Autonomous heating and hot water preparation systems are becoming common and commonplace in our country.

There is a wide range of heating systems on sale, the most efficient of which are gas boilers.

European manufacturers are recognized leaders in the production of heating equipment.

] Buderus[/anchor], which will soon celebrate its 300th anniversary, is world famous.

Let's consider one of the most popular models of wall-mounted gas boilers from this company.

Gas boiler Buderus Logamax u072 24k

The Buderus company, founded in 1731, is currently part of a holding with the world-famous Bosh concern.

This significantly increased the capabilities and increased the production capacity of the company . Gas boilers are just one of the various activities of a company that produces a wide range of equipment.

The company entered the Russian market relatively recently - in 2004. A plant was built in Engels that assembles gas boilers from branded components. This allows for cost reduction, which is ultimately reflected in the price for the end user.

The Buderus Logamax u072 model line is represented by 4 power options, optimal for use in private homes or apartments.

The 24 kW model is the most popular. It has the optimal combination of technical characteristics and price, suitable for use in various modes or conditions.

Connecting a wall-mounted boiler to the electrical network

Most modern wall-mounted gas boilers are equipped with sophisticated automation. It controls many processes, turning the heating boiler into an autonomous mini-boiler room, the operation of which requires virtually no intervention from the owner. Obviously, the control unit and various sensors require an electrical connection.

Double-circuit wall-mounted boilers are available in two versions: with a conventional socket and with a cable for connecting directly to the machine. In any case, they must be powered from the mains through an individual machine. If you purchased a model with a plug, then the individual socket for the gas boiler should be located next to it, but in no case under it. This is one of the safety requirements so that in the event of a coolant leak, a short circuit does not occur.

Photo 3: Installing a voltage stabilizer for a wall-mounted boiler

A gas boiler requires mandatory grounding. For these purposes, you can purchase a point grounding kit. It is installed in the basement or next to the house and occupies a small area of about 0.25 m².

Boiler automation is very sensitive to the quality of the supply voltage. If the level of the sinusoid at the input is insufficient or the shape is not ideal, the devices quickly fail. To prevent frequent breakdowns and extend the service life of the unit, it is necessary to connect voltage stabilizers for gas boilers. To avoid shutdowns of heating equipment in the event of power outages, you should additionally purchase an uninterruptible power supply.

What functions does it have?

Wall-mounted boilers Buderus Logamax u072 24k are double-circuit models of gas units.

They are capable of simultaneously heating the house (preparing coolant for the heating circuit) and preparing hot water for domestic needs. The letter “K” in the boiler marking means “Combined”, i.e. double-circuit.

The range of boiler functions is quite wide:

- The ability to independently detect problems using a self-diagnosis system.

- There is protection against freezing of the system.

- All models are adapted to Russian technological conditions.

- The electronic ignition function makes using the boiler much more convenient.

- The flame is constantly monitored; if it disappears, the boiler operation is immediately blocked.

- When installing additional devices, it is possible to control the operation of the boiler via a smartphone.

The functionality of boilers is abundant; according to some owners, it is even somewhat redundant.

All capabilities are implemented through a control board, the operation of which is similar to the actions of the brain of a living organism.

A system of sensors distributed across all units of the unit constantly monitors the operation and immediately signals the occurrence of malfunctions, failures or breakdowns.

IMPORTANT!

Buderus Logamax u072 24k boilers are sensitive to power fluctuations, which can cause the control board to malfunction and cause a series of errors. To eliminate this possibility, you should use a voltage stabilizer that ensures that the power supply remains constant.

Stages of work

The heating boiler piping should be carried out according to the classical scheme in order to avoid the use of complex work.

We mount the collector

Before this work, carefully study the sticker on its body. It should contain information about which line is responsible for the supply of coolant and for the outlet.

A 1.25-inch pipe on the manifold is connected to the boiler, into the pipeline of which a 1-inch diameter pipe is inserted. Those holes that will not be used are closed with plugs.

The mixing (distribution) valve is installed on the supply pipe. It is responsible for regulating temperature. If your home has a heated floor connected to the heating system, then the valve must also be installed in the outlet pipe. With its help, the temperature of the water heated floor will be controlled within the required limits.

The pump, which circulates the coolant, is built into the return line. Its installation is possible in two ways.

- The first method is a direct connection to the collector.

- Second, connection to the distribution valve.

At the final stage, pressure and temperature control devices, in-line filters, drain balancing valves, as well as air and safety valves are installed.

Specifications

Let's consider the operational parameters of gas boilers Buderus Logamax u072 24k:

| Parameter | Meaning |

| Boiler type | Gas convection |

| Installation type | Wall |

| Type of fuel | Natural or liquefied gas |

| Efficiency | 92 % |

| Number of circuits | Two |

| Primary heat exchanger | Copper spiral |

| Secondary heat exchanger | Lamellar stainless |

| Maximum coolant pressure | 3 Bar |

| Coolant temperature | 40-82° |

| DHW temperature | 35-60° |

| Gas consumption | 2.8 m3/h |

| Power supply | 220 V, 50 Hz |

Classification

To simplify the choice, all brand products are classified according to several criteria. By installation method:

- wall;

- floor

By design:

- single-circuit and double-circuit;

- with closed and open firebox;

- with atmospheric or forced-air burner:

- with cast iron or steel heat exchanger;

- with natural or forced draft.

The power of manufactured devices varies in the range of 7,000-100,000 W.

Advantages and disadvantages of the model

The advantages of Buderus Logamax u072 24k boilers include::

- The ability to simultaneously heat the room and prepare hot water for domestic needs.

- Compact, can be installed in kitchen areas without the need to create a boiler room.

- Relatively low price.

- The closed combustion chamber ensures a safe and stable combustion mode.

- The automation supports the Open Therm protocol, which makes it possible to control the operation of the system through external modules.

- Low noise level.

- The self-diagnosis system immediately informs about problems.

The disadvantages of the units are:

- Dependence on the availability and quality of power supply.

- Some components have low resistance to mechanical stress (feed tap).

- The organization of service is considered unsatisfactory by many users.

NOTE!

Most of the shortcomings of the Buderus Logamax u072 24k boiler can equally be attributed to any models of gas boilers produced by many companies, so they can be considered design features.

Design Features

If a single-circuit boiler is designed exclusively for heating, then a double-circuit boiler is also capable of providing users with hot water. Devices with two circuits can be:

- Flow-through. Water is heated in flow mode. The equipment is smaller in size, and the water is heated immediately when the tap is opened.

- Cumulative. There is a boiler - a built-in container for heating water. This is a more economical option.

One of the most popular models of the German brand is Logomax u072 183a. These are real mini-boiler rooms - energy efficient and safe. A high level of security is ensured by built-in sensors. If, for example, the burner goes out, the gas supply will be automatically stopped. There is an automatic system that maintains temperature stability. Filtration of incoming water is also provided.

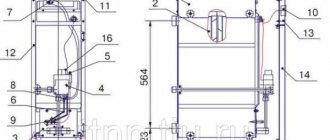

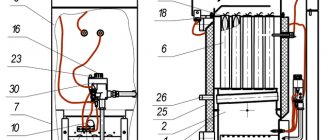

Device

Gas boilers of the Logamax u072 series have a design that differs little from the design of most similar units.

The main element is a closed-type gas burner, which heats the coolant in a copper primary heat exchanger . The hot coolant leaving it enters a secondary plate-type heat exchanger, where hot water is prepared.

After this, the OM passes to the mixing unit, where a certain amount of cooled return flow is mixed to obtain the desired temperature. The coolant then leaves the boiler and is directed into the heating circuit. The circulation pump ensures the movement of the OB.

To supply air to the heater and remove smoke, a turbocharger fan is included in the design.

Operation control and mode setting occurs via a control board with an external display, which displays current settings or system messages.

Types

There are different modifications of Buderus wall-mounted boilers.

By number of circuits:

- Single-circuit. They only provide heating of the coolant for the heating circuit.

- Dual-circuit. At the same time, they are capable of preparing domestic hot water and heating the coolant for the heating system.

By type of combustion chamber:

- Atmospheric (open) . The air required for the combustion process is taken directly from the room in which the boiler is installed. Removal of smoke and other combustion products occurs using natural stove-type draft.

- Turbocharged (closed) . The air is taken from outside and enters the boiler through the external pipe of the coaxial chimney. For this purpose, a turbocharging fan is used, which simultaneously ensures smoke removal.

For residential premises, it is more convenient to use turbocharged models, since natural draft is unstable and can be directed in the opposite direction by a strong gust of wind or a draft in the room.

By type of thermal energy transfer:

- Convection . A traditional scheme for heating the coolant in a burner flame without additional procedures was used.

- Condensation . A technique that appeared relatively recently. The liquid is preheated using thermal energy obtained by condensing water vapor from the exhaust smoke. The prepared coolant does not require intensive heating, which reduces gas consumption and softens the operating mode of the heating pad and heat exchanger. In total, this gives high efficiency (up to 108%, although this method of calculation is not correct and is a common marketing ploy), gas savings and an increase in the service life of the heat exchanger.

IMPORTANT!

Condensing models are able to fully operate only on low-temperature systems. If operating conditions do not allow the use of such modes, purchasing a condensing boiler will become impractical.

For which rooms is it best suited?

Buderus Logamax u072 24k boilers are designed for use in rooms with a maximum area of 240 m2.

This is optimal for private houses, apartments, commercial or public premises, offices.

It can be used in industrial buildings if they do not have a large number of openings or technological hatches that disrupt the heating mode and change the temperature in the room.

Advantages

The German Buderus wall heater is a leader in consumer demand and has all the possible advantages of modern heating technology. Attachments:

- compact;

- silent;

- easy to operate;

- easy to use;

- energy efficient;

- they have a stylish design and an optimal price.

How to set it up correctly

Setting the operating mode of the Buderus Logamax u072 24k boiler is done using the controls located on the control panel. The current values are indicated on the display; the user only needs to turn on the setting mode for one or another parameter and set the required temperature of the hot water supply or coolant.

Also, in accordance with external conditions, the boiler switches to summer or winter operating mode (heating circuit is turned off or activated). If an error occurs, you can reset it by pressing and holding the Reset button for 5 seconds.

IMPORTANT!

More complex settings related to gas or water pressure limits are performed by a technician from the service center. Independent intervention in the operation of the system is fraught with failure of important components of the boiler.

Basic error codes

Let's look at the most common errors:

| Code | Decoding | Ways to fix the problem |

| H11 | Problems with the DHW temperature sensor | Check the contact group, determine the functionality of the sensor, and replace if necessary |

| 2P | Coolant overheating | Check the contacts, determine the condition of the circulation pump |

| 3A | Fan stop | Check the contacts, replace the fan with a new one |

| 4C | Heat exchanger overheating | Stop the boiler, check the functionality of the circulation pump and the extract air temperature sensor, call a technician |

| 4U, 4Y | Short circuit or break in the forward line (supply) temperature sensor | Check the condition of the sensor and contacts, clean and reconnect them, if necessary, replace the sensor |

| 6A | No flame | Check the presence of gas in the system and in the boiler equipment, call specialists |

| 3C, 3L, 3P, 3Y | Fan failure | Check connection and functionality, replace |

| 6C | The system sees a flame on an idle burner | Moisture on contacts or control board, poor ground contact |

Start-up and operating instructions

Before turning on the boiler for the first time, it is necessary to install it on a wall or ramp (supporting structure), connect all communications and power supplies. These actions are performed only by gas service specialists or authorized technicians from the service center.

Be sure to check gas pipe connections using soapy water . The system is then filled with water, guided by the pressure readings on the display. It should not be brought to the limit; it is enough to provide 0.8 Bar.

When heated, the coolant will expand, causing the pressure to rise and reach its optimal operating value.

The Buderus Logamax u072 24k boiler is started using the “Stand-by” button.

In this case, the display will show the current coolant temperature . When you first start it is set to minimum, so to start working you should set the desired heating mode. The burner and circulation pump will start, and the boiler operation will begin.

Operation of the unit does not require any special actions from the user.

The temperature is adjusted periodically according to weather or climatic conditions.

Once a year you need to call a technician to carry out maintenance; if breakdowns occur, a specialist from the service center is also immediately invited.

Download instructions

Download instructions for the gas boiler Buderus Logamax u072 24k.

Types of Buderus brand units

TTC "Buderus" are divided into three types: pyrolysis, cast iron and steel. Each has its pros and cons.

Cast iron

The main advantage of boilers equipped with a cast iron heat exchanger is the ability to maintain a high temperature in the chamber - at least 200 ºС. However, they have more weight compared to cast iron, and are characterized by sensitivity to significant temperature fluctuations in the firebox.

Steel

Equipment with steel heat exchangers maintains temperatures up to 200 ºС. TTKs are quite light and more compact. They have an important feature: the design is supplemented with brick to improve heat capacity and prevent fuel burnout.

Pyrolysis steel

In recent years, the demand for pyrolysis TTC has been increasing in Moscow and the region. The main reason is efficiency and ease of use.

Advantages of pyrolysis TTC:

- Increased burn time helps reduce the number of fuel loads required.

- The operating time with one filling is extended by 2-3 times, compared to cheap units, due to the reduced consumption of raw materials. Reaches 6 hours in boilers with an upper combustion chamber and 12 hours in boilers with a lower combustion chamber.

- During the combustion process, a small amount of dry residue is formed, as a result of which the ash box needs to be cleaned less often.

The purchase pays for itself over several seasons of operation, due to low costs for firewood, briquettes and coal. Such savings cannot be achieved when operating classic TTKs running on pellets and other fuels.

Units with a lower combustion chamber of pyrolysis gases are equipped with a pressurization fan. This allows you to optimize combustion in the furnace, increasing the efficiency of the unit and at the same time reducing fuel consumption.

Gas generators are energy dependent. Models of this design usually cost 2 times more than heat generators with an upper combustion chamber for pyrolysis gases.

Price range

Prices for Buderus Logamax u072 24k boilers in different stores differ markedly and are in the range of 40-50 thousand rubles.

Such a difference is often caused by the fee included in the price for the warranty agreement, logistics surcharges or other reasons . When planning a purchase, you need to check the price with a regional representative of the company so as not to find yourself in a difficult situation.

NOTE!

In addition to the boiler, you will have to purchase additional equipment and elements - a chimney, voltage stabilizer, water filters, etc. These devices are mandatory; they must be purchased and installed immediately, from the first days of the system’s operation.

Competitors

Table. Comparison with competitors and analogues Photo ModelRatingPrice

| sample in review Buderus Logamax U072-24K | 6,9 | RUB 37,515 |

| BAXI ECO-4s 24F | 7,3 | RUB 39,387 |

| Navien DELUXE 30K | 6,5 | RUB 39,211 |

| BAXI ECO-4s 1.24F | 7,2 | RUB 36,836 |

| BAXI ECO Four 1.24 | 6,7 | RUB 36,966 |

| BAXI MAIN 5 24 F | 7,1 | RUB 36,185 |

| De Dietrich ZENA MS 24 | 6,5 | RUB 36,110 |

| Lemax PRIME-V24 | 6,5 | RUB 37,500 |

| Ferroli Divatech H F24 | 5,4 | RUB 39,050 |

| Ferroli Fortuna F 30 | 5,6 | RUB 38,188 |

Sources

- https://ExpertKotel.ru/cat/buderus/buderus-logamax-u072-24k

- https://expert-dacha.pro/otoplenie/kotly-ot/gazovye-k/proizvoditeli-gaz-k/gk-buderus/logamax-u072-24k.html

- https://www.buderus.com/ru/ru/ocs/logamax-u072-18438058-p/

[collapse]

Buderus error 3c (fourth indicator 80 flashes)

If such an error occurs, the boiler control board does not receive a signal from the differential pressure switch, that is, its contacts do not close after the fan starts. The pressure switch is used to determine the necessary conditions for removing combustion products.

The procedure for putting the boiler into operation is as follows:

- The control unit gives a signal to start the fan

- The fan creates the necessary vacuum in the exhaust pipe

- The differential relay registers the vacuum and the microswitch contacts close

- The board sends a signal to open the gas valve and ignite

Therefore, to understand the problem, you need to determine at what specific moment the boiler goes into error. If the fan starts, but the relay does not click, it is tedious to inspect the supply pipes; perhaps there is a blockage or condensation, or there is actually a blockage in the chimney itself.

If the fan does not start, you need to check whether voltage is supplied to it. A faulty electronic board may be the reason why the fan does not start.

If the fan is working, there are no problems with the chimney and the pneumatic relay tubes, you need to check the pneumatic relay itself, creating a vacuum yourself and checking for a characteristic click.

Constantly closed relay contacts or their opening during burner operation will also be regarded by the security system as a malfunction.

Buderus boilers can be equipped with a fan with adjustable rotation speed, which is controlled electronically and equipped with a sensor.

Possible causes of malfunction

- Lack of supply or insufficient gas pressure.

- Lack of grounding of the boiler body.

- Lack of dielectric insert on the gas pipe.

- Potential on the boiler body or heating system elements.

- Incorrectly selected fan speed or lack of diaphragm for boilers with a closed combustion chamber.

- Malfunction or contamination of the ignition or ionization electrode.

- Lack of air for normal combustion (poor draft).

- No signal from the ionization sensor (broken wire, poor contact).

- Burner nozzle openings are clogged with dust and soot.

- Damage to the control board.