Home / Gas boilers

Back

Published: 07/26/2019

Reading time: 4 min

0

3726

Many boiler owners have no idea what a parapet boiler is, although they have been using them for a long time. This modern unit belongs to the class of energy-efficient devices and removes flue gases using a coaxial chimney mounted in a through hole in the wall of the building.

The units are equipped with a closed firebox and can be installed in small rooms. Since the oxygen necessary for combustion is not taken from the living area, it is not dangerous. The heating unit is so compact that it can easily fit even in the kitchen under the windowsill.

- 1 What is a parapet boiler

- 2 Operating principle of parapet gas equipment

- 3 Types and prices

- 4 Installation of a parapet boiler

Design and principle of operation

The most important difference between units of this type is the isolated, closed combustion chamber.

This reduces the combustion of oxygen and increases the safety of using a gas boiler. A parapet-type gas boiler combines the best qualities of gas and convector units, it is easy to maintain, and repairs are inexpensive. https://youtube.com/watch?v=-yAVngbPA00

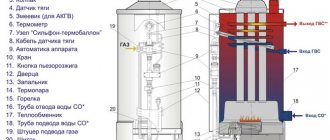

The internal structure of the boiler is simple and includes:

- a body made of steel, which also acts as a convector when heated;

- burner and gas valve;

- heat exchanger;

- closed combustion chamber completely sealed;

- flue, its purpose is to remove carbon dioxide and take in fresh air.

The operating diagram of the heat generating device is simple; when the gas boiler is turned on, the pilot burner is ignited using piezo ignition. Next, the gas flows to the main burner, and the heat exchanger is heated. Then it warms up the coolant tank involved in heating. The installed automatic gas boiler gives a signal when heated to ninety degrees and the boiler turns off the pilot burner, after cooling the process is repeated. The temperature is maintained automatically at the set level.

Also, in case of interruptions in the gas supply or emergency shutdown of the gas supply in the main, the boiler turns off. If the automation fails or malfunctions, it must be urgently repaired.

Combustion products are discharged through a coaxial chimney. The design of the chimney allows you to simultaneously remove carbon dioxide and supply oxygen due to two pipes of different diameters. A pipe with a small diameter is located inside and is intended for exhaust, and a large one is for fresh air.

Gas boilers may differ in appearance; they are made in both wall-mounted and floor-mounted versions, and are also designed for different powers: from 7 to 16 kW. The power of the unit must be calculated based on the area of the house or apartment, and natural heat loss (windows, poorly insulated walls, doors) must be taken into account.

The parapet boiler can be double-circuit, the second circuit is used for hot water supply.

Advantages and disadvantages

The main advantages of parapet boilers:

- high performance;

- closed combustion chamber ensuring complete safety;

- compactness;

- functionality;

- versatility;

- ease of use and maintenance.

The disadvantages include the need to drill a hole in the wall for the pipe, which negatively affects the supporting structures. If installing a gas boiler in a private house is not a problem, then equipping a city apartment with it is almost impossible, due to the current moratorium on such events. We should not forget about the high cost of equipment and installation work.

Strengths of parapet heating boilers

Parapet gas boilers have the following advantages:

- Compact sizes. This allows you to easily solve the problem of how to install a parapet gas boiler inside a small apartment, the owners of which have decided to acquire an individual heating system. Equipment of this type can even be installed under the kitchen table or in a niche near the window. The main thing is that the gas pipes reach there.

- High-quality smoke removal. This is ensured by the use of coaxial pipes, which can be laid at any convenient angle.

- Easy to install. This is especially true for wall-mounted parapet boilers. Before installing a floor-standing parapet boiler, you will have to equip a separate room (boiler room) in accordance with the recommendations of the gas service. A prerequisite for using floor-standing gas boilers is a chimney pipe and a wide entrance door (from 80 cm). The boiler room must be equipped with a window for regular ventilation. The chimney must be equipped with a series of small ventilation holes. Parapet boilers do not have similar installation requirements

- Possibility of connection on any part of the heating circuit. Some boilers have only a right- or left-hand installation principle, but this restriction does not apply to parapet devices. Thanks to this, the installation of a parapet gas boiler can be carried out in a convenient place.

- Aesthetics. Parapet models are distinguished by their visual appeal. Most often they are tinted in a light color, which allows them to fit harmoniously into any modern design. Very high-quality material is used to paint the devices, which retains its original decorative qualities over a long period of use. Such a surface is not afraid of sunlight and frequent wet cleaning.

- Ease of management. Gas parapet boilers are equipped with a modern control unit. Thanks to the automatic control system, the condition of the coolant is constantly monitored. If its temperature goes beyond the preset parameters, the sensors immediately send a signal to the main control panel, which turns on the heating or cooling system. The pressure level inside the pipes is controlled in a similar way. Thanks to automation, it is possible to select the most optimal mode of operation of the device, which makes it possible to save energy resources.

- Presence of piezoelectric ignition. This allows a single- or double-circuit parapet gas boiler not to depend on the availability of electrical energy in the room. This is especially convenient outside the city, where power outages often occur.

- Full set. The device is already equipped with all the necessary elements, which are compactly located under a beautiful body. A parapet boiler hung on the wall will not be hung on the sides with additional equipment that spoils the overall interior.

- Possibility of conversion to another fuel. When switching to another type of fuel (electricity, liquefied gas), you do not need to buy new boilers: parapet models can be reconfigured and the nozzles in them can be changed.

In the room where a single-circuit gas parapet boiler is located, heating radiators do not need to be installed. The fact is that the body of the device is equipped with many convection holes through which heat enters the room.

Bottom line

A parapet boiler is an excellent opportunity to solve the issue of organizing heating in any home (private house or apartment). When researching the question of which parapet boiler is better, it is necessary to take into account a number of factors. For example, if in addition to heating it is also necessary to provide heating of water for domestic use, imported double-circuit parapet boilers are available for sale. Some of them do not require connecting a chimney pipe at all. In situations where the home already has a single-circuit heater of low power, the organization of a hot water system can be carried out using a boiler

When choosing a heating parapet boiler, it is recommended to pay special attention to its power: the area that the equipment is able to heat directly depends on it.

General information

The parapet boiler got its name from its location - indoors on the wall at a height of approximately 500-600 mm from the floor, if we take the central point of the body (on the parapet).

In this case, the combustion products are released not through a shaft or chimney, but directly through the wall “out into the street” perpendicular to the central point of the housing. This design format made it possible to create the most compact contraction, all other things being equal: low cost, durability, efficiency (90% efficiency) and ease of maintenance.

After installation in a permanent place, the parapet boiler looks like a small “bedside table”, which is often located near the gas stove and is used by housewives as a stand for drying dishes, glass jars and other kitchen utensils.

Due to their small dimensions, a wide range of powers (from 7.5 to 40 kW) and the absence of a traditional “chimney”, parapet boilers are used not only for heating private buildings, but also apartments in high-rise buildings.

Parapet gas heating boilers - types

In summary, parapet boilers can be divided into the following types:

- Single-circuit. Used for heating only.

- Dual-circuit. They are used for heating and to obtain hot water for household needs.

- With natural ventilation of the combustion chamber, combustion products are released due to natural draft.

- With forced ventilation of the combustion chamber - combustion products are ejected by a turbofan.

Single-circuit parapet gas boilers. Design

In general, a single-circuit gas boiler is a welded, heat-insulated steel container for coolant (water or antifreeze), around and on which the following elements are mounted:

- Automation block.

- Gas burners: pilot, main and economical.

- Coaxial deflector - “chimney”.

- Indicating thermometer. Used to control and adjust the coolant temperature.

- Automation system thermocouple.

- Thermal cylinder of the automation system.

- Connecting threaded pipes. They can be on one side of the container or on both sides.

- Fence grille - installed on the outside of the wall to protect the “chimney” from blowing out or backdraft.

As already mentioned, the boiler may have a built-in turbofan for forced removal of gas combustion products or without it.

In the latter case, the parapet boiler can operate normally without electricity (with the appropriate design of the heating system).

Double-circuit parapet gas boilers. Design

The general design of double-circuit parapet boilers is similar to single-circuit boilers. The double-circuit boiler is additionally equipped with:

- A metal (copper, steel or cast iron) heat exchanger with the ability to connect to a cold water supply system.

- Connection pipe for connecting to the hot water distribution point.

In addition, if when selecting the power of a single-circuit boiler it is necessary to focus on the ratio - 1 kW of power per 10 m2 of heated area, then when selecting the power of a double-circuit boiler this ratio must be increased by 20% (multiplied by 1.2). This is due to the fact that part of the thermal power will be spent on heating water for household needs.

How to install a parapet gas boiler?

Gas service workers or companies with the appropriate license and package of permits have the right to install a parapet gas boiler. Self-installation of gas equipment is strictly prohibited!

Based on the installation results, the “Hidden Work Act” is compared with the wet seal of the organization and the signatures of the installers. This document is included in the package of permits for connecting gas equipment to the main gas pipeline.

To summarize, we systematize the advantages that parapet-type gas boilers have:

- Compactness.

- Lack of a chimney in the traditional sense of the word.

- Economical.

- Wide range of capacities.

- Versatility - there are parapet gas floor-mounted single-circuit and double-circuit boilers.

- Aesthetics.

- Durability.

- Low relative cost.

- Possibility of installation in a city apartment, private house, country house, cottage, etc.

Advantages and disadvantages of parapet boilers

The design of turbine and parapet boilers is similar, but the latter have a number of advantages.

Parapet boilers: pros and cons. The positive aspects include:

- Autonomy - no connection to the electrical network is required, since ignition occurs using piezoelements (sparks), which are controlled electronically. A battery is used for power supply. The equipment can operate either from a source of constant gas supply or from a cylinder.

- Ease of installation and maintenance – turbine systems are quite complex to set up and operate. They contain various kinds of sensors and controllers. Parapet boilers are simpler.

- Versatility - you can connect the equipment to a radiator system, but the boiler itself can become a heat source (through convection windows). Suitable for heating small houses and apartments. There are wall-mounted and floor-mounted models. Their compact dimensions allow them to be installed in any convenient location, subject to certain operating conditions.

- A closed combustion chamber does not take oxygen from the room - to summarize, a parapet boiler is a simplified version of turbine equipment, while maintaining quality characteristics, at an affordable price.

Experts also note certain disadvantages. Unlike turbo systems, air is forced into the pipe naturally, so the inlet pressure is lower. To improve functionality, parapet boilers are installed with built-in circulation pumps, which are connected to an electricity source, or they are battery-powered. Sometimes, in severe frosts, the outlet pipe may freeze.

Varieties in design and material

At the moment, there are various models. Externally, they are not particularly different, except in size and installation method: wall-mounted and floor-mounted. To know which one to choose, you need to understand the filling.

Single and double circuit

There are single-circuit and double-circuit devices. The difference is that the single-circuit heats water only for heating the house; in order to have warm water for domestic use, an additional water heater is installed.

A double-circuit boiler immediately heats water for batteries and household use. This smart device responds to the actions of its owners. While water is needed only for heating, he takes care of it. As soon as you open the tap to wash dishes or take a shower, water begins to flow into the tap using a special valve.

It is necessary to provide the required power of the device. The more people will take a bath or shower, the more powerful the device needed to heat it.

Typically, consumers choose double-circuit boilers. They are more functional, you do not need to buy an additional boiler, but they are also more expensive than single-circuit ones.

Floor and wall mounted

The next difference is the method of installing the boilers. There can be two of them: floor-mounted and wall-mounted.

Mounted ones are more compact, the requirements for their installation are less extensive. They do not need a separate chimney; such elements are installed even in the kitchen; it is enough to simply ensure safety during operation.

Floor-standing ones have large volumes, high power and weight. A separate room must be allocated for them; they require a lot of free space around. It will be necessary to build a separate chimney for a floor-standing boiler, since they produce noise, unlike wall-mounted ones.

For a small house or apartment, a wall-mounted heater will be sufficient. When heating a large house, you need to look after a floor-standing unit. Such models are dependent on constant voltage in the electrical network, so during surges the equipment may fail.

Combustion chamber view

The combustion chambers in these boilers are of open and closed types. The former take oxygen for combustion from the room in which they are located, so they require ventilation. But at the same time, they have a simple design, are more reliable, easier to install and cheaper.

The second type is more modern. These boilers are parapet, they provide safety, but are more expensive and more difficult to install. It is worth considering that these boilers, if properly installed and equipped with an air duct, do not pose a risk of poisoning to residents in the event of a malfunction, which cannot be said about units with an open chamber.

The choice in this case depends on the equipment room. A closed-type boiler is safer and more convenient, but only if it is possible to equip an air duct. If there is a power outage and the ventilation does not work, the heating will also turn off.

The positive side of the issue

The main advantage of gas heating systems is the low price of energy. Indeed, gas on the domestic market is much cheaper than coal, electricity and firewood.

As for parapet gas boilers, they have some additional advantages:

- High efficiency.

- Possibility to refuse additional space for storing fuel. The gas heating system is the cleanest, second only to electrical equipment in this indicator. But among appliances that burn fuel, gas boilers produce the least amount of pollution.

- Easy maintenance during use.

- The coolant heats up very quickly.

- Minimum level of environmental pollution.

- Excellent controllability of the equipment due to dosing of consumed fuel.

The only disadvantage of parapet boilers is the need to obtain numerous permits for their installation. To do this, you have to knock on the thresholds of gas services and design bureaus for more than one day. However, by obtaining all the necessary permits and paying numerous taxes, the result can be a very convenient heating system that will make your home as comfortable and cozy as possible.

In addition, some models of this type of equipment are quite sensitive to the chemical composition of the coolant. To avoid breakdowns, the jumper connecting the heating system and the water supply system is equipped with a filter to soften the water. If this is not done, the device will quickly fail due to salts. If installing a filter is impossible for some reason, you will need to inspect the boiler and clean the heat exchanger annually at the end of the heating season.

Criterias of choice

To buy effective equipment, experts recommend adhering to the following tips:

- if the device will be used only for heating, a single-circuit model is sufficient. The double-circuit version allows you to prepare water for the hot water supply system;

- it is necessary to decide where the unit will be installed, since there are wall-mounted and floor-mounted types;

- The power of the installation plays a significant role. It should be taken into account that in double-circuit devices almost 30% is used to heat water;

- When purchasing, you need to visually evaluate the heat exchanger and make sure that its walls are thick enough. This determines how long the device will last and how effective it will be. The optimal thickness is no more than 3 mm;

- automation simplifies working with the device. Models without it have a low price, but are more difficult to manage;

- if the room is not thermally insulated enough, it is better to choose a device with high efficiency;

- The dimensions of the equipment are selected depending on the free space;

- The installation location is also affected by the type of boiler connection (left-handed, right-handed and universal).

Note! The parapet unit is suitable for both a private house and an apartment, and it is in no way inferior to standard gas installations.

The history of the creation of a parapet gas boiler

The floor-mounted turbocharged boiler has a closed combustion chamber, therefore it is safe and does not require a separate room. The product was created in the early nineties of the last century, when mass private construction began and people abandoned central heating. The universal stoves used at that time could operate on any fuel, but they had an open-type burner installed. Since domestic enterprises were closing en masse, and foreign products were unavailable, it was decided to develop and put into production a boiler of our own production that meets all power and safety requirements.

The work was carried out in Ukraine and Luch Russia. In 1996, the first two-circuit samples went on sale, with a compact design, a power of 10 kW, an efficiency of 0.92 and a closed combustion chamber. These boilers became the prototypes of units that are still manufactured today.

— Hephaestus boilers with an open combustion chamber

| GAZ KSG-6 KSG-10 KSG-12.5 KSG-16 KSG-20 KSG-25 KSG-30 KSG-40 KSG-50 | GAS, HOT WATER EXTRACTION KSGV-12.5 KSGV-16 KSGV-20 KSGV-25 KSGV-30 KSGV-40 KSGV-50 |

Designed for heating and hot water supply of individual residential buildings. The boilers are adapted to operate in a closed heating system with an open expansion tank with natural or forced circulation of water in the heating system. The combustion air comes from the room where the boiler is installed.

Combustion air comes from the room where the boiler is located, and combustion products are discharged through the chimney.

The modern water-tube design of the heat exchanger allows for quick and efficient heating of the entire heating system with natural circulation.

Reliable and highly efficient automatic equipment SIT (Italy) has an economical “small flame” mode, gas pressure stabilizer and piezo ignition.

Economical gas consumption due to the high efficiency value, at least 90%, eliminates the useless combustion of gas and reduces your costs.

Burner power (flame height) automatically monitors heat loss in the room.

Combining the functions of heating and hot water supply.

Copper hot water circuit.

The BRAY stainless steel slot burner does not require air adjustment.

Quiet start of the burner and silent operation of the boiler at maximum combustion.

Powder-polymer coating of the boiler lining.

Warranty service 3 years.

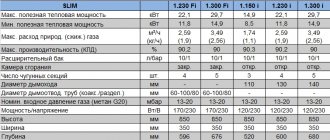

Parameters and technical characteristics of KSG and KSGV boilers:

| No. | Parameter names | Nominal heating output kW +10% | |||||||||

| 6 | 10 | 12,5 | 16 | 20 | 25 | 30 | 40 | 50 | |||

| 1 | Heated area, m² (along the outer contour of the room at a height of 2.5 m) | 60 | 100 | 120 | 160 | 200 | 250 | 300 | 400 | 500 | |

| 2 | Working water pressure in the boiler from the boiler, MPa (max) | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | 0,1 | |

| 3 | Efficiency factor, % (not less): | 82 | 85 | 87 | 89 | 90 | 90 | 90 | 90 | 90 | |

| 4 | Temperature of water leaving the boiler ºС | 40-80 | 40-80 | 40-80 | 40-80 | 40-80 | 40-80 | 40-80 | 40-80 | 40-80 | |

| 5 | Temperature of combustion products, ºС (not less) | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | 110 | |

| 6 | Rated thermal power of the gas burner, kW (no more) | 7,5 | 12 | 14 | 18 | 22 | 28 | 33 | 45 | 55 | |

| 7 | Connecting gas pressure, kPa | 0,6-3,0 | 0,6-3,0 | 0,6-3,0 | 0,6-3,0 | 0,6-3,0 | 0,6-3,0 | 0,6-3,0 | 0,6-3,0 | 0,6-3,0 | |

| 8 | Nominal gas pressure, kPa | 1,3 | 1,3 | 1,3 | 1,3 | 1,3 | 1,3 | 1,3 | 1,3 | 1,3 | |

| 9 | Overall dimensions, mm (no more): | height without water heater height with water heater width depth | 600 — 250 570 | 650 — 290 560 | 650 640 370 560 | 650 820 370 560 | 650 820 370 560 | 650 820 370 560 | 840 990 490 560 | 840 990 490 560 | 840 990 490 560 |

| 10 | Weight, kg (no more) | without water heater with water heater | 32 — | 43 — | 45 61 | 57 64 | 61 68 | 65 72 | 89 100 | 89 100 | 94 106 |

| 11 | Average gas consumption*, m³/hour | 0,4 | 0,7 | 0,9 | 1,2 | 1,4 | 1,8 | 2,1 | 2,8 | 3,5 | |

| 12 | Nominal diameter of connecting pipes, mm | gas supply heating chimney hot water supply | 15 40 90 — | 15 40 90 — | 15 40 130 15 | 15 40 130 15 | 15 40 130 15 | 15 50 130 15 | 15 50 140 15 | 15 50 140 15 | 15 50 140 15 |

| 13 | Water consumption in hot water supply mode when heated at 35 ºС, l/min | — | — | 4,5 | 6,0 | 7,0 | 8,5 | 10,0 | 14,0 | 17,0 |

*Gas consumption depends on the heated area and thermal insulation of the room.

www.gefest-wpr.ru

Where you can and where you can’t install a gas boiler

The rules for installing a gas boiler provide the following requirements for installing a HEATING boiler, regardless of whether it also provides DHW or not:

- The boiler must be installed in a separate room - a furnace (boiler room) with an area of at least 4 square meters. m., with a ceiling height of at least 2.5 m. The rules also state that the volume of the room must be at least 8 cubic meters. Based on this, you can find indications that a ceiling of 2 m is acceptable. This is incorrect. 8 cubic meters is the minimum free volume.

- The furnace room must have an opening window, and the width of the door (not the doorway) must be at least 0.8 m.

- Finishing the furnace with flammable materials and the presence of a false ceiling or false floor are unacceptable.

- The combustion chamber must be provided with an air flow through a through, non-closed vent with a cross-section of at least 8 sq.cm. per 1 kW of boiler power.

For any boilers, including wall-mounted hot water boilers, the following general standards must also be met:

- The boiler exhaust must exit into a separate flue (often incorrectly called a chimney); using ventilation ducts for this is unacceptable - life-threatening combustion products can reach neighbors or other rooms.

- The length of the horizontal part of the flue should not exceed 3 m within the combustion chamber and have no more than 3 rotation angles.

- The flue outlet must be vertical and raised above the ridge of the roof or the highest point of the gable on a flat roof by at least 1 m.

- Since combustion products form chemically aggressive substances when cooling, the chimney must be made of heat- and chemically resistant solid materials. Use of layered materials, e.g. asbestos-cement pipes, permissible at a distance of at least 5 m from the edge of the boiler exhaust pipe.

When installing a wall-mounted hot water gas boiler in the kitchen, additional conditions must be met:

- The height of the boiler suspension along the edge of the lowest pipe is not lower than the top of the sink spout, but not less than 800 mm from the floor.

- The space under the boiler must be free.

- A durable fireproof metal sheet 1x1 m should be laid on the floor under the boiler. Gas workers and firefighters do not recognize the strength of asbestos cement - it wears out, and the SES prohibits having anything containing asbestos in the house.

- There should be no cavities in the room in which combustion products or an explosive gas mixture can accumulate.

If the boiler is used for heating, then the gas workers (who, by the way, are not very friendly with the heating network - it always owes them for gas) will also check the condition of the heating system in the apartment/house:

- The slope of horizontal sections of pipes must be positive, but not more than 5 mm per linear meter of water flow.

- An expansion tank and an air valve must be installed at the highest point of the system. It is useless to convince you that you will buy a “cool” boiler that has everything provided for: rules are rules.

- The condition of the heating system must allow it to be pressurized under a pressure of 1.8 atm.

The requirements, as we see, are strict, but justified - gas is gas. Therefore, it is better not to think about a gas boiler, even a water heating one, if:

- You live in a Khrushchev block or other apartment building without a main gas duct.

- If you have a false ceiling in your kitchen that you don’t want to remove, or a permanent mezzanine. On a mezzanine with a bottom made of wood or fiberboard, which in principle can be removed, and then there will be no mezzanine, gas workers turn a blind eye.

- If your apartment is not privatized, you can only rely on a hot water boiler: allocating a room for a furnace means redevelopment, which only the owner can do.

In all other cases, it is possible to install a hot water boiler in an apartment; wall heating is possible, but floor heating is very problematic.

In a private house, you can install any boiler: the rules do not require that the furnace be located directly in the house. If you make an extension to the house from the outside to serve as a furnace room, then the authorities will only have less reason to find fault. You can install a high-power floor-standing gas boiler in it to heat not only the mansion, but also the office premises.

For middle-class private housing, the optimal solution is a wall-mounted boiler; it does not require, as for a floor one, to install a brick or concrete tray with sides of half a meter. Installing a wall-mounted gas boiler in a private house also avoids technical and organizational difficulties: a fireproof closet under the furnace can always be fenced off, at least in the attic.

How to calculate the minimum required power

In most cases, to determine power (Q), a simplified formula is used, where 1 * kW of thermal energy is taken per 10 m 2 of heated area.

- * approximate heat loss of a brick building with ceilings of 2.7 m from the central climatic zone of Russia.

For example, for a residential building of 120 m 2 located in the Moscow region, the minimum required power of a parapet gas boiler will be Q=120÷10×1=12 kW.

We also recommend making a reserve of 15–20% of the power so as not to operate the heat generator at its limit for a long time, i.e. for the same object Q≈14–15 kW. Also, if we are talking about a double-circuit model, then you will have to add about 15–20% more to provide hot water supply, the total result will be Q≈16–17 kW.

In an apartment of 120 m2 (not corner), heat loss is a priori 10–15% less, so for a unit with one circuit Q≈12.5–13 kW, with two circuits Q≈14.5–15 kW.

How to accurately calculate the required boiler power Individual calculation, formula and correction factors

How to choose the right shoes

It’s not an easy task to choose the right Antelope shoes for your baby. The size chart will help you do this. It is difficult for a child to withstand walking around the store and numerous fittings. There are several important points to consider when choosing shoes for your baby. Often the child does not feel that the shoes have become too small. You should measure your child's feet every two months, monitoring their growth and shoe size. By measuring the length of the foot with a ruler, determine what size the baby needs at the moment. You can measure a child's foot with a ruler or tape measure. For older children, you can trace the leg with a pencil on cardboard while standing.

What does a boiler consist of and how does it work?

Parapet gas boilers for heating a small private house perfectly heat the home. The inability to connect to a standard type of chimney does not affect the performance of the equipment. Before installation, it is worth studying the design of the device, the principle of its operation, so that the system works without failures after assembly.

Components

Fuel is burned in the combustion chamber to heat the liquid circulating through the pipes and radiators in a heat exchanger.

Fuel is supplied through a gas burner equipped with a valve.

The body is made of steel, from which there is a pipe for the intake of fresh air with the simultaneous removal of combustion products.

Operating principle

The heating apparatus begins its operation by activating the pilot burner through piezo ignition, which begins the active supply of gas to the burner.

Gas burning

Inside the boiler, hot gases are directed to the heat exchanger, heating the coolant.

When operating single-circuit boilers, hot air exits through convection openings on the body itself, which are covered with decorative grilles.

The liquid inside the pipeline heats up to no more than +90 ºС, at the maximum value the sensor is triggered and the gas valve shuts off the gas supply. When the system cools down, the valve opens, gas is supplied, and the burner starts working again.

When the fuel supply stops, the pilot burner goes out. The system begins to operate only with the help of piezo ignition.

DIY installation

The bulk of the work on assembling and installing the boiler can be done independently. But some steps are best left to professionals - mistakes can be very expensive. This applies to the installation of chimney pipes for coaxial chimneys, as well as the first start-up. The exact installation process varies depending on the specific model. Each boiler comes with detailed instructions, where the manufacturer describes all installation steps:

- The first thing to do is to arrange a channel where the chimney and air pipes will be routed. What should the dimensions be? The holes must match the diameter of the pipe.

- A suitable place for the chimney is next to the window. In the future, this element will need to be serviced and its condition checked.

- Next, install the first duct pipe. It is fixed to prevent displacement. Then the section for the water supply is installed.

- On the surface where it is planned to install a parapet double-circuit gas boiler, studs are fixed. The unit body is secured with nuts.

- The pipes and chimney are installed in the same way, and the fasteners are fixed. In this case, you need to try to achieve maximum compaction between all elements. It is better to place the chimney at an angle. This way condensate is removed more efficiently.

- The chimney section is connected to the pipe, and protection is installed. The gaps should be adjusted so that the burner fire burns evenly and there are no tears.

- Then radiators and pipes are connected using standard technology. It is also worth installing an expansion tank.

- After installation, the equipment is checked by gas industry specialists. Then instructions are given. Only then can operation begin.

Distinctive features of heat exchangers

The heat exchange unit of the heating device can be cast iron, steel or copper. The cast iron version retains heat for a long time, is almost not subject to corrosion due to the high wall thickness and is resistant to aggressive coolants. It is heavy and therefore mainly integrated into floor-standing boilers.

Requires great care during installation, since any impacts violate the structural integrity of the material and lead to the formation of microcracks.

The steel structure weighs little, is not afraid of mechanical stress, can easily withstand temperature changes in the coolant, and is easily transported and installed. Has some tendency to corrosion. The boiler control system helps to avoid it, which prevents the coolant temperature from falling below the critical point.

Copper elements are an order of magnitude more expensive than their cast iron and steel counterparts, but they compensate for the substantial cost with a large number of advantages. Inside the copper heat exchanger, sediment and scale are formed to a minimum and do not interfere with the normal circulation of the working fluid. The walls of the device are heated evenly and do not cause local overheating of the coolant.

Components of the strapping

Which components and elements will be included in the set of heating system components depends on the type of heating system:

- Heating with natural (gravitational) circulation of heated water (coolant) - popularly called “physics” heating;

- Forced circulation – with connection of an asynchronous circulation pump;

- Mixed scheme.

Set of strapping elements

In a scheme with natural water circulation, the set of piping elements will be as follows:

- Heating boiler - after it, the heated coolant rushes up and moves through the pipes, returning to the boiler slightly cooled;

- Heating piping pipes - most often for a “gravity” scheme, metal pipes are used that are larger than plastic pipes, with a diameter of up to 2 inches. The diameter is selected based on the need to minimize coolant resistance for its unhindered circulation;

- Expansion tank - installed at the highest point of the system, and can be open or closed in design;

- Heating devices – radiators, radiators or registers;

- Mayevsky tap - installed on the heating radiator to bleed air;

- Fittings - welded or threaded turns, doubles, tees made of cast iron, brass, bronze, copper or stainless steel, tees, drains and other types of connectors;

The advantage of the “physics” system: easy independent installation, simple circuit, common parts and assemblies, low cost of components.

Disadvantages: large size of components, inertness, insufficiently fast heating of wiring and heating devices.

Heating scheme with gravitational water circulation

Main differences and characteristics

Parapet boilers can have 1 or 2 circuits - for heating and hot water. Various models are made in floor and wall-mounted, left-hand and right-hand versions. Depending on the purpose, they are equipped with one circuit - only for heating or two - to additionally heat water for domestic purposes. Depending on the level of control, devices can be automatic or manual. For automation to work, electricity is required. If it disappears, the boiler turns off. Manually controlled products are practically independent of external conditions and can even be operated from a gas cylinder. The burner is turned on and off by a thermocouple and a constantly burning wick.

Installation of a boiler in a house: SNiP standards

Before installation work, you must obtain all permits. Self-installation is not only illegal, but also unsafe (especially if the device will be used in a high-rise building).

The basic requirements and standards for gas equipment are written in SNiP 42-01-2002 “Gas distribution systems”. Also, many requirements can be read in SNiP “Gas Supply” 2.04.08-87. This document is no longer relevant today, but it still contains useful information.

Equipment traction options

During operation of the unit, fuel burns and flue gases are generated. To remove them from a living space, natural or forced draft is necessary. It will ensure timely removal of all combustion products and released harmful substances from the apartment or house.

Natural draft modules

Boilers operating on natural draft have a simple design and take the air necessary for proper combustion from the room in which they are located. During intensive use, a certain amount of steam and various chemicals are released. Emissions are removed through a vertical chimney.

Among the main advantages of units with natural draft are reasonable cost, energy independence and absence of noise effects during operation.

In general, devices with natural draft are convenient and good, however, when the pressure in the gas pipeline drops, the quality of their work decreases significantly. At the same time, the risk of rapid burnout of the burner increases, since the fire at a reduced pressure level dies out or goes inside the burner device.

Uneven pressure in the main networks provokes serious overconsumption of fuel, which entails an increase in the amount of utility bills.

Forced draft devices

Boilers with forced draft are sometimes called forced-air or fan-type. They take air not from the room where they are located, but from the street. The modules have closed combustion chambers, and waste substances are emitted through a coaxial horizontal outlet using a powerful fan built into the system.

A coaxial bend consists of two pipe elements of different diameters inserted into one another. Through the smaller pipe, combustion products exit the room, and through the space between the small and large pipes, fresh air enters the room from the street, which is necessary for the full functioning of the boiler

Products with forced draft are easy to install, do not make any demands on the location, do not “eat up” oxygen in residential premises, work stably and accurately even with reduced gas pressure in the central main networks and do not require the installation of an additional vertical chimney.

The devices are criticized for the noisy operation of fan elements, higher cost and dependence on power supply.

Why does the boiler blow out in the wind and what to do in this case?

Blowing out may indicate a failure in the connection of the chimney and automation; more often it indicates a lack of wind protection on the head. However, in general, blowing out the burner flame by the wind is a significant and most well-known problem with parapets, which is why they never gained super popularity.

As a rule, the casing of a coaxial chimney, manufactured in a factory, already has a special insert that protects against gusts of wind. If it is not included in the kit, then you will have to look for a suitable deflector or make it yourself: give a sheet of galvanized steel the desired shape, and then attach it to the head with press washers or rivets.

Factory wind protection and an example of a homemade solution by the owners.

When the boiler still goes out after installing the protection, there is no point in doing anything further: you can, of course, continue to install new heads and deflectors, add bends to the coaxial pipe, or install a vertical chimney, but then the whole point of installing a parapet model will be lost.

Rating of the best gas boiler manufacturers

The reliability and stability of heating a private house or apartment depends on the operation of thermal equipment. Saving in its selection is impractical.

Among manufacturers producing boilers, the following brands are popular with consumers:

- Buderus is a company of German origin that produces reliable wall and floor models. There are devices with cast iron heat exchangers. The product line includes devices with open and closed burner.

- Navien is a Korean manufacturer with official representative offices in Russia, the USA and other countries. The products are famous for their unpretentiousness, low noise level, and reliability in operation. Navien boilers are distinguished by their low gas pressure requirements.

- Bosch - a company from Germany is famous for the reliability of its equipment. The manufacturer produces a full range of gas equipment for domestic use. The boilers are distinguished by increased operational safety and convenient control.

- Vaillant is a German brand popular in the gas equipment market. The company produces boilers with a closed and open combustion chamber with a power from 4 to 240 kW. The products are equipped with a reliable safety system, including protection against freezing, overheating and pump blocking. There is a wide network of service centers throughout Russia.

- Viessmann is a manufacturer that produces reliable heating and water heating equipment. The line of gas boilers includes single- and double-circuit models for floor and wall installation. The devices are environmentally friendly and have low noise levels. There is built-in protection against power surges. Many models can use both natural and liquefied gas as fuel.

- Ariston is an Italian brand, along with household appliances, offering gas equipment for heating and hot water supply. The boilers are famous for their high efficiency and low energy consumption. The devices are equipped with pump stop protection, flame modulation, and a semi-automatic ignition system. Thanks to the stylish design, the equipment looks good in the interior.

- Baxi is a company from Italy that produces water heating and heating equipment. The product line includes convection and condensing boilers of different capacities and designs. They are equipped with a good system for ensuring safe operation. There is a flame modulation mode that helps reduce fuel consumption. Built-in automation responds to changing weather conditions.

- Lemax is a Russian brand that produces reliable, inexpensive installations using components from foreign manufacturers. Models available for floor and wall installation. The devices are adapted for Russian conditions: they can be operated at low gas pressure, and the voltage range has been expanded. Composite materials are used in manufacturing. A wide network of service centers allows you to quickly resolve any problems that arise.

- ZhMZ - products of the Zhukovsky Machine-Building Plant are popular in the budget segment of the market. The devices have a full range of basic functions and are well adapted to work in Russian conditions. There is gas pressure control, non-volatile ignition, and overheating protection. German-made automation is used. The devices are designed to operate on natural and liquefied gas.

- Neva is a Russian company from St. Petersburg that produces heating equipment of several modifications. Boilers with one and two circuits are available. The copper heat exchanger is highly efficient and resistant to temperature changes. The safety system includes protection against freezing, overheating, and pump blocking. The auto-diagnosis function allows you to quickly identify malfunctions in the installation.

By choosing a boiler manufactured by one of the manufacturers listed above, you can be sure of its long-term reliable operation.

Popular models

Next we will look at Russian-made parapet gas boilers, as well as some samples from foreign brands. By the way, most models are produced in Russia.

Parapet boiler Atem Zhytomyr-M ADGV 12 SN

Our review of models starts with the energy-independent double-circuit boiler Atem Zhitomir-M ADGV 12 SN. The power of the device is 12.5 kW, the heated area is up to 125 sq. m. The model does not require connection to the electrical network, operating exclusively from the gas main. The control system here is mechanical. To operate in closed circuits, it is necessary to install a separate circulation pump with a bypass. The maximum gas consumption is 1.38 cubic meters.

m/hour. The parapet gas boiler Atem Zhitomir-M ADGV 12 SN is equipped with two safety systems - overheating protection and gas control. The equipment can operate at a pressure in the circuit of up to 2 atmospheres and at a temperature of +60-90 degrees, while the pressure in the DHW circuit can reach up to 6 atmospheres. The productivity of the DHW circuit is not the greatest, only 4.83 l/min. But the efficiency of the model is quite decent - it is 90%.

Parapet boiler ROSS Premium AOGV 16PKD

Before us is another representative of gas heating equipment.

Parapet boilers ROSS Premium AOGV 16PKD are made of durable steel 3 mm thick and equipped with steel heat exchangers. They are built according to a double-circuit scheme, providing hot water supply. The control system on board is mechanical; of all the measuring instruments, there is only a capillary thermometer. The manufacturer has done everything possible to make the ROSS Premium AOGV 16PKD parapet boilers as efficient as possible. For this purpose, gas burners from the Italian brand Polidoro are used, and turbulators are installed in the design of heat exchange units. The efficiency of these devices reaches 90% - this is an acceptable indicator for parapet-type boilers.

Parapet boiler Mimax KSG(P)-7

The presented unit is distinguished by its miniature size. Its power is only 7 kW and is designed for a small building. The device is made according to a single-circuit design, its heat exchanger is made of steel. A gas parapet boiler consumes only 0.75 cubic meters. m/hour, being economical - its efficiency is 92%. The maximum pressure in the heating circuit pipes is 2 atm.

at temperatures from +60 to +80 degrees. The safety systems provided are gas control, which prevents leaks during attenuation, as well as overheat protection, which preserves the integrity of the equipment during temperature overloads. A thermometer is provided on board to monitor the temperature. In the absence of a hot water supply circuit, it is necessary to solve the problem with the supply of hot water - the easiest way to do this is to use a boiler of 80-100 liters (depending on the number of people living in the house). You can also install a gas water heater.

Parapet boiler Danko 7UVS

Before us is a small-sized parapet double-circuit boiler that solves the problem of preparing hot water. It is built according to a non-volatile scheme and does not require connection to an electrical network for its operation. The power of the model is 7 kW, gas consumption is up to 0.8 cubic meters. m/hour. It is also possible to operate on liquefied gas with a consumption of up to 0.3 kg/hour. Connection to the heating pipes and gas pipe is made from the side.

The Danko parapet boiler heats the coolant to a temperature of +90 degrees, the maximum pressure in the system should not exceed 1.5 atm. The capacity of the DHW circuit is 160 l/hour. The automatic equipment in the device is Italian, which is a sign of a long service life and the absence of problems in operation.

Parapet boiler Fireplace KSGZV-10 AT

If your home requires not only heat, but also hot water, you should purchase a gas boiler Ochag KSGZV-10 AT. It belongs to the parapet type and has two contours. Let's present the technical characteristics of the model in the form of a list:

- Thermal power – 10 kW;

- Heated area – 100 sq. m.;

- Primary heat exchanger – steel;

- DHW circuit heat exchanger – copper;

- DHW circuit capacity – 2.5 l/min;

- The pressure in the heating circuit is not higher than 1 bar.

The characteristics are not the most impressive - the pressure limitation and the minimum DHW performance are confusing. With such a flow of water from the tap, taking a shower will not be the most comfortable.

Parapet boiler Lemax Patriot-12.5

Compact, nice, simple - this is how we can characterize this gas unit. Its power is 12.5 kW, efficiency is up to 87%. The boiler's only heat exchanger is made of durable steel, gas fuel consumption does not exceed 0.75 cubic meters. It does not require a connection to the mains and works offline.

The pressure in the heating pipes should not exceed 2 atmospheres, the maximum coolant temperature should not exceed +80 degrees. The Lemax Patriot-12.5 parapet boiler is made in a neat body, to which the word “design” is applicable - the sides are slightly beveled back, thanks to which the device is well perceived externally. The only device for monitoring operating parameters is a thermometer; it is located in the upper part of the front panel, also sloping back.

Parapet boiler Aton Compact 12.5E

Another interesting model, characterized by maximum compactness.

The manufacturer confidently states that with a power of 12.5 kW it is capable of heating up to 160 sq. m of living space. The statement is strong, but most likely applies only to the off-season, when the street temperature does not drop to serious sub-zero levels. The boiler consumes a minimum of gas fuel - a maximum of 1.39 cubic meters. m/hour, pleasing the temperature in the heating circuit up to +90 degrees. But the pressure in the pipes is limited to 1.5 atm. The Aton Compact 12.5E gas parapet boiler is made in a rectangular body in which convection holes are visible. Along with it, analogues are available for sale, differing in higher and lower thermal power. The equipment is ideal for heating private households and country houses where there is no excess free space.

Parapet boiler TERMOMAX Termomax-C 10E

This is the last device in our review. Its thermal power is 10 kW, which is enough to heat a home up to 100 square meters. m. The efficiency of the device is up to 90%, the maximum gas fuel consumption is 1.12 cubic meters. m/hour. The maximum pressure in the heating circuit should not exceed 1 atm.

at a temperature not higher than +90 degrees. It is not possible to operate on liquefied gas, so the house must be connected to a gas main. The parapet gas boiler TERMOMAX Termomax-C 10E is made in a rectangular body, devoid of any hints of design. But it is non-volatile and will work even when the power goes out.

What types of gas heating boilers are there?

Gas boiler equipment is available for sale in a wide variety, so before choosing a parapet gas boiler, you need to consider the following parameters:

- Price.

- Power.

- Set of functions.

- Type of coolant used.

- Type of burner.

- Smoke removal feature.

- Installation location.

- Presence or absence of automatic control.

- Requirement for electrical energy.

Listed above are only the main differences that are found in different models of gas boilers.

The main one is the peculiarity of installing a parapet boiler. Wall-mounted equipment is characterized by low power, relative cheapness and the ability to be used in apartments. Date: September 25, 2022

Installation process

Installation of a parapet gas boiler is carried out in the following steps:

- If the covering of the wall on which the device will be hung is flammable, it should be removed at least in an area equal to the projection of the boiler onto the wall.

- A hole is made in the wall in accordance with the diameter of the chimney. It is necessary to ensure that the pipe is placed with a slight slope towards the street to remove condensate.

- A coaxial pipe is inserted into the resulting hole and fixed. The presence of a certain slope should be checked. For example, for a wall of one and a half bricks, the outside of the pipe should be 4 mm lower than the inside.

- In accordance with the position of the installed chimney, places for fastenings are marked on the wall. Then the holes are drilled and the fasteners are installed on the wall.

- The boiler, depending on the model, is hung on the wall or installed on the floor.

- The pipe connection is attached to the unit. Heating sections are being installed.

- Heating and water supply pipelines are supplied to the boiler nozzles (depending on the model).

- The gas connection to the device and the first start-up must be carried out by a gas specialist.

Depending on the unit model, some installation points may differ slightly.

Note! In order for the heat exchanger of the parapet unit to work as long as possible, it is recommended to install a filter on the tap water inlet pipe.