A temperature sensor for a heating boiler is a device that controls the operation of the coolant. It analyzes the temperature regime and adjusts the temperature in the heating system. Thanks to the influence of the sensor, an optimal operating mode is established in the DHW system, allowing saving 25% - 30% of the energy consumed by the unit, and an emergency situation of the boiler equipment is also prevented. Today, almost any electric boiler is equipped with a temperature sensor.

How to choose an external temperature sensor for a heating boiler

Temperature sensors used in boilers can be internal and additionally external (remote).

Internal ones regulate the operation of the boiler depending on the temperature of the coolant, which implies not the most accurate measurement method and the presence of inertia. External temperature sensors transmit information about the air temperature indoors or outdoors, which allows you to accurately regulate the power of the boiler unit and stably maintain the set temperature level even with constant sudden changes in weather conditions. The cost of external sensors ranges from 1,300-2,500 rubles; you can connect and configure their operation yourself.

Temperature sensors for heating radiators in rooms, recommendations for do-it-yourself installation

At times, people are faced with the need to set the temperature regime for each room in an apartment or house. To solve this problem, you can install a temperature sensor on the heating battery. With the help of such a small device, the operating mode of heating system batteries is set. Similar devices are used with any type of radiators, except cast iron.

It is important to take into account that with the help of this device the heating of the room can always be reduced. Increasing the heating of the room with the device is only possible if the heating system has sufficient power.

The principle of operation of a temperature sensor indoors

Monitoring the operation of the heating circuit and adjusting the air temperature can be carried out using the following technical solutions:

- automatic devices responsible for timely supply of energy;

- electronic units whose task is to monitor safety;

- mixing units.

It will probably be useful for you to read about air vents, as they prevent air from heating systems.

To ensure the normal operation of these technical solutions, temperature microsensors are used. These devices are responsible for transmitting signals about the operation of devices. Monitoring microsensor readings helps to identify faults in a timely manner and quickly eliminate them.

The operating algorithm of these sensors is based on an algorithm for converting temperature conditions into an electrical signal. This makes it possible to transmit the received information over the network in digital code format. As a result, high accuracy of measurements is ensured, as well as high speed of their transfer to devices for visual inspection.

How necessary are thermal sensors?

When operating heating in an apartment or in a private house, it is important to ensure the ability to control the level of heating of coolants and heating of the air inside the heated rooms. Temperature microsensors for heating record and transmit similar information. Such information can be read visually or transmitted directly to the controller.

Types of devices for obtaining information about the temperature inside the room

Devices for receiving and transmitting heating indicators are usually divided into:

- by the method of data transmission;

- by method and location of installation;

- according to the data acquisition algorithm.

By data translation method

Based on the method of data transmission, temperature sensors are usually divided into two separate categories:

- using wires;

- having a wireless communication channel.

Now the most popular devices are wireless temperature sensors that transmit information about indoor air heating and water heating using a built-in transmitter. Installation of these devices is allowed both indoors and outdoors.

By method and location

Devices that measure temperature in coolants are also divided according to installation method and mounting location:

- Invoices. They are installed to the thermal circuit of the heating circuit of the room;

- Submersible. Such microsensors come into contact with the coolant (what flows in the heating system);

- Rooms. They are placed inside a heated enclosed space;

- External. Located on the street.

Some devices can combine several types of temperature sensors for more precise heating control.

By method of obtaining evidence

Thermal sensors are also divided according to the method of collecting data. The following types of microsensors are sold on the market:

- bimetallic;

- alcohol

The first type of sensor is a pair of plates made of different metal alloys with an indicator in the form of an arrow. An increase in temperature leads to deformation of one of the plates, which creates pressure on the dial indicator. These devices are distinguished by their accuracy. True, their disadvantages include inertia.

Alcohol heat sensors do not have this drawback. They are sealed flasks with an alcohol solution. When heated, the alcohol expands, which helps set the current temperature. This is a simple and reliable design. True, it cannot be called convenient for tracking indicators.

Types of temperature sensors

To obtain heating data, temperature sensors are used that have different operating algorithms. The most popular types of temperature sensors include the devices listed below.

Thermocouple

This microsensor consists of two connected wires made of two different metals. Due to the resulting temperature difference between the warm and cold ends, a current of 35-65 40-60 μV appears. This indicator will depend on the materials used in the thermocouple.

How does the sensor interact with the boiler?

Depending on the boiler model, there are 2 ways of interaction: directly and through the room thermostat.

You can connect a temperature sensor directly only to boiler models with this capability (appropriate automation and terminal block/connector on the boiler); this capability is reported in the technical specifications of the model. For example, models such as the Baxi ECO Four line, the Baxi LUNA-3 line, Buderus Logamax U072, Viessmann Vitopend 100-W and most other modern models of gas boilers have the ability to connect temperature sensors.

Connection of external control is directly supported by both electric and solid fuel boilers.

If the boiler has a simple, low-functional automation system, it is better to connect an external sensor via an electronic room thermostat with programming capabilities. Programming the operation of the boiler allows you to set a pattern for the operation of the heating system, for example, reducing the temperature to 15 degrees during working hours when the owners are not at home, which will allow you to significantly save on heating, regardless of the type of fuel used. The cost of a good thermostat is about 1,500-3,000 rubles, but if used correctly, it will pay for itself within a few months of operation.

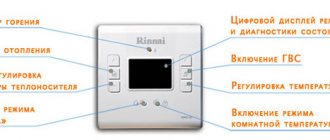

An example of a room programmable thermostat (model – Teplocom TS-Prog-2AA8A).

A room thermostat already has a built-in temperature sensor that measures the temperature in the room in which it is installed. To implement weather-dependent control, you need to purchase a universal outdoor temperature sensor. Thermostats that already include an outdoor temperature sensor are sold extremely rarely. However, the package often includes a temperature sensor for heated floors.

In general, to organize an optimal control scheme for the heating system, three temperature sensors are sufficient: external indoor, outdoor and for heated floors.

Thermostatic control valves

The thermostatic valve is a simple solution to the problem of obtaining a coolant at a given temperature by mixing colder water with warmer water. The three-way valve is shown below:

Three-way valve

Scheme for connecting a three-way valve to the heating system:

Scheme for connecting a three-way valve to a heating system

Design and principle of operation

Thermal sensors are in most cases heat-sensitive liquids or metals placed in a small sealed housing: when heated, heat-sensitive liquids expand, and the metals form a resistance or thermoelectric effect (when the contacts of connected conductors are at different temperatures).

Thus, with the help of the mechanical action of temperature-sensitive elements, information is transmitted to the thermostat or directly to the boiler automation, which regulate the burner power and turn the boiler on or off. Information from external temperature sensors is always a priority, which means that the thermostat sets the boiler operating mode (up to complete shutdown or unscheduled ignition) regardless of the internal automation program.

Outdoor models are additionally placed in a plastic protective case that protects them from mechanical stress and moisture.

Homemade external thermostat for the boiler: instructions

Below is a diagram of a homemade thermostat for a boiler, which is assembled using Atmega-8 and 566 series microcircuits, a liquid crystal display, a photocell and several temperature sensors. The Atmega-8 programmable microcircuit is responsible for compliance with the specified parameters of the thermostat settings.

Scheme of a homemade external thermostat for a boiler

Strictly speaking, this circuit turns the heating boiler on or off when the outside air temperature decreases (increases) (sensor U2), and also performs these actions when the temperature in the room changes (sensor U1). It is possible to adjust the operation of two timers, which allow you to adjust the time of these processes. A piece of circuitry with a photoresistor affects the process of turning on the boiler depending on the time of day.

Sensor U1 is located directly in the room, and sensor U2 is located on the street. It is connected to the boiler and installed next to it. If necessary, you can add an electrical part of the circuit that allows you to turn on and off high-power units:

The electrical part of the circuit allows you to turn on and off high-power units

Another thermostat circuit with one control parameter based on the K561LA7 chip:

Thermostat circuit with one control parameter based on the K561LA7 microcircuit

The thermostat is assembled on the basis of the K651LA7 microcircuit and is simple and easy to adjust. Our thermostat is a special thermistor that significantly reduces resistance when heating. This resistor is connected to the electricity voltage divider network. This circuit also contains resistor R2, with which we can set the required temperature. Based on this scheme, you can make a thermostat for any boiler: Baxi, Ariston, Evp, Don.

Another circuit for a microcontroller-based thermostat:

Circuit diagram for a thermostat based on a microcontroller

The device is assembled on the basis of a PIC16F84A microcontroller. The role of the sensor is performed by a digital thermometer DS18B20. A small relay controls the load. Microswitches set the temperature, which is displayed on the indicators. Before assembly, you will need to program the microcontroller. First, erase everything from the chip and then reprogram it, and then reassemble it and use it to your health. The device is not capricious and works fine.

The cost of parts is 300-400 rubles. A similar regulator model costs five times more.

A few final tips:

- although different thermostat options are suitable for most models, it is still desirable that the thermostat for the boiler and the boiler itself be made by the same manufacturer, this will greatly simplify the installation and operation process itself;

- before purchasing such equipment, you need to calculate the area of the room and the required temperature in order to avoid “downtime” of equipment and changes in wiring due to connecting devices of higher power;

- before installing the equipment, you need to take care of the thermal insulation of the room, otherwise high heat losses will be inevitable, and this is an additional cost item;

- if you are not sure that you need to purchase expensive equipment, then you can conduct a consumer experiment. Buy a cheaper mechanical thermostat, adjust it and see the result.

Reading time: 6 minutes No time?

Automation of heating equipment is used for ease of control and economical consumption of energy resources. To correctly use a thermostat for a heating boiler (temperature regulator), you need to study modern engineering solutions. An overview of the current market situation will be useful. It is also necessary to evaluate the possibility of performing installation operations yourself, without resorting to expensive professional services.

Read in the article

Existing types

Classification by temperature measurement method

- thermocouples are the very first and highly accurate sensors, but the accuracy of their readings is quite difficult to take and interpret into an automation program. Their action is based on the interaction of two different metals soldered together. When they are heated, a weak electric current occurs;

- thermistors are simpler to interpret and more accurate sensors, the action of which is based on an increase in the resistance of heat-sensitive materials as the ambient temperature increases;

- pressure sensors - their action is based on the expansion of a heat-sensitive liquid or gas when heated, which creates a certain pressure in a closed volume;

- digital are modern sensors (digital thermometers) that work on the principle of calculation and conversion. They are distinguished by high accuracy (up to 0.5°C) and a wide range of measured temperatures (from -55°C). Well-known examples are DS18B20, LM75A.

Wall-mounted outdoor temperature sensor in a protective housing.

Classification by placement method

- overhead – applied to pipes, radiators or water heated floor systems;

- submersible - immersed in a coolant, for example, again, in a system of water heated floors;

- room - weakly protected from external influences, having a small range of measured temperatures and therefore intended for measuring air exclusively indoors;

- outdoor - resistant to mild mechanical stress and moisture, often additionally protected by a housing, have a higher range of measured temperatures.

Please note that there are no small wireless sensors, since they require at least a controller to power them, read them and transmit the signal. Therefore, a thermostat that includes a room sensor can be wireless, but not the small temperature sensor itself for the heating boiler.

How to choose a remote temperature sensor

The choice depends on how the sensor will interact with the boiler: directly or through a thermostat.

Connected directly to the boiler

The choice here is small: as a rule, these are 1-3 models developed by the same manufacturer as the boiler. Their compatibility with specific models or lines of boiler models is indicated in the technical specifications and instructions. The cable for connecting the temperature sensor to the boiler (usually two-core with a cross-section of 0.5 mm 2) must be purchased separately. The exact requirements for cross-section and resistance are indicated in the sensor instructions.

Connectable to thermostat

In rare cases, an outdoor sensor comes complete with a room thermostat, but most often the kit includes a sensor for measuring the temperature of heated floors. To take into account the outdoor temperature, universal outdoor temperature sensors are connected to the thermostat: from Gira, Tim, Shuft (ATF2-NTC10K) or Teplolux (TST02). It is important to pay attention to:

- range of measured temperatures - for example, for Teplolux TST02 it is from +5 to +45 ° C, which is not applicable in the cold season;

- degree of moisture protection;

- measurement accuracy/error – an error of +-1°C is considered acceptable, a good result is +-0.5°C;

- cable length - as a rule, a 2-6 m long cable is already connected to the temperature sensor.

Criterias of choice

When choosing a sensor, you should consider the compatibility of a particular model with a thermostat. The technical parameters and operating conditions of the device should also be taken into account.

Temperature range

In the range of measured temperatures from room temperature to +55ºС - +80ºС, the temperature sensor must be:

- especially sensitive and “respond” to the slightest changes in temperature;

- respond with minimal delay to cooling/heating of the controlled environment.

Technical features

Before installing the device, you should consider some technical nuances. It is necessary to choose the correct type of device (submersible or fixed) and provide sufficient space for installation at the location.

Measurement conditions

It is necessary to create such conditions for subsequent measurements under which the negative influence of external factors on the accuracy of measurements would be minimized. For stable and correct operation, the device must be protected from:

- on the coolant body, moisture or dirt;

- drafts, place away from cold bridges;

- sunlight, protect from extraneous heat;

It is not recommended to place the device near electrical wiring or electrical appliances. If possible, it is necessary to shield the sensing element from sources of electromagnetic fields.

Sensor characteristics

When choosing a device, you should be guided by several selection criteria. The product should be selected taking into account the main technical characteristics and operating features:

- the need for power supply from an external voltage source;

- speed of response to changes in the situation transmitted to the control device;

- permissible measurement error range;

- Possibility of operation in the specific conditions of the serviced facility.

Service life, maintenance periods, need for calibrations

The warranty period for a thermal converter is usually 6 months from the date of manufacture, and the average service life is 8–12 years. Maintenance periods are determined by the manufacturer and are given in the accompanying documentation for the product. It is necessary to regularly perform temperature calibration (verification) of the temperature sensor on reference equipment. Typically, installation-free verification of the sensitive element is carried out once every 4 years.

Output value

The magnitude of the generated voltage of sensitive elements without an external source (thermocouples) is low and ranges from microvolts to millivolts. Therefore, the output signal is amplified before further processing.

How to connect a temperature sensor to a boiler

An outdoor temperature sensor for a heating boiler is installed on the outside of the wall of a heated building in compliance with the following requirements:

- the wall should be exclusively north or northeast to avoid direct sunlight. If a hit is still expected, it is necessary to protect the sensor with a visor;

- If possible, it is necessary to avoid installing the sensor in places of high humidity and a high degree of mold formation;

- the wall must have a thickness and degree of thermal insulation sufficient to prevent the sensor from heating up with the heat of the heated room;

- It is also not recommended to install the measuring device near an air conditioner, chimney, exhaust or supply ducts, or any other structures that can affect the measurement results.

The sensor itself is attached to the wall with anchor bolts, for example 5x25, connected to the corresponding connector/terminal of the boiler or thermostat using a two-core cable (cross-section and resistance parameters are indicated in the temperature sensor instructions), the connections are hermetically sealed with a coupling.

Correct installation and connections do not cause any special problems, since detailed algorithms are always described in the instructions.

Temperature sensors do not require adjustment or calibration, and their performance and accuracy are tested in practice (at room temperature).

Source

Connecting a temperature sensor for the boiler

All temperature sensors must be connected to a thermostat or a special control controller responsible for the operating modes of the boiler. In this case, it is necessary to carefully study the connection instructions so that the connection requirements match the technical characteristics of the sensors.

It is generally recommended to purchase sensors that are recommended by the boiler manufacturer. This is due to their high compatibility and guarantee of proper operation. If they are not available for sale, then you need to pay attention to certified analogues.

Connecting an outdoor sensor

The outside temperature sensor for the boiler is mounted on the outside of the wall of the house, subject to the following requirements:

- it is necessary to prevent direct sunlight from hitting its surface;

- the contact surface of the wall must be non-metallic;

- laying cables in places with high humidity, in the presence of chemical or biological factors that can damage the insulation, is prohibited;

- the height of the sensor on the wall should be at 2/3 of the height of the house, if the number of floors is up to three, or between the second and third floors, if the building is multi-story;

- it is necessary to exclude negative factors that reduce the sensitivity or measurement accuracy of the sensor.

External temperature sensor for the boiler

sensor is connected when the power supply to the boiler is turned off. For connection, a solid cable with a core cross-section of 0.5 mm2 and a length of up to 30 m is used. The places where the wires are connected to the boiler and sensor must be sealed and insulated.

When connecting, it is important to observe polarity, depending on the type of temperature sensor. If a section of cable runs along the street, it should be protected with a special corrugated tube.

After completing all installation work, you need to check their quality and then adjust the thermostat. If mistakes were made, they should be corrected, otherwise there is a high probability of boiler breakdowns or insufficient heating of the premises.

Connecting a room sensor

The room temperature sensor for the boiler is mounted on the external wall of the building from the inside of the room. The requirements for choosing a location are as follows:

- lack of nearby sources of heat or cold;

- constant access to the space of the room (absence of decorative items, interior items that can obscure the sensor and affect the reliability of measurements);

- height from the floor should be 1.2-1.5 m;

- When installing electrical sensors, it is important that there are no sources of electromagnetic radiation nearby: laid electrical wiring, installed powerful electrical appliances, etc.

Room temperature sensor for a boiler

The connection method is similar to the method for an external temperature sensor, and is carried out in accordance with the requirements of the boiler manufacturer. It can be mounted in a specially prepared recess in the wall or on the surface, the main thing is that the sensitive element is not covered from the outside.

Connecting a sensor for a gas boiler

A wireless temperature sensor for a gas boiler is mounted directly on the controller or on the gas valve. Wired temperature sensors are connected in the manner provided by the manufacturer and described in the instructions.

Connecting a water temperature sensor

A water temperature sensor for a boiler in a multi-circuit system is installed on the surface of the heating return pipe or inside it, and installation on a circulation pump is also permissible. This situation is due to the need to prevent high-temperature coolant from getting back into the boiler.

In a single-circuit or single-pipe system, the option of installing the sensor on the return pipe with coolant is prohibited. If the heating increases, the circulation will be blocked and a significant temperature gradient will arise between the far and near rooms.

TOP 5 DTS temperature sensors for boiler rooms

In modern boiler houses, the coolant for heating systems is prepared and heated. Boiler houses are stationary, block-modular or roof-mounted, and depending on the type of boiler they are divided into: steam, hot water and mixed.

Depending on the type of coolant, they can be gas, liquid fuel or combined.

For trouble-free and efficient operation of boiler houses today, automated control systems are used. To measure temperature, of course, you need temperature sensors.

We have compiled for you the TOP 5 sensors - DTS resistance thermometers from OWEN, used in boiler rooms.

- The first in the rating is a sensor for measuring the temperature of the direct and return coolant of the heating system and domestic hot water supply DTS035:

- To measure the outside air temperature use

If the sensor is installed on the sunny side, then you can purchase a screen for protection from sunlight.

Full specifications on our website

- To measure the coolant temperature in heating circuits, sensors with a cable outlet - DTS014 - are also used.

- Another switching head sensor is DTS105.

Here the fitting is already motionless and is located at the base of the head. All characteristics are the same as DTS035.

- And our top list is completed by an overhead sensor for the pipeline, which is attached with a clamp - DTS224.

The sensor is available with an MGTFE cable outlet, as in the case of DTS014.

Has a brass sleeve 43 mm long and 6 mm in diameter.

All other characteristics are the same as DTS014.

Full range of characteristics of sensors with switching head and cable outlet.

Source

Construction of a double-circuit gas boiler

In order to understand the principle of operation of a gas double-circuit boiler, it is necessary to understand its structure.

It consists of many individual modules that heat the coolant in the heating circuit and switch to the DHW circuit. The coordinated work of all components allows you to count on trouble-free operation of the equipment. Knowing the structure of a double-circuit boiler, you can understand its operating principle. We will not consider the design of double-circuit boilers down to the screw, since it is enough for us to understand the purpose of the main components. Inside the boiler we will find:

Design of models with two circuits: heating and DHW circuit.

- The burner, located in an open or closed combustion chamber, is the heart of any heating boiler. It heats the coolant and generates heat for the operation of the DHW circuit. To ensure accurate support of the set temperature, it is equipped with an electronic flame modulation system;

- Combustion chamber - the above burner is located in it. It can be open or closed. In a closed combustion chamber (or rather, above it) we will find a fan responsible for pumping air and removing combustion products. It is this that is the source of quiet noise when the boiler is turned on;

- Circulation pump – ensures forced circulation of coolant through the heating system and during operation of the DHW circuit. Unlike the combustion chamber fan, the pump is not a source of noise and operates as silently as possible;

- Three-way valve - this is the thing that is responsible for switching the system to hot water generation mode;

- The main heat exchanger - in a double-circuit wall-mounted gas boiler, it is located above the burner, in the combustion chamber. Here the coolant used in the heating circuit or in the DHW circuit for heating water is heated;

- Secondary heat exchanger - this is where hot water is prepared;

- Automation - it controls the operating parameters of the equipment, checks the temperature of the coolant and hot water, controls modulation, turns on and off various components, monitors the presence of flame, records errors and performs other useful functions.

At the bottom of the buildings there are pipes for connecting the heating system, cold water pipes, hot water pipes and gas pipes.

Some models of gas double-circuit boilers use dual heat exchangers. But the operating principle remains almost the same.

You may notice that the design of the geyser differs only in the absence of a heating circuit.

We found out the structure of a double-circuit wall-mounted gas boiler - it seems a little complicated, but if you understand the purpose of certain components, the difficulties will disappear. Here we can note the similarity with a gas instantaneous water heater, from which a burner with a heat exchanger remains here. Everything else is taken from wall-mounted single-circuit boilers. An undoubted advantage is the presence of a built-in piping - this is an expansion tank, a circulation pump and a safety group.

When analyzing the operating principle and design of a gas double-circuit boiler, it should be noted that water from the DHW circuit is never mixed with the coolant. The coolant is poured into the heating system through a separate pipe connected to the heating. Hot water is prepared using part of the coolant circulating through the secondary heat exchanger. However, we will talk about this a little later.

Design and principle of operation

Heating boilers can be supplemented with temperature sensors, both internal and external (remote).

The built-in ones are responsible for adjusting the heating installation depending on the temperature of the liquid inside the heating system.

External ones help to adjust the operation of the heating installation in accordance with the readings of either room or street temperature. The joint use of a pair of such sensors makes it possible to more accurately regulate the operation of the boiler installation, which means there is energy saving when weather conditions change.

The operation of the devices consists of constant measurement of processes:

- resistance;

- pressure;

- thermal expansion.

Which are in direct connection with the temperature of the heating system filler.

Automatic thermostats work according to the program embedded in them, controlling the operation of heating devices.

Mechanical controllers, when exposed to high temperatures, are capable of changing their thermal conductivity by closing/opening the connections of the corresponding valves.

All temperature sensors are placed in a special, small-sized block housing with installation directly into the heating structure.

The results obtained can be transmitted over a wireless communication channel, such as WI-Fi, or transmitted over wires.

Both electric and solid fuel boilers can be controlled by temperature sensors.

The programming function using a thermal relay paired with temperature sensors allows you to automate the procedure for adjusting the heating system. In addition, this makes it possible to significantly reduce heating costs.

In general, the entire structure can be equipped with three temperature monitoring devices:

- Indoor.

- Street.

- For water-based underfloor heating systems.

DIY repair

You can fix some problems yourself. The main thing is to follow our recommendations.

Water heater does not turn on

First of all, check if there is voltage in the network. You can check this with a screwdriver with an indicator: it should light up on “Phase”, but not on “Zero” and “Earth”. If the cable insulation is damaged, it is not recommended to carry out repairs. It is better to replace the element immediately, but make sure that the new cable matches the old one in terms of parameters.

A short circuit or lack of grounding leads to permanent shutdown of the RCD. A breakdown of the heating element on the body also leads to similar consequences. In this case, the element is diagnosed and replaced.

The RCD machine could break. To confirm your guesses, press RESET on the instrument panel. Is the light on? This means food is being served. Then press TEST and RESET again. If the indicator lights up again, the RCD is working normally.

Boiler does not heat water

Check the tightness of the contacts between the plug and the socket. If everything is in order and the voltage is supplied normally, you need to check the heating element. Do you have a storage type of boiler? Then drain the water from it first. A volume of water of 50-80 liters can be removed through the tap. It is better to drain 100 liters or more using a valve.

Remove the housing from the wall. Now you need to pull out the flange to which the heating element is attached. In Ariston 80 liter models, the flange is secured with only one bolt. In other cases, you will have to unscrew 5 bolts.

Disassembly is done like this:

- Rotate the flange along the axis.

- Take it out of the tank.

- Heater diagnostics are carried out with a multimeter. Read more in the article: “Replacing the heating element in a water heater.”

- If the multimeter needle moves, the part is working. Is it standing still? You need to install a new one.

Have you noticed that the water takes longer to heat up than usual? This does not mean that the heater is broken. Perhaps the reason is scale: over time it grows in a thick layer and interferes with normal heat transfer. Clean the element with special means.

Lack of heat may indicate a broken thermostat. Perform a reset on the boiler panel. If the appliance cannot be restarted, the thermostat is faulty.

A tester will help diagnose the breakdown more accurately:

- Set the multimeter to the maximum position.

- Attach the probes to the contacts of the thermostat (located next to the heating element).

- Does the arrow on the screen move? The device is working.

There is another option:

- Heat the thermostat with a lighter.

- Set the multimeter to "minimum".

- Place the probes on the contacts.

- If the arrow moves away from zero, then the part is functioning normally.

If there is a malfunction, the thermostat needs to be replaced. Disconnect the wiring from the part and pull it out of the hole.

Installation is carried out in reverse order.

Classification of types of temperature sensors

In order to choose the right boiler temperature sensor, you need to know where it (temperature) will be controlled:

- from inside the boiler plant;

- ambient air temperature in the rooms;

- coolant inside the heating structure itself.

The correct installation location of the meter affects not only the efficient operation of boiler equipment, but also the safety of its use.

There are two main criteria by which the temperature sensor is selected correctly:

- How is temperature determined?

- How the sensor interacts with the thermostat.

Types of sensors by method of determining temperature

There are several ways to measure temperature:

- Dilatometric. It is directly dependent on the state of the bimetallic plate with a large coefficient of thermal expansion, which can expand under the influence of heat. Magnets specially placed inside increase the sensitivity of the sensor.

- Thermoelectric. It consists of a pair of dissimilar conductors, which, during thermal expansion, are capable of producing thermo-emf. It is distinguished by increased accuracy due to the fact that the length and cross-section of the cables do not have a significant impact on the measurement result.

- Manometric. They measure how much the state of liquids or gases in a certain limited volume changes when heated.

- Resistive. Special alloys with high thermal expansion are used. They are sensitive to the slightest temperature changes. Usually presented in the form of a coil with copper-plated wire, placed in a plastic case.

- Semiconductor. Available in two versions:

- nonlinear temperature thermistors with a simultaneous decrease in resistance when heated;

- posistors with a nonlinear dependence, which is expressed in an increase in the resistance coefficient when heated.

Classification

It is customary to divide existing temperature sensors into two large groups. In the first group, sensors are classified depending on the method of determining temperature, and in the second group - according to the method of interaction of the device with the thermostat. One does not exclude the other: one model can be present in the classifier of each group of temperature sensors.

By method of determination

The correct operation of the temperature sensor at the facility depends on the method for determining temperature. There are several types of sensors, differing in price and accuracy of determining the parameter.

Dilatometric

A dilatometric (volumetric) sensor is a bimetallic plate or spiral made of a material with a high coefficient of thermal expansion. When heated, the plate bends and the contact at the end of the plate opens with the stationary relay contact, preventing the flow of current. Delayed thermostats use a coil that slowly opens or contracts as the temperature changes.

Resistive

Resistive temperature sensors use a thermistor (thermistor). This is an unusual resistor made of copper, nickel or platinum, the electrical conductivity of which varies in direct proportion to temperature. Depending on the resistance of the thermistor at the current moment, the heating or cooling mode of the boiler is automatically selected.

Thermoelectric

The action is based on the property of a thermocouple - a thermoseal made of two metals of different types (iron-nickel, nickel-chrome) to produce an emf when heated at the point of contact, proportional to the temperature, up to 40–60 µV. Such low voltage values impose special requirements on the equipment used in signal processing: precise, multi-bit converters with a minimum level of intrinsic noise are used.

In a simple non-volatile boiler, a thermoelectric sensor directly controls the solenoid valve for supplying gas to the main burner after heating the thermocouple with the pilot flame.

Gauge

The operating principle of pressure sensors is based on changes in gas/liquid pressure in a closed volume. They do not require an external power source, which is convenient for remote measurements. The disadvantage is the high inertia of readings and the low sensitivity of this type of device.

By type of interaction with the thermostat

The type of interaction with the thermostat is selected depending on the location of the sensor, taking into account the ergonomics of the hot water system. Along with the traditional wired connection method, wireless connection schemes are gaining popularity.

Wired

By definition, wired boiler fixtures transmit data through wires. Conductors connect the sensor to the control unit of the heating unit.

Wireless

The operation of a wireless device is similar to the principle of working with Wi-Fi. The signal enters the radio module, the receiving module in the water heating installation receives it, and the built-in controller of the control unit processes and converts it into a control pulse.

By placement method

Depending on the ability to be placed in space, thermal sensors are divided into several types. There are overhead, submersible and indoor types of devices.

Overhead

Overhead sensors are called sensors with external mounting to the heating circuit. The sensitive element is placed on the outside of the supply or return pipe and is attracted to it with clamps, after which it is tightly wrapped around the outside with a heat-insulating sleeve.

Submersible

Submersible products are in direct contact with hot water or coolant. They are installed in special mounting holes on the pipeline, provided for by the design of the equipment, at the outlet of the heat exchanger. The disadvantage of submersible products is the need to drain the coolant from the hot water system when replacing.

Indoor

Room devices are devices located inside residential or office premises. The room in which the air has the most constant temperature is selected. The most suitable place to locate the sensor/thermostat is a wall. The device should be placed at a height of no more than 120–150 cm from the floor.

External

External (outside temperature sensor) is located in the open air outside the building. It adjusts the microclimate of the interior depending on the ambient temperature outside, thereby implementing weather-dependent thermoregulation.

Where can I buy

Electronics for heating boilers are available for purchase in specialized stores in your city. But there is another option that has recently received significant improvements. You no longer need to wait a long time for a parcel from China: the AliExpress online store now offers the opportunity to ship from transshipment warehouses located in various countries. For example, when ordering, you can specify the “Delivery from the Russian Federation” option.

Follow the links and choose:

Placements

Naturally, the sensor must be placed in the zone of influence of the heater. Therefore, they are distinguished by the method of placement:

- overhead - installed with tight contact directly on the heated surface;

- submersible - placed inside the coolant;

- room - the room temperature is controlled;

- external - the state of the external environment outside the house is measured. They have a waterproof body.

The sensor controls the boiler

In order to more fully ensure comfortable living in a house with a minimum of thermal energy consumption, various devices are used. Such a temperature sensor for a gas boiler allows it to be programmed for different operating modes. The user just has to set the necessary parameters.

Mechanical thermostats

These models are the simplest. Without extensive functionality. They work through the use of membrane sensors located in a sealed capsule filled with liquid. When heated, the liquid expands and at a certain temperature puts pressure on the membrane and the thermostat makes it clear to the heating boiler that the power can be reduced/increased.

Mechanical devices are equipped with an expressive temperature selection dial. Due to their 3-4° accuracy and the wired connection method, these regulators are inexpensive.

Electromechanical

A slightly improved version of the previous temperature controller - electromechanical devices.

The principle of temperature regulation is similar to mechanics, but the operating principle is slightly different. The design uses heat-sensitive metals. When the heating changes, a micro-discharge is created or the resistance changes.

There are models with a small display for heating control and the possibility of adjustments in reduced steps. These changes were reflected in a slight increase in the accuracy of the device and in its price - it became more expensive than mechanics.

Electronic

More accurate electronic models are the most popular. These are more modern thermostats. They are multifunctional and easy to use.

- Can be used in conjunction with underfloor heating temperature sensors.

- Possibility of programming.

- There is protection against overheating and freezing.

- Warns that the circulation pump has stopped working.

- The measurement error is within 0.5–0.7 °C.

More advanced versions are equipped with built-in Wi-Fi for wireless connection to the boiler. Such a wireless room sensor, despite its high price, has a short payback period if used correctly.

Operating principle of sensors

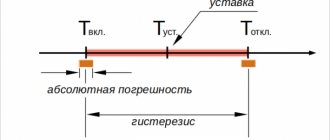

Thermostats, as well as programmers, essentially work on the same principle. You set the temperature threshold when it falls below which the boiler heating is turned on. The difference between the devices is only in their response threshold, which directly depends on the quality. Chinese analogues of well-known devices, as a rule, have a longer response threshold than the European original.

The normal threshold is considered to be one degree. For example, if you set the temperature to maintain at 20 degrees, then at the normal threshold, when the temperature drops below 19, the boiler will start working. And when it rises above 21, it will turn off.

Chinese analogues have expansions of up to two degrees or more, which accordingly affects the quality of the burner. At the same time, more expensive and high-quality models from European manufacturers may have an error of only 0.2 degrees for example.

How to choose a remote temperature sensor

What to look for when buying a temperature sensor? There are several options:

- A temperature meter needs extreme sensitivity and a wide range of measured temperatures. To quickly respond to changes in heating;

- sensor type - submersible or external. Is there a place for installation? It must match the dimensions of the water heater;

- temperature sensor parameters. Is there a need for additional voltage? At what speed is the signal transmitted and with what error. Ability to work in the right conditions;

- service life, maintenance frequency, need for additional calibrations;

- output signal level;

- permissible current, resistance, etc.;

When going to the store to buy a new device, it is better to take with you the technical data sheet for the heating installation.

Paired with thermostat

See how the temperature sensors will work with the boiler - with thermostat support or directly.

Many modern thermostats have the ability to adjust heating control depending on the weather. In this case, the power of the heating installation can be adjusted automatically if the thermostat is paired with an outdoor temperature sensor.

An outdoor thermostat is a single structure consisting of the sensor itself and a long (2–6 meters) wire for connection to the thermostat.

- in what temperature range can the sensor for a gas boiler operate;

- level of moisture protection;

- the magnitude of the error in indoor air measurements. Permissible ± 1 °C. Good ± 0.5 °C;

- connecting cable length. Out of the box there is a wire up to 6 meters long with an attached temperature sensor.

Direct connection to the boiler

As a rule, those boilers that are purchased are already equipped with temperature meters and they are developed by the same supplier. If you want to install remote control of the boiler using a controller, you need a cable (usually two-wire). But you need to buy it yourself. The wire cross-section and resistance can be found in the instructions for the sensor.

Water level sensors

These sensors are installed in a well, borehole, or container. It is advisable to use them with submersible pumps, although they are compatible with surface pumps. There are two types of sensors - float and electronic.

Float

There are two types of water level sensors - for filling the container (protection against overflow) and for emptying - just protection against dry running. The second option is ours, the first is needed when filling out. There are also models that can work either way, but the principle of operation depends on the connection diagram (included in the instructions).

The principle of operation when used to protect against dry running is simple: as long as there is water, the float sensor is raised up, the pump can operate, as soon as the water level has dropped so much that the sensor has dropped, the contactor opens the pump power circuit, it cannot turn on until until the water level rises. To protect the pump from idling, the float cable is connected to the open phase wire.

Level control relay

These devices can be used not only to control the minimum water level and dry running in a well, well or storage tank. They can also control overflow (overflow), which is often necessary when there is a storage tank in the system, from which water is then pumped into the house or when organizing a water supply for a swimming pool.

Electrodes are lowered into the water. Their number depends on the parameters they monitor. If you only need to monitor the presence of a sufficient amount of water, two sensors are enough. One - goes down to the level of the minimum possible level, the second - basic - is located slightly lower. The work uses the electrical conductivity of water: while both sensors are immersed in water, small currents flow between them. This means that there is enough water in the well/well/container. If there is no current, this means that the water has dropped below the minimum level sensor. This command opens the pump's power supply circuit and stops working.

These are the main ways in which protection against dry running of a pump is organized in the water supply systems of a private home. There are also frequency converters, but they are expensive, so it is advisable to use them in large systems with powerful pumps. There they quickly pay for themselves due to energy savings.

The device is designed to automatically turn off surface and borehole pumps and automatic water supply stations in the absence of water in water intake systems. Turning off pumps and stations protects them from damage as a result of operation without water (dry running mode). Serves to control any electric pumps operating from a single-phase 220 V network with a power of up to 1.5 kW. The device is installed in the pressure pipeline line. In this case, the power supply of the pump is connected to the device, and the power cable is connected to the 220V electrical network. The installation location of the device must be protected from the risk of flooding and in a well-ventilated area.

OPERATING LIMITATIONS:

- Working environment temperature: 0°С - 110°С

- Maximum permissible pressure - 6 Bar

- Connection 1″ (external and internal)

- Maximum permissible water flow – 100 l/min

DESIGN FEATURES:

- Switching voltage - 220 -240V ~ 50Hz

- Maximum operating current: 10A

- Degree of protection - IP65

- Restart - automatic

- Shutdown condition - flow less than 2 l/min

Technical characteristics of the product and photos may differ from those indicated on the website; please check the technical characteristics of the product at the time of purchase and payment. All information on the website about products is for reference only.

Operating and safety features

Thermal sensors help improve the microclimate, but their normal operation depends on following simple rules:

- the element itself that measures room temperatures must be immersed as much as possible in the environment where it is necessary to improve heat transfer;

- Correct and long-term service of the room temperature detector depends on timely inspection and calibration in full accordance with the recommendations from the manufacturers;

- eliminate the negative impact of external factors that may affect the accuracy of temperature measurements for boilers;

- Operation of electrical sensors with damaged insulation is prohibited;

- Do-it-yourself disassembly of the thermostat is strictly prohibited;

- All preventative work is carried out with the equipment disconnected from the 220V network.

General conclusion

The use of a wireless thermostat for a gas boiler simplifies the operation of heating equipment. The simplest models are inexpensive. But their installation involves laying wire communications. Therefore, total costs may increase significantly compared to the preliminary plan. More complex sets use radio frequency to transmit control and control signals. Installing such products is not difficult to do yourself. Their high cost is due to their advanced functionality.

Replacement and connection

If the thermostat breaks down, then finding out the source of the breakdown is not difficult at all and can be done by the owner of the heating installation:

- If the water does not heat up, the source of the disease lies in both the temperature sensor and the thermostat. In this case, we do not consider the breakdown of the heating element. We assume that it is working properly.

- The temperature sensor is removed from the boiler and all wires are checked for breaks using a tester in the “continuity” mode.

- If the temperature measurements show zero when the thermostat is running, it is definitely faulty. You can’t fix it yourself; it’s better to buy a new one and replace it.

- If the thermostat responds to the boiler in the “call” mode, you need to set the minimum temperature value and take measurements again.

- If it is working properly, then in the “heating” mode its contacts should be open, and the resistance at the input and output should increase.

Replacing the thermostat with a similar one is described in detail in the instructions for the heater. If there is no such thing on sale, a similar one with the appropriate parameters is looked for.

Devices with horizontal plates

The water flow sensor for a boiler of this type is suitable for a wide variety of pumps. The conductivity of models depends on the dimensions of the chamber itself, as well as the channel. Additionally, the diameter of the fitting is taken into account. Many experts recommend installing two-chamber modifications. Their pumping force, as a rule, does not fall below 5 N. The protection system is quite often used in the P50 series. All this suggests that the manufacturer guarantees a high degree of sealing and overall reliability.

When choosing a device, it is important to evaluate the valve parameters. If it is made of ordinary plastic, then it is not able to last long

Copper analogues perform well, but are expensive. The main bulb of the sensors is made of plastic. Modifications with transition contacts are very rare. Relay modifications can boast high conductivity. They are not afraid of overloads. And they use high-quality protection systems.

The water supply system of a private house is impossible without a pump. But you have to somehow turn it on and off, and make sure that it doesn’t work in the absence of water. A water pressure switch is responsible for turning the pump on and off, and the presence of water should be monitored by protection against dry running of the pump. We will consider further how to implement this protection in different situations.