Requirements for standards for hydrotesting of heating

According to document SNiP 41-01 of 2003, a similar process for water heating systems is allowed to be carried out at above-zero temperatures in the building. The system must function as efficiently as possible and withstand a fluid pressure of 0.6 MPa, otherwise depressurization and damage to some components cannot be avoided.

Pipelines and fittings together with devices should not be subjected to the maximum pressure values that were provided for during installation. Hydrostatic tests assume the use of a load equal to 1.5 times the operating state of the system, but not less than 0.2 MPa, in relation to the lower part of the pipeline.

The work can be considered successful if all communications last for 10 minutes; the pressure during this period should not drop by more than 0.02 MPa.

Structural device of a manual pressure testing pump

A typical manual pressure test pump for a heating system consists of:

- pressure part 1 with handle 5 installed on the cover 6 of tank 2.

- A pressure hose 3 is connected to the outlet of the injection unit, which is connected through a special fitting to the line under test.

- Plunger pump 1 is the main unit of the unit and includes a cylindrical head 4, a distribution fitting 15, internal valves, two valves 7 and 8.

- Valve 7 opens and closes the hole for draining the liquid, and valve 8 serves to turn off the device after the required pressure is pumped into the line.

- Water enters the system under test through a cylindrical head 4 and a liquid suction pipe 10 with a filter placed at the end, secured with a nut 11.

- For ease of use, the side of the tank is equipped with a hook for attaching a handle, which is also used for carrying the unit.

- To monitor equipment pressure, the device is equipped with a built-in pressure gauge 9 with a dial indicator.

Rice. 4 Design of a manual hydraulic crimping machine

Purpose of testing

The main must be checked for integrity and tightness; this is precisely why the system was developed; testing of pipes and components makes it possible to timely detect gaps in threaded pipes and assess the tightness of heating or hot water supply connections.

Without such actions, one cannot count on a minimal threat from leaks and flooding of premises. Before putting the highway into operation, an inspection is carried out; this process is mandatory for implementation.

Price

The cost of crimping depends on several factors:

- length (internal volume) of the system;

- the age of the system and the condition of its constituent elements (amount of rust and dirt and salt deposits);

- type of equipment used.

Prices from different performers, even within the same city, may differ by 2–3 times. Private teams and craftsmen charge the cheapest for their services.

On average, for flushing and pressure testing the heating system of a building with an area of 400 sq. m (two-story) performers charge from 7 to 15 thousand rubles. As practice has shown, if you know how to bargain, you can agree to complete this amount of work for 4–5 thousand rubles. The work will be completed in 1 – 2 days.

The same work in a building of 5 thousand square meters. m (5 floors) will cost from 30 to 80 thousand rubles.

Some performers indicate prices per unit of volume (150 - 250 rubles / cubic meter) or time (500 - 1000 rubles / hour).

If you want to install the washbasin yourself, be sure to take care of connecting the water seal. Water seal for sewerage: types, purpose and installation features.

You will learn about the types of antiseptics for cesspools in this review.

Pipeline hydraulic testing technology

Using liquid for the process is a fairly popular method; with the help of such manipulations it will be possible to test all the circuits of the system.

Water is pumped through a special tap, which is located at the bottom of the pipes. It is not prohibited to use automatic pumps for work; manual ones connected to the water supply can also be used.

High rates of detection of possible excesses are the main positive side of this method; manipulations can also be performed without much difficulty. Visually, you can identify fluid accumulations in weak spots and troubleshoot problems in the line, which is quite convenient and practical.

Preparatory work

There are special pressure testing pumps; this equipment is prepared first. There are both manual models and electrical samples; specialists choose the most convenient version for testing. You also need to use a pressure gauge in the process to monitor changes, because some units are capable of pumping from 40 to 100 bar.

Pressure test pump

The Ministry of Energy draws attention to the correct approach to performing the flushing procedure, and the accuracy class of the measuring device should not be lower than 1.5. The circumference is important in the process; the body should be selected taking into account data exceeding 160 mm.

Determination of strength and tightness

To identify problem areas, the procedure must be carried out at operating pressure; a visual inspection is carried out by tapping a rounded shape with a hammer. When it comes to pipes made of non-ferrous metals, a wooden specimen weighing no more than 0.8 kg is used.

Tests for strength and tightness can be considered satisfactory if the pressure during exposure does not fall below the established norm; the data must be viewed on the pressure gauge. Welds, connections and other fittings must be dry; if such problems are detected, all excesses are eliminated, and the work must be repeated to obtain a hydraulic test certificate.

Testing

The detailed algorithm of actions is quite simple, it is important to adhere to the sequence of manipulations, it all looks like this:

- Using a pressure tester, it is necessary to fill the entire circuit with water, which should be at least 45 degrees. The air is released through special taps, they are called vents.

- Injection lasts 10 minutes, during which time it is necessary to carry out a visual inspection of the fittings, joints, seams and connections.

- The pressure can be increased to the maximum, and held for a certain time; it should be noted that products made of polymer materials, the pressure in them must be left for 30 minutes, for better manipulation.

- Using a pressure gauge, you can identify deviations in readings; if they are normal, then the result of the work should be considered satisfactory.

After such manipulations, the system will be operated as productively as possible; all areas are suitable for use. Otherwise, the nuances should be eliminated; if leaks or fluid accumulation occur, the unit or pipe section should be replaced.

Pipeline testing pressure

This point should be taken seriously, because there are some requirements that should be taken into account and fulfilled. It goes like this:

- For steel pipes with values of 4 kgf/cm2 and specimens with a wall that allows operation at temperatures above 400 degrees, 1.5 working pressures are maintained, but not less than 2 kgf/cm2.

- With indicators of 5 kgf/cm2, 1.25 is enough.

- Cast iron, glass, plastic, 1.25.

- Pipes made of non-ferrous metals will require a pressure of 1 kgf/cm2.

- Phaolite samples 0.5 kgf/cm2.

Mobile type plunger pumps are considered to be in greatest demand for work. Piston hand units can also be used; presses, gear-type drives and operational models are perfect for pumping up the required parameters.

Drafting of documents

The owner of a private building will need to contact the district offices, while residents of multi-apartment buildings can count on help in this matter from utility companies. When filling out the application, you must carefully consider all points; the information is entered exactly as it is in reality; the address is also required. The report form must include information about who carried out the inspection; the organization provides papers with an approved signature from the chief power engineer.

When is pressure testing carried out?

Work related to testing and checking the system is carried out in the following cases:

- upon completion of installation and commissioning of the system;

- after repair of any heating device;

- when replacing parts of the pipeline;

- in preparation for the heating season.

By the nature of the test work, crimping is a leak test. What it is?

They measure the instantaneous speed of each wheel and, in the event of braking, the deceleration of each tire is calculated to assess its propensity to lock up. Once the danger has passed, the original pressure will be restored. Acceleration This is a quantity that relates the change in speed to time and is measured in meters per second squared. This is the result of averaging measurements in both directions of acceleration to the vehicle's maximum capability on a solid horizontal reference. When the speed decreases, we talk about negative acceleration.

Let's say that this procedure involves the following actions:

supplying the system with water or air under pressure using a hydraulic or pneumatic pump;

- identification of system leaks;

- determining where water or air has penetrated the system.

Modern systems make it possible to carry out such tests without involving a large number of personnel. Violations of tightness are determined by special equipment.

Who carries out the pressure testing

Intake This is the first time in the four-stroke engine cycle during which air is introduced into diesel engines or a mixture of air and gasoline in the cylinders. The suction created by the piston as it descends forces the mixture or fuel into the cylinder. When the intake timing does not match the point indicated on the engine diagram, it is referred to as delayed intake. In this case, the piston begins to descend when the intake valve is not yet open. During this cycle, the crankshaft rotates half a turn.

When excess pressure is created inside the system, faulty devices, components and emergency areas will become unusable. The performance of suitable system elements does not suffer from such testing.

Sequence of work

Pressure testing and flushing of heating systems is carried out after turning off the entire system and removing the coolant (water or antifreeze) from it. When carrying out such a check, it becomes necessary to monitor pressure indicators to prevent rupture of the main pipeline.

It's handy to know that there is a variable intake type that is increasingly being used that is used to improve cylinder filling regardless of rotation speed. There are two types of variable intake manifolds: the most widely used are multi-plane variable-length machines, in which electronically controlled butterflies regulate air flow or mixture so that long and narrow ports are used at low speeds, rotating, wide and short when the rhythm is brighter.

Thus, the length to diameter ratio of the pipeline decreases as the linear speed of the piston increases. The second type is resonant variable intake manifolds, in which the pressure waveforms are synchronized when air in the manifold hits a closed valve. By controlling said wave selections so that they are pushed towards each other just as the valve is about to open, the filling of the cylinders is improved.

What features of the heating system are taken into account when determining specific test parameters:

- pipeline characteristics (material, wall thickness);

- characteristics of fittings;

- number of floors;

- type of wiring.

Pressure testing and flushing of the heating system includes the following preparatory work:

Airbag Airbag in English. In a severe crash, this airbag inflates for 30 thousandths of a second or less on the occupant - or their side in the case of side airbags - to prevent them from being hit by hard parts of the car's interior. The bag deflates again in tenths of a second once its cushioning mission has been achieved. The system is activated when a series of deceleration sensors detect that an accident has occurred. Thus, the signal is sent to the electronic control unit, which is responsible for activating the mechanism.

- prevention and preparation of the system;

- directly carrying out work to create pressure inside the system;

- preparation of documentation on the work performed;

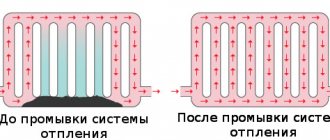

- flushing the entire heating system.

Certificate for hydraulic testing of the heating system

You can download a sample act here.

After filling out the header, information about the acceptance committee is entered into the document, which includes:

- Customer.

- Contractor.

- Representative of the installation organization.

The last name, first name, and position columns are filled in sequentially; such manipulations are performed with each member of the commission. The fact that hydraulic tests were carried out is definitely mentioned, after which they move on to the next part of the regulatory document.

The block concerning direct work is not difficult to fill out; the algorithm of actions is simple:

- The pressure that was maintained during the test, these data are indicated in two options: kgf/cm2 and MPa.

- A drop in performance during the process.

- The presence of excesses and defects that were discovered by specialists.

Conclusions are based on real facts; the installed system can either meet the requirements or not. After passing the inspection, all those present sign, confirming the authenticity of the hydrostatic test report. The process cannot be called complex, but there are some nuances that should be taken into account long before targeted actions.

Experts advise addressing the issue before starting finishing work, because hydraulic tests of the heating system may fail. Repair work of a decorative nature will certainly suffer; eliminating the consequences will take not only time, but also extra money.

As soon as a report is drawn up based on the results of the inspections, construction or reconstruction of the premises can continue, if the building is at this stage. You can familiarize yourself with the document in detail quite easily; you just need to look at the example of a completed hydraulic test report for heating system pipelines.

Similar

| Instructions for the installation of lightning protection of buildings, structures and industrial communications from 153-34. 21. 122-2003 The instructions are intended for use in the development of projects, construction, operation, as well as in the reconstruction of buildings, ... | Methodological documentation in construction an approximate procedure for implementing measures for the construction and renovation of buildings and structures, taking into account the needs of older people procedure of Realization of the Requirements of building and renovationDeveloped by the Federal State Unitary Enterprise "Institute of Public Buildings" (A.M. Garnets, V.L. Tsvetkov), JSC TsNIEP im. . B. S. Mezentseva (N. B. Mezentseva, G.... |

| Preliminary program of the scientific and practical conference “Energy-saving solutions in the construction and reconstruction of buildings and structures” | System of regulatory documents in construction building norms and rules of the Russian Federation GSNR-2001 collection of estimated cost standards for the construction of temporary buildings and structures during repair and construction work GSNR-81-05-01-2001Mtss) Gosstroy of Russia (headed by I. I. Dmitrenko) together with the Department of Pricing and Estimated Standardization in Construction... |

| Department of "PGS GIF" Examination questions in the discipline "Inspection and testing of buildings and structures" Method and means of applying forces when studying the load-bearing capacity of structures and structures | The system of regulatory documents in construction, building norms and rules of the Russian Federation, by the Central Research and Design and Experimental Institute of Industrial Buildings and Structures (JSC Tsniipromzdanii)… |

| Monitoring and management of engineering systems of buildings and structures. General requirements (approved by order of the Federal Agency for Technical Regulation and Metrology dated March 28, 2005 N 65-st) Safety in emergency situations. A structured system for monitoring and managing engineering systems of buildings and structures.... | Methodological documentation in construction recommendations for smoke protection in case of fire Approved by the Scientific and Technical Council of the Santekhniproekt State Industrial Complex and recommended for publication |

| Electrical installations of buildings Part 7 requirements for special electrical installations of electrical installations of buildings and structures with electrically heated floors and surfaces Developed by the All-Russian Scientific Research Institute for the Electrification of Agriculture (VIESH) and the All-Russian Scientific Research Institute ... | Plan for the preparation of buildings, structures and heating systems for the 2012/2013 academic year Section “Repair, construction work” Plan for the preparation of buildings, structures and heating systems for the 2012/2013 academic year |

Documents

Documents

Thermal testing of CO

This type of inspection is carried out to determine the effectiveness of the CRM. Work is carried out when the CO is put into operation and (or) when the configuration of the heating circuit is changed. The main condition for carrying out such a test is the supply of coolant with a temperature not lower than +60°C. The process lasts about 7 hours, during which work is carried out to balance the CO and adjust its elements. The results of the inspection are recorded in a report, a sample of which is shown below.

The degree of heating of individual sections and elements of the circuit is determined by a thermometer or thermal imager. The act includes readings of heating equipment heating and room temperature.

Advice: today it is particularly difficult to test floor-mounted CO systems that use a polymer pipeline. To prevent emergency situations, these heating systems should be checked at a coolant temperature of 25°C with an increase of 5°C every day until the design parameters are reached.