European companies are considered recognized leaders among manufacturers of heating equipment.

They own all the most advanced developments and conceptual solutions in this area.

One of the leaders is] Buderus[/anchor], which will soon turn 300 years old.

Today it is part of the Bosch Thermotechnik GmbH holding, which significantly strengthens its position among its competitors.

Let's consider one of the company's activities - wall-mounted gas boilers.

Wall-mounted gas boilers Buderus

Buderus products are manufactured in several European countries. In Russia there is a plant in Engels, where, among other heating equipment, wall-mounted gas boilers are produced.

This makes it possible to produce installations that are fully adapted to the technological and climatic operating conditions in Russia, and it also becomes possible to reduce the cost of boilers for the end user.

The production uses advanced technical and design developments to ensure stability, durability and efficiency of components and parts. The main emphasis is on maximum automation of work, as well as ease of control and maintenance of the units.

A revolutionary system for optimizing boiler operation is used, taking into account external factors - additional heat sources, climatic conditions, etc.). It is possible to remotely control the operation of the system using a special application on a smartphone.

Types

There are different modifications of Buderus wall-mounted boilers.

By number of circuits:

- Single-circuit. They only provide heating of the coolant for the heating circuit.

- Dual-circuit. At the same time, they are capable of preparing domestic hot water and heating the coolant for the heating system.

By type of combustion chamber:

- Atmospheric (open) . The air required for the combustion process is taken directly from the room in which the boiler is installed. Removal of smoke and other combustion products occurs using natural stove-type draft.

- Turbocharged (closed) . The air is taken from outside and enters the boiler through the external pipe of the coaxial chimney. For this purpose, a turbocharging fan is used, which simultaneously ensures smoke removal.

For residential premises, it is more convenient to use turbocharged models, since natural draft is unstable and can be directed in the opposite direction by a strong gust of wind or a draft in the room.

By type of thermal energy transfer:

- Convection . A traditional scheme for heating the coolant in a burner flame without additional procedures was used.

- Condensation . A technique that appeared relatively recently. The liquid is preheated using thermal energy obtained by condensing water vapor from the exhaust smoke. The prepared coolant does not require intensive heating, which reduces gas consumption and softens the operating mode of the heating pad and heat exchanger. In total, this gives high efficiency (up to 108%, although this method of calculation is not correct and is a common marketing ploy), gas savings and an increase in the service life of the heat exchanger.

IMPORTANT!

Condensing models are able to fully operate only on low-temperature systems. If operating conditions do not allow the use of such modes, purchasing a condensing boiler will become impractical.

Buderus boiler error 6a how to fix

First of all, you need to exclude the accidental occurrence of an error and simply reset it.

If the error occurs again and the boiler does not start, then the problem requires a solution. In most cases, ignition problems can only be corrected by a qualified specialist. The simplest thing that can be done is to inspect the combustion chamber and electrodes for contamination and clean if necessary. If the boiler makes unsuccessful attempts to ignite, visually check that the spark is striking the burner and not somewhere else. If you hear a crackling sound, but there is no spark between the electrode and the burner, the insulation of the electrode is probably damaged somewhere and needs to be replaced. The gas valve can only be adjusted by a specialist. Checking the presence of proper network gas pressure can be done through a gas stove. If you light all the burners on the stove at the same time, they should work without interruption. If this is not the case, we can assume that the incoming pressure is not enough and you need to call the gas service.

In our practice, there was a case when a crack in the combustion chamber inspection window was the cause of a malfunction.

If the boiler lights up, but goes out after a while, this may be due to a faulty electronic board. You can check by replacing the board with a known good one.

Advantages and disadvantages

The advantages of Buderus wall-mounted boilers are:

- High build quality, reliability of units and parts of the unit.

- Easy to control, convenient display with intuitive symbols for operating mode adjustment controls.

- Possibility of remote control of the system from anywhere in the world.

- Compact, able to fit into the interior of a small kitchen.

- Relatively low cost compared to similar models from other companies.

There are also disadvantages:

- Boilers are energy dependent, require stable voltage, need to install stabilizers.

- Some parts are made entirely of plastic, which makes them short-lived under harsh operating conditions.

NOTE!

The disadvantages of Buderus boilers are not decisive and are completely offset by the undoubted advantages that all models have.

Kinds

The industrial giant produces several types of boilers for burning fuel - this allows the consumer to select equipment according to his financial capabilities and needs, according to the total area for heating and the power capabilities of the equipment. Units can be distinguished by purpose and material of manufacture.

Among the huge number of Buderus products there is a classification according to purpose:

- Wood boilers. As is clear from the classification, these units require wooden logs, which can be purchased almost everywhere. It is perfect for pumping heat into the water heating system of a small country house and a huge cottage. But the logs themselves must be of a certain length, since the firebox has certain dimensions, and not all firewood can be used. It works on the principle of the well-known Russian stove, and there are no innovative ideas in it. The cost of this equipment is low and is affordable to the average consumer;

- Pyrolysis units. Such units can pump heat throughout the day from just one load of solid fuel, and it can be either wood or coal. As is known, during combustion gas is released and coals are formed, but with the use of a minimum amount of air necessary to maintain the combustion process. The mass is heated and the temperature reaches maximum values, as a result of which the gas released from combustion becomes a heat exchanger entering the heating system, and at the exit from the system it loses all its dangerous properties. The cost of the equipment is higher, but the efficiency is significantly higher than that of the previous type.

- Combined designs. The capabilities of such boilers are higher; for their operation, you can use a combination of solid fuel with any type of liquid fuel, which allows you to increase the power of the equipment and the quality of heating.

What series and models are wall mounted?

Buderus wall-mounted boilers are represented by one large Logamax line, which consists of 4 series:

- Buderus Logamax U042/U044 . Double-circuit installations with a power of 24 kW. Equipped with a bithermic heat exchanger, which allows you to simultaneously heat both the coolant and hot water. There are models with a closed (042) and open combustion chamber (044).

- U052 / U054 K. Single- and double-circuit boilers with an open (054) and closed (052) combustion chamber. For dual-circuit models, the designation contains the letter “K” (combined). Two models are available with a power of 24 and 28 kW.

- U052 T / U054 T . Model with a power of 24 kW, with an open or closed combustion chamber. A special feature is the presence of a 48-liter hot water storage tank, which allows you to meet high demands for hot water.

- U072 . The most popular series of turbocharged boilers with a capacity of 12, , and kW. Single and double circuit models are available. High demand is due to the relatively low cost of boilers. Equipped with two heat exchangers - primary (for coolant) and secondary (for hot water supply). The most popular boilers are 24 and 35 kW, producing up to 12 and 16 liters of hot water per minute, respectively. Capable of heating 240 and 350 m2 of residential, public or commercial areas.

When choosing a boiler, you should compare its characteristics with the size of the room and the family’s need for hot water. The manufacturer provides a choice for any conditions, which allows you to get the best option.

Review of the Logano boiler range and their costs

The Logano series of boilers is represented on the sales market by models with cast iron and steel heat exchangers. It should be noted that cast iron equipment weighs much more than steel. It is also more sensitive to sudden temperature fluctuations inside the combustion chamber.

Today, several Buderus models are popular:

- Logano S131;

- Logano S171 W;

- Logano G221/A;

- Logano G221;

- Logano S111-2;

- Logano S121-2;

- Logano S181 E.

Features of Logano S131

The model is a solid fuel boiler designed for heating a private house with a small area. Currently, this model is presented in one variation with a power of 15 kW.

The unit is partly a long-burning TTK. Using the settings, you can set the mode of slow burning and gradual smoldering of the fuel. Increased reliability is the main advantage of the presented equipment.

The combustion chamber has a volume of about 38 liters, the combustion time is more than two hours with this load. The main disadvantage is that the grate must first be dismantled to clean it. The efficiency of its operation depends, as a rule, on the quality of the chimney.

Prices for the Logano S131 boiler model

Logano S131

Logano S171 W

It is a complete pyrolysis boiler made of high-strength steel. Due to the fact that this material cannot provide reliable protection and heat retention, the manufacturer additionally used fireclay brick for the lining, which has good heat capacity and increased resistance to high temperatures. According to the characteristics specified in the technical documentation, with proper installation and installation, the efficiency of this model will be about 87%.

The unit is presented in several versions, differing from each other in power and volume of the loading chamber:

- 20 kW - 110 l;

- 30 kW - 110 l;

- 40 kW - 133 l;

- 50 kW - 133 l.

The coolant in all devices usually heats up to 70–85 ºС, and the period of continuous operation on one pad can last from 3 to 8 hours.

The equipment is equipped with the latest electronic automation, making it energy-dependent. This feature cannot be considered a disadvantage, since the control unit increases safety and efficiency. It is possible to configure the boiler so that in offline mode SMS messages are sent to the phone indicating the status of the device.

Logano G221/A

The design of models equipped with long-burning cast iron heat exchangers is reliable and simple. Typically, such boilers are installed in private homes and industrial premises with an area of no more than 400 square meters. m.

Not only coal and wood, but also coke can be used as fuel. Pyrolysis is the main method of burning wood. The operating temperature of the liquid in the heat exchanger does not fall below 90 ºС. The efficiency indicator is not higher than 78%. This model is represented by a whole line of devices of varying power: 20, 25, 32 and 40 kW.

The manufacturer presents Logano G221(A) as a highly efficient universal boiler that can operate without problems with various devices running on diesel fuel or gas.

The main advantage of the model is the presence of an improved special unit with automatic supply of fuel (pellets or coal) to the combustion chamber, which helps to increase the efficiency of the TTK in continuous mode.

Logano S181E

The unit is a long-burning pellet TTK. The design is equipped with a spare chamber, which ensures automatic supply of fuel: pellets and coal. A one-time download is enough for uninterrupted operation of the device for more than forty hours. During this time he works independently.

If a problem occurs, the automation instantly notifies the user via SMS about what happened. The company introduced three variants of models of different power to the market: 15–25 kW.

Prices for the Logano S181 E boiler model

Logano S181E

Logano G 221

The equipment belongs to the TTK, which are used for heating industrial and residential premises with an area of up to 410 square meters. This device is safe thanks to the upgraded protected heat exchanger, adapted for sealed systems.

Models G221 are low-power cast iron boilers operating in the range from 20 to 42 kW. The compact model can last at least 30 years. A distinctive feature is a very spacious firebox, which allows you to reduce the frequency of adding fuel. The efficiency of G221 is about 78%, but for conventional TTK this is considered a good indicator.

The design allows for the door to be placed on the right or left. If we add to this the modest dimensions of the case, then the unit can be called quite convenient for installation and maintenance in a fairly cramped room. G221 is a simple-to-use equipment, and yet, it has a thermostat that regulates the draft in the firebox, which prevents the water in the heat exchanger from boiling.

Logano S111-2

This model is made of steel and costs much less than cast iron. It is corrosion resistant due to the use of special alloys. The unit is available in seven versions with different power levels - from 12 to 32 kW. These heating devices are more popular among owners of country houses. The efficiency is 74-76%.

Prices for boiler models Logano S111-2

Logano S111-2

Logano S121-2

This long-burning TTK model is fundamentally different from all models in that it does not just burn wood, but reuses the pyrolysis gases released. As a result, equipment productivity increases significantly without increasing fuel consumption.

However, to control these processes, it is necessary to clearly control the air supply to the main chamber and to the pyrolysis burners. Automation is responsible for this. The S121-2 series is represented by four types of boilers of different power: from 18 to 38 kW. This range is enough to choose a suitable model for heating a country house of any size, up to 360 m2. The owners note that the filling burns out almost completely, leaving only a small ash residue, which reduces the cleaning time of the unit.

Purchasing equipment can cost the following approximate amount:

- Logano g221 20 – 115,000 rubles;

- Logano g221 25 – 125,000 rubles;

- Logano g221 40 – 140,000 rubles;

- Logano g211-20D – 70,000 rubles;

- Logano g211-32D – 100,000 rubles;

- Logano s111-2-WT-12 – 70,000 rubles;

- Logano s111-2-WT-24 – 95,000 rubles;

- Logano s111-2-WT-32 – 10,000 rubles.

A fairly wide range allows the buyer to choose the most suitable option for himself.

Specifications

Let's look at the technical characteristics of Buderus wall-mounted boilers:

| Parameter | Meaning |

| Boiler type | Gas convection or condensation |

| Installation method | Wall-mounted (mounted) |

| Fuel type | Natural or liquefied gas |

| Power | 12, 18, 24, 28, 32 and 35 kW |

| Efficiency | 93 or 108% |

| Maximum coolant pressure | 3 Bar |

| Maximum DHW performance | 16 l/min |

| Chimney type | Separate or coaxial |

| Power supply | 220 V 50 Hz |

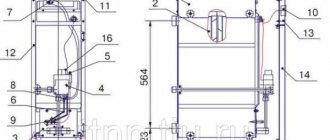

Device

The main components of Buderus wall-mounted boilers are:

- Gas-burner.

- Heat exchanger (bithermal or conventional type).

- Turbocharger fan.

- Circulation pump with automatic air removal.

- Secondary plate heat exchanger made of stainless steel.

- Three way valve.

- Control equipment for pump and fan operation.

- Control board with sensor system.

- Connecting pipelines, connecting pipes.

The coolant enters the primary heat exchanger, where it is heated to the maximum possible value.

Then it goes to the secondary heat exchanger, where excess heat is transferred to prepare hot water.

After this, in a three-way valve (mixing unit), it receives the set temperature by mixing a certain amount of colder return flow, after which it exits into the heating circuit.

All work is controlled by a system of sensors that send signals to the control board. The occurrence of problems is immediately detected, the owner is notified by displaying an error , and in difficult cases the boiler operation is blocked .

Main faults of Siberia

The simple design of these boilers does not cause serious malfunctions, especially when users carry out systematic maintenance of the main modules. For this reason, there is practically no interest in spare parts for Siberia gas floor equipment.

The most common operational failures are:

- The piezo igniter or the main burner device does not light well.

The most common cause of this failure is poor traction. A possible reason for the lack of combustion is a clogged wick or base burner. Sometimes there are problems with ignition - The pilot burner goes out after 5-15 seconds. This failure indicates reverse draft in the chimney. The reason for this is often an incorrectly designed gas duct: it is too short or too long and there is no deflector.

- The boiler unit does not raise the temperature of the heating water above 60 C. Most often, this occurs due to a clogged gas valve.

- Software failure E01, it indicates the absence of a torch. This can happen when the gas tap is turned off, there is a significant pressure drop in the gas network or surges in the electrical network.

- Failure E04 - pressure drop in the water system is less than 0.7 bar. As a rule, this is due to air locks, leaks, breakage of the expansion tank or safety relief valve.

Operating and setting instructions

Operating Buderus boilers is not particularly difficult. All functions of the unit are simple, their adjustment is not difficult and is done using the corresponding buttons on the control panel.

The user does not perform any actions with the boiler, except for filling or draining the system.

A suitable tap or drain valve is used for filling. It must be remembered that adding cold water to a hot boiler is prohibited, otherwise the heat exchanger can be destroyed. After a long period of inactivity, it is necessary to carry out thermal disinfection.

The transition to summer or winter occurs at the user's request by changing and saving the mode on the control panel.

Installation and configuration of Buderus boilers must be carried out only by certified specialists from the service center, otherwise the warranty agreement will be considered terminated at the initiative of the owner.

Download instructions

Download instructions for Buderus wall-mounted gas boilers.

What to pay attention to during installation?

Steel gas boiler Navien Ace

Since instructions are included with the equipment, there are no problems with installing and connecting the device. Doing it yourself is not a problem. Even a non-professional can understand the instructions. Moreover, it is written in Russian.

The only thing that experts ask you to pay attention to is the method of removing carbon monoxide. They can be discharged through a regular atmospheric chimney connected to the smoke exhaust system of the house or installed as a separate structure

But if you are not satisfied with any option, you can make a coaxial chimney. Its installation is several times simpler. But keep in mind that coaxial structures are used only when the heated area of the house does not exceed 110 m². They can be installed with boilers whose power does not exceed 11 kW.

Price range

The price range for Buderus wall-mounted boilers is approximately 30-60 thousand rubles.

For top-level equipment, this slightly and significantly increases demand and relevance among users.

When planning a purchase, you need to check with your regional representative about the cost of the units and find out the amount of additional costs (warranty agreement, cost of additional equipment, etc.).

IMPORTANT!

An attempt to save money on concluding a warranty agreement will result in even greater costs for repairs or maintenance of the boiler.