Here you will learn:

- Types of devices for taking temperature

- How does the sensor interact with the boiler?

- How many temperature sensors are needed for heating?

- Thermostats for gas boilers

- Temperature sensor selection criteria

- Prices for popular sensors

- Do-it-yourself installation recommendations

In essence, a thermostat is a device that allows you to regulate the temperature in a room automatically. It can be argued that it is easy to regulate the operating modes of the boiler without automation, that is, manually. At the same time, the thermostat becomes an unnecessary luxury, entailing unnecessary costs. Let's consider the pros and cons of installing such accessories.

When gas boilers operate, the microclimate in the premises is controlled by changing the temperature of the coolant. When the set value is reached, the boiler turns off, and when it decreases, it turns on again. When outside temperatures change, it is necessary to change the parameters of the heating system, and this must be done manually. As a result, intervention in the operation of boiler equipment is required throughout the heating season.

The time and attention required by the boiler when manually adjusting its operation are not the most important problems. In this mode, frequent starts/shutdowns of the boiler occur, which does not have the best effect on its performance, and on the reliability of the system as a whole. There is one more problem. When the boiler is operating in constant on/off mode, the circulation pump continues to function. Being an energy consumer, it increases electricity costs, which increases financial costs for heating. Not to mention the negative impact on the operation of the system.

As you can see, manual control for a high-tech gas boiler is not the best option. Now let's look at what the thermostat can change. The device has room temperature sensors that monitor the temperature of the air in the rooms rather than the water in the system. As a result, the boiler turns on/off when there is a deviation from the set temperature, and not when the water heating decreases. The frequency of starts/shutdowns is significantly reduced. When programming the device, you can set the optimal threshold for triggering such a sensor. In addition, you can set a delay time for turning on or off the boiler when the sensors are triggered. This will minimize the likelihood of starting the heating device during a short-term drop in temperature, for example, as a result of a draft.

As practice shows, installing a programmer allows you to save 25–30% of energy. The device does not allow excessive fuel consumption. When the boiler is turned off, the circulation pump is automatically turned off, which saves energy. All this speaks in favor of installing room thermostats.

The return on investment for such accessories is beyond doubt. There are various models of thermostats on the market, differing not only in technical parameters, but also in price. Finding the optimal accessory is not difficult. Examples include thermostats TAM0 11MI, Menred RTC 70, Raychem TE Basic, DEVIreg Touch, Nest, domestic MCS 300, etc.

Types of devices for taking temperature

Thermal devices can be classified according to a number of important criteria, including the method of transmitting information, the location and conditions of installation, as well as the algorithm for taking readings.

By method of information transmission

According to the method of transmitting information used, sensors are divided into two large categories:

- wired devices;

- wireless sensors.

Initially, all such devices were equipped with wires through which thermal sensors communicated with the control unit, transmitting information to it. Although such devices have now replaced their wireless counterparts, they are still often used in simple circuits.

In addition, wired sensors are more accurate and reliable in operation.

To ensure consistent operation of a wired sensor used in a composite device, it is advisable to combine it with equipment that is made by the same manufacturer

Currently, wireless devices have become widespread, which most often transmit information using a radio wave transmitter and receiver. Such devices can be installed almost anywhere, including a separate room or open air.

Important characteristics of such temperature sensors are:

- presence of battery;

- error of measurements;

- signal transmission range.

Wireless/wired devices can completely replace each other, but there are some peculiarities in their functioning.

By location and method of placement

Based on the mounting location, such devices are divided into the following types:

- overheads attached to the heating circuit;

- submersible, in contact with the coolant;

- indoor, located inside a residential or office space;

- external, which are located outside.

Some units may use several types of sensors simultaneously to control temperature.

According to the mechanism for taking readings

According to the method of displaying information, devices can be:

- bimetallic;

- alcohol.

The first option involves the use of two plates made of different metals, as well as a dial indicator. As the temperature rises, one of the elements is deformed, creating pressure on the arrow. The readings of such devices are characterized by good accuracy, but their big disadvantage is their inertia.

Bimetallic and alcohol thermostats are often installed on heating equipment, such as boilers. They allow you to monitor heat, exceeding which can lead to fatal consequences.

Sensors whose operation is based on the use of alcohol are almost completely free from this drawback. In this case, an alcohol-containing solution is poured into a hermetically sealed flask, which expands when heated. The design is quite elementary, reliable, but not very convenient for observations.

Design and principle of operation

The operating principle of temperature sensors is based on measuring resistance, pressure, physical dimensions (thermal expansion), thermal emf, which have a strong dependence on temperature in a specific range. Data on the amount of heating can be obtained based on the calibrations of the sensors when recalculating using the appropriate formulas.

In automatic thermostats, these formulas are embedded in the control program, and in mechanical thermostats, special devices are installed that regulate operating modes in some simple way, for example, mechanical or electrical relays that close or open the necessary contacts.

Thermal sensors have a relatively simple design - a small housing with fasteners, inside which the sensor itself is located. They can be sealed or open, depending on the detection method. To transmit measured data, they can be equipped with wireless sensors or connected via a wired connection.

How does the sensor interact with the boiler?

Depending on the boiler model, there are 2 ways of interaction: directly and through the room thermostat.

You can connect a temperature sensor directly only to boiler models with this capability (appropriate automation and terminal block/connector on the boiler); this capability is reported in the technical specifications of the model. For example, models such as the Baxi ECO Four line, the Baxi LUNA-3 line, Buderus Logamax U072, Viessmann Vitopend 100-W and most other modern models of gas boilers have the ability to connect temperature sensors.

Connection of external control is directly supported by both electric and solid fuel boilers.

If the boiler has a simple, low-functional automation system, it is better to connect an external sensor via an electronic room thermostat with programming capabilities. Programming the operation of the boiler allows you to set a pattern for the operation of the heating system, for example, reducing the temperature to 15 degrees during working hours when the owners are not at home, which will allow you to significantly save on heating, regardless of the type of fuel used. The cost of a good thermostat is about 1,500-3,000 rubles, but if used correctly, it will pay for itself within a few months of operation.

An example of a room programmable thermostat (model – Teplocom TS-Prog-2AA8A).

A room thermostat already has a built-in temperature sensor that measures the temperature in the room in which it is installed. To implement weather-dependent control, you need to purchase a universal outdoor temperature sensor. Thermostats that already include an outdoor temperature sensor are sold extremely rarely. However, the package often includes a temperature sensor for heated floors.

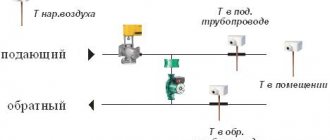

In general, to organize an optimal control scheme for the heating system, three temperature sensors are sufficient: external indoor, outdoor and for heated floors.

Features of operation

When operating temperature sensors, you must follow the following rules:

- the sensitive element must have maximum contact with the heat exchange medium,

- Maintenance and calibration must be carried out in accordance with the manufacturers' recommendations,

- It is important to exclude negative external influences that may affect the measurement results.

Thermal sensors for boilers are quite easy to select and relatively simple to install and connect. To do this, it is important to follow the connection instructions and perform all installation steps sequentially.

How many temperature sensors are needed for heating?

If for a conventional heating scheme only one room temperature sensor is used for a gas boiler, then with a radial collector heating scheme there may be several such sensors. In this case, temperature adjustment occurs for each room individually. A temperature sensor for heating located in each room sends information to the controller, which, through the control unit, regulates the independent supply of coolant from the collector to the desired room to maintain the set temperature. You can read more about automation for boilers in our article “Existing automation for heating boilers.”

Pressure sensors for heating

Pressure sensor for heating

Pressure sensors in the heating system must be provided in a circuit with forced circulation. In fact, they display the degree of expansion of the coolant as a result of heating. Therefore, experts recommend installing pressure sensors in the heating system along with thermometers.

The main indicator for pressure gauges is the pressure limit values. In the autonomous network of a private house or apartment, the normal value is from 1.5 to 2.5 MPa. Accordingly, the maximum permissible value for the water pressure sensor in the heating system must be no less than these data. In practice, it is recommended to install models with an upper limit of 6 MPa. An important factor is the mechanism by which the pressure gauge displays readings.

Spring sensors

Diagram of a spring pressure gauge

The pressure sensor for heating has a special tube as a sensitive element. It may have a round or oval cross-section. Under the influence of the pressure of the coolant, it is displaced, as a result of which the arrow on the dial moves.

The advantage of devices of this type is reliability and affordable cost. The operating time depends on the frequency of exposure to the sensitive element, as well as the excess of the maximum permissible pressure. In addition, the following requirements apply to spring pressure sensors in the heating system:

- Deviations from the error value are unacceptable. If, in the absence of pressure, the needle is not at the zero mark, the device cannot be exported;

- The accuracy class for household pressure gauges must be at least 2.5;

- During mechanical impact on the device, the sensitive element of the pressure sensor may be displaced. Then changes in the heating system will not be recorded, or the error will exceed acceptable standards. To avoid this, you need to check it before the start of the heating season.

Installation of spring water pressure sensors in the heating system is simple. To do this, you need to install it on the threaded connection of the supply pipe. You cannot use FUM tape - only winding designed for critical values of pressure and temperature.

An alternative to spring pressure gauges can be membrane sensor models. They give more accurate readings, but are prone to frequent breakdowns due to the sensing element.

Electric contact sensors

They are an improved model of a spring pressure sensor. Used for heating with automatic adjustment of indicators. In addition to the main arrow, the pressure gauge has 2 additional ones. They are set to maximum and minimum pressure values. When one of them reaches the main arrow, the electrical contact closes and the corresponding signal is sent to the control element. Such devices are used in large autonomous systems. For autonomous heating, their installation is impractical.

It must be remembered that each pressure and temperature sensor in the heating system must display actual values. Therefore, you must first make an accurate calculation of the entire system, and then, based on the obtained indicators, select the optimal model of the device.

In the video you can see the use of a temperature sensor in the design of a solar collector - one of the types of heating:

Thermostats for gas boilers

By installing a small box with electronics, you can save almost 30% of gas at home when operating a gas boiler. Devices are divided into several types :

- central;

- for radiator;

- local purpose;

- indoor

A central thermostat, according to experienced consumers, is capable of ensuring the safety of the entire boiler room. This device is installed together with gas equipment. It transmits information through wires, is powered by electricity and operates autonomously from the boiler. A thermostat is necessary to regulate the operation of the heating unit.

Room and local devices help regulate the temperature in each individual room. This allows you to create the desired microclimate. For normal operation, it must be located next to the boiler, but away from doors and windows, otherwise the readings will be unreliable.

According to experts, thermostats for radiators will control each individual heating device. The regulators are quite simple and have a valve that regulates water consumption. The thermostat is equipped with such a regulator that regulates the decrease or increase in liquid flow.

The principle of operation of a temperature sensor indoors

Monitoring the operation of the heating circuit and adjusting the air temperature can be carried out using the following technical solutions:

- automatic devices responsible for timely supply of energy;

- electronic units whose task is to monitor safety;

- mixing units.

It will probably be useful for you to read about air vents, as they prevent air from heating systems.

To ensure the normal operation of these technical solutions, temperature microsensors are used. These devices are responsible for transmitting signals about the operation of devices. Monitoring microsensor readings helps to identify faults in a timely manner and quickly eliminate them.

The operating algorithm of these sensors is based on an algorithm for converting temperature conditions into an electrical signal. This makes it possible to transmit the received information over the network in digital code format. As a result, high accuracy of measurements is ensured, as well as high speed of their transfer to devices for visual inspection.

How necessary are thermal sensors?

When operating heating in an apartment or in a private house, it is important to ensure the ability to control the level of heating of coolants and heating of the air inside the heated rooms. Temperature microsensors for heating record and transmit similar information. Such information can be read visually or transmitted directly to the controller, this is how telemetry .

Temperature sensor selection criteria

The selection of a temperature sensor should be carried out taking into account the following criteria:

- range of measured temperatures, the sensor must be as sensitive as possible and respond to heating changes with minimal delay;

- technical features of the installation: submersible or fixed, is there enough space for installation, etc.;

- measurement conditions under which it is possible to minimize negative influencing factors;

- characteristics of the sensor: the need to supply voltage, the speed of the transmitted signal, the measurement error, the admissibility of operation in specific conditions;

- service life, maintenance periods, need for calibrations;

- output signal value.

Immersion temperature sensor for boiler

Classification of types of temperature sensors

The choice of sensor depends on the environment in which the temperature needs to be monitored: inside the boiler, in the room or in the heating system. The efficiency and safety of heating equipment depends on the correct choice.

The temperature sensor for a heating boiler is classified according to the following criteria:

- by the method of determining temperature,

- by type of interaction with the thermostat.

Types of sensors by method of determining temperature

According to the method of determining temperature, sensors are:

- Dilatometric, which are bimetallic plates or spirals, the operating principle of which is based on the thermal expansion of metals or other types of solids.

- Resistive, having a strong dependence on temperature in a certain measured range, which manifests itself in the form of sharp changes in electrical resistance.

- Thermoelectric, which are thermocouples (alloys of two dissimilar conductors, for example, chromel-alumel), in which thermo-EMF begins to induce at certain temperature intervals.

- Manometric, the principle of operation of which is based on changing the pressure of a gas or liquid in a closed volume.

Dilatometric sensors are made from materials with a high coefficient of thermal expansion that respond to minimal temperature fluctuations. The principle of their operation is based on the closing or opening of electrical contacts. To increase their sensitivity and quality of contact, magnets are used in structures.

Resistive temperature sensors are made from special alloys of conductors or semiconductors. Structurally, they consist of a coil with a wound thin copper, platinum or nickel wire and a ceramic housing or semiconductor wafers placed in a plastic or glass housing.

Semiconductor resistors come in two types:

- thermistors having a nonlinear temperature dependence, characterized by a decrease in resistance when heated,

- posistors, which also have a nonlinear dependence on temperature, but differ from thermistors by increasing resistance when heated.

Thermoelectric sensors are made of two specially selected dissimilar metals or alloys, at the point of contact of which, when heated, a thermo-emf is induced, the value of which is proportional to the temperature difference between the two junctions. In this case, the measured value does not depend on temperature, length and cross-section of wires.

Gauge sensors allow you to determine temperature in a non-magnetic way without the use of energy sources, which allows them to be used for remote measurements. However, their sensitivity is an order of magnitude worse than that of other temperature sensors, and there is also an inertia effect.

Types of sensors according to the method of interaction with the thermostat

Temperature meters based on the type of interaction with the thermostat are divided into the following types:

- wired, transmitting data to the controller via wires,

- wireless – high-tech modern devices that transmit data at a certain radio frequency.

Wired temperature sensor for boiler

Prices for popular sensors

| Manufacturer and model | Peculiarities | Cost, rub. | Our rating, 0-5 points |

| BAXI KHG | Mechanical, inexpensive and reliable | 1 350 | 3,9 |

| TEPLOCOM TS-Prog-2AA/8A | Programmable, wired, functional, best in price-quality ratio | 3 300 | 4,5 |

| TEPLOCOM TS-Prog-2AA/3A-RF | Programmable, wireless, functional, expensive | 5 500 | 4,3 |

| TEPLOLUX MCS-350 | Programmable, wired, functional, with Wi-Fi module and touch display, with additional. sensor, modern stylish design | 5 100 | 4,9 |

How to choose a remote temperature sensor

The choice depends on how the sensor will interact with the boiler: directly or through a thermostat.

Connected directly to the boiler

The choice here is small: as a rule, these are 1-3 models developed by the same manufacturer as the boiler. Their compatibility with specific models or lines of boiler models is indicated in the technical specifications and instructions. The cable for connecting the temperature sensor to the boiler (usually two-core with a cross-section of 0.5 mm2) must be purchased separately. The exact requirements for cross-section and resistance are indicated in the sensor instructions.

Connectable to thermostat

External temperature sensor for the Gira 130200 thermostat.

In rare cases, an outdoor sensor is included with a room thermostat, but most often a sensor for measuring the temperature of heated floors is included in the kit. To take into account the outdoor temperature, universal outdoor temperature sensors are connected to the thermostat: from Gira, Tim, Shuft (ATF2-NTC10K) or Teplolux (TST02). It is important to pay attention to:

- range of measured temperatures - for example, for Teplolux TST02 it is from +5 to +45 ° C, which is not applicable in the cold season;

- degree of moisture protection;

- measurement accuracy/error – an error of +-1°C is considered acceptable, a good result is +-0.5°C;

- cable length - as a rule, a 2-6 m long cable is already connected to the temperature sensor.

Do-it-yourself installation recommendations

Such devices are widely used for various purposes: they are equipped with radiators, heating boilers and other household appliances.

Before starting installation, you should carefully read the instructions: it indicates not only the installation features (for example, dimensions for connecting to the pipe), but also the operating rules, as well as the temperature limits for which the measuring device is suitable.

It is also necessary to take into account the size of the sleeve, which can vary between 120-160 mm.

Let's consider the two most common cases of installing a temperature sensor.

Connecting the device to a radiator

It is not necessary to equip all heating devices with a thermostat. According to the regulations, sensors are installed on the battery if its total power exceeds 50% of the heat generated by similar systems. If there are two heaters in the room, then the thermostat is installed only on one, which has a higher power rating.

The temperature sensor is a mandatory component of temperature controllers that allow you to reduce or increase the heating of radiators, heated floors and other heating devices

The device valve is installed on the supply pipeline at the point where the radiator is connected to the heating network. If it is impossible to insert it into an existing chain, the supply line must be dismantled, which can cause some difficulties.

To carry out this manipulation, you need to use a tool for cutting pipes, while installing a thermal head can be easily done without special equipment. As soon as the sensor is mounted, it is enough to align the marks made on the body and the device, after which the head is fixed with a smooth hand press.

Replacement and connection

If the thermostat breaks down, then finding out the source of the breakdown is not difficult at all and can be done by the owner of the heating installation:

- If the water does not heat up, the source of the disease lies in both the temperature sensor and the thermostat. In this case, we do not consider the breakdown of the heating element. We assume that it is working properly.

- The temperature sensor is removed from the boiler and all wires are checked for breaks using a tester in the “continuity” mode.

- If the temperature measurements show zero when the thermostat is running, it is definitely faulty. You can’t fix it yourself; it’s better to buy a new one and replace it.

- If the thermostat responds to the boiler in the “call” mode, you need to set the minimum temperature value and take measurements again.

- If it is working properly, then in the “heating” mode its contacts should be open, and the resistance at the input and output should increase.

Replacing the thermostat with a similar one is described in detail in the instructions for the heater. If there is no such thing on sale, a similar one with the appropriate parameters is looked for.

How to connect a temperature sensor to a boiler

An outdoor temperature sensor for a heating boiler is installed on the outside of the wall of a heated building in compliance with the following requirements:

- the wall should be exclusively north or northeast to avoid direct sunlight. If a hit is still expected, it is necessary to protect the sensor with a visor;

- If possible, it is necessary to avoid installing the sensor in places of high humidity and a high degree of mold formation;

- the wall must have a thickness and degree of thermal insulation sufficient to prevent the sensor from heating up with the heat of the heated room;

- It is also not recommended to install the measuring device near an air conditioner, chimney, exhaust or supply ducts, or any other structures that can affect the measurement results.

The sensor itself is attached to the wall with anchor bolts, for example 5x25, connected to the corresponding connector/terminal of the boiler or thermostat using a two-core cable (cross-section and resistance parameters are indicated in the temperature sensor instructions), the connections are hermetically sealed with a coupling.

Correct installation and connections do not cause any special problems, since detailed algorithms are always described in the instructions.

An example of an installation algorithm from the instructions for the Baxi temperature sensor.

Temperature sensors do not require adjustment or calibration, and their performance and accuracy are tested in practice (at room temperature).