Home/Types of heated floors/Water heated floor. Installation of a warm water floor./Water or electric heated floor - Which one is better to choose?

Underfloor heating is a new innovative technology that serves as a source of heat supply to the room. This modern installation is divided into water and electrical structures. These models have distinctive features and qualities. Therefore, before choosing a water or electric heated floor for heating buildings and rooms, you need to familiarize yourself with all their characteristics.

Types of warm water floors

When choosing a heating design, take into account the type of installation, room parameters, coating materials, strength of supporting structures and the requirements.

The classic option is concrete technology, when the water floor is installed in a concrete screed with preliminary installation of insulation and moisture insulation.

There are also flooring systems made of wood or polystyrene. There are rack and modular types. To install a rack structure, use edged boards, and for a modular structure, use ready-made sheets (modules).

After laying the base, cover it with sheets of chipboard or plywood and lay a finishing coating of laminate or linoleum.

Types and types of electric floors

From the point of view of technical equipment, all modern electric floors can be divided into 3 main types:

- classic cable, which has several varieties;

- innovative infrared-carbon, rod and film;

- and thermomats, that is, thin cables on a mesh.

All these types of electric floors have a number of general characteristics:

- they require a dry mounting base;

- they need thermal insulation with grounding;

- they are equipped with a special thermostat.

In addition, they are all reliable and durable systems for additional heating of premises.

There are also several types of electric floors, which may belong to the same type (or may not), but differ from each other in:

- features of installation technologies;

- combination with various types of floor coverings;

- quality of generated heat.

Water heated floor installation

The liquid moves through the pressure pipeline, is discharged to the heating circuit, and as it passes through it it releases heat to the floor surface.

The cooled water returns back, entering the boiler and heating up again to the desired temperature.

Special limiters are installed in the base that connect the floor temperature with the volume of water in the heating circuit (so that the base is heated, creating an optimal microclimate).

An attempt to connect underfloor heating to an indirectly heated domestic water heater. Rationale

Calculation and design of a heating system for any of us represents the implementation of a task in which there must be two answers - saving money and achieving the desired result. In many cases, we try to make it easier for ourselves, to make heating in our own apartment very efficient, while spending little money. Actually, this reason forces us to look for other options for connecting heating circuits. The idea of using a storage water heater for this purpose is not considered exemplary, but such an option has the right to life.

The main difficulty is that the operation of a storage water heater in such an embodiment will be considered an inappropriate use, which naturally can lead to premature failure of the heating device. Home storage water heaters are designed to provide home residents with hot water at home. Placing an additional load on an electrical device means fundamentally changing the manufacturability of the device.

The decision to use an electric storage water heater as a source of heating the heat carrier can only be driven by an urgent need and desire to quickly get rid of the problem with heating a home.

Characteristics

The wooden floor structure consists of the following elements:

- base coat base;

- edged board, OSB, chipboard;

- aluminum distribution plates;

- pipelines for coolant;

- substrate for laying the finishing base;

- prefabricated screed GVLV;

- fine coating.

Wooden structures are used in old, frame and wooden houses, where a concrete screed is not suitable.

For installation, determine the appropriate option:

- modular type consists of ready-made elements;

- rack type is mounted from ready-made boards.

For the modular type, ready-made sheets of chipboard or polystyrene with grooves for installation of pipelines are used. The base is laid on logs, which are mounted in 60 cm increments on the old base or subfloor. The internal space is filled with a heat insulator.

Next, the modules are fixed to the logs, pipelines are laid and the system is connected to the hot water supply. Heat distribution plates made of metal with grooves into which plastic pipes are attached are laid out into modules.

The rack design is based on the use of boards with a thickness of 28 mm, which are laid at a distance of 20 mm from each other (to form grooves into which pipelines are mounted). Modular floors are used less frequently, but are durable and reliable.

The technique for laying a concrete system involves the use of screeds.

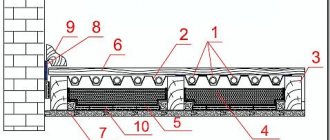

Scheme for laying a warm water floor:

- base;

- thermal insulation layer;

- reinforcing mesh;

- heating pipes;

- concrete pouring;

- substrate for the final coating and top layer (laminate, parquet).

Warm water floors are used in two-pipe heating with forced circulation of coolant and manifolds for distribution to equipment.

It includes the following elements:

- Boiler group and boiler. They create a non-stop supply of coolant to the risers (heating supply lines). After passing through the heating devices, the cooled coolant returns through the main line.

The boiler runs on solid or liquid fuel, pellets, from a heat pump, electricity, etc. The boiler room includes a pump, boiler, safety group and expansion tank;

- Radiator manifolds for pipes and heating devices;

- Return and supply lines that feed radiator manifolds, a mixing unit with a heated floor manifold. Cabinets with collectors are installed on each floor.

A suitable option in the heating design is to connect the boiler to the inlet to the pumping system. Due to the fact that the heating of the coolant reaches 35-45 C, a mixing unit is used to reduce this value. A two- or three-way valve is installed.

After this, the supply pipe for the heated floor is connected to a special manifold with outputs to circuits, thermostatic valves and flow regulators. Taps are placed on the supply and return pipelines (for possible shutdown of the operating circuit).

There are options for laying the contour:

- snake The technology is simple, but there is a drawback - the difference between the temperatures at the end and beginning of the circuit. Moving from the supply manifold to the return manifold, the coolant cools down. The method is suitable for installation in border areas;

- snail The technology is complex to implement, but ensures uniform temperatures;

- combined option. This type of installation is often used, in which the outer zones are laid with a snake, and the rest - with a snail.

Each method can use a variable masonry pitch, which in the outer zones is 100-150 mm, indoors 200-300 mm.

Pipes for warm water floors:

- made of metal-plastic. They are easy to install, hold their shape and are low cost;

- made of cross-linked polyethylene. It is inconvenient to work with them, since pipes made of this material straighten when heated;

- from copper. Pipes are expensive and must be covered with a protective layer due to corrosion.

Installation of a core floor

How to make a warm floor under tiles? It's simple. DIY installation!

Technology of laying rod-based heated floors with laying of cable mats. First, a layout is made for the placement of the canvas, and the amount of material required is calculated.

Rod floors are sold as a kit, but sometimes it is necessary to purchase additional components. The required power is calculated by analogy with the cable mats that we discussed above.

Laying a core floor consists of several stages:

- Preparatory work - determining the location for the temperature sensor, cleaning and leveling the base, placing the foil backing - these works are carried out in the same way as when installing any electric floor. If the floor is planned to be screeded, then the perimeter is covered with damper tape.

- Installation of rods - the rod roll unwinds on the surface, the distance between adjacent strips should be 50 - 70 mm. The length of one strip should not exceed 25 m. The strips are fixed to the substrate with tape.

- Connection - a thermostat is installed in the prepared area, to which the floor wires are connected. The sensor, placed in the corrugation, is placed in the groove of the substrate and connected to the regulator, which in turn is connected to the power source. A prerequisite is to conduct a test test of the system before the next stage of work.

- Pouring the screed - this can be concrete mortar, dry adhesive mixtures, or dry screed, layer thickness 20 - 30 cm.

- Installation of the finishing coating - only after the screed has completely dried is the finishing material applied. When laying tiles, no screed is required; the mats are filled with tile adhesive.

It is permissible to lay a core heated floor on an old coating. The installation principle is the same as when installing a thermomat.

Advantages of water heated floors

- efficiency. Heating large areas while reducing cash costs and water heating costs;

- uniform heat distribution and microclimate control;

- aesthetic design; there are no pipelines or heating radiators on the walls. Therefore, designers can implement different projects. In addition to a heated floor, a water heated towel rail can be used in the bathroom;

- adaptation to any energy sources, floor designs and materials;

- durability;

- safety and absence of electromagnetic field;

- readiness for installation of all finishing coating options (laminate, linoleum, parquet, etc.);

- operational installation.

When laying a wooden structure, the plus is the prevention of moisture ingress and rapid insulation.

The advantage of a concrete screed is reliable installation, strength and integrity of pipes, but the cost of such a floor will be higher due to concrete pouring.

How to achieve maximum savings

Any underfloor heating system must perform its functions as efficiently as possible. When choosing a specific model, first of all, pay attention to the power characteristics and installation specifics. However, during operation problems may arise with excess energy consumption.

This is often due to ineffective heating control systems. It is different for each type of heated floor, so it is impossible to give general recommendations - you need to consider all the examples.

Minuses

A water floor is suitable for furnishing private houses and cottages. For multi-apartment buildings with central heating, such a system will not be suitable, since it will be necessary to collect a lot of documents to obtain permission.

Other design disadvantages include:

- The need to perform complex calculations for installation;

- The need to raise the floor level by a few centimeters, reducing the height of the doors.

- If there are leaks on a concrete floor, you will have to open the base. The system is heavy and not suitable for old objects.

Therefore, first familiarize yourself with the advantages and disadvantages. It is better to install the floor in a house under construction, making the necessary calculations during the design, which will reduce installation costs.

Selecting a circuit laying scheme and its installation

When choosing an installation scheme and calculating the pitch, you should take into account that the liquid cools down as it passes through the circuit, so installation must be done from the outer walls. This will help protect the heated room from cold air entering.

The level of heating of the room depends on the layout of the heating element:

- “snake” is the easiest way for self-installation, the degree of heating decreases gradually;

- “snail” - the process is more complicated, but the room with internal walls is heated evenly.

When installing a warm water structure, the calculation data and installation diagram are taken into account. The standard laying step is 15 cm, and contours longer than 100 meters must be divided into several. In addition, each room should have a separate circuit.

Couplings or fittings are installed only when eliminating breaks or carrying out repair work on heated floors.

In addition, when preparing the calculation and diagram, the hydraulic resistance is taken into account; it depends on the number of turns; the more there are, the higher the resistance. Each circuit connected to the manifold must have the same given value.

How to choose

To choose a high-quality water floor, pay attention to the components:

- type of floor;

- finishing base;

- coolant temperature;

- room microclimate, etc.

According to the requirements of SNiP, the minimum thickness of the screed is 20 mm, but if reinforcement is not used, the figure increases to 40 mm (with a pipe diameter of up to 25 mm).

Above pipes, the thick layer does not exceed 55-65 mm in residential premises, car showrooms, fitness clubs and restaurants - up to 200 mm, for hangars and production workshops the figure rises to 300 mm.

For a water floor, pipes made of cross-linked polyethylene or polypropylene (with fiberglass) with a diameter of 16-20 mm at a critical pressure of 10 atm and a heating temperature of 95 degrees are suitable.

Control valves (to smoothly change the supply of coolant to the heating circuit) or shut-off valves (to completely disconnect the circuit from the heating) must be installed on the collectors. The manifold is equipped with an air valve and a drain outlet.

The manifold cabinet includes a pair of combs with valves. Design and develop it together with the heating, in accordance with the number of connected circuits. It is installed above the level of the structure, from where the pipes pass down.

Thermostats are installed in the collector group.

When calculating a water floor, the linear parameters of the rooms, the material and thermal insulation of the walls, the type of finished base, the parameters and type of pipelines used, and the temperature of the incoming coolant are taken into account.

Using these indicators, the length of the heating circuit, the pitch of the pipes and the layout of the screed are determined.

The water floor temperature is 29 C for the kitchen, corridors and living rooms. An exception is children's rooms, where a special operating regime is established. Near windows and external walls (with high heat losses) the temperature should be 35 degrees, and in bathrooms up to 34 C.

A properly designed and installed structure will save 12% of the released energy, preventing heat loss. Additional energy savings are provided by automatic regulators.

First, the heat loss of the house is determined, calculated taking into account the number of doors and windows, the nature of the insulation of the roof, floor and walls. Typically this figure is 40-300 W/m2.

The highest indicator is manifested in rooms with thin brick walls, without insulation, and the lowest - with excellent thermal insulation and double-glazed windows.

Heat losses are also compared with the normal output of a heated floor. It is taken into account that there remains a distance between the walls and the edges of the substrate.

That is, the total area of the system cannot exceed 70%, since the placement of household equipment and furniture in the room must be taken into account. Due to low power and limited space, the design may not heat the room completely.

The design power and the level of heat losses are calculated (the area is multiplied by the heat loss indicators). If the indicator exceeds the heat transfer, then the use of the system is irrational.

Which water heated floor is better

Components of the best water heated floor:

- concrete slab;

- waterproofing;

- damper tape;

- insulation;

- reinforcing mesh;

- pipes and concrete screed.

Waterproofing can be done with polyethylene film or special materials. The insulation is selected depending on the climate and the thermal insulation of the floors.

The contours are laid in a snail pattern. In the area of their largest accumulation, the part is covered with a heat-insulating tube.

Criterias of choice

One of the factors in selecting a liquid heated floor is the manufacturer. Systems produced by Korean companies are becoming quite popular. Therefore, you should beware of low-quality fakes. Capillary equipment for heated floors can be found from a Russian manufacturer, which produces, under license, a device similar to the Unimat Aqua heated floor.

Before purchasing an electric-water heating system, you need to determine its purpose. XL Pipe heating equipment is suitable for large rooms. In small rooms and bathrooms, you can use capillary heated floors.

The power of the device is of no small importance. It is selected taking into account the volume and thermal insulation qualities of the room. Also, before purchasing, calculations of the required contour length are made.

Exploitation

A warm water floor helps create comfortable living conditions. To create an optimal microclimate, the following indicators are supported:

- water temperature 23-27 degrees;

- air temperature 26-30 degrees;

- you should turn on the heating system in advance due to slow warming up, when the first cold weather sets in;

- To simplify maintenance and automate heating and maintain temperature conditions, automatic thermostats are installed.

You can use water floors for a year, turning off part of the structure. Branches are used that pass under the ceramic tiles, which remain cold even in the summer.

The system is resistant to the installation of furniture, equipment and other interior items; it is not afraid of overheating. But the coolant temperature should not exceed 55 degrees, which will be dangerous for the pipe material and concrete screed.

Premises requirements

Before installing a heated floor made from water pipes, it is necessary to find out whether the interfloor ceiling will withstand the additional load. With the correct installation according to SNiPs, the concrete screed above the laid pipeline with coolant should rise by 45–50 mm. It is not possible to make it thinner due to the low strength of the resulting layer, and it is not recommended to make it thicker because the energy consumption for heating the concrete increases.

Each square meter of DSP screed with grade M300 and a height of 10 mm is approximately 22 kg. Plus, the weight of the fittings and insulation, as well as the flooring, is added here.

As a result, the total load on the floor from the “warm floor” in a room of 15–20 square meters often exceeds a couple of tons. If the slab between floors is not able to withstand such additional mass, then the heating system in question cannot be built.

The installation room must be closed. It may not be heated, but sudden changes in air temperature must be excluded.

Hardening concrete and temperature fluctuations are incompatible things. Also, to dry it, you cannot resort to prematurely turning on the water floor for “heating,” which will lead to the appearance of local areas with overheating in the concrete layer. In these cases, the screed will inevitably crack and lose its strength.

Thermal conductivity of different materials

Guarantee

The durability of the structure depends on the quality of the materials, the novelty of the technologies, the professionalism of the installation of the system and the correctness of the design.

If the warranty period for the operation of an electric heated floor is designed for a period of 25 years, then for a water system it will be longer; the duration depends on the selected pipe manufacturer and the quality of the pipelines.

The warranty for equipment and materials is provided by the manufacturer. It is important to comply with the technical conditions. Please review the list before use.

The installation is guaranteed by the installers. Warranty obligations will be considered valid subject to compliance with the operating conditions that are listed in the annex to the contract.

The warranty period for work performed is from 12 months to 5 years from the date of drawing up and approval of the work completion certificate. Its duration depends on the elements used.

After the expiration of the warranty period for service, a contract may be concluded to extend the service on individual terms.

When using a water floor, attention is paid to its effectiveness (do not place it under furniture, cabinets, sanitary equipment), insulation of floors or the foundation of the 1st floor.

Varieties

There are few models of the new electric-water heated floor being produced. There are only two types of such equipment on the modern market - XL Pipe and UNIMAT AQUA. The systems differ in design characteristics, but have almost the same operating principle.

Warm electric water floors XL Pipe

The system from the Korean company Daewoo Enertec has a new heating element structure. The design of the device is a polyethylene pipe with walls 20 millimeters thick into a cavity, through which a special electrical cable is inserted.

The heating conductor consists of woven chrome and nickel threads, coated in a protective sheath of Teflon. The pipes in which it is placed are filled with liquid coolant.

The working process of such liquid equipment occurs according to the following principle:

- when the device is connected to the electrical network, current flows through the cable, heating the coolant;

- thanks to the high power of the wire and a small amount of liquid in the pipe, rapid heating of the system is ensured;

- the heated coolant increases in volume, contributing to an increase in pressure in the pipe.

Due to this process, the system quickly reaches the required operating temperature.

Electro-water heated floor XL Pipe

The manufacturer produces several models of XL Pipe underfloor heating. They differ in power and circuit length. The maximum pipe length is 84 meters. Such equipment is designed for power up to 3360 watts.

When properly installed and maintained, the XL Pipe underfloor heating unit can last over 40 years. The system does not require the installation of additional heating devices. Its main advantage is considered to be safety of use and the ability to install pieces of furniture in places where the circuit is laid.

Capillary electric floor

The representative of such a heating system is the manufacturer Caleo. The Korean company produces capillary-type floor heating equipment Unimat Aqua. The closed system consists of a device of numerous small-diameter tubes that are connected to an electrical device with an operating power of 2400 watts.

The operating principle of the capillary floor is similar to the XL Pipe electric-water equipment:

- the electrical device is connected to the network, helping to heat the coolant in the tubes;

- in this case, pressure is created in a closed circuit and intense heating occurs.

Unimat Aqua underfloor heating is used to heat rooms with a small area, since one heating system is designed for a room with a volume of 20 square meters. The service life of such equipment is short - up to 5 years.

The main advantage of capillary floor heating is considered to be a unit with a multifunctional control method. With its help, you can maintain control of the temperature of the system, as well as set the mode for automatically turning on and off the heating function. The timer is designed for twelve hours.

The maximum length of capillary tubes is 140 meters. The maximum heating of the coolant is 70 degrees, which corresponds to an air temperature in the range of 30 - 40 degrees. The disadvantages of the system include uneven heating of the floor covering. This error is due to the fact that the hot liquid that the block heats has time to cool slightly as it passes through the tubes.

Malfunctions and repairs

The water floor structure is simple in structure, which causes few problems. Heating may deteriorate as a result of:

- no noise from the circulation pump when power is supplied;

- lack of system functioning. The distribution panel should be checked on each circuit where the shut-off valves should be in the open position;

- air intake.

Troubleshooting:

- Removing air from the heating structure. The operation of underfloor heating may be defective even with high-quality installation.

The main problem is airing due to a sharp drop in pressure in the heating circuit, excessive heating, leaks and leaky connections, and improper installation.

The manifold may be installed incorrectly, the pipes may be sloping, there may be no valves to eliminate excess pressure, or air may not be pumped out of the manifold assembly during initial start-up. The system will not heat up due to the small thickness of the pipelines.

The problem is solved by overlapping all and leaving one contour, after which each branch is run separately.

In this case, the circulation pump turns on at low speeds, the pressure in the system increases to 1 kg and operates in this mode for some time at a temperature of 55 degrees.

By lowering the flow meter, the performance of the structure improves. A separator can be used to automatically remove air from pipes.

- Setting up the system. To set it up correctly, you should study the principles of operation of the collector that directs the flow of waste and warm liquid. Typically, the operation of the circuits is adjusted in accordance with the balancing table.

At the same time, the cap is removed from the valve and it is closed. Using the table, the speed in each circuit is determined by turning the valve so many times.

- Low temperature due to insufficient boiler power , which needs to be cleaned, preventive maintenance carried out or temperature sensors checked.

Heat transfer is reduced in the presence of furniture and carpets or due to poor insulation (rework and installation of high-quality insulation may be necessary).

- Uneven heating. If the system has been de-aired, but the floor does not warm up, the reason may be an inadequate vapor barrier or its absence. You can check this factor by gluing polyethylene to the floor.

If condensation appears on it within 24 hours, the system must be replaced.

- Mechanical damage (during covering installation) . First, the water is turned off, the damaged area is protected, and access to the pipeline is cleared.

The damaged area is cut, the ends are unraveled, a press coupling is put on the pipe and secured with press pliers. The tightness is checked using internal hydraulics.

- Incorrect installation.

Incorrect installation of the floor is possible with low door openings, incorrect location of the collector, installation using the “snake” technology, increased pipe spacing, and incorrect calculation of heat loss.

This is possible with an unprepared base, insufficient insulation thickness, or short pipeline length.

CONNECTING THE DHW BOILER

Let's install a hot water supply system in your home. There is such a thing as a storage water heater. This is a barrel of water that is heated by an electric heating element. So, in our DHW (hot water supply) system we also use a storage water heater, only it will be heated not by a heating element, but by a boiler and a heating power of not steam, but a couple of tens of kilowatts. Such a heater is called an indirect heating boiler (IHB). The BKN device is shown in the figure below.

The BKN is a barrel through which clean water flows (from a well). Inside the barrel there is a heat exchanger (usually a coil) through which the coolant, heated by the boiler, circulates. Pure water and coolant do not mix.

It is recommended to supply 50 liters of BCN for each person living in the house. Those. if four people live in your house, then the volume of the BKN is 4 * 50 = 200 liters. The heating power must be at least 1/4 volume, i.e. in this case 200/4=25 kW. BKN of the specified parameters allows you to obtain hot water without restrictions for almost all home uses.

Let's connect the BKN to our heating system.

This BKN connection scheme works perfectly and allows you to do without expensive three-way valves, the use of which is often questionable. Stop, you say, where did the radiator bypass line go? And we removed it, now it is not needed, since the role of the bypass in this circuit is taken over by the BKN, because the flow through it never stops.

So, we installed BKN in the system and now we have hot water

Amazing! But you can do even better!

You know that feeling when you open a hot tap and cold water comes out and you have to wait for hot water. Let's get rid of this expectation by installing a DHW recirculation system.

Noticed the changes? We have added a so-called DHW recirculation pump. It does not create pressure in the DHW system, but constantly drives hot water past your faucet. Once you open the tap, hot water will travel not tens of meters of cooled pipeline, but only 30-50 centimeters. Those. hot water comes out of the tap almost instantly. Yes, and don’t forget to install a check valve behind the mixer.

Do you know why else we need a hot water recirculation system? It allows you to connect heated towel rails even in summer, when the heating system is turned off and only domestic hot water is running.

So, DHW recirculation is connected.

Now everything is very good! But some kind of chill still remained!

Yeah, my feet are cold. We forgot about warm floors. Let's connect them.