If you are deciding which is better - polystyrene foam or polyurethane foam, you should compare properties these materials. In addition, it is necessary to take into account terms of Use, because in different rooms it may be preferable to use one or the other option. To conduct a full comparative analysis, the following factors are taken into account: structure, service life, strength and thermal insulation characteristics, hygroscopicity, noise absorption efficiency, density and some other parameters. The cost of the product is also important.

Briefly about 2 materials

Expanded polystyrene (EPS) is a gas-filled, closed-porous material based on polystyrene; its cells contain natural or carbon dioxide; there is also a vacuum version. There are 2 types:

- foamed;

- extruded (extruded).

Polyurethane foam (PPU) is a group of gas-filled plastics. The material is based on polyurethane. It can be rigid, elastic and self-foaming. If the characteristics of polyurethane foam and polystyrene foam are considered, you should know that both options are similar in most respects.

General information

polystyrene is often called polystyrene foam in everyday life. It is available regular and extruded. The latter has better qualities due to increased density.

Expanded polystyrene

Polyurethane foam is the same as foam rubber. It also has varieties. For domestic purposes, soft material of the indicated type is usually used, and in construction, hard material is used.

Polyurethane foam

Comparative table of characteristics of polyurethane foam and polyethylene foam

These types of insulation are approximately equally popular, due to their properties. If you are interested in the question of polyurethane foam or polystyrene foam - which is better, it is recommended to compare them according to their main characteristics. The result can be seen in the table:

| Options | Polyurethane foam | Expanded polystyrene |

| Density, kg/m³ | 25-750 | 45-150 |

| Thermal conductivity coefficient, W/(m*K) | 0,019-0,028 | 0,04-0,06 |

| Structure | Closed-cell | Closed |

| Operating temperature, °C | -160…+180 | -100…+60 |

| Environmental friendliness | Polyurethane foam retains its properties and does not emit harmful substances when heated to the maximum value (+180°C). | Expanded polystyrene at a temperature of +60°C begins to release a compound dangerous to human health - phenol. |

| Duration of operation, years | With proper installation, the service life is unlimited, in other cases it is 50 years. | 42278 |

| Fire hazard | Incombustible | More susceptible to combustion. In high temperature conditions, burning areas can become separated, which contributes to the spread of fire. |

| Hygroscopicity | Does not absorb moisture. | It is more susceptible to liquids and is able to partially absorb them. |

| Appearance | Does not lose properties throughout the entire period of operation. | Over time, it shrinks and undergoes deformation due to loss of properties. |

What to choose

Unfortunately, there is no ideal material that will suit absolutely everyone. For some, it will not be suitable due to the high price of polyurethane foam; for others, the service life of polystyrene foam will not suit them. Therefore, weigh all the pros and cons, but keep in mind that the disadvantages are not complete contraindications for use. Knowing the properties of insulation, you can make the best choice and not regret later about the money spent.

For example, if you want to insulate a garage or a wooden house on your property, choose cheaper polystyrene foam. 10-15 years of foam service life will be quite enough for this type of building. If funds allow, purchase extruded polystyrene foam. Just remember that ultraviolet rays destroy foam.

If you want to improve the thermal insulation of your home or apartment for many years, it would be wise to choose polyurethane foam. The costs will be higher, but you will enjoy the benefits of insulating your home for many years to come. The higher costs of quality installation will pay off over time.

Read about the technology of wall insulation with polystyrene foam here.

For an overview of the advantages and disadvantages of polystyrene foam, watch the video:

Comparison by cost

Protecting surfaces with polyurethane foam insulation is a more expensive technology. So, thermal insulation of 1 m² will cost 150-1500 rubles. In this case, the price is formed taking into account the thickness of the material: from 10 to 100 mm. This means that in order to insulate a surface of 1 m² with a 50 mm thick layer of polyurethane foam, you need to prepare about 850 rubles. The high price of this type of thermal insulation is due not only to the production technology of the material, but also to the high cost of the equipment.

If you are deciding which is better - polyurethane foam or polystyrene foam, you should know that the latter option is offered at a lower cost. For comparison, insulating an area of 1 m² with EPS boards will cost several times less - 300 rubles, provided that the thickness is 50 mm. Good polystyrene foam boards, characterized by large dimensions and high density, are more expensive.

Features of polyurethane foam

Polyurethane foam is one of the most popular and multifunctional materials, which often acts as insulation. It is made from an artificial polymer, which has a closed porous structure. Products made from polyurethane foam are highly durable and light in weight.

Polyurethane foam has become so popular because of its ability to replace many building engineering plastics, rubber and natural materials.

The material is characterized by its low weight - this allows it to be used for insulating facade systems of various types. Polyurethane material is easy to manufacture, transport and install. The material is often used for external insulation, as it is able to withstand temperature changes and exposure to a variety of precipitation.

Features of polyurethane foam:

- The strength of polyurethane foam is many times greater than the strength of many rubber and plastic products. It can also deform back.

- The operating temperature at which polyurethane can be used is from -70 to +120 degrees.

- The material can be used where aggressive chemical environments predominate.

- Polyurethane foam is not afraid of radiation.

Polyurethane foam is a product that, under the influence of a foaming agent, combines isocyanate and polyol. The foaming process leads to the formation of microcapsules that are filled with air. To give the material certain qualities, various additives can be added to the material.

For what purposes is it better to use?

PPU and PPS have their own advantages over each other; for this reason, in some conditions it is preferable to use one or another insulation option. For example, it is better to use PPU if the following tasks arise:

- it is necessary to create effective wind protection;

- it is necessary to realize the requirement of high adhesion;

- creation of a seamless thermal insulation structure;

- short installation time.

When polyurethane foam and polystyrene foam are considered, the comparison is made not only in terms of parameters, but also in terms of operating conditions. For example, if you plan to use EPS, it is necessary to ensure high-quality moisture protection, which is facilitated by film materials. Expanded polystyrene and structurally similar analogues (foam plastic) need to create conditions in which the risk of fire will be low.

Summary

If you plan to purchase polystyrene foam or polyurethane foam, you must take into account that in terms of the main parameters the second option wins. It is non-flammable, has a high density, wear-resistant, lasts a long time, and is non-hygroscopic. Expanded polystyrene is cheaper, but at the same time it has a fairly low thermal conductivity, which is often also an important criterion when choosing.

If self-foaming polyurethane foam is considered, its installation requires the use of expensive equipment. However, it is not advisable to purchase such equipment for one-time use. It must be said that polyurethane foam and polystyrene foam are universal insulation materials, but you should choose the appropriate option based on operating conditions.

A couple of reviews about EPPS

Leonid, 35 years old, Omsk: Used polystyrene foam to insulate the walls of a residential dacha. The house is small and heated in winter, so there were no problems with the appearance of moisture inside the insulating “pie”. I carry out repairs every 5-7 years, which means that during this time the insulation will not have time to sag and lose its qualities.

Vitaly, 45 years old, Khabarovsk: Expanded polystyrene does not weigh down the structure and retains heat well, so I chose this material. I heard that it is flammable, but the house uses a minimal amount of fire-hazardous coatings, for the most part concrete, brick, plastic, and metal are used everywhere.

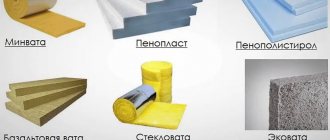

Mineral wool

Service life is 50 years for some manufacturers, a good indicator. Thermal conductivity is 0.032 - 0.12, this is the coldest insulation of those compared. Moisture resistance is low, warm air passes through well. During installation, there is a problem associated with protecting the installer from fine dust, which causes irritation to the skin and respiratory system.

For walls you need one type of mineral wool, for the ceiling another, for partitions a third.

Additional protection of mineral wool is required in the form of a vapor barrier device, counter-lattice, all this increases the cost of installation and the time it takes to put the facility into operation. The price is the lowest per square meter.

Remember, the stingy pays twice, first for the mineral wool, then for its dismantling and spraying of polyurethane foam.

During operation, shrinkage and changes in the size of the insulation are possible. It is possible for small particles of mineral wool to enter the living space, which causes allergies and skin irritation. No wonder people in Udmurtia are dismantling old mineral wool and switching to polyurethane foam.

In the photo of a house insulated with mineral wool, on the attic roof you can clearly see how the snow melts from heat leaks through the insulation. This can be clearly seen using .

Polystyrene

Polystyrene (PS) is a durable, colorless material capable of transmitting up to 90% of visible light rays. Included in the group of synthetic polymer products, class - thermoplastics . Manufactured by polymerization of styrene.

Used in construction, medicine, mechanical engineering, electrical engineering and other fields.

Poor properties include poor wear resistance, flammability, low operating temperature and high fragility. To minimize these disadvantages, PS is mixed with other polymers .

What is the difference between polyurethane and foam baseboards?

To better understand which one will be best for you, let's determine what is the difference between polyurethane and polystyrene foam?

Polyurethane skirting boards

An example of working with polyurethane skirting boards

These are baguettes made of foam plastic. The properties of polyurethane are impressive:

Polyurethane ceiling plinths are used for rooms with complex geometry, where there are curved walls and suspended ceilings, as well as for the design of arches and portals. Especially for these cases, a separate series of flexible skirting boards marked flex is produced.

To the touch, such plinths resemble a rubber surface; during bending, the pattern on them does not deform, unless, of course, you have chosen a high-quality plinth.

Be careful when choosing polyurethane skirting boards: many analogues have appeared on the market, which can be distinguished by their uneven geometry, looseness, lack of markings on the back, as well as information about product certification.

Foam or polystyrene baseboards

An example of working with foam plinth

Properties of foam skirting boards:

Expanded polystyrene skirting boards are often chosen when there is a risk that a heavier product (polyurethane or plaster) may come off the walls. And even when the budget for repairs is limited. It is important to paint such skirting boards; their snow-white appearance in a “raw” form is deceptive: the surface turns yellow if you do not cover it with paint.