. A boiler with a closed firebox can be installed even in unventilated areas, because it consumes slightly more oxygen than a conventional gas burner.

- Economical fuel use and higher equipment efficiency.

- Environmental friendliness: since the raw materials are completely burned, fewer pollutants are released into the atmosphere with smoke.

- Quick installation and commissioning.

- Possibility of combination with any heating device, as well as use for multi-apartment residential buildings with a height of several floors.

- If installed correctly, this can significantly increase traction.

Disadvantages of the system:

- Formation of condensate containing toxic substances and requiring special storage and disposal conditions.

- The second drawback follows from the first: the need to coordinate the installation with the Sanitary and Epidemiological Supervision Authority and obtain a permit, as well as a fine in case of improper disposal of toxic waste.

- Quite a high price. Plastic parts are more affordable, but they will not last long. To save money, some users try to make a pipe from improvised materials. However, this is unsafe, as it can lead to breakdown and subsequent severe or even fatal poisoning from toxic gases. So in this case, frugality is inappropriate.

- It is limited in the design of heating devices, as it is only suitable for gas ones with a closed firebox.

- Without insulation, at temperatures below -10°, the external exit may become covered with ice, and insulation requires additional costs and work.

Advantages and disadvantages

What are the positive characteristics of a coaxial chimney system?

- The air required for combustion is taken from the street, which does not create a stuffy environment;

- Minimal heat loss, since air is supplied through an external pipeline, and it is heated by the internal structure;

- Meets all environmental requirements: a gas boiler has a high percentage of efficiency, and all fuel burns completely, so components harmful to nature and humans are practically not emitted into the atmosphere;

- Meets all fire safety requirements: both pipes compensate for heating and cooling, and therefore even if they come into contact with flammable objects, a fire cannot occur;

- The compact design allows installation in any, even small, room;

- Installation does not involve violating the integrity of the roof of the house.

There are very few disadvantages of such a chimney exhaust system, these include high cost and low aesthetic perception: if you install it in the basement, it can slightly reduce the harmony of the room.

How and where to properly install a coaxial chimney of a gas boiler

A gas outlet of this type is installed on condensing and turbocharged heating devices with a closed combustion chamber or on a convector. Air supply can be natural or mechanically driven, for which a supply fan is usually used. This gas exchange method is suitable for any autonomous heating system with one or two circuits.

Such a system consists of two separate pipes with a diameter of 80 mm. One of them is intended for supplying air to the combustion chamber, the second is for removing flue gases. In terms of design, there are no differences between the “inlet” and “exhaust” parts.

How to make the right choice

Note that all gas equipment manufacturers currently produce turbocharged boilers. It is impossible to say that one brand is better than another.

So, what you need to pay attention to when choosing a gas boiler with a turbine:

First of all, pay attention to the power of the boiler. It must exactly correspond to the thermal output of the entire heating system, where the ratio is used: 1 kW of thermal energy must be allocated per 10 m² of heated area

This ratio will only apply if the ceiling height in the house does not exceed 3 m. Next comes the functionality of the unit. Let's face it, double-circuit gas boilers with a turbine are better than single-circuit ones. After all, with their help you can also organize a hot water supply system. So to speak, this is a two-in-one unit. You should not discount the size of the heating boiler. If you own a small house or city apartment, then the wall-mounted option is the optimal solution. Moreover, it is possible to make a hole in the wall and bring out a coaxial chimney there. It's simple, it's cheap, it's an opportunity to do the work yourself. Now let's turn your attention to the structural elements of the boiler. Its main element is the heat exchanger. If you want to install a heating device that will save you money by reducing fuel consumption, if you want it to work efficiently, then purchase a turbocharged boiler with a copper heat exchanger. Automation of the gas boiler will play an important role in terms of efficient operation and fuel economy. A large number of different monitoring and regulating devices creates certain problems that are associated with inconvenience of operation. But at the same time, it is a well-functioning automatic system that ensures reliability and stability of operation. When choosing a turbocharged boiler that runs on gas, pay attention to this fact. Are there any service departments in your city or area that can service or repair it? If there are no such services, then there is a high probability that in unexpected situations you will simply suffer with this equipment. And the last thing is the price. Although it is necessary to pay tribute that this indicator sometimes becomes the main one. Let's just say that turbocharged boilers are more expensive than regular ones. This is how it should be, because additional parts in the form of a fan and outlets cost money.

Installation

The process must be carried out by professionals in accordance with fire safety rules in the Russian Federation and design standards, and upon completion an operational check of the entire system is required.

- Installation is carried out from the heat generating apparatus upward to the mouth.

- The chimney duct must be attached to the supporting structure of the building using brackets or clamps to avoid vibration and noise.

- The individual elements must be connected to each other using a socket system.

- After installation, the tightness of the channel must be checked under operating pressure.

- If the chimney axis is located in a horizontal plane, the channel is laid with a slope of 0.5 - 1.5% in the direction from the boiler.

- Before starting operation, it is necessary to check the permeability of the condensate collection tubes and the temperature on the surface of the chimney. If necessary, insulate it.

- It is recommended to assemble the elements using silicone sealant that is resistant to acids and temperatures up to 200°C.

The installation kit comes with an assembly manual so you can do it yourself. The most important point is the selection of the exit location. In a small private house, you can determine it yourself, but in an apartment building, design will be required, even at the stage of construction of the building. If the position is horizontal, it cannot be directed at neighboring windows if the distance between buildings is less than 50 m. The height from the device body to the external exit is also important.

According to the standards, the floor-standing type of equipment requires a meter height; for wall-mounted equipment this figure is half as much. According to the standards, the length of the coaxial pipe for installing a chimney to a double-circuit gas boiler can reach 5 m in a horizontal position, with all turns and angles. The joints are sealed with special couplings: silicone sealant or sealant is not suitable for this task. It is recommended to assemble the chimney elements using a silicone mixture that is resistant to acids and temperatures up to 200°C.

Insulation is also necessary to prevent the formation of ice.

In a foam block building, the gas outlet is mounted inside the wall. Brick buildings allow it to be installed outside. When installing the outlet, both the characteristics of the building envelope and SNiP standards are taken into account.

The installation includes several sequential steps:

- The exit point can be sealed with polyurethane foam and then decorated with special decorative grilles for an aesthetic appearance. They are placed on glue or secured with liquid nails, and the equipment is covered inside with a plasterboard box.

- The connection is made using an adapter and then connecting a tee with a condensate receiver to it. The diameter of the pipe of the boiler and the chimney must be the same. This part is placed on top or on the side of the body; the first option is much easier to install.

- Pipe extension. One end is inserted into the other, then they are secured with crimp clamps. For corners, 45° and 90° couplings are used, which are also included in the supplied equipment. In total, the structure should include no more than 3 elbows and have a total length of up to 3 meters. Rigid fixation with clamps is very important, as it provides good traction.

Coaxial chimneys from the best manufacturers are the key to reliability and quality ↑

Coaxial chimney Ariston

Ariston chimneys made in Italy are suitable for most modern boilers. They also come with sealing gaskets and wall trims.

Coaxial chimney Baxi

The chimney in its design should have a length of up to 5 m. If it is directed towards the street, it is given a slope at the rate of 1 cm for each meter of its length. For Russian climate conditions, insulated options with the following changes made to the design are more suitable:

- head lengthened

- the design of the air intake duct is especially protected,

- made of composite material.

Such a system makes it possible to prevent icing of the chimney and cause the boiler to stop in emergency mode if the outside temperature drops to -50 C.

Coaxial chimney Proterm

These products are very easy to install and help increase the efficiency of the corresponding Protherm boilers. In addition to them, the company also offers extensions for chimneys, adapters designed for separate smoke removal, and more.

Coaxial chimney Vaillant This company is considered one of the leaders in the European market. Its products have been quite in demand in recent years.

When choosing a chimney, it is especially important that its cross-section matches the cross-section of the Vaillant boiler pipe. During installation, it is necessary to ensure a distance of at least 100 mm between the chimney and flammable structural elements. Viessmann coaxial chimney

Viessmann coaxial chimney

In addition to the coaxial outlet (diameter 60/100, 90°), the kit usually includes: a coaxial pipe equipped with a tip (diameter 60/100, length 0.75 m) and wall linings. Its special design prevents the pipe from freezing in winter.

Regulatory documents and installation rules

- SP 60.13330.2012 Heating, ventilation and air conditioning (SNiP 41-01-2003. Updated edition) (733.0 KiB, 6,365 hits)

- SP 60.13330.2012 Heating, ventilation and air conditioning (SNiP 41-01-2003. Updated version): pdf file (5.3 MiB, 2,664 hits) dec007f9af930ef54d024d0bebe54610.jpg:large

4d01afbefb8dd909a26bbc b60c52edcf.jpe - Installation rules for coaxial chimneys De Dietrich: classification, standards (8.0 MiB, 6,592 hits)

2020 stylekrov.ru

- Safety

- Types of roofs Mansard

- Flat

- Pitched

- Glass

Roofing materials

- Keramoplast

Natural Ondulin Polycarbonate Slate Roofing work Soft roofing Metal Repair and maintenance

- Types of jobs

Sealants Leakage Rafter system

- Mauerlat

Sheathing Tile

- Flexible

Metal tiles Roofing Insulation and insulation

- Hydro- and vapor barrier

Thermal insulation materials Insulation I-beams and channels Roof elements

- Ventilation

Drains Chimneys Ridge Stairs Low tide Snow guards Pediment

Installation requirements

- In multi-storey buildings, the condition of location away from doorways and windows that are at the same height must be observed: a minimum of 0.5 m, and for an opening located directly above - 1 m or more. Contrary to popular belief, there is absolutely no danger of poisoning from harmful combustion products. The smoke quickly dissipates into the atmosphere and, if installed correctly, does not affect residents of apartments on the upper floors of the building. However, if the installation is incorrect, condensation saturated with harmful substances may form on the glass of windows located nearby.

- Compliance with fire safety rules: in a wooden building, it is necessary to lay non-combustible materials (ideally, thermal insulation based on basalt fiber) in the gap between the chimney and the wall.

- If the pipe is laid horizontally through an adjacent non-residential premises, then its length should not exceed 3-5 m.

- When installing a chimney cap on the facade of a building, its location should not be less than 2 m above ground level.

- The diameter of the outlet hole in a brick wall should be larger than the cross-section of the chimney pipe by 1 cm, and in a wooden structure - by 5 cm.

- The gap between the pipe and the wooden wall should be 5 cm.

- It is prohibited to discharge waste flue gases from the condensing boiler into an ordinary pipe.

- According to the standards, the minimum distance to the windows and doors of neighboring housing is 1.5 m (if the smoke exit is not directed towards them).

- In multi-apartment residential buildings, it is prohibited to discharge flue gases from equipment with natural exhaust and mechanical exhaust into one gas exhaust system.

- There must be a minimum distance of 30 cm from the wall.

Kinds

Depending on the installation method, chimneys can be vertical, through the roof, or horizontal, through a wall or window. Durability and performance parameters are determined by the properties of the material from which they are made.

Aluminum

It is lightweight and can withstand temperature fluctuations and all kinds of corrosive effects without damage. But due to the low operating temperature, it is extremely rarely used for the production of coaxial chimneys. Typically used in combination with plastic.

Stainless steel

For the manufacture of chimneys, acid-resistant stainless steel is used, which can safely withstand sudden temperature changes and can operate at temperatures up to 550 ⁰C. Guaranteed service life - at least 30 years. Manufacturers produce two varieties:

- Pipes without insulation are used in heating systems in industrial and domestic facilities. The disadvantage is the formation of a large volume of condensate during operation. To reduce it, it is necessary to install a layer of thermal insulation.

- Insulated - most often used as vertical collective chimneys in multi-storey buildings. They have improved aerodynamic properties. The rules do not prohibit the connection of heating systems with both forced and natural draft. Installation is carried out during the construction of the house according to a project developed by a specialized organization.

Double-channel plastic chimneys

They are made of heat-resistant material with operating temperatures up to 205 ⁰C. Plastic is inexpensive, weighs little, and is easy to install. Coaxial structures of this type are designed to work with gas condensing boilers with low-temperature flue exhaust. Disadvantages include a short service life and restrictions imposed on use in conventional gas boilers.

When choosing coaxial pipes, it should be taken into account that some manufacturers produce boilers with non-standard pipes. Therefore, for installation it is necessary to use components from the same manufacturer.

Incorrect slope problem

It is recommended that the chimney tilt angle is no more than 2-3° towards the heating device. With another option, conditions are created for possible condensation to drain onto the ground of the adjacent area, which is strictly prohibited, since it is saturated with toxic substances.

Also, if the calculation is incorrect in winter, frost and even icicles form on the tip, which lead to damage to the part if too much ice has accumulated and shutdown of the gas boiler. The reason for this phenomenon is that the outer part of the device heats up slightly and cannot quickly melt the ice. Therefore, large icicles can form on a pipe that slopes toward the ground in winter.

There has been a long debate about whether the amount of condensation formed is actually inversely proportional to the diameter of the outlet. But the problem was solved by creating a special part of the device - a condensate receiver. Together with a three percent slope, it completely eliminates the problem of leakage of droplets of the resulting liquid.

How to reduce the temperature of flue gases in a chimney

The combustion of natural gas produces carbon dioxide, steam, sulfurous salt-forming oxides, etc. The optimal temperature of the flue gases at the chimney outlet should be 100–110 °C.

If the temperature of the flue gases is below the dew point, that is, the condensation temperature of the air, then the water vapor contained in the combustion products will settle on the walls of the chimney. If this happens constantly, the chimney can quickly collapse.

If the temperature of the flue gases is too low, condensation will form at the outlet of the chimney, and the outer part of the pipe will begin to freeze.

In addition, the presence of constant condensation in the smoke channel leads to a weakening of natural draft. Therefore, it is so important to monitor the temperature of the flue gases, which directly depends on the cross-section of the chimney.

From the above we can conclude that with correct calculation, the temperature of the flue gases will be in the region of optimal values. If the temperature is too high and needs to be reduced, this directly indicates that the cross-section of the chimney does not correspond to the power of the gas boiler. To reduce the temperature of the exhaust gases, it is recommended to reassemble the smoke exhaust system taking into account the standard values.

Video: condensation in the chimney

Selecting the installation type

A coaxial chimney can have a horizontal or vertical outlet. Both options have their significant advantages and disadvantages.

The horizontal one is easier to install, it requires fewer parts, but the vertical one allows you to bring the outer part in the usual way - onto the roof, and without making a hole in the wall. Vertical is often installed in multi-apartment buildings with a height of more than one floor, when it is necessary to remove combustion products from several heating devices at once.

In private houses, horizontal ones are more often used, diverting exhaust gases to the local area from the back of the building, where they are dispersed in the air. This method has a limitation: according to sanitary standards, there should be no housing within a radius of 50 m.

Installation diagram and selection of components

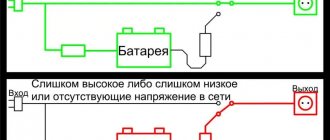

There are only 2 basic installation schemes for coaxial systems, the rest are their variations:

- horizontally from the boiler outwards using the shortest route;

- vertically through the ceiling and roof.

In the case of double-walled chimneys, the second scheme is rarely used, since it is quite complex to implement. Laying through ceilings is implemented in situations where it is impossible to bring the channel into the wall - a high fence is built end-to-end, there are several windows nearby and other factors that interfere with proper installation.

The most commonly used scheme is No. 1 - horizontal installation of a coaxial chimney. You outline the pipe laying route, measure the length and buy a ready-made set of parts listed in the first section of the publication.

Options for laying coaxial channels in a private house

What nuances need to be taken into account:

- The diameter of the channel is selected strictly according to the coaxial output of the water heating apparatus. Most heat generators use 2 sizes - 60/100 and 80/125 mm. The first number shows the diameter of the flue, the second - the external air duct.

- To connect the air-smoke duct to the heating unit, an adapter is used - an adapter suitable for a specific boiler model.

- The gap between the pipe and the wall casing is sealed with fireproof material - basalt wool, asbestos cord. Do not fill the cracks with polyurethane foam.

- The chimney can be extended (increased with additional straight sections) without exceeding the value specified in the boiler passport. The indicator depends on the performance of the fan.

- If the flue is too short, you need to install a restrictive diaphragm of a certain diameter. Otherwise, the smoke exhauster will pump more air into the firebox than necessary.

- In regions with cold climates, you should use a nozzle that prevents icing of the tip.

- It is better to insulate a smoke duct passing through an unheated room from the outside with a layer of basalt fiber.

Reference. The passport of the Viessmann Vitopend forced-air boiler indicates the diameters of the installed diaphragms depending on the length of the chimney. For example, a 60/100 mm pipe up to 3 m long is equipped with a 44 mm diaphragm.

When it is necessary to vertically remove a coaxial flue from a basement or ground floor, an inspection section with a condensate drain fitting must be installed. If the total length of the route exceeds the permissible limit, instead of a double-walled single pipe, 2 separate pipes are laid - a chimney exhaust and an 80/80 mm air duct. A special separator adapter, shown in the photo, is connected to the boiler output.

Ventilation

According to the rules, such systems can be installed even in completely enclosed spaces. But there is a need to maintain air circulation in the room to regulate humidity, which increases the risk of corrosion processes.

Corrosion over time leads to destructive changes in the equipment body, and ultimately to its failure and shutdown. In this case, some toxic gases may still enter the room. To avoid poisoning by them, regular ventilation and a good mechanical exhaust ventilation system are recommended. For example, duct centrifugal fans, domestic and industrial, are perfect for these purposes.

Air conditioning in rooms with a boiler room is not required. In a small room, simple but regular ventilation through a window or door will be sufficient.

Advice from professionals

Reliable connection of pipes will be ensured by transition units. All joints must be covered with sealant and a protective casing.

In order for gas equipment to be accepted for warranty by the service center, it is necessary to install the recommended coaxial chimney system for the selected boiler.

You should not neglect the help of specialists and carry out the installation yourself without the proper experience.

Incorrect calculation leads to a change in outlet temperature and increased condensation formation. As a result, ice accumulates on the tip. It is mandatory to install metal shields in wooden rooms.

Protective units increase the cost of the structure, while increasing its performance. When installing vertically, a valve is always installed to increase draft and a condensate collection kit is installed.

Horizontal systems are additionally equipped with an anti-icing module, wind protection and a diaphragm.