A steady upward trend in energy costs encourages owners of private houses and apartments to take measures to insulate their homes . In addition to traditional materials, the thermal insulation market offers innovative solutions. These include sprayed polyurethane insulation, the application of which requires special installations . To simplify the installation procedure and make it accessible to the common user, manufacturers began to produce an alternative version of this material - polyurethane foam in cylinders.

Possibility of using foam fillers

Then manufacturers began to produce sprayed insulation in compact-sized cylinders, which led to a reduction in the cost of the method. To spray such a mixture of steel, complex installations and specialists in thermal insulation finishing are not needed, since the material itself is filled into small containers and the possibility of manual spraying is provided. Each cylinder is designed to cover one square meter of base (layer up to 60 mm thick). One person can process up to one hundred square meters per day.

As a result, calculations showed that working with insulation such as Polynor is much more profitable in terms of labor costs, costs for the materials themselves and surface preparation. If a professional team of workers charges up to one and a half thousand rubles for insulating one square of wall, then using Polinor insulation with the same amount of material, you need to spend only about 500 rubles. You can work independently, which eliminates the need to look for experienced workers, reduces finishing time, and saves money.

The choice of thermal insulation of this type remains the only optimal option that is available to people without special training. Foam can be used to create insulation for foundations, basements, walls inside and outside buildings made of brick, stone, concrete, and blocks. This option is also suitable for thermal insulation of non-load-bearing coatings, including floors on joists, as well as pitched roofs and attic floors.

Since Polinor is suitable for application to bases made of almost any material, it can be used as thermal insulation for plumbing fixtures and sewer pipes or fittings. In such cases, foam insulation in cylinders can be used indoors or in open areas. There is only one limitation on the use of balloon thermal insulation, which is that the material cannot be used to foam voids. It can only be applied to a dense base.

https://youtube.com/watch?v=HzNxMCfzjrE

Differences in the characteristics of mineral wool and polyurethane foam

Distinctive parameters of insulating building materials:

- thermal insulation qualities. Polyurethane foam as a spray creates a solid insulation sheet, without cracks or joints. Heat loss from the home is virtually eliminated. Mineral wool is not free from the formation of “cold bridges” through which heat escapes;

- toxicity. Polyurethane foam is non-toxic. Not flammable. Does not emit dangerous poisons into the atmosphere. Allowed for use in rooms with a high level of fire hazard. Although mineral wool is non-toxic, at high temperatures it emits toxic vapor that is dangerous to humans. She is smoldering. Not recommended for use in flammable areas;

- quality and speed of insulation installation. Cotton wool is produced in sheets. Laying requires the creation of lathing for additional fixation and cutting of the material. PPU in the form of a spray insulates the facade of the house quickly and efficiently;

- transportation. Although the cotton wool is light in weight, it is large in size. Takes up a lot of space. PPU is made directly at the point of use. Presented in the form of a small bottle. Doesn't take up much space;

- When working with cotton wool and polyurethane foam, it is recommended to use eye and respiratory protection and wear a protective suit;

- The cost of mineral wool is significantly cheaper, but if you compare how much money is required to transport it and how much scraps are left, then overall the difference is not great. Cotton wool consumption is 20-30% more than polyurethane foam. Plus, it is necessary to additionally provide vapor and waterproofing. Especially if you take into account the safety of the insulation - polyurethane foam;

- Vata is divided into several varieties. Various insulation options are used for walls, roofs and ceilings. PPU is universal. It is used in one variation for the entire home. There is no need to purchase different types of products. The task of insulating the house is simplified;

- polyurethane foam sprayer makes it easier to create the required insulation thickness. Cotton wool is purchased in the required size. It is difficult to change the thickness of the insulation on site. Is it possible to fold it in half?

- durability. The manufacturer indicates 50 years of service life for insulating materials. In practice, in just a couple of years, the material loses its thermal insulation qualities by 40%. The feasibility of using an insulating coating is 2-3 years. Polyurethane foam shows the best results, provided that reliable protection of the coating from ultraviolet radiation is provided. Otherwise, the material is not afraid of anything.

Features of the material

Sprayed polyurethane thermal insulation refers to a substance formed by mixing two components (polyol and isocyanate). To lay the finished material, pouring or spraying can be used. The first method is well suited for insulating large areas and filling voids inside engineering structures. The spraying method allows you to create a higher quality surface. In this case, the components are mixed under pressure inside special generators, and then supplied to the outside using a spray gun.

For use in everyday life and in local areas (inside cracks, gaps, openings), one-component polyurethane foam compositions were developed, placed under pressure in liter cylinders. There is no need to pre-prepare the substance here: foaming and subsequent polymerization occurs during spraying. Polyurethane reacts with oxygen, resulting in a monolithic coating of microscopic cells. The liquid consistency helps the material reach hard-to-reach areas, ensuring their sealing and insulation.

Advantages of sprayed thermal insulation

Working with polyurethane insulation is not much different from using the already familiar polyurethane foam. It does not require special skills, and all manipulations are performed quite quickly. The technological process does not require electricity or additional equipment. The tool for applying the composition is a mechanical gun with a nozzle. Polinor itself is produced in liter cylinders. This volume is calculated per square meter of surface, with a finished insulation layer thickness of 5 cm. Convenient packaging allows you to accurately calculate the required amount of material.

The positive qualities of polyurethane insulation include:

- good adhesion to most building materials,

- low thermal conductivity compared to most insulation materials,

- high speed of work production,

- waste-free use,

- long service life (up to 50 years).

Advantages of polyurethane foam insulation

Among the main advantages of the material, in addition to low thermal conductivity, the following advantages should be noted:

- excellent sound insulation characteristics;

- moisture resistance (except for open-cell material);

- possibility of application to any type and type of surface, including curved elements and filling voids;

- creation of a heat-insulating layer without seams and joints, which eliminates the appearance of cold bridges;

- high adhesion to any surface - the only exception is polyethylene, but elements from it are rarely used as a building material;

- long service life of the insulation, ranging from 25 to 50 years or more, depending on operating conditions;

- the shortest possible time required for carrying out the work, since the application of insulation, its subsequent expansion and setting occurs quite quickly. In addition, applying insulation by spraying allows you to immediately process large surfaces;

- insulation, in addition to its main task, also performs the functions of corrosion protection for metal elements;

- the low weight of the sprayed material allows it to be used for insulation without creating additional load on the load-bearing structures of the building;

- the insulation is environmentally safe and is not subject to destruction by microorganisms, and also does not require the installation of additional wind, steam or water protection.

It should be noted that, although polyurethane foam is not a non-flammable material, its use is quite safe given its ability to self-extinguish, but it is important to remember that in such cases there is an intense release of poisonous and toxic combustion products

In addition, you need to pay attention to its high adhesive ability, which is a boon for thermal insulation of surfaces, but in case of contamination of nearby areas that cannot be treated, it can only be removed mechanically, which leads to damage to the latter. Therefore, before starting work, you should protect all surfaces on which spraying is undesirable.

Therefore, before starting work, you should protect all surfaces on which spraying is undesirable.

Disadvantages of PPU

Of the negative properties of the material, it should be noted:

- relatively high price;

- the need to strictly adhere to the technology of performing the work, which creates certain difficulties when applying insulation independently;

- the lack of vapor permeability of the material requires the creation of an effective ventilation system in the room;

- vulnerability to ultraviolet radiation. All surfaces that may be exposed to sunlight must be protected with an outer layer of cladding: a curtain wall, plastering, etc.

Another significant disadvantage is the need to use special equipment and a reliable personal protective kit, consisting of a suit, respirator, and goggles.

In addition, spraying polyurethane foam requires certain skills in working with both the material itself and the equipment.

Therefore, it is often more profitable to invite professional craftsmen for this work, especially taking into account the fact that purchasing equipment for one-time use or renting it is not economically profitable, and it will not be possible to apply thermal insulation manually using auxiliary mechanisms.

But if we are talking about sealing small construction cavities or areas, then it is quite possible to do the work yourself, for example, using polynor, a sprayed material used for heat and sound insulation.

Available in cylinders and does not require special skills to use. Polinor is completely ready for use and is a material in the form of a foamed mass, in which the ratio of carbon dioxide to solid particles is 9 to 1.

The capacity of one cylinder is either 800 mm or 1000 mm - this volume of material is enough to treat an area of 1 to 2 m2, depending on the thickness of the applied layer.

When processing cavities, it should be taken into account that the insulation not only perfectly fills the space, but can also cause damage or even destruction of the structure as a result of the expansion of the material after hardening.

Therefore, such work must be carried out with the utmost care, for example, performing such foam insulation in several approaches.

pros

PPU in cylinders has the following advantages:

- Savings on transportation . Cylinders can be transported in a regular passenger car: there are no special precautions in this regard.

- Light weight . The finished hardened thermal insulation is so light that even with mass use it does not cause weight to building structures or increase the load on the foundation. This opens up great opportunities for insulating areas of a building with limited support (for example, roofs).

- Monolithicity . When hardened, polyurethane foam creates a dense, seamless surface. The absolute absence of joints and transitions protects the home from heat leakage to the outside and moisture from entering inside.

- Environmental Safety . Sprayed thermal insulation contains no components harmful to people and the environment.

- There is no need to equip load-bearing frames . In terms of ease of installation, sprayed polyurethane foam is superior to mineral wool, polystyrene foam and other traditional materials.

- Excellent adhesion . The substance “sticks” well to almost any building base. After hardening, it can be painted or plastered.

- Resistant to climatic and chemical influences . Polyurethane foam is not afraid of temperature fluctuations, direct exposure to moisture or aggressive chemicals. It, unlike other insulation materials, does not need to be equipped with vapor or waterproofing. This explains the significant service life - up to 50 years.

- High level of energy saving . In this regard, the material is superior to the popular mineral wool.

- Low requirements for installer qualifications . Any beginner can master laying polyurethane foam in cylinders: its application is very similar to working with polyurethane foam. The presence of several nozzles in the set allows you to cover surfaces of various shapes (including uneven or angled ones).

- Biological inertia . PU foam does not rot and does not attract the attention of harmful insects and small rodents.

It is important for beginners to remember that despite its high adhesive qualities, it is advisable to lay polyurethane foam on a prepared base. It must be cleaned of dust, dirt, and flaking fragments. If there are oil stains, degrease the surface.

Comparison of Polinor with PPU and Penoizol

Polinor can be used to insulate any metal tanks.

Polinor insulation, according to reviews, meets all expectations. The material is new, it appeared in 2013, but many people have learned about it in a few years. This is a complete replacement for liquid polyurethane foam, and the final cost of insulation will be lower. In addition, Polinor can cover at least 1 square meter, but polyurethane foam requires equipment that needs to be transported. Naturally, this only makes sense on large objects.

Almost 100% of the PPU structure is closed cells, while for Polinor this figure is only 70%. Accordingly, it allows steam to pass through better, which is important when insulating wooden houses. PPU is a two-component material, it is more dense. Its flammability level is lower. But still, do not forget that this is a material for professionals, which cannot be used without expensive equipment.

If we compare Polinor and Peoizol, the differences are more striking:

- penoizol with an open-cell structure;

- allows steam to pass through;

- distributes and removes moisture;

- does not burn.

Despite the fact that these two materials belong to the group of liquid insulation materials, these are completely different compositions. For more information about Polinor insulation, watch the video:

Polynor spray insulation is designed for small objects. This is a one-component, self-expanding composition with a closed-cell structure. Available in cylinders identical to polyurethane foam for professionals (for a gun). Apply a layer of 5 cm using a construction foam gun. One cylinder is enough for 1 sq. m. Thermal conductivity 0.025 W/mK, does not allow water and steam to pass through, elastic. Afraid of ultraviolet radiation and constant exposure to water. Flammability group G3, at 120 degrees the decomposition process begins. Sprayed under finishing, or under paint or plaster. Serves for at least 35 years.

Interesting on the topic:

- Insulation of facade under plaster

- Insulation of a house made of gas silicate

- Geotextile dornite: application and technical.

- Insulation of concrete with foam plastic

Technical characteristics of Polynor sprayed thermal insulation

- Type of container: cylinder

- Type of cylinder for a pistol

- Volume, l 0.89

- Weight, kg 0.89

- Productivity (coverage area), m² from 1 to 3

- Sound insulation, dB 55

- Curing time of one layer, min 20-40 min

- Complete curing time, h 24 h

- Maximum temperature of use, °C +30

- Minimum temperature of use, °C +5

- Min cylinder temperature, °C +18

- Max cylinder temperature, °C +25

- Thermal conductivity coefficient, V/mK 0.25

- Complete hardening time, h 24 h

- Seasonality all-season/winter

- Fire resistance no

- show more

How to choose from all the varieties

The choice of type of insulation depends on the situation, as well as the area of application; let’s consider some common cases in which foam insulation is used:

- You can use polyurethane if you need to repair cracks or eliminate other defects on the walls. Do not expose it to direct sunlight.

- To fill large volumes, use penoizol. In this case, it is necessary to purchase a special high-pressure apparatus, since a regular cylinder will not be enough for this.

- To seal cracks and thermally insulate a small surface area, select mounting samples in cylinders. It does not ignite when interacting with fire, does not support combustion, has an environmental composition and hardness after hardening.

Remember! Polyurethane foam is categorically not suitable for insulating the entire building, since it does not have the appropriate characteristics.

To eliminate defects that have been detected externally, foam, which contains polyurethane, is applied using direct method technology, using a machine or a special cylinder. Errors within the layer that foam insulation creates require a long hose to push the material through. To fill the air gaps inside the insulation, holes are made in the wall.

Area and method of application of Penoplex

Penoplex Fastfix heat insulator is used for coating relatively small areas that cannot be insulated using conventional methods, namely:

insulation of a balcony or loggia in any design;

sealing gaps (for example, between the frame and the wall, etc.);

filling voids between other types of insulation;

thermal insulation of complex surfaces (for example, sink or bathtub, transitions, corners, etc.).

The applicator is screwed onto the container, which allows you to apply the coating in cracks of 8...10 mm. There is a nozzle for applying foam to a horizontal surface (ceiling, roof slope). The air temperature during surface treatment is allowed in the range of -10...40° C, but the container must have a temperature of 10...30° C. Before use, the container must be shaken vigorously at least 20 times.

The coating is applied to a cleaned and dust-free surface from a distance of 20...30 cm. In closed and slotted cavities, the time of pressing the gun is determined experimentally on the basis that a layer of 5 mm foams up to 20...25 mm. The coating on the surface should be carried out in layers after the previous layer has cured (10...15 minutes). Excess foam is cut off with a knife after complete curing after 12 hours. It is recommended to slightly moisten the surface before applying foam.

How to properly insulate with polyurethane foam?

The technology of insulation using polyurethane foam has some features, and the technology for performing the work must be strictly followed - otherwise it will be impossible to achieve the desired result.

It should be borne in mind that it is naturally more convenient and best to carry out work at the stage of construction and/or renovation of a house. But it is quite acceptable to carry them out in a building in use, especially when it comes to exterior work.

But it should be taken into account that when insulating walls indoors, you will still have to do cosmetic repairs afterwards, since a decorative cladding will be required for the applied layer of thermal insulation. But another factor must be taken into account: internal insulation always loses to external insulation, and primarily due to a possible shift in the dew point, which may appear either inside the wall, contributing to its gradual destruction, or on the inner surface - in this case, problems associated with the fight against mold and mildew , can't be avoided

But another factor must be taken into account: internal insulation always loses to external insulation, and primarily due to a possible shift in the dew point, which may appear either inside the wall, contributing to its gradual destruction, or on the inner surface - in this case, problems associated with the fight against mold and mildew , can't be avoided.

Before insulation is carried out, its future thickness should be correctly calculated, which is directly determined by the climate characteristics of a particular region, as well as the thermal conductivity of the material from which the walls of the building are constructed.

And before you begin directly applying polyurethane foam, you should carry out the necessary preparatory work.

First you need to clean the surface to be treated from old coating and paint, from remnants of thermal insulation and other types of finishing.

Particular attention should be paid to areas with oily stains that can reduce the adhesion of the insulation and the surface - they are removed mechanically

In addition, weak areas of the surface also deserve attention - they also need to be removed, and if necessary and large-scale such damage will need to be repaired using repair compounds or, for example, cement-sand mortar.

What is polyurethane foam and what does it come in?

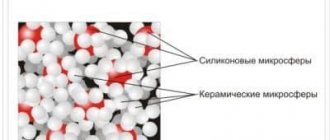

This material is a type of plastic. It has a cellular foam structure, and the composition of polyurethane foam is dominated by a gaseous substance - from 85 to 90 percent. Numerous tiny cells, isolated from each other, are filled with gas. The remaining few percent of the volume is the solid part - the thin walls of these cells.

Polyurethane foam was invented by German scientists from the company IG Farben, led by the famous Otto Bayer. However, in those days this name was not yet popular. So, in the laboratory of the city of Leverkusen, after a series of experiments, a new material was obtained, the properties of which turned out to be unique. It became clear that this substance had a lot of potential applications.

Various types of polyurethane foam are in great demand today - after all, they are very simple to produce, and right away on the construction site. In this case, the two liquid components, when mixed, enter into a chemical reaction. If the required proportions are observed, a polymer is synthesized, which is a hardened foam. By modifying the preparation recipe, you can obtain polyurethane foams that differ in properties from each other. Some of them are suitable for thermal insulation of windows and doors, others for insulating houses made of brick or reinforced concrete, and still others for a variety of pipelines.

Video. The process of producing polyurethane foam

So, depending on the proportion of the starting substances, we obtain polyurethane foams with cells of different sizes, the walls of which have different thicknesses and, accordingly, strength. We will not list all types of polyurethane foam that can be obtained by changing the recipe. Let's look at the two most popular materials of this group.

1. The familiar foam rubber, scientifically called elastic polyurethane foam, has a density of 5 to 35 kilograms per cubic meter. We encounter this material every day in the form of washcloths and sponges, filling in chairs and sofas, lining in shoes and clothes, as well as shockproof packaging.

2. Rigid polyurethane foam has recently begun to be used in construction work. But today scientists can already say what will happen to it in 30 or 50 years - the material is being studied and tested. In addition, some laboratories conducted experiments in which polyurethane foam was subjected to an artificial aging procedure. Both the results turned out to be the same.

It is safe to say that polyurethane foam does not like contact with mineral acids and organic solvents. But he is not at all afraid of water and oil products.

In our country we use a fairly large number of brands of rigid polyurethane foam – about 30. They are used both individually and in various combinations with each other. It all depends on the purpose of the application - it could be insulating a house, protecting it from noise, or creating an insulating layer on refrigeration equipment. This material has received such wide application possibilities due to its wonderful properties.

Spraying polyurethane foam on the insulated surface.

2 Features of installation of sprayed thermal insulation

In terms of the complexity of arranging insulation, Polinor foam insulation differs from rolled and slab thermal insulation materials for the better.

Using PPU Polinor can perform thermal insulation of any surfaces: horizontal – floors, flat roofs; vertical and inclined – walls, facades, roofs; and objects with complex shapes - water supply pipes, well caissons, etc.

Insulation with Polinor can be done by one person, without the need for any outside help. Foam thermal insulation is produced in compact cylinders containing enough insulation to cover one square meter (based on the thermal insulation thickness of 6 centimeters).

It is worth noting that such packaging has a positive effect on savings, since it is extremely simple to calculate the number of cylinders required to insulate an object, knowing their productivity.

Before starting thermal insulation with Polinor, it is necessary to carefully prepare the insulated surface. The wall, floor, or roof of the house is cleaned of dust and mechanical impurities.

If any damage is detected in the structure of the house, the defects must be eliminated to prevent their further spread. In case of cracks in brick, concrete, or gas silicate walls, the damage must be repaired with a mixture of glue and cement.

Next, the insulated surface is degreased using any organic solvent - acetone, toluene, 748. This must be done due to the fact that Polinor’s adhesion to an oily surface is much worse than to a clean brick wall.

Preparing the Polinor mounting gun

The PPU cylinder, before starting work, must be stored at an air temperature of 18 to 30 degrees. Before application, shake the container for 2-3 minutes.

Thermal insulation is sprayed using a special gun, which must be purchased separately, since it is not included with Polinor cylinders.

Together with a polyurethane cylinder, you will receive a universal nozzle that controls the flow and supply of PU foam, which allows you to spray Polynor with any foam gun.

It is necessary to mount the nozzle onto the barrel of the gun (until it clicks), after which the cap is removed from the end of the cylinder, after which the gun rod is screwed into the PU foam cylinder, which is in a vertical position.

As a rule, the thickness of the Polinor thermal insulation layer should not exceed 6 centimeters. The foam flow rate is regulated by the pressure of the release handle of the mounting gun. The cylinder itself must be shaken every few minutes of operation (you need to hold on to the cylinder itself, and not to the mounting gun).

When spraying thermal insulation, it is necessary to strictly adhere to safety regulations, since uncured polyurethane foam can cause harm to the human body.

Polyurethane foam can cause irritation to the eyes, mucous membranes, and areas of the skin that it comes into contact with, therefore, installation of Polinor must be carried out in a protective suit, or, in the absence of special protection, use construction glasses and gloves.

Thermal insulation of attic walls with Polinor

Victor, 29 years old, Rostov:

Oleg, 39 years old, Moscow:

Installation features

Cylinders with insulation must be kept in a warm room until they are used. This is an important point, since negative temperatures can have a bad effect on the characteristics of foam insulation.

The thermal insulation mixture can be applied both to a clean surface and to the sheathing, it all depends on the chosen method of finishing the room. It adheres well to almost any materials. Spraying is easy, even with the hands of a non-professional.

In addition to the walls and facades themselves, Polynor foam can easily be used for thermal insulation of various communication pipes, well caissons and complex construction sites.

Before applying any insulation, including Polynor spray insulation, the surface is thoroughly cleaned of dirt and debris. If defects or damage to the surface are found, they should be repaired. A crack in the wall, for example, cannot affect the insulation in any way, but it may well spread under the insulation layer. Therefore, it is better to immediately begin repairing it using glue and cement composition.

Then the insulated surface is thoroughly degreased with special compounds. This must be done due to the fact that Polinor insulation does not adhere well to an oily surface.

Then spraying is carried out with an aerosol gun, to which is attached a nozzle for controlling the consumption of material and the supply of foam.

A nozzle is installed on the barrel of the gun, and then the gun rod is screwed into the cylinder freed from the cap. The cylinder is ready for use.

Foam insulation is applied in a layer about 5 centimeters thick. The feed is regulated by pressure on the trigger of the construction gun. The foam container must be shaken every few minutes of use.

Advantages and disadvantages

The material has a number of advantages over other analogues, which justifies the demand for products using it. Here are the main advantages:

- The light weight and flexibility of the springless design makes it easy to transport. The product can simply be rolled up and compactly placed with luggage.

- Production features provide the ability to produce models of any shape and size. The material is used for the manufacture of individual orders.

- The density, flexibility, elasticity and thickness of the product can be easily adjusted during manufacturing. They can be selected depending on the purpose of the element.

- The cost of the finished product can be reduced through the partial use of polyurethane foam. At the same time, filling the corners of the mattress and a thin layer on the springs will significantly improve the sleeping properties of the product and extend its service life.

- Does not cause allergic reactions like natural fillers.

- No dust collects inside the product and no parasites appear.

Based on these properties, the consumer often chooses items with polymer filling. Let's take a closer look at how useful it is to use products with polyurethane foam padding in everyday life.

What harm can PPU cause to human health?

It is generally accepted that orthopedic mattresses that adapt to the shape of the body are beneficial for sleep. Softness and comfort can ensure healthy sleep and good rest.

- In this case, there is a serious danger to the human spine. This is due to the fact that the soft filler does not fix the spine in a straight position, and over time it becomes curved. It is better to choose a mattress for a child with hard natural padding to eliminate problems with posture.

- Similar to similar polymers, the filling for a sofa or mattress made of polyurethane foam is susceptible to moisture, direct sunlight and high temperatures. This may result in parts being damaged.

- Depending on what components were used for production, the product may pose a danger in the form of toxic substances. Their gradual release can lead to poisoning of the human body. You need to be especially careful with cheap goods.

- The ability to absorb moisture can also be an unpleasant aspect. This is due to the fact that dampness can accumulate and drying can take a long time.

Durability of products with polyurethane foam filling

If we compare polyurethane foam with other synthetic materials, we can distinguish products made from holofiber and latex from competitors.

The exact parameters of the product service life depend on the quality of raw materials, manufacturing technology, operating conditions and other factors. The estimated service life of polyurethane foam is at least 10 years.

By comparison, latex products can last longer than 20 years. Hollofiber is considered more durable and its durability under certain conditions can reach 30 years.

How to choose the right filling for a sofa

Since a sofa is a favorite place to relax for all household members, when choosing a sofa you need to be extremely attentive to the density and composition of the filling.

The price varies greatly depending on the properties of the material. Therefore, the budget should be taken into account. The best option may be a combined filler.

Pay attention to the case. If it is removable, you can easily care for the product and change the filler if necessary.

This is always more profitable than purchasing a new sofa.

What is polyurethane foam

A new type of insulation for Russia, polyurethane foam, is rapidly expanding its niche in the construction market. Poor knowledge of the characteristics of the material, aggressive advertising by manufacturers and anti-advertising of competitors have led to the fact that this material is full of myths and conjectures, among which not only ordinary consumers, but also professional builders are lost.

This is what foamed two-component polyurethane looks like.

The problems start with terminology. By polyurethane foam insulation, many understand foam rubber, familiar to everyone from childhood. But this is a soft and very elastic type of polyurethane foam, which can be used to insulate entrance doors in a building, but not structural elements. Real insulation is in liquid form.

But even here, consumers and experts make inaccuracies, considering simple polyurethane foam to be the same as polyurethane foam insulation. At first glance, they are right: both materials are made of polyurethane foam. But there is still a significant difference. PPU insulation consists of two components: “A” - polyol and “B” - polyisocyanate. When mixed, they enter into a polymer synthesis reaction with the release of carbon dioxide. The result is a foamed material with a rigid structure and closed cells. Polyurethane foam can be purchased in barrels or pre-filled cylinders.

Polyurethane foam consists of one component, which, when exposed to air, comes into contact with water vapor (which is why there is a recommendation to wet the surface before applying foam) and polymerizes with oxygen, creating open cells of frozen foam. Hence the completely different physical and technical indicators. To make it clear what we are talking about, we present a table with the main characteristics of the materials.

Table 1. Main indicators of polyurethane foam and polyurethane foam.

| Types of polyurethane foam / Indicators | PPU | Polyurethane foam |

| Thermal conductivity, W/(m×°K) | 0,022-0,035 | 0,025-0,045 |

| Number of closed cells, % | More than 90.0 | Less than 50.0 |

| Change in foam volume compared to the beginning of the expansion process | 1 in 40 | 1 to 70-90 |

| Vapor permeability, mg/(m*h*Pa) | 0,02-0,05 | 0,07-0,17 |

| Density, kg/m3 | 20,0-80,0 | 8,0-18,0 |

| Moisture absorption,% | 1,0-3,0 | 10,0-60,0 |

| Compressive strength, kgf/cm2 | 1,53-10,19 | About 1.02 |

| Bending strength, kgf/cm2 | 3,3-19,37 | About 17.0 |

One type of polyurethane foam is polyurethane foam.

The next myth is that the insulation is new, little studied. Therefore, it is better to give preference to a well-tested, albeit not the best, heat insulator.

Indeed, in Russia this type of insulation began to be used only in the mid-90s of the last century. It is finding its niche with difficulty, since consumers still prefer traditional insulation materials: expanded clay, glass wool and basalt fiber wool.

The late appearance of PPU in the CIS countries does not at all mean that it appeared in the countries of Europe and North America at the same time. There it has been known since the late 30s of the 20th century (invented by the German chemist Otto von Bayer). Today, the lion's share of the insulation market in the USA and Europe is occupied by two-component polyurethane foam.

Difference from polyurethane foam

Both polyurethane foam and Polinor are essentially polyurethane foam, but they have different qualities:

- A) Thermal insulation: polyurethane foam has open cells, in Polinor 70% of the cells are closed;

- B) Moisture absorption: polyurethane foam absorbs and then releases water, Polinor does not absorb it;

- C) Polinor is a self-extinguishing product in relation to combustion, i.e. does not support combustion;

- D) The main distinguishing feature of Polynor sprayed polyurethane foam is the “torch” for high-quality spraying.