Heating elements are a sealed tubular electric heating device made of steel, titanium or aluminum. Inside this tube there is a filler, contact rods and one or more spirals made of metal (usually nichrome) with a high resistivity.

To prevent a short circuit from occurring, the space between two metal elements - a tube and a spiral - is filled with quartz sand, magnesium oxide or periplast, which serves as a dielectric and conducts heat. During the passage of current, due to the content of nickel and chromium in the spirals, the product is galvanized - it becomes stronger and more reliable.

Heating element device

Radiator electric heating at home

Diagram for installing a heating element in a radiator

Before installing a heating element into the heating system, you need the parameters of the radiator. The main one is the diameter of the connecting pipe. Currently, manufacturers produce products in two sizes - 1/2 and 3/4 inches. Then a comparative analysis of the heating parameters is carried out before and after installing the heating element.

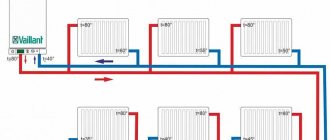

Connecting the heating element to the existing heating

If it will be used as an additional method of heating water, you need to take into account the change in hydraulic pressure when passing through the radiator. Since the flow diameter of the system this month will be smaller, it is recommended to install a pump of higher power.

When connecting a radiator to the system, installing a heating element for heating the house will not be possible. To do this, you must either change the connection diagram to the top, or install a heating element on the top of the battery, which is not recommended by experts.

They are often installed in old cast iron batteries. Before performing work, you must first check the direction of the thread of the pipe (right or left) and also measure its diameter. Then you should follow this scheme:

- Coolant drain. It is prohibited to install a heating element into a heating radiator if there is water in it;

- Checking the battery level. Even at a slight angle of inclination, the likelihood of air pockets significantly increases;

- Installing the heating element into the pipe. To seal the holes, you must use the gaskets supplied with the heating element or make them yourself;

- Installation of a unit with a thermostat, if included.

An example of installing a heating element in a cast iron radiator

After this, you need to fill the system with water. Using the installed Mayevsky crane, possible air pockets are removed. Before switching on, to ensure safety, a tester is used to check any possible heating coil-battery circuit. If there is one, you need to dismantle the heating element and install it again, improving the sealing.

Radiator electric heating

When organizing heating using heating elements made by yourself, installation of a pipeline is not necessary. A heating element must be installed on each radiator. At the same time, it is possible to install models of different power depending on the thermal conditions in a specific room of the house. The advantages of such a system are as follows:

- Saving on the purchase of materials and reducing the labor intensity of installation work;

- If you use a heating element with a thermostat for heating and a temperature sensor connected to it, the degree of heating of the room will be adjusted automatically;

- Minimum system heating inertia.

But all these positive qualities can be offset by the total cost of service. Therefore, before heating with electric heaters, you need to calculate not only the cost of purchasing materials and components, but also the subsequent costs of electricity. Only after this should a heating system of this type be introduced.

It is recommended to purchase factory radiators with installed heating elements. Their operating efficiency is higher than that of homemade ones, since special oil is used as a coolant. Even when the heating element is turned off, it will give off heat to the room for some time.

Innovative types of heating elements

New heating elements blocks are designed specifically for boilers of this brand - modifications Dymok-M, Carbon, Mix, Master, Pellet and Stakhanov, and are installed as an option to increase the autonomous operation of the solid fuel unit. The heating element system turns on automatically after the firewood is burned.

The company produces:

- TENB Zota single-end, double-end and block (consists of three tubular elements that are twisted into a spiral);

The power range of the block element is from 3 to 16.7 kW, the tube diameter is from 7.4 to 13 mm, the block diameter is G1/G2 or G2, it is equipped with a polymer cap on top that protects the product from leakage and short circuit, the length depends on the power of the product : TENB-3 has an unfolded length of 336 mm, a spiral length - 274 mm, TENB-16.7 - 525 and 463 mm, respectively;

- Heating element 2” Zota is a block heating element with a reinforced configuration.

Its device includes a control panel (PU EVT-I1), coolant and air temperature sensors, a connecting copper cable with a cross-section of 4 mm² and a length of 2 m. The power varies from 3 to 15 kW. The presence of a 2” heating element allows you to adjust the temperature throughout the night, protect the system from freezing, and save fuel and energy.

The same devices are used for Zota Topol-M and Magna boilers. Installed instead of a plug. Made from stainless steel. Antifreeze can also be used as a coolant. The ability of Zota brand heating boilers to switch to natural and liquefied gas, to use solid fuel and heating elements ensures maximum energy independence for the device and makes it the most adapted unit to climate change.

TENB 2”

How to choose heating elements

Heating element for heating with plates

How to choose the right heater for a heating system? Currently, there are many manufacturers who offer similar products. However, both quality and technical parameters do not always meet the required

Therefore, before purchasing, you need to pay attention to the following operational characteristics of the heater:

- Rated and maximum power. If a heating element is needed for a heating boiler, its power should be sufficient for the system to operate. The simplest method of calculation is per 10 square meters. at home you need 1 kW of thermal energy;

- Electrical network type. For models with power up to 3 kW, you can use a 220 V home network. If you plan to install a heater for a heating system of higher power, you should install a three-phase 380 V network. This may be due to difficulties in completing the documentation;

- The presence of a thermostat. For a radiator electric heating system, this is the main selection factor. If you purchase a heater without the ability to adjust the power, it will constantly work at maximum mode. This will dramatically increase electricity costs;

- Price. The average price of a 2 kW model starts from 900 rubles. The cost of more powerful ones can be up to 6,000 rubles. They are often made to order.

The appearance of the heating element can also affect its performance and efficiency. The best option would be to purchase a finned heating element for a heating boiler. It differs from conventional ones in that additional heat exchange plates are located on the protective shell.

Thanks to them, the heating area increases. This design is typical for heating elements in heating radiators of larger diameter. Reviews about them indicate increased heat transfer even at minimum operating mode. But their overall dimensions do not always make it possible to install them in a battery. Therefore, simple tubular type heaters are most often purchased. To increase efficiency, you can buy a block of heating elements with a thermostat. It differs from traditional ones by the presence of several heating elements on one base.

Minimum required power

For an average house in the climatic zone of the Moscow region, with 2 bricks and a ceiling height of 2.7 m, the minimum required power is calculated using a simple formula: 1 kW for every 10 m2. We also recommend setting aside a power reserve of 20-30%.

For example, for the average house described above with an area of 100 m2, the minimum required power of heating equipment is 100/10 * 1.3 (30% reserve) = 13 kW. Boilers of this power are not found on the market, so we round up to the nearest higher value - 14 or 15 kW.

When choosing a double-circuit boiler, it is recommended to add another 10-15% to the result, since when heating hot water, the heating circuit is not heated.

How to accurately calculate the required boiler power Individual calculation, formula and correction factors

Calculation of device power

In order not to overpay for electricity and prevent emergency situations, it is necessary to calculate the required power before installing heating elements in the heating system. And it won’t be possible to do this “by eye”. Calculations are made based on the fact that for heating 10 sq.m. the premises require 1 kW of thermal energy. The formula for calculating the power of the heating device is as follows:

where Pm is the design power, m is the mass of the coolant, T1 is the initial temperature of the coolant before heating, T2 is the temperature of the coolant after heating and t is the time required to heat the system to the optimal temperature T2.

Let's consider calculating power using the example of an aluminum radiator in 6 sections. The coolant volume of such a radiator is about 3 liters (precisely indicated in the model data sheet). Let's say we need to heat the radiator by connecting the heating element to the heating battery, in 10 minutes from 20 degrees to 80. We substitute the values into the formula:

Рм=0.0066*3(80-20)/10 = 1.118. that is, the power of the heating element should be about 1-1.2 kW.

The heating element is installed in the lower section of the heating radiators

However, this is only valid if water is used as the coolant. If you need to make calculations for oil or antifreeze. then a correction factor is applied, which is about 1.5. Simply put, the power of heating elements for heating oil heaters should be increased by about one and a half times. Otherwise, the estimated time to reach the optimal temperature will increase.

How to assemble an electric boiler yourself

To assemble a boiler yourself, where heating elements can be used, you need to familiarize yourself with its design. It consists of the following parts:

- block and heating element installed in it;

- security and departure systems.

Homemade boilers are smaller in size than factory ones; they can be moved from one place to another if necessary. To work on making a boiler you will need the following:

- block of heating elements;

- thermostat and temperature sensor;

- steel case with one zone for the heating element, and the second for the control unit.

Since the heating element in the heating system must be kept in water all the time, install a liquid level sensor. The permissible power of a homemade boiler is 9 kW.

Finned tubular type electric heaters

Finned heaters also belong to the tubular type of elements, but they also have ribs that are located in planes perpendicular to the axis of the heater tube. Such ribs are made from metal tape, and they are attached to the tube using washers and clamping nuts. The device itself is made from stainless steel or structural steel.

This type of heating elements are used in heating devices that heat air or gas. They are often found in devices such as thermal curtains or convectors (read: “Electric heating convectors: how to choose - little tricks”). They are used to heat rooms using thermal air mass.

Pros and cons of using heating elements for heating a home

The main disadvantage of this heating method, as in the case of other electrical appliances, is the cost of operating costs. Electricity is still the most expensive source of heat (unless, of course, you have the opportunity to use free solar or wind energy and are connected to the main power grid). Another disadvantage is the impossibility of repair if the spiral fails. However, there are some positive aspects that in some cases may become a priority.

- Environmental friendliness of the heating system. When using electric heating devices, there is no need to stock up and store any fuel, and there are no harmful combustion products that enter the environment;

- Possibility of autonomous installation of a heating system in the absence of access to other thermal resources (for example, gas);

- Small dimensions and a large selection of models in terms of power and functionality;

- Possibility of automating the heating process: installation of heating elements with a thermostat;

- Low purchase and installation costs. There are models whose cost does not exceed 1000 rubles. And you can install heating elements in heating radiators yourself.

And finally, some tips for installing tubular electric heaters yourself. How to properly install a heating element into a heating system? First of all, you need to choose the right model by measuring the diameters of the radiators where the heating element is supposed to be installed and making power calculations. Then carefully read the instructions for the device, which should indicate whether additional sealing is required or not. This is one of the most important points, since contact of the conductor with the heat-conducting liquid will cause your radiators to be energized, and this is dangerous for residents. If the manufacturer indicates the need for additional sealing, then it must be done. In addition, it is unacceptable to use electrical heating devices without grounding.

Location of heating elements in a cast iron heating radiator

Installing heating elements in cast iron heating radiators has a number of features. They are related to the diameter of the pipe and the direction of the thread. In general, the procedure for installing heating heating elements into an existing system is as follows: disconnect the heating system from the heat source, drain the water, install the heating element, fill in the coolant, check the functionality of the system. When using heating elements with thermostats in the heating radiator system, it is also necessary to check their functionality after installation. It is also advisable to install water sensors and check the angles of the radiators. Since air locks can significantly affect the operation of the entire system and damage the heating element.

What to do if the heating element in the boiler breaks down

Electric heating elements, despite their reliability, can often fail. What to do in this case? If you are dealing with a factory product, it is better to repair it yourself when you have enough experience. Otherwise, it is better to contact a specialized service center, where they will not only qualitatively repair the heating element, but also check the integrity and operability of other parts of the heating system.

If you decide to solve the problem yourself, familiarize yourself with the design of your device; information can be obtained from the website of its manufacturer or from its technical data sheet.

Before removing the heating element, you need to turn off the power to the device and then drain the coolant. The performance of the structure is checked using an indicator . Compare the indicators with those indicated in the data sheet, and if they do not match, then the device must be replaced.

Heating elements in the heating system

Different types of heating elements

Electric heating devices are often used to heat rooms. One of the varieties of such heating heating elements is tubular electric heaters. What is this widespread device? A heating element is a device for medium-temperature heating of a coolant. Structurally, it is a thin-walled metal tube with a spiral placed inside, which is made of a high-resistance material - nichrome. The ends of the spiral come out in the form of a contact rod, are sealed and are used for connection to the electrical network.

The tube itself is made of steel, carbon or stainless steel. After placing the spiral inside and centering it, the tube is filled with a special coolant - periclase and sealed. Being under high pressure, periclase fixes the spiral along the axis and after that the heating element is bent and given the required shape, depending on the model.

Regardless of how exactly the heating elements will be used - in a solid fuel heating boiler or in an infrared heater - there are certain rules for installing and operating heaters of this type. At the same time, electric heating elements can be used for a variety of purposes: to heat the garage. home heating, for installation in heating boilers or radiators. Let's take a closer look at how to use heating elements for heating.

Tubular electric heater design

Reviews of universal household electric gas boilers: advantages and disadvantages

| Advantages | Flaws |

| Dimensions correspond to single-fuel models | The simplest functionality due to the lack of modern automation |

| The cost of a combination boiler is cheaper than two single-fuel boilers | Lower efficiency compared to single-fuel counterparts |

| According to reviews from owners, a heating element with a power of 6 kW is enough to maintain a comfortable temperature all night in a house with an area of 100-120 m2 | Limited selection of models: today there are only about 8-12 models, some of which are difficult to find on sale |

| Can use both fuels at any time | Owners often note the high noise level of the burners, which is not comparable to the operation of standard burners of gas boilers |

| There are also dual-circuit models | In more than 98% of cases, you need to purchase an additional burner separately, often in another store |

| Lower installation and connection costs |

Correct choice of heating element model

When going to purchase a heating element, the buyer needs to know a number of technical characteristics:

- required power of the device;

- length, diameter and shape of the tube;

- length of the insulating cap;

- overall length;

- connection type;

- method of fastening.

To calculate the power of a heating element intended for heating water of a certain volume, use the formula:

P – power of the heated element, measured in kW;

m is the mass of the heated coolant circulating in the device, in kilograms;

tH – initial temperature of water or liquid, in °C;

tK – final temperature of water or liquid, in °C;

T – heating time of water or liquid.

Heating element in a heating radiator - video review:

Using TENs

Recently, more and more people are thinking about the possibility of autonomous heating of their home. Every year the cost of traditional heating increases, so quite often with the help of an autonomous system there is a chance to save money.

Also, sometimes there is simply no possibility of connecting to a central heating system - this is especially true for holiday villages. The only option to heat the house in this case is to install a heating boiler. Solid fuel and gas boilers continue to be the most popular, but their use is also not always possible - access to the main gas pipeline is not always available.

The best way out of such situations is to install electric heating equipment, since electrical networks are available almost everywhere. The main element of any such heating device is TEN. The efficiency of the heating system largely depends on its type. Typically, household heating equipment uses tubular heating elements, as well as elements with a thermostat. The latter make it possible to regulate the operation of the heating system.

Electric heating systems are very convenient to use: they do not emit harmful substances, since they do not form combustion products, do not require installation in a separate room, are safe to use, and are easy to install and adjust. But still, when installing electric heating equipment, you should first check whether the electrical network can withstand the high load. You also need to prepare in advance for the fact that you will have to pay a lot of money for electricity.

What is a solid fuel boiler equipped with electric heating elements?

Faced with the phenomenon of heating system defrosting, a technically reasonable engineering solution was found. Manufacturers decided to equip a conventional heating device that runs on coal or wood with electric heating elements. This modernization was made possible thanks to the design features of the heating device.

*

The main operation of the boiler is carried out by burning fuel placed in the combustion chamber. Due to the combustion process, the boiler operates in operating mode, supplying the house with heat and ensuring the operation of the hot water system. A heat exchanger is installed above the combustion chamber, being the main element of the entire structure. Unlike conventional solid fuel devices, this equipment is equipped with one, usually two or three thermoelectric heating elements - electric heating elements. Such devices can be installed directly into the heat exchanger.

In normal mode, coolant circulation through the pipeline is carried out due to gravity or forcibly, using a circulating pump. As soon as the intensity of combustion in the furnace decreases, the temperature of the coolant in the system decreases, as indicated by the temperature sensor. Electric heaters are switched on, providing the necessary heat to the cooling coolant. Accordingly, due to a decrease in heating intensity, the circulation of boiler water in the system slows down. Thus, in a nutshell, we can describe the operating principle of a solid fuel boiler with electric heating elements.

Note: There are many options for installing electric heating elements. In each individual case, the manufacturer himself determines the optimal design option for the heating device. The final result directly depends on the location of electric heating devices.

Advantages of heating elements

Heating elements (heating elements) have many positive characteristics:

- economy and efficiency - when converting electricity into heat, there is practically no energy loss;

- simple installation - you can even install a heating element for a heating battery yourself and for this you do not need to obtain a special permit from various authorities. Each device is accompanied by detailed instructions from the manufacturer, explaining the connection procedure and operating rules;

- durability - it is achieved through chrome and nickel plating;

- compactness;

- safety;

- an electric heating element with a thermostat for capillary-type heating allows you to regulate the temperature with a high degree of accuracy;

- save energy consumption by allowing the device to operate in pulses;

- affordable price;

- availability of additional functions.

In addition to its positive qualities, a device such as a heating element for heating batteries has several disadvantages:

- high cost of electric heating of residential premises due to electricity prices;

- Not in all settlements throughout the country the electrical power from the substation allows the use of these devices.

What are electric heaters?

Nowadays, tubular electric heaters for heating are popular, they consist of one or several nichrome spirals in a metal shell. Periclast is placed between the spiral and the shell - this material has excellent insulating qualities.

Modern devices have heating elements that have good strength and at the same time can change their size and shape when exposed to high temperatures. At the same time, TENs do not change their technical characteristics. These electric heating elements are used in the production of not only heating equipment for domestic purposes, but also various industrial devices. Heating elements in industrial devices must have high power. Any tubular element, regardless of its type, has a long service life. Today there are several types of heating elements produced by manufacturers of electric heating equipment. First of all, they differ in the manufacturing method, but also have other features. Manufacturers take into account the needs and interests of consumers: some heating devices are produced in large quantities, while others are produced in small quantities. Heating equipment produced in small quantities is usually used in heating systems that have certain features. Accordingly, electric heating elements in such devices are more expensive.

Equipment Features

The operating principle of the heating element is to convert electrical energy into thermal energy. During this process, the generated heat is transferred to the coolant - water. The water heats up and transfers heat through the pipes to the surrounding area.

The electric heater itself consists of a ceramic or metal tube, which is filled with a heat-conducting substance. Most often these are distilled water. Inside the tube there is a spiral that heats up and transfers heat to the heat conductor. At the junction of the spiral with the body of the heating element, bushings are installed that isolate the contacts of the spiral from the body. It is necessary to buy heating elements for boilers for anyone who wants to ensure that they do not have to constantly prepare solid fuel.

The durability of mechanisms largely depends on the quality of assembly. Most often, flange connections are used to secure the electric heater. This system perfectly isolates the internal environment of the heater from the environment.

Before you buy a heating element for a boiler, carefully study all its elements. Inspect hollow bent pipes: they are most often made of stainless steel or copper. Naturally, steel is more popular. A spiral of nichrome wire is installed inside the boiler. Manufacturers most often use quartz sand or magnesium oxide as an insulator. This is an ideal solution for those who live in climates with harsh winters. It is these heating systems that most reliably protect the boiler from freezing. If such a boiler is installed in your house, there is no need to constantly drain the coolant and mechanically drain the pipes. All you have to do is constantly maintain a low positive temperature inside the vessel.

Anyone who has standard 220 t sockets installed in their home can buy a heating element for a boiler. As a rule, most models do not require a power higher than 9 kW for stable operation, and ordinary sockets for such a device are quite sufficient.