Coolers and radiators are an important part of many ventilation and heating systems. Since water is present in the systems, it is very important to ensure a clear adjustment of the volume of supplied and discharged water. A two-way valve most often plays the role of a regulator in these devices. The principle of operation of such a valve is similar to the principle of operation of a ball valve or seat valve.

Such a valve is an effective unit for regulating the heating system

Mechanism of action and connection diagram

The operating mechanism of valves of any type starts after force is applied to the actuator.

It triggers the downward movement of the plunger, which, in turn, closes the free space inside, simultaneously increasing the flow of water or steam and decreasing the pressure. Fully lowering the valve will completely stop the movement of coolant in that part of the line that is located after the shut-off device. The locking structure consists of more than just a plunger. Another part is a special saddle. Valves are available with both one and two seats. The double-seat valve allows you to clearly control the coolant flow or stop it completely in cases of significant pressure drop. A single-seat device will not be able to cope with such a task.

You will need to install 2 or more similar valves

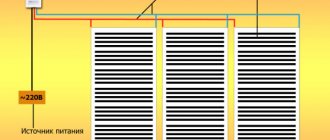

The valve must be connected to the system in a parallel circuit. It can be implemented by using 2 or 3 circuits through which water or steam will move. The scheme must include:

- heating pipes and collector;

- shut-off and control valve;

- circulation pump;

- Control block.

To control the flow and pressure of the coolant in such a circuit, you will need to install one or more two-way valves. When installing multiple devices, the parallel connection method must be followed. Placing a three-way valve with a temperature sensor in this case will be impractical, since it is characterized by a small throughput.

This connection method has a drawback regarding the temperature regime of the coolant. The temperature of the water entering the circuit will be equal to the temperature of the water leaving the return circuit to the boiler. This will provoke unequal distribution of the coolant in different parts of the circuit.

Purpose and design

The classic configuration of the device is as follows:

- thermostatic valve;

- thermal head with remote sensor;

- thermal head valve;

- limit sensor that takes into account temperature;

- meter;

- circulation pump;

- water filter;

- check valve

Two-way adjusters are used everywhere, but a lot depends on what material they are made of. Considering the design features, we will immediately make a reservation that valves come with one or two seats. Using the second type, the flow of the working medium is regulated and blocked, and significant pressure drops are allowed, which a valve with a single seat cannot cope with. The valve itself looks like a separate part with a mechanical or electronic drive. It happens that an additional energy source is not provided, so it is installed after installation of the device.

*

Advantages of a two-way valve:

- simple design;

- easy to install;

- does not require human involvement to work effectively;

- repairable;

- reliable;

- lasts a long time;

- hermetically sealed;

- characterized by low hydraulic resistance;

- available.

Paying attention to the design of the element, it will seem that it is similar to a standard valve, but the mechanisms differ significantly. For example, the main closing element of a valve is a stem or ball. That is, a rod located in a horizontal or vertical position, or a ball rotated around its axis by 90 degrees, is responsible for limiting the flow of water. The device operates according to a simple scheme - a special hole opens and liquid is transported through it. In order for these structural elements to function, an actuator is connected to the valve, which requires electricity or compressed air. The drive itself is combined with separate instruments that take into account pressure in the system, temperature and other characteristics.

Valve design

Design differences between devices

Depending on the shape of the device body, there are:

- straight, installed on straight sections of pipelines;

- angular, with a rotation of 90 degrees;

- two-valve, in the event that it is necessary to sum two flows into one, then during assembly a tap with two valves is installed.

Two-valve device

Two-way fittings by type of control:

- Adjustment is made using the handle. For large pipeline diameters, a flywheel with a gearbox is used to smoothly regulate the flow.

- With remote electrical control. There are two types with a solenoid valve or with an electric motor. The solenoid valve is installed on small-diameter taps, and the electric motor on main pipelines. Smooth flow control and closing in an emergency are possible.

- Adjustment using a pneumatic drive. A pneumatic cylinder is installed on the fitting, with the help of which, when air is supplied, closing or opening occurs. The disadvantage of such a system is the need to wire an air line.

How to install a rotameter on a manifold comb

Rotameters are often used on underfloor heating manifolds; they are necessary to control flow. Depending on the model, the device can be adjusted to different flow rates from 0 to 5 l/min. The setting is made only when the pump is turned on. It is necessary to remove the decorative protective cap and tighten the fixing nut into the desired position. After setting up the flow meter, the plug is installed in place.

Rotameters differ for the return comb and the feed comb. Inside the glass flask of the device there is a rod with a plate. In the non-working state, the rod plate is pressed to the zero value by a spring. The coolant is always supplied under the valve seat, since the flow opens the valve. On reverse rotameters the rod is at the bottom, and on feed rotameters it is at the top (the numbers will increase from above).

Differences between the rotameter on the feed and return combs.

If you confuse the supply and return rotameter, the coolant flow will press the rod against the seat, and the system will not work. Some devices do not allow you to record the required flow rate, but only measure its value; to distribute flows along the contours of heated floors, it is advisable to use the first option.

Installation Features

The procedure itself boils down to connecting the valve to the necessary pipelines. In order for the fittings to work for a long time and without problems, the connection should be implemented correctly, taking into account all the tips and recommendations. If you lack experience, it is recommended to contact specialists. Otherwise, the heating system will not be as efficient and economical as it should be.

Before starting installation work, pay attention to the two-way valve - its body has an external or internal thread onto which the union nut (or fitting) of the pipeline is screwed. For a reliable connection, experts advise wrapping the thread with a sealant, which is suitable for FUM tape

The fittings are supplied with special gaskets that ensure the proper level of tightness. If these are not available, then you will have to purchase them separately, of the appropriate thickness and diameter. The main task is to ensure a tight connection, without distortions on the threads, which will prevent possible leaks. No special tools or devices are required.

Expert advice:

During installation, ensure that there is no force in the piping. Before installing the element on the water supply system, the latter should be thoroughly cleaned, removing all impurities

They negatively affect the condition of the sealing materials, which leads to the valve’s tightness being compromised. Over time, the device may need to be repaired or dismantled, so it is necessary to leave enough free space around it. It is important to carry out careful installation. If a flange connection is used, it is recommended to tighten the corresponding screws alternately to avoid internal stress

With the threaded installation method, adjustment links are used, which will allow the valve to be dismantled in the future. If you need to blow out or flush the entire pipeline system, the valve is removed and an adapter is installed in its place.

Valve in the heating system

Installation process

Installation of a two-way valve for heating consists of its correct connection to the pipeline. The connection should be made using internal or external threads. To do this, you will need to screw a union nut or fitting onto it. The pipeline thread must first be protected with a sealing material (FUM tape or natural sealant). Installation must be carried out taking into account the fact that high temperature affects the tightness of the threaded connection of parts, weakening it.

Two-way valves are complemented by special gaskets that must be used during installation. They will make the connections as tight as possible and prevent possible leakage of coolant from the main line. If necessary, they can be replaced with the same gaskets, suitable in diameter and thickness.

Operating principle of a two-way valve

The main feature of the two-way fitting is that the supply volumes can be adjusted only in the direction of flow along the arrow indicated on the body. The flow is not adjusted in the reverse direction; such a connection may lead to failure of the device.

The flow rate is changed by turning or lifting the shut-off element, which is done by the valve handle, or using an electromagnetic drive.

Diagram of a two-way valve

When the shut-off element is completely closed, the flow of the working medium stops, and the system behind the valve is completely sealed. To prevent various abrasive particles from damaging the mirror surface of the lock, it is recommended to install a filter in front of the entrance.

Expert advice

Before choosing control equipment, you need to decide what area needs to be heated. If you will be heating a bathroom, part of the floor of a bedroom or a children's room, there is no need to purchase fittings with a thermal head - it is easier to use a manually operated three-way valve than to install a full-fledged expensive mixing unit.

The cost of a mixing and distribution unit with shut-off and control valves, a manifold, a pressure gauge, and a Mayevsky tap exceeds the cost of all pipelines (if they are made of polymer and not expensive copper).

If the underfloor heating system includes several rooms, then it is necessary to order a project from a qualified plumbing engineer before installation - it will indicate the characteristics of the valve. If there is a large area of heated floors and a large number of rooms, one or more mixing units will be needed.

The connection diagram of each unit includes a manifold - a distribution comb, to which heating pipelines are connected. A three-way mixing valve and pump are installed in front of the manifold. The valve can be with a thermal head or with sensors, a controller and an electric drive.

Why are valves needed in underfloor heating systems?

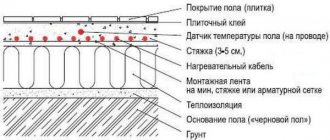

In most cases, boilers heat water to the temperature required by high-temperature radiators.

As a rule, it is 75-95 °C. Taking into account sanitary standards, the surface of a warm water floor should not have a temperature above 35 °C. This temperature ensures a comfortable stay on the floor covering; in addition, the higher temperature of the water-heated floor can have a destructive effect on the finishing coating - especially laminate or linoleum, and lead to its deformation. Taking into account the thickness of the heated water floor screed in which the heating circuit pipes are located, as well as the thickness and type of floor covering, the coolant temperature should be about 50 °C. If the water heated floor is connected to a centralized heating system or the water comes directly from the boiler, then its temperature will be too high.

To lower the temperature of the water in the system at the entrance to the heating circuit of the water heated floor, a mixing unit is installed, which has a two-way or three-way valve. They mix hot and cold coolant coming from the return circuit of the water heated floor.

As water passes through a two- or three-way tap, the temperature decreases and becomes suitable for the system - a coolant with a temperature of 90-95 °C enters the heating radiators, and a temperature of 50-55 °C enters the heating circuit of the water underfloor heating system.

When the heated coolant enters the collector, its path is blocked by a safety valve equipped with a thermostat. If the coolant temperature is higher than required, the two-way or three-way valve will operate, which will lead to the supply of cold water from the return circuit. The mixing will be carried out, the hot and cold coolant will mix, and when the temperature reaches the desired value, the tap will turn on again and the supply of hot water will stop.

Areas of use

*

As noted above, this type of control valve is used in heating, ventilation and air conditioning systems. We will separately consider the features of its use in a circuit with a “warm floor”.

If a boiler is installed in the house, then its task is to heat water and, as a rule, its temperature is quite high, suitable for radiators (from +75 to +95 degrees Celsius). For a “warm floor” system, such heating is not needed, since sanitary standards regulate a maximum of +35 degrees Celsius. This indicator is enough to comfortably walk on the floor covering. If the temperature is higher, this will not only cause inconvenience to residents, but will also negatively affect the finishing floor covering. For example, linoleum or laminate are easily deformed.

The “warm floor” is installed under the screed; in addition, different flooring materials are used. To do this, the coolant is heated to +50 degrees Celsius. When a heated floor is directly connected to a boiler or centralized heating system, the resulting temperature is too high. To reduce it at the entrance to the circuit, install a mixing valve for a warm floor, with a two-way or three-way tap already provided. Based on the name, the purpose of such fittings is to mix hot and cold water circulating along the circuit. That is, the process of fluid passage changes - for the radiator, the water remains hot, but the already mixed water, which has a lower temperature, is supplied to the warm floor.

Installed valve

Types and characteristics of electric drives

The operation of valves with a servo drive is based on the conversion of electrical energy into mechanical force, leading to movement of the locking mechanism. The following drive options for such devices are distinguished:

- Electric drive. It is a combination of an electric motor, a transmission mechanism and a control system. Valves of small diameter are equipped with single-phase power elements of direct and alternating current, and control valves of higher power are equipped with three-phase asynchronous ones. The electric valve drive allows you to control the parameters of the moved medium from a distance using a remote device.

- Electromagnetic drive. It is used for valves that are equipped with one of the actuators - solenoid or with an electromagnetic clutch. Solenoid electric drives are used to control two-position control systems represented by shut-off valves. In devices with automatic control of the functions of the actuators, electromagnetic friction or sliding clutches are used. The electromagnetic drive can be block or built-in, and quickly responds to the supplied signals.

The variety of configuration options for electric drives allows us to produce devices for use in various fields. Their popularity is due to the performance properties and technical characteristics of the actuators.

How to choose

Installing a heated floor, even in a private house, is a rather complex engineering system with ambiguous results. If the adjustment is poor, all the benefits may disappear, so you cannot save on the manifold assembly and control valves. Good three-way valves are not cheap, and there is a high probability of purchasing low-quality products on the market or on the Internet.

For a heated floor system, it is better to buy equipment in a hypermarket or specialty store. A certificate is a must! Or a passport with a “wet” stamp and a completed guarantee. The receipt must be kept.

Usually they buy products made of brass. Stainless steel valves are more expensive and less commonly sold. Silumin is not even worth considering - products made from it do not tolerate constant opening and closing, and the control valves cost a lot.

When purchasing in a store, you need to inspect the valve to ensure there are no chips, cracks, or jams. You need to try to look inside the valve - on brass products without coating, the inside should be golden (and not white-silver, like silumin). You can navigate by weight. Silumin products weigh much less than brass ones - the density of brass is approximately three times greater than that of silumin.

Popular manufacturers

In first place in terms of quality are the products of the Swedish company ESBE. The company has been producing pipe fittings for various purposes for over a hundred years. The second place is occupied by the American company Honeywell. Fittings from HEIMEIER, HERZ, Navien, Danfoss, Mut, Oventrop, Siemens are common. The cost of these products outstrips the quality. The products of the joint Italian-Russian manufacturer Valtec have a more reasonable price.

approximate price

The table above is the prices for a Three-way valve with a thermal head. To find out how much equipment costs in your region, it is better to contact the nearest construction hypermarket. Approximate prices for a three-way valve with electric drive:

Types of control valves

Reinforcement differs in several ways.

Depending on the design features, there are 2 types:

- walk-through - in them the pipes have the opposite arrangement;

- angular - located at an angle of 90 degrees.

Pay attention to how the valve is controlled. According to this parameter, there are 3 types:

According to this parameter, there are 3 types:

- pneumatic;

- hydraulic;

- equipped with electric drive.

The electrical drive device is a low-power electric motor or retractor solenoids. Of course, there are products with manual control, but they are more difficult to operate, since they do not allow you to set precise parameters. The devices operate from an electrical network with alternating current 220 V or direct current 24 V.

Certain pass-through units operate in autonomous mode, without power supply. Such fittings are controlled and regulated by means of a membrane and a counteracting spring. As feedback, a circuit is used along which the coolant moves - it also directs the membrane in the desired direction.

What does a two-way valve provide:

- consumption is regulated, resources (water) are distributed and saved;

- more economical heat consumption;

- equipment and networks are protected from pressure surges;

- If used correctly, the valve extends the life of the connected equipment and the network itself.

The devices are mounted using flanges, threads or welding. One of the subtypes of a threaded connection is a pin-type fastening, in which the valve is screwed into another device. When the installation is welded, special pipes are used.

We will separately highlight the valve with remote control, which is the easiest to operate. Such devices are complemented by electric drives or remote controls. It is the control rooms that accept all the current characteristics and parameters of the system. The pressure decreases remotely, the pressure increases, or certain branches of the heating network are blocked.

A type of two-way valve

Material of manufacture and application

A two-way valve should be installed in areas where pipes do not branch. This type of shut-off valve has an angular and straight design. If the valve has one inlet and outlet, then, regardless of the configuration, it is called a two-way valve.

Fastening of such devices can be: flanged, threaded and welded. Occasionally, a threaded connection is a pin-type connection (the valve is screwed into the body of some device). The welded type of valve connection implies the presence of pipes for welding.

Types of Danfoss two-way valves

These valves are designed for automatic or manual control of the flow of working fluid. According to the principle of operation, the models are saddle and rotary. In the latter, the displacement of the rod occurs when the locking mechanism is turned. Saddle bars provide better performance because the locking is done by pushing. Return to the starting position in two ways - using a spring or an electric drive.

Technical and operational characteristics:

- diameter – 15-250 mm;

- connection methods with pipes - threaded (fittings required) or flanged;

- throughput – 0.25-400 m3/hour;

- body material – brass, bronze, cast iron, steel;

- maximum coolant temperature – +130-150°C;

- nominal operating pressure in the system is 16-40 bar.

Some models have a pressure relief device. This reduces the risk of emergency situations. But they are installed in large diameter two-way control valves. A separate category is control devices for water and steam. They are characterized by increased insulation, which eliminates leaks. Operating steam temperature up to +190°C is allowed.

Danfoss.

What materials is it made from?

*

Cast iron, brass and steel products are now common. For example, fittings made of cast iron and steel are installed in pipeline systems with large flows of water or steam. Brass valves are often found in ventilation systems. Their main advantage is their compact size, so the element can be installed even in small rooms with limited water consumption.

It is recommended to use a steel or cast iron control valve. Steel products are common, which are just as strong as their cast iron counterparts, but are much cheaper. When choosing a material, the pressure characteristics in the system and the dimensions of the fittings themselves are taken into account.

Steel valve

Installation and operation rules

Before installing a two-way control valve, you should study the instructions and connection diagrams. The direction of movement of the working fluid is taken into account. It is indicated by an arrow on the device body. When making a threaded connection, use pipe winding - FUM tape, flax, plumbing thread. For flange contacts, the bolts need to be tightened one at a time, adjusting the pressure on the walls.

It is recommended to install strainers to minimize the reduction in the valve bore diameter. After 3-4 seasons of operation, a build-up may form on the surface of the rod, preventing its movement. Before starting the heating system, you need to check the functionality of the elements and, if necessary, repair or replace defective ones.

TM-K-3/4-SP.

Danfoss two-way control valves are reliable and have a simple connection diagram

It is important to perform installation correctly and observe operating conditions

Remote controlled valves

It is much easier and more convenient to control a two-way valve remotely than a three-way valve. However, this control method necessarily requires the presence of electric drives and a remote control (one or more). Such control rooms will receive all the information about the condition of different sections of the heating main. From one of these rooms you can manage the process of functioning of the heating network. You can reduce or increase pressure, or block specific branches.

p, blockquote 24,0,0,0,0 —> p, blockquote 25,0,0,0,1 —>

Summarizing all of the above, it is worth mentioning the advantages that a two-way control valve has:

- regulates the consumption and distribution of resources (environment), thereby ensuring their savings;

- protects networks and equipment from pressure surges;

- the device is easy to install and repair;

- Thanks to this device, the devices will work efficiently and without failures for a long time, the main thing is to find the right use for it.

after —>

Source

Design and principle of operation of a three-way valve

The design of a three-way mixer includes the following elements:

- Sealed housing with three T-shaped pipes.

- Valve with internal T- or L-shaped channels. Most often, the bolt mechanism has the shape of a ball, less often a cone or cylinder.

- Stuffing box.

- A rod that transmits movement to the bolt mechanism.

- Control unit - handle (butterfly or lever) or drive.

The operating principle of a three-way valve is based on the rotation of the valve inside the body. An L- or T-shaped stroke drilled into the valve serves to pass flows. By turning, the shutter either opens all the holes in the pipes or closes one of them.

Let's consider the principle of its operation using the example of a heating circuit. A three-way valve is installed in the circuit so that one of its pipes is connected to the pipeline coming from the boiler.

The pipe located in the middle is connected through a bypass connection to the “return”, where the coolant has a lower temperature. The third pipe connects to the pipeline going to the radiators.

The shutter position is set by turning the handle:

- In the first position, transported flows are mixed, simultaneously coming from the circuit supplied from the heat generator and from the “return” circuit.

- In the second position, only hot coolant from the boiler is supplied to the heating circuit.

- In the third position, the flow of hot coolant is blocked, only cooled water from the return circuit is supplied to the system.

Additional components

To control valves, Danfoss offers three types of actuators - thermoelectric, gear and electro-hydraulic. The most common are gear drives of the AME and AMV series. The design includes an electric motor that transmits torque to a gear reducer. Terminals for connecting to regulators are provided for control. The condition is the use of a three-position pulse signal.

What to look for when choosing:

- methods of connecting to the valve - nut, clip-latch, glass;

- rod stroke – 2-50 mm;

- mains voltage – 24 or 220 W;

- type of control signal – analog, three or two-position;

- automatic return of the rod when there is a power outage.

Speed – the speed of the rod displacement by 1 mm. According to this parameter, drives are divided into “slow” and “fast”. The time for moving the rod by 1 mm for the former is 8-15 seconds. They are used for heating systems. “Fast” ones are installed to regulate the flow of liquid in hot water supply. The rod displacement time is 3-4 seconds.

ESBE VLE222 kvs 10, PN16, DN 10.

Features of Three Way Mixing Valve

Three-way mixing valve with thermostat for heated floors

The three-way mixing valve ensures the operation of the water heated floor in a comfortable mode. The shut-off element mixes the hot coolant coming from the boiler with cold water from the return circuit. The three-way valve, despite its versatility, has several disadvantages.

For example, when a signal is received from the thermostat, the device for supplying coolant from the boiler opens completely. Because of this, water with a temperature of 85-90 ° C enters the heated floor system and can cause overheating of the surface or rupture of the pipeline.

In addition, a three-way valve has a lower throughput compared to a two-way valve; this leads not to a smooth, but to a wave-like graph of coolant temperature fluctuations. The device is suitable for systems with a heating area of more than 250 square meters. m.

The three-way valve is made of bronze or brass; a washer is installed in its upper part to regulate the flow, under which a heat-sensitive element is located. When the valve operates, it is pressed against the operating rod extending from the body. The rod contains a fixed cone, which is hermetically adjacent to the seat. The operation scheme of a three-way mixing valve is simple - the coolant flows through the right and front nozzles until the temperature mark rises or falls to the set value. During operation, the device maintains the desired outlet water temperature within the established limits and mixes hot or chilled water from the pipes.

If the coolant begins to cool or heat up, the drive is pressed against the rod. During the movement, the cone is disconnected from the seat and opens all three channels. The front inlet pipe is closed after the temperature of the coolant changes.

Three-way valves differ in the type of external drive. They can be equipped with:

- Thermostatic drive. It presses on the rod in the process of expanding the liquid composition contained in it, which is sensitive to temperature changes. Most three-way valves used in water floor heating systems are equipped with just this type of drive.

- Thermostatic head, which contains a highly sensitive thermoelement that responds to changes in temperature in the room air. To make adjustments, the three-way valve is equipped with an external temperature sensor. The sensor is placed in the pipeline through which the coolant passes. This adjustment is the most accurate.

- An electric drive controlled by a controller. The controller continuously receives data on the temperature of the coolant in the water floor pipeline. If they change, a three-way valve equipped with a servo drive makes the adjustment.

- Servo drive. In such a locking mechanism there is no controller, and the tap is controlled directly through the drive based on signals from temperature sensors. In most cases, the servo drive is equipped with valves that are equipped with a sector or ball distribution element.

Connection diagram

For warm hydraulic floors, the valve is very often installed in a parallel circuit. To implement it, 2 or 3 heating circuits with a circulating coolant must be used. The supply and water pressure are varied by one or more valves installed in parallel. When mixing the heat carrier in parallel, it is necessary to separate the heated floor lines in advance.

Basically, control taps are adjusted on their own, manually, where the required volume of water flow is set.

Important! If a parallel circuit is used, it is recommended to replace the circular pump with a bypass valve. This is done in order to reduce the operating load and save electrical energy supplied to the pump.

The circuit has a minus - the coolant entering the circuit will be the same temperature as the water leaving the return circuit to the boiler. Due to this, hot water is distributed unevenly along the contours.

Installation diagram for underfloor heating

Two-way lock block design

An assembly drawing of this mechanism will clearly demonstrate what a two-way valve is. At a minimum, three main components are disassembled:

- hollow body;

- a plug valve having a through hole;

- inlet and outlet pipes prepared for installation with a water or gas pipeline.

Based on the shape of the movable valve, which is used to block the flow, taps are divided into several types:

- ball;

- cylindrical;

- conical

The most common form, which is considered the safest due to its simplicity, is a ball plug. A channel passing through the technical medium passes through it, and turning the attached handle rotates the plug. As a result, in the operating position, liquid or gas passes through the system unhindered, and when turned 90°, the valve closes tightly. Such a valve is not designed to partially block the flow, but it is the most common among shut-off mechanisms.

This is interesting: Technical characteristics of cast iron sewer pipes - read in detail

The advantage of warm water floors with a collector device

- First of all, you should pay attention to the cost-effectiveness of these systems. They do not require additional energy consumption due to the use of coolant from the main heating system.

- Using this principle of heating rooms, it is possible to create an optimal microclimate in the room.

- There is a potential for savings if weather-compensating type controllers are used. When the temperature outside the room decreases or increases, the heating system is automatically adjusted depending on the existing heat loss. This is much more convenient than manually controlling the valve of the faucet, which is responsible for the flow of coolant.

- Warm floors are completely safe. They have a comfortable temperature, and when touching the surface it is impossible to get burned, which cannot be said about other types of heaters.

- With the help of such heating systems you can save up to 30% of energy costs. Water heated floors are considered the most economical and rational method of heating.

- Increased hygiene characteristics are also present. Quite often, the floor is the optimal environment for the proliferation of pathogens due to the constantly high humidity during the cold season. The use of water heating systems eliminates this possibility because the floor coverings are always well dried.

Equipment Features

The main difference between the device and other valves is that it is designed to allow water to flow in only one direction. If reinstalled, it may not work correctly or fail.

Differences

Generally speaking, it has a design similarity with standard valves and a number of differences. For example, the locking element of the device may be a ball or a rod of a special design.

In this case, adjustments are made by yourself by turning the ball with a hole by 90? near the axis or by moving the rod in the vertical direction using a lever on top of the device body. Such work can also occur thanks to electric or pneumatic drives connected to temperature and pressure sensors.

Design

Depending on the features and purpose, the two-way valve may be made of various materials. Much more often this is not uncommon:

| Steel, cast iron | The control device is used in systems with a huge flow of steam or water. |

| Brass | The design has small overall dimensions and is used in ventilation systems of small rooms and buildings. |

The crane is also available in single- and double-seat versions. In the latter case, the instructions allow, through design features, to regulate up to the point of shutting off the flow, in which there is a huge pressure drop that interferes with the operation of single-seat valves.

The device can be equipped with electric drives of different operating principles, as well as:

- low power electric motors;

- retractor solenoids.

A two-way control valve can be the main control element of a cooler or heater, changing the flow of coolant to the heat exchanger. This adjustment method is the simplest, but it is not without its drawbacks, so it is best to use it in the simplest cases.

Serious knowledge

The device is created by many firms and companies in the world. Everyone tries to make personal adjustments related to the modernization and ease of use of the crane in production and in domestic conditions.

Below you will determine what you need to remember and know when choosing a device:

- It is designed to regulate the flow of oil, steam, cold and warm water in steam and heat supply systems.

- Control is carried out by electric drive, pneumatic drives, thermostats and differential pressure regulators.

- The faucet is a regulating valve, so you should install a mesh filter in front of it in order to avoid its mechanical damage. The price of the latter is small, but it does a great job. This will allow you to store the equipment for a long time without damage.

- The valve can be single- or double-seated. By splitting the flow, the latest design of the device allows the actuator to close it under high pressure drops, which is not possible with a single seat valve. The disadvantage is higher leakage when the valve is completely closed.

- The material of the faucet body gives it certain features. In most cases, steel, cast iron and brass are used (the latter can be found on sale much more often). High pressure for which the valves are designed:

- brass – up to 16 atm.;

- cast iron - up to 25 atm.;

- steel – up to 40 atm.

A two-way valve made of steel can be used at extremely high temperatures and pressures. Brass is the least resistant to these parameters.

Varieties

As already noted, the name “two-way” indicates that the device has an output and an input. But his angular or direct execution does not play a significant role. It is selected according to need.

Both straight and angle taps can be equipped with an automatic control system. It is usually implemented using an electric drive, which can operate independently. You can also control it using a remote control.

Automatic two-way control valve

Such a device is produced with a set of sensors, an electric drive and a microcontroller. Thanks to microcontroller control of the crane, it is possible to receive and process information provided by sensors. Further developments depend on how the device is programmed.

A two-way valve may not be a shut-off valve, but only a control valve. In this case, it will not be able to provide you with high-quality shutoff of the liquid flow. This is why it is necessary to additionally install separate shut-off valves. If the device is a shut-off and control valve, then there is no need for auxiliary elements of shut-off valves.

There are pass-through units that can function autonomously, and their operation does not require electrical power. This is a rod fitting with a membrane and a counteracting spring. The rod is controlled and adjusted by a diaphragm and a spring. Feedback is provided by a contour along which water moves from the route. Thus, it will direct the membrane in the right direction and at the same time move the rod to which the locking element is attached.

Types of two-way valves

Drawing of a two-way valve

Based on the shape of the body, two-way valves are divided into straight and angular. In the second case, the body is bent at an angle of 90°, which allows it to be used not only to block the flow, but also to change its direction when installing water supply systems.

By type of material

The case material can be different: in addition to metal, which are the most durable, there are also plastic models designed for a short service life in systems with low pressure media. The plastic model has a low price. This is the only thing that a two-way assembly drawing will not tell you about the crane: the body is identical in shape to the metal model, but is light and fragile. The remaining elements in it are metal, but you shouldn’t expect that such a model will last long. At best, such a two-way tap prevents the country hose from leaking for irrigation. It is strictly prohibited to use it in plumbing or heating systems of apartments. For these purposes, brass, cast iron or metal alloy taps are produced. The longest service life is built into the brass model.

Dividing type

The dividing type of three-way valve is designed to separate the main flow into two parts. For this purpose, the device has two outlets and one inlet. This option is required to distribute the coolant flows into two flows. If you include boilers and convectors in the system, then you cannot do without such a valve. A separation type valve functions in a hot water supply system to separate the liquid. Quite often it is used in air heater piping.