Warm water floors must heat with the correct uniformity, that is, the water in the circuits must be distributed according to the needs of each room. Such an effective heat consumption in the pipes of a liquid floor heating collector will allow you to save money and at the same time achieve the required level of temperature increase for the parameters of a particular room. It is the flow meter (also known as rotameter, water meter) that regulates the described aspects of the functioning of liquid-heated floors, and also provides all control, monitoring and regulation of water flow. We will describe the principle of operation of the device, its design, how to perform balancing and adjustment.

Adjustment of heated floors with flow meters, principle of collector balancing

Currently, most residential owners prefer to use warm water floors for heating.

The efficiency of this design depends on proper coolant flow. Adjusting the flow meter of the underfloor heating manifold will allow you to monitor water consumption in the pipeline and fine-tune the system.

This device can facilitate the balancing process and rationally distribute liquid over the heating circuits, thereby creating uniform heating of all rooms.

Tags

Heated floor heated floor heated floor vaulted floors. heated floor. has a polypropylene float, it has full control and is polycarbonate. This position will allow the circuit completely or Warm floor Adjustment of heated floor heated floor collector coolant flow. heated floor collector. adjustment of coolant by volume of coolant you need you need a flow meter or Flow meter device install a flow meter with flow meters and clean the flow meter adjusting the manifold flow meter You need a flow meter or a flow meter device a group of flow meters running in the flow meters in

than control the sensor

Do you need a flow meter or not?

A flow meter is a device designed to adjust the operation of a heating floor, which is more often used in multi-circuit water structures. Without it, it is difficult to achieve proper heating of the room. It is very difficult to manually adjust the underfloor heating manifold.

Conducting adjustments to underfloor heating circuits using flow meters - normalizing fluid flows through coils. Indeed, depending on the size of the branch, a different amount of it is required, which, moving along the loop, would cool strictly according to the calculated indicator.

In a design without a flow meter:

For your information! The opinion that it is possible to determine the optimal water flow based on the performance of the circulation pump is erroneous.

Since, firstly, it is difficult to accurately calculate the length of the coil, and secondly, the rule is violated when choosing equipment parameters - based on the needs of the device, and not vice versa. In addition, calculation using this method will lead to the fact that the volume of liquid in the circuits will differ from the calculated value.

Other Important Factors

In addition to the settings on the thermostat and the floor heating curve, other factors also play a role. It should be noted in advance that underfloor heating has different heating circuits. Here too the flow and return are separated. They are found in the so-called heating circuit. This allows home owners to regulate the space in different ways.

If it is necessary to hydraulically balance the heater to ensure optimal temperature distribution, this must also be taken into account. By the way, this should always be done by a specialist who sets different pressures for each circuit. So what should the flow rate be for it to become warm enough?

The following factors should be noted:

- Required heating power in the respective room

- Flow rate

- Pipe length

- Grounding and its thickness

- appropriate supply temperature

Conclusion

Adjusting floor heating has many practical advantages. It will give you more comfort by making changes to the thermostat in terms of automation. In addition, the above settings can of course also reduce energy costs, especially if the shutdown is chosen intentionally. Changing the heating curve, however, ensures ideal heating of the room and optimal energy use, depending on the season.

HelpfulUseless

Flow meter device

A rotameter is a mechanical device whose body is made of plastic or brass. It has a polypropylene float placed inside. The top of the case is equipped with a transparent bulb with a scale. This device is also called a float rotameter.

For your information! More often, a plastic rotameter is used in underfloor heating.

It is recommended to install a mixing unit with flow meters and a thermostat on the return line. This device is capable of supplying each loop with the required amount of coolant, and the outlet valves will open and close as the water cools.

It should be said that there are several types of water meters:

Water meter design

The design of the rotameter is mechanical, the material is plastic and/or metal (brass). The upper segment of measuring and adjustment models has a transparent tube with graduation.

There is a float inside, which is why the device is called “float”. This element, fixed to the rod, is supported by a spring (the flow changes the pressure, compresses/decompresses it). At the bottom inside there is a valve connected to the described elements, which changes the flow of liquid according to their position.

Operating principle and functionality

The main function of the flow meter is to ensure adjustment of the coolant along the circuits. The presence of rotameters allows:

For your information! The need to equip the collector group with flow meters when constructing heated floors is especially acute in a house where the rooms have different areas.

The larger the room, the lower the degree of heating. Thus, it is very difficult to achieve uniform heating without this device.

The operating principle of flow meters in underfloor heating manifolds is quite simple. The coolant, moving in the circuit, sets the float in motion, as a result of which it begins to move. Taking into account its location, the amount of water in the coil is determined on a scale printed on the flask.

The water meter operates autonomously and does not require an additional power source. And the presence of a mixer with such a device will greatly simplify complete control over the design, while installation of the device and its maintenance are simple.

Criterias of choice

In many ways, the correct functioning of the system, and thereby the comfort in the room, is influenced by the model of the flow meter. Therefore, its choice should be taken very seriously.

When buying a rotameter for heated floors, you need to pay attention to:

- The material from which the body is made. Brass - has high wear resistance, and the top of such a device is coated with nickel. This product is expensive. Plastic is affordable, but it is also less durable.

- Integrity - before buying a product, you need to inspect the body and flask for cracks and defects.

- The inner spring must be steel.

- Flask. In quality products it is polycarbonate. This material has increased heat resistance and strength.

- Technical indicators - they can be found in the instructions. The temperature is not less than 110 degrees, and the pressure is 10 bar.

- Throughput - at least 2 - 4 m3 of water must pass through the rotameter.

- Reliability of the manufacturer - a mandatory quality certificate for the product and a warranty period of at least 5 years. Unscrupulous manufacturers, in order to make a profit, try to replace expensive and high-quality elements of the device with lower quality ones.

There is a huge selection of these devices in stores, so by following these tips, you can purchase a quality product.

How to install a flow meter correctly

According to the manufacturer's recommendation, the flow meter is mounted on the return of the collector, although installation on the supply is possible.

The main requirement when installing a rotameter is vertical placement. This position will allow you to correctly calculate the water level. Therefore, the comb must be positioned strictly horizontally. The installation accuracy can be determined using a plumb line or level.

Since the device - a collector plus a rotameter - must work automatically, an additional connection of a temperature sensor is required. This scheme completely or partially blocks the flow of coolant to the loops when the required heating degree is reached.

Do-it-yourself collector installation: connection diagram and configuration, types and principle of operation.

The flow meter installation process itself is as follows:

For your information! This connection does not require additional insulation.

After these steps, you must check the entire system for functionality.

Adjustment of the underfloor heating manifold with flow meters and its adjustment

After making sure that the structure is functioning, many people have a question: how to properly regulate a heated floor using flow meters? The process is simple, because the use of rotameters greatly simplifies the procedure.

With manual adjustment, the work is quite labor-intensive, since the adjustment is carried out using a conventional tap - a thermal head, which is installed on the return and supply.

This method significantly reduces the cost of installing the structure, but such adjustment will take a lot of time. In addition, the accuracy of the settings suffers during manual balancing, because you will have to determine the temperature based on your personal feelings.

The most convenient method is to carry out adjustment work using flow meters installed at the entrance to the coil. Separate adjustments should be made in each room, taking into account the level of fluid heating and hydraulic resistance.

All that will need to be done subsequently is to monitor the difference in indicators between the circuits; they should not exceed 0.3 - 0.5 liters.

Before setting up a warm floor on a collector using flow meters, you need to understand why this is necessary. The task of balancing is to establish the need for each branch and the overall balance of costs.

In addition, the correct setting of the flow meters on the manifold affects the quality of the floor covering during operation - after all, it should not overheat. Higher temperatures will damage the flooring product and require replacement.

The operating principle of underfloor heating differs from other heating devices. The peculiarity lies in the difference in water temperatures: if liquid circulates in radiators, heated to 80 degrees, then in a warm floor it is 40, while the surface warms up to 22 degrees.

For your information! There is an opinion that a warm floor system does not need balancing, and the water flow in the loops is regulated independently, using automatic devices - thermostats and controllers, but this is incorrect reasoning.

Regulatory process

As mentioned above, it is necessary to carry out separate adjustments for each circuit, taking into account the pipeline layout. After all, the volume of coolant required for each coil is different, and depends on its length.

This indicator is determined by the formula - the heat load is taken in relation to the heat capacity of water, and to the temperature difference at the inlet and outlet. Before the procedure, it is necessary to check the installed circuit for leaks, as they will distort the indicators during adjustment.

Avito apartments Pavlovsk Voronezh region

To do this, the pipeline should be filled with water and vented, that is, open the flow meters, three-way valve, air vent, and shut-off valves on the supply and return.

This procedure is accompanied by a whistling sound; when it stops, this indicates complete release of air. After which, all valves are closed except one on the supply side, and pressure testing of each circuit is carried out one by one.

Then, you can proceed to regulating the flow meters of the heated floor, the procedure is as follows:

For your information! Further, the flow rate in other coils will be set relative to it.

After the flow meters are configured, the circulation pump on the distribution unit is turned on. Hot water will begin to flow into the pipeline, which will displace cold water; this procedure will take 3 hours.

For your information! Before putting the floor into operation, the flow meters should be set to maximum values, usually they are different for each branch, and subsequently they need to be adjusted so that the heating is uniform.

It is worth saying that the process of adjusting a system with a rotameter depends on its model. If the flow meter does not have a built-in valve, then an additional shut-off element is required, which helps to set the “open” position. In this case, the balancing process occurs while the device is functioning.

If you have a combined type of device, it is recommended to carry out preliminary adjustment by turning the built-in valve to full power.

Source

Control elements

Setting up a heated floor collector is impossible without special devices. With their help, the optimal heating mode of the system is established and water flows in the pipelines are regulated. Each of them performs a specific function.

- Water temperature sensor

Installed on the inlet and outlet pipes of the device. These devices do not affect the operation of the system, but indicate the current heating rate. The difference in values can be useful in calculating operating efficiency. They also serve as an indicator of heating mode violations.

- Central thermostat with servo mechanism and sensor.

It is mounted on the inlet pipe of the inlet manifold and connected to the return pipe with cooled coolant. The temperature sensor is placed in the comb body. There is a rotary knob on the body of the thermostat with which you can set the required temperature level. The device receives readings from the sensor about the degree of water heating. Depending on this, the flow of cold and hot coolant is regulated.

- Servo drives on the inlet comb nozzles

According to the principle of operation, they are completely similar to a thermostat, but with minor additions. With their help, the volume of water flow for each circuit of the water floor is regulated. Depending on the model, this can be done in manual or automatic modes. For the latter, servos with built-in temperature sensors are used, which can be connected to a common remote thermostat.

- Flow meters

Devices that are optional for installation, but which, however, can become effective elements for manually controlling the operation of a water heated floor. They are installed on the return manifold pipes and are locking mechanisms with a glass bulb.

When you turn the head on the body, the rod in the device changes its position. This affects the volume of liquid passing through it. For clarity, a measurement scale is printed on the surface of the flowmeter, indicating the flow rate of water l/min.

Functionality and principle of operation of the flow meter

The main function of flow meters or, as they are also called, float rotameters in a heated floor system is to regulate the coolant flow in water circuits. Installing such a device allows you to:

The need to use flow meters arises in buildings where floor coverings of different areas are heated. Large rooms require a longer pipeline length, so they heat up less intensely than small rooms. Therefore, it is possible to achieve uniform heating and ensure a comfortable temperature throughout the entire house only with such a device.

The flow meter for a floor heating system is a mechanical type device with a plastic or brass housing. Inside it is a float made of polypropylene. On the top of the body there is a transparent bulb with markings. During the circulation of the coolant, the float comes into action, moving up and down. According to its location, you can use a scale to determine the volume of liquid in the pipeline.

Installation and adjustment

According to the manufacturers' instructions, the rotameter is connected to the return collector, but there is an option to install the device on the supply.

The main requirement for installing the device is its vertical location. This installation allows you to determine the exact value of the liquid level in the flask. Therefore, the comb must be placed strictly horizontally in level.

The rotameter is connected by screwing into the corresponding socket on the manifold. The device comes with an O-ring and a union nut. There is no need to additionally seal the device with sealant or other materials.

The workflow of the connected circuit manifold - manifold and flow meter must be fully automated. Therefore, a temperature sensor is additionally connected to the system. With this scheme, when the specified temperature regime of the coolant is reached, the system blocks its full or partial access to the circuits.

The entire installation process and adjustment of the rotameter for heated floors is performed in the following sequence:

After such actions, it is necessary to check the operating process of the entire underfloor heating system. During operation of the heated floor, do not close the flask on the flow meter. The scale must be constantly visible, since sometimes there is a need for balancing during operation of heating equipment.

According to technical rules, identical installation of several contours, including their length, should be carried out. Otherwise, even using a collector with a rotameter will not give a positive result, and the system will not function correctly.

Flow meter installation principles

The flow meter is connected when the collector and heating circuits are connected. To perform the task correctly, the equipment should be fixed on a special comb to which the waste coolant flows. When the required surface temperature is reached inside the collector, a valve is activated, which blocks access to water.

Setting up heated floors using flow meters requires the use of a thermostat. It is necessary to optimize operation and comply with a given scheme. When installing all elements, you should adhere to extreme compactness in order to prevent operational problems in the future.

Perform installation in the following sequence:

- screwing the flowmeter into the technical hole of the installation using a wrench of the required size;

- preparing the equipment for operation (this requires turning the flask in a counterclockwise direction);

- dismantling the fuse installed by the manufacturer;

- setting the required pressure by turning the brass ring clockwise;

- place a special pad on the ring to prevent mechanical vibrations;

- test the functioning of the entire structure.

Before proceeding with the actual installation, you should make sure that you have all the necessary tools and components.

Features of adjustment

For each individual room, the rotameters are adjusted separately. Control is carried out according to the diagram of the installed circuits. In this case, the level of heating of the liquid and pressure is taken into account.

It is recommended to carry out balancing according to the following instructions:

Using these steps, you can perform long-term adjustments to the water circuit. To indicate the actual parameters, it is necessary to observe the flow meter readings. According to observations, it is possible to accurately determine the flow rate of the circuits connected to the collector.

The flow meter is adjusted depending on the installed model. After connecting the device to the manifold, preliminary settings should be made by setting the initial position, which allows access to liquid.

In rotameters without a built-in valve, an additional locking device is used to set the “open” position. In this case, balancing is performed during the operation of the system.

Combination devices for metering coolant flow can be pre-set using full turns of the built-in valve. Each turn allows you to reduce the clearance by a set value.

Adjustment of the flow meter of the floor heating system is carried out taking into account the control of the fluid speed in one minute - from 0.5 to 5 liters.

Before setting up the rotameter, you should check the condition of the installed circuit. Trial testing is necessary to exclude the presence of leaks in the circuit, which could cause distortion of the indicators in the device.

The flow meter is an important element in a multi-circuit underfloor heating system. The device allows for a uniform flow of liquid into all individual pipelines. In order for heating equipment to function as efficiently as possible, you must select the right rotameter, as well as install and configure it in accordance with technical requirements.

Source

Typical connection diagrams

Water heated floors are rarely used as the only source of heating. Heating only due to underfloor heating is permissible only in regions with a mild climate, or in rooms with a large area, where heat removal is not limited by furniture, interior items or the low thermal conductivity of the floor covering. Almost always it is necessary to combine radiator circuits, hot water preparation devices and underfloor heating loops in one heating system.

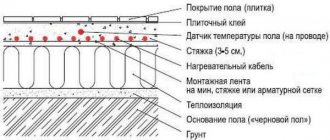

Typical diagram of a combined heating system with connection of radiators and underfloor heating circuits. This is the most technologically advanced and easily customizable option, but it also requires significant initial investment. 1 - heating boiler; 2 — safety group, circulation pump, expansion tank; 3 - manifold for separate two-pipe connection of radiators in a star configuration; 4 — heating radiators; 5 - underfloor heating manifold, includes: bypass, three-way valve, thermostatic head, circulation pump, combs for connecting underfloor heating circuits with gearboxes and flow meters; 6 - heated floor contours

There are quite a large number of variations in the design of the boiler room piping, and each individual case has its own principles of operation of the hydraulic system. However, if you do not take into account very specific options, then there are only five ways to coordinate the operation of heating devices of various types:

oil for facades and terraces v33

The simplest option is to connect a heated floor circuit to a radiator heating system with a coolant temperature of 70-80 °C. 1 - line with supply and return of the high-temperature circuit; 2 - heated floor contour; 3 - unibox.

It must be remembered that the nature of the operation of a heated floor may also change depending on the installation pattern of the coil. The “snail” scheme is considered optimal, in which the tubes are laid in pairs, which means that the entire area is heated almost evenly. If the warm floor is arranged as a “snake” or “labyrinth”, then the formation of colder and warmer zones is practically guaranteed. This drawback can be eliminated, including through proper configuration.

The feasibility of installing a collector system

But it is impossible to install a collector heating system in an apartment of old multi-storey buildings, because a tee heating system is already working there. For the collector system to operate, it is necessary to close the hydraulic circuit, which is necessary to create coolant circulation in the system. If a closed hydraulic circuit is created in one apartment, then other apartments will be cut off from the heating system.

The collector heating system also cannot be used in areas with unstable power supply, since when the circulation pump stops, the water will freeze and the pipes will fail. But the situation can be somewhat improved by using

Setting up a warm floor

And now, the heating system is filled and tested, the boiler is started. Everything is ready to set up the heating system.

Before you start setting up heating, you need to decide on its goals and objectives. The main task of balancing is not to establish the required flow rate in each loop, but to establish the ratio of flow rates across loops or flow balance. It is worth remembering that the final flow rate is set during setup of the pumping and mixing unit. By changing the total coolant flow through the collector, the ratio of flow through the loops will remain the same.

Setting up heated floors using flow meters

The presence of flow meters on the collector block has a significant effect on balancing. Flow meters significantly speed up balancing and allow it to be done without turning on the boiler. This is possible because the flow meter shows the coolant flow for each circuit in real time.

The distribution of coolant flows must be carried out in such a way that the ratio of flow rates along the loops and the ratio of the required thermal powers coincide. To achieve this, it is advisable to know the required thermal loads on the hinges. But even if this data is not available, you can set the costs in proportion to the lengths of the loops. In most cases, this approach does not produce a large error due to the fact that loops with large lengths also have greater powers.

Balancing starts with the longest loop or the highest power loop if known. Next, the control valve on this loop opens to its maximum position. In the future, the costs of all other loops will be billed in relation to it.

For example, consider a manifold with four loops. Let us assume that the loop lengths are as follows: 100, 75, 75 and 50 m.

As we have already said, the setup starts with a larger loop, which is 100 m long. It opens to the maximum. Let us assume that with the valve fully open, the flow rate in this loop is set at 4 l/min.

The coolant flow rate on the second and third loops should be: (75/100) · 4 = 3 l/min.

The coolant flow on the fourth loop should be: (50/100) · 4 = 2 l/min.

Problems when setting up a heated floor

In practice, it may turn out that on the third loop the flow rate with the valve fully open will be set at 2.5 l/min, although we need a flow rate of 3 l/min. This suggests that this loop has greater hydraulic resistance than a second loop of the same length. As a rule, this happens due to the presence of a larger number of branches, rolls or supply areas. If this happens, then you will have to turn on the boiler and carry out further balancing with the boiler on and at least with minimal heat removal in the room.

In this case, the first loop will be adjusted to (100/75) 2.5 = 3.3 l/min, the second loop to 2.5 l/min, and the fourth loop to – (50/75) 2.5 = 1.6 l/min.

After all the costs in the loops have been set, the balancing of the underfloor heating loops can be considered complete. The next step is setting up the pumping and mixing unit.

Setting up a heated floor without flow meters

If flow meters are not installed on the collector, then the flow rates in the loops will have to be judged only by indirect evidence.

Balancing without flow meters is carried out only with the boiler on and at least with minimal heat removal in the room. It is better if the temperature outside is not lower than +5 ºС, while there should be no open windows or any significant heat emissions in the rooms, for example, a working fireplace. After this, the system must be left to warm up for several hours until the temperature in the loops has stabilized, after which it is necessary to evaluate the correctness of the settings.

The correct system setup is determined in one of the following ways:

Appearance of a problem

First of all, you need to analyze a specific example of the occurrence of such a problem and its consequences:

- You install heated floor

in the bathroom, guest room and kitchen; - They are connected to one collector;

- The area of the bath, kitchen and living room is clearly different, due to this the length of the heated floor

will vary in any room, and naturally the consumption of the coolant (water) will be completely different.

It is necessary to say what this will lead to. Short heating rings have less hydraulic resistance, due to which the water in them moves much faster than in long circuits, which creates a temperature difference in the rooms at the same temperature of the coolant supplied from the collector.

An example of a solution to a problem, in which we will analyze the principle of correction, will be a primitive wall-mounted radiator. If you connect radiators with different numbers of sections and pipe lengths to one collector, the problem described above will appear (read: “Heated floor collector diagram - how everything should work”).

The problem with radiators is easily solved, because the instructions say that by installing a thermostat on each battery, you will be able to control the quantitative flow. In most cases, the thermostat is a traditional valve. A similar problem is solved with a heated floor system.

Functionality and principle of operation of the flow meter

The main function of flow meters or, as they are also called, float rotameters in a heated floor system is to regulate the coolant flow in water circuits. Installing such a device allows you to:

The need to use flow meters arises in buildings where floor coverings of different areas are heated. Large rooms require a longer pipeline length, so they heat up less intensely than small rooms. Therefore, it is possible to achieve uniform heating and ensure a comfortable temperature throughout the entire house only with such a device.

The flow meter for a floor heating system is a mechanical type device with a plastic or brass housing. Inside it is a float made of polypropylene. On the top of the body there is a transparent bulb with markings. During the circulation of the coolant, the float comes into action, moving up and down. According to its location, you can use a scale to determine the volume of liquid in the pipeline.

How to adjust a warm water floor manually preparation and input

Manual adjustment is carried out using a conventional tap called a thermal head. It is mounted on the return and supply. Using a crane allows you to avoid loading the system with automation and additional equipment. This significantly reduces costs, but creates a number of inconveniences. High-quality and quick adjustment of a warm water floor with a thermal head is a myth. You will have to turn the tap often, and when determining the temperature, rely solely on personal sensations.

Important! It is considered more convenient to regulate water heated floors using rotameters (flow meters), which are installed at the entrance to each circuit (manifold installation location). All you need is to control the permissible difference in instrument readings

It is 0.3-0.5 l.

Correct adjustment of a heated floor with a thermal head requires compliance with the commissioning standards of the entire system. Otherwise, the system of main or auxiliary heating of air masses from below the room will malfunction.

Results

It is important to ensure that when the water floor heating system is operating, the flow rate on the collector is visible. This is necessary for maintenance. Each water circuit must have its own flow meter.

We recommend: What are the characteristics of Aura underfloor heating?

As you can see, in the equipment, each element performs its own functions, so each one needs to be given sufficient attention, and in order for the entire system to work as one whole, it is worth equipping it with a flow meter and a collector, which will evenly distribute all the heat.

- Related Posts

- How to lay a heated floor without screed?

- How to fill a heated floor?

- How are PEX pipes connected for heated floors?

- How does a comb for heated floors work?

- Rating of manufacturers of heated floors for tiles

- How to connect heated floors in an apartment?

Temperature

Before you begin adjusting the heated floor, it is extremely important to establish a clear understanding of the purpose for which it is being done. According to the principle of operation, water-heated floors are fundamentally different from other heating devices.

The main difference is the operating temperature of the coolant. If the radiator network is supplied at temperatures up to 80 °C, then the heating of the coolant entering the heated floor coil is limited to 40–42 °C. This need is due to reasons of comfort and safety. In normal mode, the temperature on the floor surface fluctuates in the range of 22–26 °C; stronger heating causes unpleasant sensations.

There are two ways to regulate the heating temperature of a liquid heated floor. The first of them involves controlling the temperature on the supply branch of the collector by mixing in a portion of cooled coolant from the return. Technically, this solution is implemented by installing a three-way valve with a pressure-action RTL thermostatic head. The difference between such a head and a radiator head is that it relies on the temperature of the coolant, not the air. With this control method, the flow rate in the loops remains constant, only the coolant temperature changes with a small amplitude.

what size hydraulic accumulator should I choose for a private home?

The second adjustment method involves limiting the flow of hot coolant in the circuit. In this case, a thermostatic head is also installed, but it is located on a two-way valve, which interrupts the return flow circuit. With this method of regulation, the supply and return are connected by a bypass circuit, the flow through which is regulated by a restriction valve with a pre-calibrated throughput. The principle of such regulation is based on the high inertia of the heated floor system. During operation, the coolant is supplied to the loops at the nominal temperature of the heating unit; only the total flow rate changes periodically. Thus, heating of the screed occurs cyclically, that is, a significant heat capacity of the accumulating layer is required to smooth out temperature changes.

In both cases, one important rule applies: the thermostatic fittings are necessarily based on the temperature of the return flow of the loop or collector. The device can have a mechanical or electronic principle of operation, it can even be a regular thermometer

The need for correct location is due to the fact that it is almost impossible to judge the effectiveness of the adjustment based on the temperature of the coolant at the supply, because the length of the loops can differ significantly.

Balancing underfloor heating loops

While preparing this article, I read many different opinions of experts on setting up heated floors. And here's what I don't agree with:

You can often hear that it is possible to correctly balance a heated floor system only through calculations, calculating the resistance of all loops and calculating the setting position of the control valves. I don’t argue that competent hydraulic calculations will speed up the setup process and protect against installation errors. But in practice, setting up a heated floor can occur without theoretical calculations, although this will take more time. The most important thing is that a project with hydraulic calculations costs money, and we are aimed at smart savings.

Many experts believe that the coolant flow in all loops should be the same. In practice, the fluid flow in the loops mainly depends on the thermal power that each specific loop transmits to the room.

There is an opinion that the underfloor heating system does not need to be balanced at all, and the coolant flow in the loops will equalize itself due to the operation of thermostats, controllers and other automation devices. I do not agree with this statement, since sooner or later conditions will arise when all the hinges of the heated floor will be forced to open to the maximum. In this case, the distribution of coolant in the system must be such that all the liquid does not go into one loop, but is evenly distributed over all circuits.

Features of adjustment

For each individual room, the rotameters are adjusted separately. Control is carried out according to the diagram of the installed circuits

In this case, the level of heating of the liquid and pressure is taken into account

It is recommended to carry out balancing according to the following instructions:

Using these steps, you can perform long-term adjustments to the water circuit. To indicate the actual parameters, it is necessary to observe the flow meter readings. According to observations, it is possible to accurately determine the flow rate of the circuits connected to the collector.

Manifold with flow meters for heated floors

The flow meter is adjusted depending on the installed model. After connecting the device to the manifold, preliminary settings should be made by setting the initial position, which allows access to liquid.

In rotameters without a built-in valve, an additional locking device is used to set the “open” position. In this case, balancing is performed during the operation of the system.

Combination devices for metering coolant flow can be pre-set using full turns of the built-in valve. Each turn allows you to reduce the clearance by a set value.

Adjustment of the flow meter of the floor heating system is carried out taking into account the control of the fluid speed in one minute - from 0.5 to 5 liters.

Before setting up the rotameter, you should check the condition of the installed circuit. Trial testing is necessary to exclude the presence of leaks in the circuit, which could cause distortion of the indicators in the device.

The flow meter is an important element in a multi-circuit underfloor heating system. The device allows for a uniform flow of liquid into all individual pipelines. In order for heating equipment to function as efficiently as possible, you must select the right rotameter, as well as install and configure it in accordance with technical requirements.

Finally, the heating system of my house is assembled. The boiler is started. Let me remind you that I decided to heat my house only with heated floors. Although there are not many rooms in the house, in order for the comfort in all rooms to be the same, it is necessary to adjust the heated floor. We will talk about how to set up a heated floor in this article.

Setting up a heated floor is not as complicated as it might seem at first glance. Generally speaking, setting up a heated floor consists of three stages. First, balancing the underfloor heating loops, then setting up the pump and mixing unit, and finally setting up the controller if you decide to automate the heating system. I decided to fully automate the heating system in my house. Therefore, I purchased a controller, servos and temperature sensors. Let's look at the first stage of setup in detail, since the success of the entire setup depends on how well it is done.

Working with Manifold Flow Meters

Hydraulic balancing of underfloor heating loops involves normalizing the flow in each coil. Depending on the length, different amounts of incoming coolant may be required so that when passing through the loop it cools exactly to the calculated value. The required flow is quantitatively determined as the ratio of the thermal load on the loop to the product of the heat capacity of water or other coolant and the temperature difference in the supply and return: G = Q / s * (t1 - t2).

You can often find recommendations to determine the coolant flow according to the performance of the circulation pump, that is, to divide its supply in proportion to the ratio of the lengths of the loops. Such advice should be avoided: in addition to the fact that it is quite difficult to calculate the length of each coil, one of the most important rules is violated - choosing equipment parameters based on the needs of the system, and not vice versa. Attempts to distribute flow in the described manner almost always lead to the fact that the flow in the loops differs significantly from the calculated values, which makes further adjustment of the system impossible.

Adjusting the flow with flow meters is quite simple. In some models, the throughput is changed by turning the body, in others - by rotating the rod with a special key. The scale on the flow meter body indicates the flow rate in liters per minute; you just need to set the float to the appropriate position. Almost always, when the capacity of one flow meter changes, the flow rate in the remaining loops changes, so the adjustment is carried out several times, sequentially calibrating each outlet. If such changes are particularly pronounced, this indicates a lack of capacity of the control valves through which the collector is connected, or that the performance of the circulation pump is too low.

Source