Home » Building a house

Alexander Korovaev 03/28/2020

16941 Views 2 comments

Thermal insulation materials for a residential building are selected depending on the type of structure and the type of future cladding. We will tell you in detail how to insulate a private house with your own hands in each specific case.

Is it possible to insulate a house from the inside?

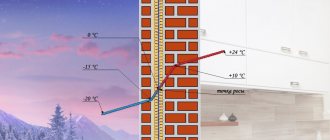

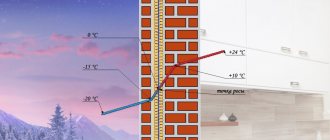

If you do not want to live in a room where the humidity exceeds all permissible limits, and the corners are covered with layers of frost and black fungus, never insulate the building from the inside. Freezing of the walls in this case will occur due to a shift in the boundary of the dew point - a section of a certain temperature at which the steam floating in the air begins to condense and turn into water.

Moisture loss always occurs at the boundary between cold and warm air. Proper thermal insulation implies the obligatory displacement of this area outside the building. When insulating a building from the outside, a sharp temperature difference will be observed somewhere at the boundary of the insulation, that is, outside the room.

When laying a heat insulator inside the house, the dew point will be located between the cold wall and the warm cladding, that is, in the building itself, which is unacceptable.

Dew point in the wall of a building

It is not very successful to choose a thin layer of insulation for small wall thicknesses. In this case, the dew point will be closer to the center of the wall, which can also lead to freezing of the corners and condensation in the house.

Features of the process of insulating a building from the outside

The materials from which the walls of permanent structures are erected can be different: brick, concrete, slag or aerated concrete blocks, wood, sandwich panels - these are just their main types.

Some of them do not require insulation at all: for example, sandwich panels. But other options need it to varying degrees.

Why do you need to insulate from the outside? Many people attribute this to the fact that if an insulating layer is installed inside a building, useful spatial volume is stolen from the interior.

This is partly true, but this is not the main reason. A critical parameter is where the dew falls.

A dew point forms on a surface where there is a temperature difference when pressure changes.

And if you install thermal insulation inside the room, it means that the walls of the building themselves will be cold, since the insulation will save heat inside the space and prevent it from reaching the enclosing structures.

Insulation from the inside is fraught with the fact that the dew point will form inside the building, most likely on the inner surface of the main wall, which is insulated with insulation

How to choose the thickness of insulation?

To reduce heat loss and ensure an acceptable temperature in the premises when insulating, the thickness of the walls, their heat-insulating properties, type of foundation, climate of the area and prevailing wind loads are taken into account. If the walls are thick enough, made of materials with high heat-insulating properties (for example, made of brick or logs), insulating the facade is not necessary.

The thermal insulation of a house assembled from cinder blocks should be maximum - this material is not capable of retaining heat for a long time. When calculating the thickness of the walls, the thermal conductivity coefficient of the insulation itself is taken into account. The best characteristics are provided by materials such as polyurethane foam, polystyrene, and mineral wool.

For example, a 50 mm layer of polyurethane can retain heat in the same way as 1720 mm of brick.

Thermal conductivity of materials

Professional builders use quite complex formulas to calculate the thickness of insulation. When choosing a heat insulator for a private home, it is convenient to use online calculators. You only need to indicate your region of residence, the size of the building, the types of basement and attic floors, the thickness and material of the walls, and the type of roof.

Even with significant wall thickness, a small layer of insulation along the facade is still worth laying. After all, upon contact with cold air and temperature changes, cracks form on their surface over time, leading to premature destruction.

Insulation with penoplex and polystyrene foam

They are typically used for brick, block and concrete walls. The surface must be dry, especially in the case of foam.

The sheets are glued, pressing well against the wall. It is advisable not to limit yourself to plumb lines and to secure yourself by attaching a horizontal bar at the bottom. It will be easier to lay out the first row on it. For reliability, you can drill the insulation with “fungi” dowels in the center and in the corners.

Photo: Instagram stepmaster_omsk

The second and subsequent rows can be glued as the first layer sets, with the joint offset (like brickwork). The seams are covered with reinforcing tape, and the finished wall is covered with plaster mesh. Penoplex can be “sanded” with a needle roller to improve the adhesion of finishing materials to it.

Photo: Instagram vysotnye_raboty.kg

Then the wall is primed, plastered and given a decorative appearance to the facade.

When can you start insulating a building?

There is a basic rule in construction - it is necessary to begin finishing work on buildings after the house has completely settled. This may take about a year. Moreover, shrinkage occurs not only in wooden houses, but also in brick, monolithic frame buildings, etc.

Installation of thermal insulation is preferably carried out in dry weather - the house is well dried beforehand. The house should already have a roof, external waterproofing of the foundation, ventilation, windows, doors.

All work on finishing a log house begins only after it has settled

You should not start work either in frost or heat - you must wait until the temperature reaches above zero of 5-25°C. The optimal time to start finishing the facade is late spring or early autumn.

Cellulose insulation

It is difficult to lay ecowool manually, especially on vertical surfaces: it is too loose. First, the material is transferred into a large container, fluffed up using a mixer or a puncher, and placed into the cells of the frame by hand.

Photo: extrawool.ru

Construction companies use compressors that blow in ecowool. They also have installations that wet the material with water and allow you to spray it on the wall. This is much faster than laying it yourself, but for uniform application the craftsmen require high qualifications.

Photo: Instagram fiberwood

Insulation of the facade. Basic methods

Ventilated curtain façade with siding

There are several ways to decorate walls:

- by creating ventilated curtain facades: by attaching facing materials to the frame; a ventilation gap is formed between the insulation and the wall, protecting them from condensation and moisture accumulation

- plastering method: the system consists of 3 layers, a heat-insulating layer (most often inexpensive foam plastic is used, which is attached to a special adhesive composition), a reinforcing mesh and a decorative layer (plaster)

- through ready-made plaster systems (thermal panels) , heat-insulating materials with a decorative layer already applied

- using siding (high-strength stacked panels): in essence, the method is a type of ventilated facades.

Methods of wall insulation

Experts identify three main options for insulating walls outside.

The first is called a “wet facade”. The insulation is attached to the outer wall, then plastered.

Photo: Instagram fasad.ug

The second is the construction of walls consisting of three non-ventilated layers. The insulation is fixed on the first of them, then a small air cushion is left and another brick-thick wall is built.

Photo: Instagram encon.co.uk

The third is ventilated facades. A wind barrier is attached to the insulation, and siding or other decorative material is placed on top.

Photo: Instagram ziasfacadesystem

What materials can be used to insulate a facade?

Materials used for thermal insulation of walls must have a number of technical characteristics:

- sufficiently low thermal conductivity coefficient: reliably store and do not lose heat

- low degree of water absorption - after all, when moisture is absorbed, they almost completely lose their thermal insulation properties

- rot-resistant

- sufficient vapor permeability: the walls of the house must “breathe”, that is, allow air to pass through and give off moisture; When the walls are covered with insulation that has low vapor permeability, the humidity in the house will always be increased

- strength and resistance to wind loads and other physical influences

- fire resistance: they should not be highly flammable

- long service life

Types of insulation

Unfortunately, there are no universal insulation materials that fully meet these requirements.

Each of them has both undeniable advantages and disadvantages:

- polystyrene foam: capable of storing heat for a long time, but is very vulnerable to ultraviolet radiation, plus it has low strength and fire resistance, so it requires additional finishing; moisture absorption is average

- penoplex: has a low thermal conductivity coefficient, moisture resistant, fire resistant; There are two disadvantages - poor vapor permeability and a fairly significant price compared to polystyrene foam.

- mineral wool: its undoubted advantages include low thermal conductivity and high fire resistance; but, since this material quickly absorbs moisture, it requires mandatory waterproofing

- warm plaster: a cement-based mixture in which sand is replaced with heat-insulating components - sawdust, vermiculite, perlite, pumice or foam granules; subsequently covered with a layer of decorative plaster

- penoizol: in fact, it is liquid polystyrene - lightweight insulation that excellently stores heat, applied by spraying; its main disadvantages are poor resistance to aggressive chemical environments and fire

- liquid polyurethane foam: also applied by spraying using special devices, filling every crack; it is very convenient to work with it on inclined planes when insulating the roof; but its cost is quite high

Finishing with foam plastic followed by plastering

When insulating a facade with foam plastic, to increase the fire safety of a building, the so-called method of cutting slabs using fire-resistant mineral wool is often used.

Wall insulation: basic information

First, let’s look at what the market for materials suitable for thermal insulation is rich in today:

- extruded polystyrene foam (EPS, known commercially as penoplex),

- Styrofoam,

- mineral wool,

- polyurethane foam (PPU),

- cellulose.

Photo: extrawool.ru

Photo: extrawool.ru

You can insulate walls both from the inside and outside.

Photo: Instagram fasadof__

Advantages of external insulation:

- protection of walls from adverse weather conditions,

- all moisture remains outside and does not penetrate inside,

- the usable space in the house is not consumed,

- good sound insulation from street noise.

The downside is that the workflow depends on the weather.

Photo: Instagram edvercompany

Advantages of internal thermal insulation:

- allows you to preserve the exterior decor of the house if the owners do not want or are not able to dismantle it,

- you can insulate living quarters if there is no access to external walls (prolonged rains or the apartment is in a high-rise building).

This option has at least three disadvantages: the usable area of the premises is reduced, fungus and mold may appear, and “bare” walls on the street side are susceptible to destruction.

Photo: Instagram izzystroy

So, facade insulation is preferable. It better protects the house from temperature changes, prevents the effects of moisture, frost and sun on the building, and maintains optimal humidity inside. Technologies for installing materials inside and outside are no different.

Photo: Instagram tihonov.vitalick

Materials for foundation insulation

The foundation, which separates the soil and the structure, is considered one of the main sources of heat loss. However, not all types of materials can be used to insulate it. Mineral wool or basalt slabs are not suitable for these purposes - they will absorb moisture from the soil and quickly become unusable.

Foundation insulation with expanded clay

The most common foundation insulation materials are:

- expanded polystyrene: perhaps the ideal option in terms of price-quality ratio; if it is not practical to use it for wall decoration due to low vapor permeability, then for insulating the base, a material that is not afraid of rotting is ideal; plus it is light in weight and easy to install; high flammability in this case is not significant - after all, it is laid underground;

- expanded clay: excellent environmentally friendly heat insulator; due to its high porosity, it forms an air cushion that reliably protects the base of the building from the cold; requires additional waterproofing with coating or roll materials; but the high cost does not allow it to be widely used as foundation insulation;

- liquid polyurethane foam: similar in properties to expanded polystyrene, but without special equipment it is impossible to use it independently.

Types of insulation - which is better?

For proper internal insulation of a wooden house, insulation materials are used that, while maintaining thermal insulation properties, do not cause an unpleasant odor over time, are fireproof and environmentally friendly.

The most common options for internal insulation are:

- mineral basalt wool . It is the most popular material for wall insulation. The features of this material are: good thermal insulation properties, high level of sound insulation, fire resistance, strength, high hygroscopicity, due to which it is necessary to install piping from vapor barrier films;

- foam boards . Because the material can release styrene, extruded polystyrene foam is used, which requires a containment system. The material has good thermal insulation, has soundproofing properties, however, it is quite fragile;

- glass wool It has greater thermal conductivity than mineral wool, but the price of the material is significantly lower than basalt slabs. The material crumbles a lot, so it should be laid in protective equipment: crumbs of material are harmful to health. In addition, it is necessary to install enclosing structures;

- isoplat . Insulation, which consists of compressed flax fibers and wood board. An ideal thermal insulation material from the point of view of environmental friendliness, and also durable enough that it does not require the installation of fencing systems;

- polyurethane foam , which is installed by spraying it onto the surface, is installed using special equipment. Modern and quite expensive material.

Comparative characteristics of thermal insulation

The type of insulation should be chosen based on the characteristics of the building, climatic conditions, and the purpose of the building.

Thermal insulating materials for roofing

As you know, warm air tends only upward. If the roof covering is not insulated enough, it will go away unhindered, and the house will quickly dry out. If up to 15-20% of the heat evaporates through the walls, then about 10-20% escapes through the roof. This fact should not be neglected.

Thermal insulation of the roof with polyurethane foam

For thermal insulation of roofs, any types of materials can be used, from mineral wool to slag or sawdust. When using expanded clay, it is most often mixed with foam granules - this helps reduce the weight of the insulation and enhance its effect.

Rolled eco-, glass, mineral wool, as well as liquid polyurethane foam are used mainly for inclined surfaces. Rigid slabs and bulk insulation are used for laying on floor slabs.

Thermal insulation of the roof must be thought out even before laying the structure - after all, when using heavy backfill materials, the load on the foundation will increase significantly.

Bulk materials

As a rule, such materials are environmentally friendly and inexpensive. Especially in forest regions where there is a lot of sawdust. Bulk insulation is convenient because it is very easy to use.

- For example, to insulate the roof from the attic side, it is enough to simply pour a certain thickness of sawdust or vermiculite and cover it with a waterproofing film. You don't even have to cover it with film.

- The bulk material absorbs and allows moisture to pass through well. Rodents don’t like them, which is also a big plus; they won’t make holes in it.

True, this type of material also has its disadvantages: expanded clay is heavy, so it is not suitable for a light foundation. But vermiculite is also not very light, and it does not absorb moisture.

Range of thermal insulators

The range of heat-insulating materials sold on the market today is quite wide.

Let's consider only the main ones:

Foam plastic (cellular plastic)

Inexpensive material made from foamed plastic (mainly polystyrene). The excellent thermal insulation properties of polystyrene foam are explained by the presence of multiple individual granule cells, separated by partitions and filled with gas. An 8 cm thick slab is equivalent in thermal protection to 25 cm of wood or a 1.5 m brick wall.

Polystyrene foam is lightweight, easy to cut, and easy to install. Plates made from it are quite elastic and, unlike rolled materials, do not sag over time.

External foam insulation

The density and strength of polystyrene foam depend on the technology of its processing and the type of raw materials. For façade cladding, it is better to use high-density material - it crumbles less when cutting and has a longer service life.

Despite the fact that the foam itself does not rot, colonies of microorganisms can easily attach to its rough surface and can spread to other structural elements.

Due to its tendency to ignite, as well as the ability to be destroyed under the influence of sunlight, this insulation must be covered with a layer of plaster or used in ventilated facades.

Extruded polystyrene foam

Despite the fact that expanded polystyrene, like polystyrene foam, is made on the basis of polystyrene, its technical characteristics differ significantly. If foam foaming occurs under the influence of steam, then in polystyrene bulk granules are obtained by introducing a foaming reagent and then pressing it through an extruder. As a result, the material acquires a more uniform structure and strength.

All of its air granules are closed and have the same size, which is why polystyrene foam is less fragile than polystyrene foam.

Foundation insulation with polystyrene foam

The service life of this material is up to 40 years. It has minimal water absorption (up to 0.4%) and lower thermal conductivity - on average it is 0.029-0.034 W/(m K). The thermal insulation properties of polystyrene foam are very high - even a thin sheet is enough to create a reliable barrier to the cold.

But still, polystyrene foam is not able to “breathe”; it is better not to use it for wall decoration, otherwise they will get wet. The main purpose of expanded polystyrene is thermal insulation of plinths and foundation blind areas. A special high-strength, high-density material is used in construction as auxiliary or even load-bearing structures.

Assortment of insulation materials

For a certain type of structure, it is better to select appropriate materials. Thus, the insulation of a house under siding will be carried out using one type, and a wooden structure under another. What construction does not need this procedure is a frame house.

- There are also types that are only suitable for horizontal surfaces. And there are varieties that can be used on any type of wall.

- Now manufacturers care not only about technical characteristics, but also about versatility.

- Bulk material can not only be placed in cracks, but also mixed into cement to screed the floor or fill it.

- Mineral wool can be used on wet and suspended facades, and can also be used to insulate floors and walls.

- In addition, it is a heat-resistant material, so it can be used on appropriate buildings - baths or saunas, including in the house.

There are a lot of forms, so it’s easy to choose one that suits a specific area and structure. Bulk material can be used to insulate a basement, and large areas can be insulated with rolled material.

Types of mineral wool

Mineral wool is a group of materials with a fibrous structure, which includes:

- rock wool: obtained from molten rock minerals; it is what is most often called mineral wool; one of its varieties includes more moisture-resistant basalt wool

- glass wool: fine fibers obtained from molten glass or sand by heating at extremely high temperatures

- slag wool: the cheapest material, which is based on blast furnace slag; due to increased hygroscopicity, it is not used for insulation of buildings

The advantages of mineral wool include:

- high thermal insulation properties

- low flammability

- rot resistance

- reasonable cost

Types of mineral wool

Most types of mineral wool absorb moisture and have low mechanical strength, so it must be covered with a layer of vapor barrier and then sheathed with airtight sheathing.

It is not advisable to use rolled mineral wool for finishing facades - it has less thermal protection and shrinks, forming “cold bridges” over time. For finishing the building, it is better to use material in the form of dense slabs.

Stone mineral wool

Excellent technical characteristics plus a reasonable price ensured sufficient demand for this material. This type of mineral wool has low thermal conductivity, almost does not absorb moisture, and thanks to its cellular structure it is able to “breathe”, that is, allow air to pass through and condensate to escape.

Stone mineral wool

Depending on the type of raw materials and production method, it may have varying degrees of hardness. Stone wool is produced in the form of sheets, semi-rigid mats or high-strength slabs. Due to its high fire resistance and high degree of thermal insulation, it is widely used in construction - it is used as insulation and sound insulator for facades and roofs of buildings that have an increased risk of fire.

It is allowed to use stone wool to insulate underground communications, chimneys, and cladding rooms with installed stoves or boilers.

To avoid the appearance of “cold bridges” when using any type of slab insulation, all seams must be additionally taped.

Glass wool

Due to its low density and increased hygroscopicity, it is not recommended to be used for finishing facades. Plus, glass wool can melt under the influence of elevated temperatures, completely losing its thermal insulation properties.

Glass wool

This inexpensive rolled material is most often used for thermal insulation of pipelines and technical premises.

When working with it, special care is required - thin fibers break off and get on the skin, causing irritation. When inhaled into the lungs, small particles of glass wool can cause inflammation.

Basalt wool

This material is more expensive than ordinary stone wool, but it is more durable and voluminous. Another advantage is the lower degree of moisture absorption and shrinkage. Formaldehyde, which is part of basalt sheets, can repel rodents that often live in insulation.

They easily tolerate significant temperature changes without loss of quality, do not rot, and do not ignite. Their heat-insulating properties are also high.

Basalt wool

Basalt wool has a significant drawback - high fragility. Therefore, you need to work with it carefully, always wearing protective clothing, goggles and a respirator. The dust generated when sawing it causes irritation to the skin. It can also settle in the lungs.

Just as in the case of stone wool, for cladding facades it is better to use more durable slab material rather than rolled material. Basalt wool is also applied by spraying using a special technique - in this case, a special type of material is used in the form of granules.

What is the best way to insulate walls outside?

Each type of modern insulation for exterior walls of a house has its own characteristics and price range. But their main differences are:

- low thermal conductivity coefficient;

- minimum values of water absorption and vapor permeability;

- the ability to regulate the indoor microclimate;

- high sound absorption rates;

- environmental cleanliness;

- fire resistance and fire safety;

- resistance to chemical attack;

Comparative table of thermal conductivity of building materials - resistance to biological and mechanical influences (molds, insects, rodents);

- strength and durability;

- elasticity and lack of shrinkage;

- low weight;

- possibility of installation without seams, joints, voids;

- ability to fill complex and hard-to-reach areas;

- ease of installation.

It is also important to take into account how the consumer prefers to install insulation for the walls of the house outside. Nowadays you can find enough videos showing the possibility of doing the work yourself (as well as other manuals).

The optimal insulation for walls is selected taking into account the material of construction.

Water absorption and vapor permeability are taken into account to ensure maximum protection of the room from moisture and are selected taking into account the climate and depending on the installation method. Thermal conductivity is used to calculate the required thickness of thermal insulation material.

The most commonly used types of insulation are:

- expanded polystyrene (foam);

- extruded polystyrene foam (eps, penoplex);

- polyurethane foam;

- mineral wool;

- basalt insulation;

- liquid thermal insulation.

Materials for external wall insulation

Expanded polystyrene (foam)

Polystyrene foam (expanded polystyrene) is one of the modern polymer insulation materials for house walls and is used in this capacity in almost all areas of the construction industry: civil and industrial.

First of all, this material is characterized by low thermal conductivity (from 0.037 to 0.052 W/m*K, depending on density) and water absorption, resistance to biological and chemical influences, and high sound insulation and windproof properties. It belongs to the group of environmentally friendly substances and is quite durable: its service life exceeds 50 years.

Fact! A layer of foam plastic 50 mm thick is equivalent to a wall of one and a half bricks in terms of heat retention.

Among its other advantages are flexibility and light weight. This helps reduce the cost of delivery and installation, ease of work, and reduces the load on the walls, which, in turn, eliminates the need for additional strengthening of the foundation.

The disadvantage of polystyrene foam is its flammability, however, the low price makes it possible to insulate all the outside walls of the house with foam plastic.

Extruded polystyrene foam (eps, penoplex)

Extruded polystyrene foam (penoplex) is one of the latest generation of thermal insulation materials. In its production, graphite is used in the form of nanoparticles, which increases the strength and energy saving of the product.

Insulation of walls with penoplex followed by cladding with siding

The thermal conductivity coefficient of penoplex insulation ranges from 0.029 to 0.031 W/m*K. It is resistant to mold, chemicals, insects and rodents, and is an excellent sound insulator.

Thanks to this, it is possible to use penoplex as insulation outside: for the walls of wooden houses and other buildings, and inside: thermal insulation of ceilings (especially when installing “warm” floors), basements, balconies and loggias.

Polyurethane foam

Polyurethane foam is a type of plastic with a cellular foam structure. The mass of cells filled with air is 90% of the total weight of the product. Due to this, the thermal conductivity coefficient of polyurethane foam is one of the lowest - from 0.023 to 0.041 W/m*K.

Liquid polyurethane foam creates an airtight coating with excellent vapor and waterproofing.

Polyurethane foam has a high level of adhesion to all types of surfaces: concrete, brick, wood, metal - due to which an airtight coating is created with a guarantee of excellent vapor and waterproofing.

A seamless application method (using a compressor and a hose) and high elasticity make polyurethane foam an indispensable material for blown-in thermal insulation when insulating the outside walls of buildings of complex shapes and frame houses. Insulation for external walls using the blow-in method can be applied at temperatures up to 100ºС, the service life is up to 30 years.

Liquid polyurethane foam can be used as blow-in insulation between the building wall and the cladding.

The only disadvantage of the material is its high cost and the need to use expensive equipment for installation.

Mineral wool (basalt insulation, stone wool, glass wool)

Mineral wool is a product of processing slag (waste from the metallurgical industry) or rocks: basalt and dolomite. It is distinguished by strength, non-flammability, durability, environmental friendliness, elasticity, high degree of sound absorption, ease of installation and low cost. The thermal conductivity of this material is in the range of 0.034 – 0.037 W/m*K.

Mineral wool is characterized by fire resistance, environmental friendliness, a high degree of sound absorption and low cost.

For insulation work, mineral wool is used in the form of basalt slabs or in rolls with a wide range of sizes. Mineral wool is used as insulation for the outside walls of a house. The dimensions of the produced slabs can be as follows:

- 1000 x 600 x 50 mm;

- 7000 x 1200 x 50 mm;

- 9000 x 1200 x 50 mm;

- 10000 x 1200 x 50 mm;

- 10000 x 1200 x 100 mm.

Expanded polystyrene boards may have joint grooves for ease of installation

Basalt insulation is used in buildings for any purpose, especially for insulation in dachas, wooden houses and buildings made of timber, brick or foam blocks. It is possible to work with this material at temperatures ranging from -60ºС to +220ºС, which is definitely convenient when installing on walls outside. Insulation in dachas, houses made of wood, brick or foam blocks, garages, warehouses and other buildings - this is an incomplete list of possibilities for using mineral thermal insulation.

It is most preferable to use mineral wool or basalt slabs when installing insulation for the walls of a house outside under the siding.

It is most preferable to use mineral wool to insulate a house from the outside, followed by siding.

It is also popular to use mineral wool (along with polyurethane foam) to create blow-in insulation. With this method, using a compressor unit, the material is blown between the wall of the house and the finishing facade, which also serves as formwork.

Liquid thermal insulation

Liquid thermal insulation materials can be called new generation insulation materials. They can be used for thermal insulation of metal parts (pipes or frames) and as insulation for houses made of foam blocks. On the outside, on the walls, these ceramic multi-component substances look like acrylic paint.

However, they differ from paint in the content of vacuumized voids (up to 80%), due to which they acquire the properties of a heat insulator.

Liquid insulation is similar to acrylic paint

Interesting! Liquid insulation has a record low thermal conductivity coefficient (from 0.0011 to 0.0015 W/m*K). For comparison, the thermal conductivity coefficient of vacuum is 0.

With a liquid consistency, these materials do not require professional skills and complex equipment for application to any surface: concrete, brick, metal, wood. They are applied using painting tools: brushes, rollers, airless spray guns - and fill all voids and crevices.

After 6 hours of drying, a solid, highly mechanically resistant coating is formed.

Fixation of sheets of polystyrene foam or expanded polystyrene is carried out with special fastenings of the “mushroom” type.

Due to their low thermal conductivity, liquid insulation for the walls of a house helps reduce heat loss, even if applied externally in a thin layer. They protect the surface from weather influences (operating temperature range - from -60 to +260°C), solar radiation and precipitation, and metal parts from corrosion.

Interesting! Water absorption of most liquid insulation materials within 24 hours does not exceed 0.4% by weight.

Coating with liquid insulation is one of the effective ways to prevent the formation of condensation and protect an industrial or residential premises from freezing and the development of all types of mold fungi.

Thermal panels

Facade thermal panels are ready-made systems consisting of two layers: thermal protection and facing. They do not require any additional finishing or painting. Polyurethane foam or polystyrene foam is often used as insulation.

The decorative layer is usually made of brick-like clinker tiles or colored marble chips. Recently, products with porcelain stoneware finishes have also been produced. Thermal panels can be mounted on any type of wall from concrete, brick to timber or cinder blocks.

Their technical characteristics and service life depend on the material of manufacture. Installation of such structures is simple - they are simply attached to profiles.

Facade thermal panels do not require additional finishing

Improved versions of thermal panels have a tongue-and-groove side fastening, which eliminates the appearance of cold bridges. Such panels do not require additional processing of the seams or filling them with mortar.

Through poorly insulated windows and doors, up to 20-30% of the heated air can escape from the house, so do not forget about careful finishing and plastering of the slopes. It is also necessary to think about the ventilation system - if it is installed incorrectly, up to 30-35% of the heat can be lost.

Insulation with polyurethane foam

It also needs a sheathing underneath, although vertical posts are enough. The material is produced in liquid form in cylinders, from which it is then sprayed onto the walls under pressure. Very soon, after about half an hour, the foam increases in size and hardens. The excess needs to be cut off.

Photo: Instagram uteplenie_ppu_krasnodar

Photo: Instagram uteplenie_ppu_krasnodar

In addition, polyurethane foam is used when the owners decide to additionally insulate the house without removing the finishing. Polyurethane foam is poured between the outer wall and the sheathing.

Photo: Instagram nsfera.ru

Thermal insulation plaster

This type of heat insulator is another novelty in the construction market. The main binder in it is lime or Portland cement. Various stabilizers and plasticizers are also added to them. But the main component (up to 40-75%) in heat-insulating plaster is porous insulation in the form of foamed perlite, vermiculite or foam balls.

A layer of such a mixture of only 50 mm is equal in its thermal insulation properties to a masonry of 2 bricks. Plus, you can use it, just like a regular one, to level walls and use it as a decorative finish. Moreover, it weighs 3-4 times less than ordinary plaster. Warm plaster can be used for ceilings, walls, window and door slopes, pipelines, as well as interior finishing work.

A layer of thermal insulation plaster

The technology for applying heat-insulating plaster is almost identical to the usual method - the mixture is distributed using a conventional spatula or mechanical sprayers. It adheres well to the surface, so a small layer can be applied even without a reinforcing mesh.

This material is able to “breathe”, allowing steam to pass through, and has sufficient water-repellent properties. Due to the absence of seams, warm plaster does not form cold bridges. In addition, it is non-flammable and can protect buildings from accidental fire.

Insulation of a house from the inside - technologies for installation work

The choice of method for insulating the interior space of a residential building depends on the physical design of the heat insulator. In any case, work begins with preparing the base. It must be cleaned of old finishes and protected from fungus and corrosion. In the case of a wooden log house, additional caulking of joints is carried out if necessary. Today it is easier to find rolled jute or tow for this.

Do-it-yourself insulation of walls from the inside

The sheathing for insulation is assembled based on the size of the slabs. For cotton materials, minus 5-10 cm to ensure a tight fit of the edges to avoid cold bridges. If the thickness of the canvases is noticeable, then you can take thin ones and lay them in 2 rows in a checkerboard pattern, overlapping the previous joints. On the contrary, styrene insulators leave a small gap due to different thermal expansion rates. The voids are subsequently filled with foam.

If the insulation was carried out with mineral wool or expanded polystyrene, then the next step is to install a vapor barrier. The canvas is often fastened using a construction stapler. The overlap of the edges should be on the support. The width is maintained at about 15-20 cm.

Under polyurethane foam, the sheathing is assembled from wooden beams with a cross section of 40*40 or 50*50 mm. The step between the workpieces is about 60 cm. Spraying is carried out into the formed cells. After about 12 hours, you can begin cutting off excess material, focusing on the sheathing and the rule.

To work with polyurethane foam you will need certain skills and equipment

Penoizol

Liquid carbamide foam plastic (penoizol) is convenient because it can be poured directly at a construction site. It perfectly fills all irregularities and voids without expanding in volume. However, it is possible to obtain a high-quality coating without cracks only at temperatures up to +5°C.

Working in the cold with it is strictly prohibited.

Carbamide foam is also produced in the form of slabs or crumbs, called thermal wool, blown into hollow frames. The absence of seams is the most important advantage of the material. It is used to insulate walls, attics, roof spaces or as a layer in brick walls.

Thermal insulation with foam insulation

In terms of service life, it exceeds conventional foam plastic or extruded polystyrene foam - the service life can be up to 80 years. Builders often complain about its low strength, but this is due to the use of penoizol of insufficient density. The improved material is not inferior in strength to flexible and dense polystyrene foam.

The porous structure of carbamide foam allows for good vapor removal. However, due to its ability to absorb liquid, it requires moisture protection. Not only film followed by finishing with durable panels, but also cement-sand plaster can serve as waterproofing.

How best to insulate the walls of a house

There are two ways to insulate a building - use internal insulation of the premises or make insulation for the walls of the house outside. Which insulation is better to use? The answer is hidden in a short expression - “dew point”.

Thermal insulation of the room from the outside will ensure the correct location of the dew point.

Dew point is the temperature value at which condensation occurs. The point with this temperature can be located in the thickness of the wall, inside it or outside. Its coordinates depend on the physical properties of the wall materials, the thickness of their layers, as well as external and internal temperature and humidity.

Important! The dew point position will be more optimal even in a completely uninsulated wall than in one that is only insulated from the inside.

The correct location of the dew point (outside the wall) can only be obtained by installing the insulation of the walls of the house outside, selected taking into account the properties of the material and thermal calculations for thickness.

Liquid polyurethane foam

Application of liquid polyurethane foam

This material is produced using two components: a polyol and a polyisocyanate. The release of carbon dioxide during their interaction makes it possible to obtain surfaces with a foam structure.

Polyurethane foam is available in two modifications:

- with closed voids: has better strength and heat-insulating characteristics, but removes moisture from the walls worse; it, like slab polyurethane, is best used for insulating foundations

- with open voids: widely used for finishing walls, roofs, attics, especially inclined structures

Liquid polyurethane foam is more expensive than penoizol, but has better technical characteristics. It is more durable and elastic, absorbs less moisture. According to manufacturers, this heat insulator, subject to application technology and proper operation, can last up to 50 years.

The disadvantages of liquid polyurethane foam include poor resistance to ultraviolet radiation - surfaces filled with it cannot be left open for a long time. It also does not adhere well to cold walls, so it is necessary to work with it only at positive temperatures. Just like sheet polyurethane foam, the material is flammable and therefore requires additional protection.

Installation of insulation under plaster

When installing insulation under plaster, for exterior walls of houses, polystyrene foam, basalt insulation boards, sheets of mineral wool or penoplex insulation are most often used as a heat insulator.

The insulation is fixed to the outside walls of the house using an adhesive solution and reinforced with fiberglass reinforcing mesh.

Special “mushroom” type fasteners provide additional fixation of foam sheets or basalt insulation slabs. For the exterior walls of the house, plaster (the “wet facade” method) or facing materials are used as finishing materials. “Wet façade” insulation system

Three-layer non-ventilated wall

A three-layer non-ventilated wall is formed by the outside walls of the house, insulation and facade finishing, laid out taking into account the air gap. This method is used for installation with exterior brick finishing for the walls of a house. Various types of insulation materials are used in this option, including heat-insulating materials for blow-in installation.

This method is used for insulating various buildings, both brick or foam concrete, and wooden or timber.

Non-ventilated facade with blown-in insulation

Facade finishing is done with facing slabs, decorative or building bricks.

Granular thermal insulators

This group of thermal insulators includes expanded clay, perlite and vermiculite, which have the form of granules filled with air. In the first case, the cellular structure is obtained by swelling of low-melting clay. Perlite granules are obtained by heat treatment of rocks of volcanic origin.

Vermiculite is a thermal insulating bulk material with a cellular structure, the production of which uses mica (volcanic glass). The advantages of granular materials include high sound and heat insulation properties, environmental safety, and frost resistance. Such bulk materials are used mainly for insulating floors and ceilings.

When using expanded clay, it is recommended to use three types of fractions - granules ranging in size from 0.5 (the smallest), 0.2 and 0.4 cm. In this case, cold air layers will not form between the granules.

Roof insulation with expanded clay

Vermiculite is more expensive than expanded clay, but has higher thermal insulation properties compared to other materials . Moreover, even when moisture is absorbed, they hardly change. After drying, it completely restores its properties.

Vermiculite has less weight than expanded clay, which is important when insulating roof slabs . Since its granules are very small, a much smaller layer of backfill is required to create a reliable layer of thermal protection.

The main disadvantage of all granular heat insulators is the need to use reliable waterproofing, because they have a high degree of water absorption. Since such materials are prone to dust formation, they are used indoors only in screeds.

For example, perlite, like vermiculite, does not lose its properties after absorbing water. However, since it is capable of absorbing up to 300% of liquid (in this perlite is seriously inferior to expanded clay and permiculite), its weight increases many times over.

Comparison of perlite and vermiculite

According to the author of this video, not all house structures need insulation. In his video, he gives a detailed description of heat transfer methods and talks about the main mistakes that arise when installing insulation.

Insulation of the house

Materials

A huge number of thermal insulation materials are offered on the modern market. Conventionally, they are divided into synthetic and natural.

The first group includes mineral wool (manually insulating a house with mineral wool is one of the most popular methods of thermal insulation), polystyrene foam insulation, and films. Natural materials include fluff and straw.

Floor insulation

Do-it-yourself floor insulation

If the ceilings in the house are well insulated, then the floors of the floors in the house will be warm. However, cold from the basement (in panel houses) can pass through the floor of the first floor. When choosing a method of insulating a cottage, you need to take into account the type of foundation. If we consider a frame house, it most often stands on a pile-screw foundation. Using this example, we will consider insulation work:

- The first stage is waterproofing, regardless of the type of insulation. In addition to the membrane, a structure is needed to hold waterproofing and insulation. It is mounted under the joists.

- From below, on top of the waterproofing, boards are nailed. The step should be sufficient to ensure that the insulation does not fail. When it is impossible to get under the house, the board is stuffed under the joists. After this, a waterproofing membrane is attached to them from the inside.

- The base for the insulation is ready, now it’s time to lay the mineral wool without gaps or voids.

Note! If you want to simplify installation, select in advance the distance between the bars to the width of the insulation. For example, 58-59 cm for mineral wool, since its slab width is 60 cm. Each layer must overlap the joints of the previous one.

A vapor barrier is placed on top of the mineral wool. This will protect the insulation layer from internal moisture and the house from wind.

Note! Mineral wool itself does not protect from the wind. To create wind protection, gently apply membranes to the walls of the house. This way you can avoid moisture and drafts between the floor and walls.

Plywood, OSB, and boards for finishing are already placed on the membrane.

Roof insulation

Insulating the roof of a house

Often, together with the ceiling, the roof of a frame building is insulated with mineral wool. For example, if the attic floor is residential and heated. If the attic is not heated, the floors between floors should be insulated. A prerequisite for insulation is stretching the waterproofing material over the insulation to protect it from environmental influences. How to make the roof insulation process easier?

It is more convenient to carry out work outside. If you decide to insulate with mineral wool from the inside, be prepared to handle an uncomfortable material that crumbles onto your face and head. After installing the skeleton of the pitched roof, a layer of vapor barrier is hemmed from below, which is stuffed from the inside with boards, plywood or sheathing material. This way you can easily lay sheets of insulation on the outside according to the scheme for insulating other parts of the house.

The sheathing and roofing material are pressed onto a waterproofing membrane laid on top of the insulation. Of course, if the roof is already ready, there is nothing left to do but insulate it from the inside using temporary fasteners.

On a note! When using roofing sip panels, there is no need for additional insulation. The panel resembles a sandwich of two OSB sheets with a layer of 200 mm foam. The panels are laid on a wooden base and connected into grooves with beams.

In houses made of timber, roof insulation is also carried out. Usually, basalt wool is used for this, slabs of which fill the space between the rafters. A vapor barrier is installed on the attic side, and a membrane film is protected on the roof side.

Choosing the type of insulation for a frame house

After the construction of the house, additional insulation of the house can be carried out both in the outer part (insulation of facades) and from the inside.

There are a variety of ways to insulate houses. Almost all existing insulation materials are also suitable for insulating frame structures erected for subsequent living. They usually differ in breathability, environmental friendliness and, of course, price. As a rule, problems with insulating a frame house do not arise, because upon completion of construction we have even and smooth walls without unnecessary protrusions. Sheathing such walls with insulation is a pleasure.