Surely, you don’t know what difficulties you may encounter if you decide to use stove heating with a water circuit in a wooden house! There is a “hackneyed” stereotype that it is difficult to heat a house with a stove if you do not run a water circuit throughout the house, but this is not true! The water circuit in the furnace causes a lot of problems both during installation and operation.

In this article I will try to weigh the pros and cons, and it’s up to you to decide... And at the end I will show a short video from a real house under construction, where the furnace-boiler is made with a water circuit. We will talk about wood stoves.

Review of various schemes of water heating furnaces

One of the simplest stove designs with a U-shaped heat exchanger installed directly in the firebox. The heater with flat surfaces is made of 4 mm thick sheet metal; it is better to use heat-resistant steel. Another option is a coil in the form of a register, welded from pipes (possibly water and gas pipes) with a nominal diameter of 50 mm and a wall thickness of at least 3.5 mm. The figure shows a diagram of a water-heated furnace of a similar design.

Drawing of a stove with a built-in heat exchanger for water heating

1 – heat exchanger in the combustion chamber; 2 – door for cleaning chimneys; 3 - supply to the heating system.

The principle of operation here is simple: a steel register with a coolant is heated directly from the flame in the firebox, and the combustion products rush upward and make 3 strokes, simultaneously giving off heat to the brick walls and oven for cooking.

A slightly different stove for a home with water heating is a dual-purpose hob with a heater built into the firebox. The stove does not have long chimney channels, since it provides for the extraction of heat from combustion products by a water heat exchanger. The dimensions of the heat source are 1030 x 650 x 780 (height), the heater power is about 9 kW. The latter is made of pipes with diameters of 57 x 3 mm and 48 x 3 mm. The design of the furnace is shown in the photo.

Oven with hob

1 – firebox; 2 – ash chamber; 3 – door for cleaning; 4 – oven; 5 – hob; 6 – clay solution; 7 – water heater; 8 – chimney channel; 9, 10 – respectively, return and supply pipelines of the heating system.

The fuel, when burned, heats the coil directly. Additionally, it is heated by flue gases, which then enter the channel between the hob and oven, go around the latter and are discharged through the chimney. The heated coolant circulates from the register into the system, and the impulse can be either natural or forced. Thus, the water heater removes heat from the firebox and combustion products, cooling them to 150-200 ºС, due to which water heating from the stove is realized.

Despite all the advantages of such a design, there is an irrational grain in its work. The fact is that the combustion products, from which the hob warms up, are strongly cooled by the heat exchanger. It turns out that during cooking it is necessary to reheat the stove in order to warm up the hob, and at this time the water heating of the house will function at full capacity, and this is irrational and uneconomical. To limit the temperature of the coolant, you will have to install a buffer tank - a heat accumulator, otherwise in the autumn-spring period the rooms will become unbearably hot.

The two-chamber wood-burning stove with water heating by K. A. Dmitriev is devoid of the significant drawback described above and is considered the most common option in central Russia. It has separate chimney channels and two separate fireboxes - one for heating the oven and cooking floor, and the second for water heating from the stove. Separate chimneys at a height of 2 m are combined into one. The overall dimensions of the stove are 1500 x 680 x 770 mm (height), the developed thermal power is 9.5 kW, which is already significant, since it is enough for a house with an area of 100-120 m2. The design can be studied in detail using the drawings.

Structural diagram and cross sections of the furnace

1 – ash chamber; 2, 5 – combustion chambers; 3 – oven; 4 – ash pan door; 6 – cooking floor; 7, 8 — connection to water heating; 9 – heat exchanger; 10 – valve.

When the first firebox is operating, flue gases wash around the metal oven and enter the flue located underneath it. The water heater is not involved in the process, so this mode is convenient in the summer and transition period. In the cold season, a second chamber is heated, which is used only to heat a private home and does not affect the operation of the hob and oven. This version of the brick stove is optimal and economical, showing good results in the efficiency of burning solid fuels (efficiency - 50-55%).

Recommendations for carrying out construction activities

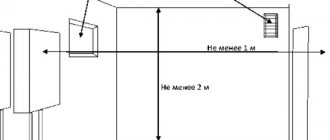

When constructing a stove with a hob and a water circuit, the following standards must be adhered to:

- The stove and nearby surfaces must be separated by a safe distance. For these purposes, a metal sheet is additionally installed in front of the firebox to protect the floor and partitions.

- To make the masonry as strong as possible, every 4th row of bricks is reinforced with metal pins.

- A clay mortar of medium plasticity is used as a mounting mixture. A small ball rolled from it should not crack or crumble when it hits the floor.

- The chimney must have a height of at least 5 m: the presence of a head is a prerequisite. This element is designed to protect the chimney from climatic precipitation and blockages. In addition, it helps to increase traction and decorate the building.

Building a home stove with a boiler with your own hands usually does not cause any particular difficulties. Quite often you can find metal structures that are not inferior to brick ones in terms of external aesthetics. Such a product can greatly decorate a home interior. For the construction of brick kilns, a special building material is selected. The best option is fired ceramic red bricks. They are distinguished by their uniform color and metallic sound when tapped.

It is not recommended to take risks with burnt and unburnt elements, because... in this case, there is no guarantee of quality and operational safety. In fireboxes with very high heating levels, it is recommended to use a refractory refractory material, which usually does not cause problems during operation.

Gas generator furnaces

Gas generator furnaces have a number of distinctive features:

- Economical. The stove operates for about 12 hours on one load of fuel.

- Compact sizes.

- High efficiency - about 85%.

- Possibility of adjusting combustion intensity.

- Possibility of using different types of fuel.

- Easy to connect water circuit.

It would seem that the choice in favor of gas generator furnaces is obvious. But before installing such a model, you need to evaluate a number of nuances:

- Essential requirements for the installation of a chimney.

- There is a high probability of condensation forming on the chimney walls.

- Manual adjustment takes some getting used to. Only in this case can all the above benefits be achieved.

- You can use different types of fuel, but there are a number of requirements, non-compliance with which can lead to a deterioration in the quality of heating.

How to build a water stove at home

- There are three ways to do stove heating with a water circuit with your own hands:

- buy a steel stove from a manufacturer whose services include system installation;

- hire a craftsman - a specialist will select the material, make the device, lay out the stove and install the boiler;

- do it yourself.

How to make such a stove yourself

The principle of a boiler for water heating

Can you make such a system yourself? Quite, just experience in welding and bricklaying when building a furnace is enough. First you need to prepare the boiler (register, coil, heat exchanger).

You can buy such a device or make it yourself using sheet iron and pipes. Since the full process of manufacturing and installing a water circuit cannot be summarized in a short review, the main recommendations are presented below.

Manufacturing options and recommendations

Water heating from a wood-burning stove - diagram

For the boiler, a sheet of metal with a thickness of at least 5 mm is used, and its design is made in such a way that there is maximum heating of the water for further circulation. The boiler, welded from sheet steel, is easy to manufacture and operate – it is easy to clean.

But such a heat exchanger has a smaller heating area, unlike a pipe register. It is difficult to make a pipe register at home yourself - you need an accurate calculation and suitable working conditions; usually such boilers are made to order by specialists who themselves install the system on site.

The simplest method of a solid fuel heat exchanger is a regular potbelly stove with a built-in water system. Here you can take a thick pipe as a basis, then there will be much less welding work.

Attention! All welding seams must be made double, since the temperature in the firebox is not lower than 1000 degrees. If you weld ordinary seams, there is a chance that this place will quickly burn out

Complete the register drawings in accordance with the dimensions of the stove at home. The layout of the rooms of the house and the arrangement of furniture also need to be taken into account.

Here you need to pay attention that it is better to choose a scheme with sheet-metal boilers - they do not have pipe bends connected into one continuous circuit. It is not so troublesome to build such a structure

It is also convenient because after installation you can use the hob without any problems, which is not the case with some tube boilers.

Register made of smooth pipes - drawing

When the coolant moves by gravity, you need to raise the expansion tank higher and use larger diameter pipes. If the pipes are of insufficient size, then you cannot do without a pump, since there will not be good circulation.

Boilers equipped with pumps have their pros and cons: you can save money by installing pipes of a smaller diameter and not raising the system so high, but there is one significant disadvantage - when the electricity is turned off or the circulation pump burns out, the heated boiler may simply explode.

It is better to assemble the structure at home, on site, since the device, like individual parts, has a very large weight and dimensions.

System installation

Heat exchanger made of cast iron battery

- Before installation, a solid foundation is poured, on top of which it is better to lay a layer of brick.

- The grate can be laid at different stages: before the boiler, if there is a double structure, the lower part of which can be equal to or higher than the upper part of the grate, when the stove is low and the system is placed a little higher, then the grate, doors, corner on the stove are usually installed after installing the boiler .

- The housing is installed - usually it consists of two containers connected to each other by pipes.

- The entire heat exchange system is welded to the boiler: the exhaust pipe goes to the expander, goes in a circle, through the radiators, and on the other side the return pipe is welded to the boiler from below.

Stove heating with a water circuit allows, firstly, to use firewood much more rationally, and secondly, to evenly distribute warm air throughout the heated room.

If you decide to make your own heating system at home with a water circuit using wood, think through all the stages of the work, and if you have doubts about the successful outcome, it is better to contact specialists.

Principle of operation

Units with a water circuit are equipped with a heat exchanger built into the firebox or chimney duct. There are models that can operate in steam circulation mode.

A wood heating stove can be made of boiler steel or cast iron, designed to operate under high steam pressure. These devices are used both as additional equipment and as the main heat source.

A heat exchanger is installed inside the furnace unit. Heated gases move through the channels of the heating reservoir, transferring heat to the liquid. A furnace with a boiler in its design can have several tanks at the same time, which can significantly increase its efficiency. Water is heated in one tank, and with increased heating, the process of vaporization occurs in the second.

To heat a large building with traditional furnace heating, several furnaces will be required, and the consumption of coal or fuel will be quite high. Therefore, a more economical and alternative option would be a stove for water heating a house using wood, equipped with a special hot water boiler built into the firebox. Even in severe frosts, heating the stove twice a day is enough for such a heating system.

Such devices are capable of heating the building even during breaks between fireboxes. During the cooling process, the pipelines give up their heat for another 5-6 hours, thereby providing heating without consuming fuel. Water heating from a wood-burning stove has an efficiency of 80-85%.

Positive sides

The use of stoves for heating homes has a long history. They are still often used due to many advantages that are not available to modern heaters:

- complete autonomy and independence from external factors if there is a supply of fuel. To operate such heating there is no need for electricity, gas, or water;

- the cost of installing furnaces is several times lower than the cost of installing equipment for using other types of heating;

- the frequency of the process and the availability of firewood in some regions, coupled with its low price, make this type of heating economical.

If you have sufficient skills, it is possible to do stove heating for a private home yourself. In its design, most often there is no liquid coolant, which is used as water. This makes it possible to stop the combustion process for a long time and resume it at any time, regardless of any conditions. The last factor is most relevant for buildings with temporary presence of people, for example, for dachas and garden houses. However, water heating can be added if desired by installing pipes and radiators.

When constructing a furnace, there are various options available. At the stage of construction of the stove, you can make it in the form of a fireplace, provide in the design of stove beds, dryers, stoves, and build in tanks for heating water.

Tips for setting up the system

At their core, such designs are the progenitors of modern solid fuel boilers. But unlike them, heat transfer is carried out not only through piping and a radiator system, but also from the stove itself.

Plus, installing brick stoves with water heating yourself is much easier and cheaper than installing a solid fuel boiler.

A few words about the register

Without exaggeration, the metal register can be considered the heart of the entire heating system. This design is installed directly in the firebox itself and is responsible for the heating level of the coolant.

Lateral arrangement of registers.

The simplest and most affordable option is to install a rectangular metal tank directly into the firebox. Such a tank is made of heat-resistant steel, with a thickness of 3 mm or more, most often from stainless steel.

To heat a house of 200 m², a tank 750 mm long, 500 mm wide and 300 mm high is sufficient. The outlet is made from the top of the structure, the return line cuts into the bottom of the tank.

Registers welded from stainless steel pipes with a wall thickness of at least 3 mm are considered more functional. In this case, the heating area increases several times, hence the efficiency of the system is disproportionately higher.

Advice: it is not difficult to find cast iron registers on the market now; according to most experts, they are the best option. Firstly, cast iron is little susceptible to corrosion, practically does not burn out, and most importantly, this material is considered the best heat accumulator.

Stainless steel registers.

During installation, pay attention to the location of the register. The more contact with fire, the higher the productivity

But at the same time, regardless of the configuration of the tank, there must be a compensation gap of at least 5 mm between it and the walls of the furnace. Otherwise, during heating, the metal will begin to expand and the walls of the firebox will crack.

Diaphragm tank

Installing a register into the firebox is only part of the story; it is equally important to properly arrange the piping. Any heating system built on this principle must be equipped with an expansion or membrane tank

As a rule, it is installed on the return pipe, but this is not important; some craftsmen prefer to mount it at the highest point of the system.

Operating principle of a membrane tank.

In a system with natural coolant circulation, its function is performed by an ordinary metal container. But now, in most cases, owners prefer to install circulation pumps. It is advisable to install a real membrane tank in such a system.

The device is a sealed metal container, in the upper part of which there is a valve. Air is forced through the valve, creating excess pressure in the system. As the temperature rises, the coolant expands proportionally, squeezing the excess into the membrane tank. During the cooling process, the air that presses on the membrane compensates for the pressure drop in the system.

Some aspects of laying a furnace

As mentioned earlier, you can build water-heated brick stoves with your own hands, but if you are not confident in your abilities, it is still better to invite a specialist.

Although in any case, there are general rules that it is not advisable to break.

- All brick ovens are made of solid red brick. It is not advisable to use hollow brick even for cladding. The fact is that hollow blocks are a heat insulator, and in this case this can only do harm.

- If you plan to burn with wood, then the firebox can be made of ordinary baked brick. But if there is a possibility of using coke or high-grade coal, such as anthracite, then we would advise making the firebox from special fireclay bricks, which are used in the construction of blast furnaces.

- There is no need to save on wall thickness; in addition to the weight of the oven itself, the load from the registers will also be added here.

- And yet, any stone structure needs a reliable foundation; as for stoves, the foundation should be laid separately and in no case should it come into contact with the general foundation of the house, the minimum distance between them should be 50 - 100 mm.

Circulation pump in the system.

The video shows some of the intricacies of installing the system.

In this case, we were talking about heating a house. But it is worth noting that if a metal water container is inserted into the system in parallel, it will act as a passive boiler, as a result of which hot water will still appear in the house for domestic needs.

System Features

A conventional brick stove consists of components such as a combustion chamber, an ash pan, grates and chimneys. These components of a simple Russian stove are probably familiar to any village resident. Visually, modern types of stoves are practically no different from traditional village designs.

Main characteristics of water-heated furnaces

Traditional ovens have the following characteristics:

- A simple village stove can produce more than 6500 Kcal of heat in one hour. This amount of heat is quite enough to heat a house with a small area. Such a heating system would be an ideal solution for a small country house. A water-heated furnace, in which the main component is a water boiler, will be approximately 2.5 times more efficient. Using such a heating system, you can heat a house with a much larger area. In order to heat a house, the same amount of fuel will be required, which means that such a system will be more economical.

- A heating system that combines a stove and a boiler will also be effective. If both systems work simultaneously, their productivity increases many times over. A tandem of two such heating systems can release more than 21,000 Kcal of heat in one hour of operation. This amount of heat is enough to heat a house with an area of up to 300 square meters. meters.

Stove connected to water heating

- Most often, such a heating system uses fuel such as coal or wood. The price of such fuel is not high, and its transportation should not cause any particular difficulties. Firewood can be combined with coal at the same time.

- There is no need to constantly heat water-heated stoves. Fuel can be added to the stove several times a day. You can create comfortable conditions indoors, no matter what the weather or temperature is outside.

- If we compare the efficiency of traditional stove heating with a combined system, this figure will increase from 50% to 85%. For heating with wood, this figure can be called ideal.

- The materials that are necessary to organize such a heating system are quite affordable and are not included in the expensive price category.

Disadvantages of water-heated stoves

Stove heating also has its disadvantages, and it would be unfair not to list them.

A brick stove with water heating can be installed not only in a rural or country house, but also in luxury cottages. Typically, owners of luxury homes strive to ensure that such a water heating stove, in addition to its usual functions, also plays a decorative role. During operation of such a combined system, it is necessary to follow some safety and system care rules:

A stove for water heating at home must be under human control at all times.

This applies not only to the issue of loading fuel, but also to cleaning the ash chamber. Smoke ducts also require attention. Before starting a fire in the lever, you must make sure that the smoke channel valves are in the open position. Such systems can only be used in the cold season

During the warm season, using such a heating stove with a water circuit for cooking will be impractical. If you need to cook food, it is better to use another alternative heat source for this purpose.

If you want to make custom-made stoves for water heating at home, it is better to turn to professionals for help. If your stove is manufactured by an unqualified person, there is no guarantee that the stove will function properly or be completely safe. Overheating of the oven can cause some problems that will eventually lead to complete breakdown of the oven.

A conventional stove is usually designed to heat a small room

Since the flame has high temperatures, it will eventually damage the integrity of the boiler walls. This means that the time will come when the heat exchanger will need to be replaced. This is not so easy to do, since you need to remove a good part of the masonry.

Integrating a stove into an existing heating system

If you already have a heating system that has previously been used with a different type of heating, you can connect a furnace to it. For example, it can become a replacement for a gas boiler.

Modern heating equipment usually does not contain a heating tank. But, it has a heat exchanger that performs a similar function.

The cost depends on a lot of factors - material, size, efficiency, maximum permissible heated area, etc. Moreover, there are models that allow not only to heat the house, but also to provide a full-fledged hot water supply system.

Factory stoves usually allow the use of both classic wood and coal, and pellets, which is a compressed wood material used as fuel.

Wood boilers

Boilers that use wood as fuel have a simple operation scheme, which simplifies their operation and repair.

The basis of the design is the combustion chamber. Logs are placed in it, then they are set on fire. As combustion proceeds, fuel is added and the products of the process exit through a heat exchanger.

Heat-resistant pipes are heated by heat, transferring heat to the furnace body and then into the room.

Under the chamber there is a stand that collects ash. This part of the device is cleaned 2-3 times a week to avoid clogging. The remaining fuel can be saved for further fertilization of the soil.

The operation of a wood-burning boiler can be described as follows:

- As the fuel burns, it releases heat that passes into the heat exchanger.

- Heat is transferred to media: the furnace body or the water circuit.

- Heat carriers warm up the room.

The type of heating affects the type of device. A conventional stove transfers heat to the room where it is located. Water heating involves heating water, which warms the house through radiators. Air heating involves the removal of smoke through ventilation, the shaft of which is laid along the rooms. The heat gives off heat, and the cooled coolant leaves the house.

Advantages:

- Low cost of device and fuel. Dried logs from fallen trees are suitable for heating rooms.

- Wood heating does not require special permission, like gas heating.

- The wood boiler is easy to operate. It is enough to light a fire, periodically adding fuel. The ash stand is cleaned every two days. The chimney is cleaned every few months.

- Wood-burning boilers are safer than their gas and electric counterparts, as they are made of heat-resistant materials.

Flaws:

- The boiler requires care and supervision. As combustion progresses, fuel must be replenished; logs must be stored in advance. The ash stand and chimney need to be cleaned.

- Although wood-burning boilers are inexpensive, truly high-quality designs come at a high cost.

- Fuel storage requires a separate building with low humidity.

- The product of combustion, smoke, leaves behind an unpleasant odor in the presence of poor-quality draft.

- Some stoves are bulky and require more space in your home.

Popular device models

It is worth highlighting well-known and high-quality brands of wood-burning boilers:

- NMK Sibir-Gefest KVO 15 TE.

- Protherm Beaver 20 DLO.

- Bourgeois-K MODERN-12.

The first model has enough power to heat a building with an area of 150 square meters. The efficiency of the device is 70-75%. The boiler is heated with wood or coal. The coolant obtained through combustion of fuel has an average temperature of 70 °C. The heat exchanger is made of heat-resistant steel. The device is equipped with a 4 kW tubular electric heater. NMK Sibir-Gefest KVO 15 TE weighs 115 kg and holds pressure up to 2 bar.

The second model has better performance. The power is enough to heat 190 square meters, and the efficiency is about 90%. The coolant temperature is directly controlled and ranges from 30 to 85 °C. The heat exchanger is made of cast iron, consists of several sections and is divided into two strokes. The high efficiency of Protherm Beaver 20 DLO allows you to recoup the cost of the device by saving fuel. The device is equipped with temperature and pressure control systems.

Photo 2. Wood-burning boiler NMK Sibir-Gefest KVO 15 TE. The device is made in a combination of black and orange.

Bourgeois-K MODERN-12 is a pyrolysis wood boiler. Control is carried out manually, although there are devices with electronics. The power is enough to heat 120 sq. m. The cost of the boiler is due to its high efficiency - 92% and the ability to operate on any fuel: wood, coal, peat, etc. The coolant reaches a temperature of 95 °C by activating the compressor. Along with the previous model, Burzhuy-K MODERN-12 is equipped with temperature and pressure control systems.

Price

The price of a wood-burning boiler depends on the factory characteristics and the manufacturing company. It is influenced by the heat exchanger material and the presence of electronics that automate control. Cost of the presented models, in rubles:

- NMK Sibir-Gefest KVO 15 TE - 18 thousand;

- Protherm Beaver 20 DLO - 45 thousand;

- Bourgeois-K MODERN-12 - 55 thousand.

Instructions for building a stove heating system with a water circuit

- A hole is being dug.

- A “cushion” is laid, consisting of broken bricks, crushed stone and medium-sized rubble. The width of this layer is approximately 20 cm. Natural materials are compacted and filled with cement mortar.

- Bricks are being laid. It is laid in two rows on cement, and covered on top with a waterproofing layer of roofing felt, parchment and roofing felt.

- A brick foundation is being built with clay mortar.

- The first continuous row is laid. In the second row, an ash chamber begins to form, for which a special door is installed. The third row repeats the previous one.

- The fourth row is formed. It serves as the basis for the fuel chamber made of refractory bricks; grooves are provided on it for installing the grate.

- A U-shaped boiler made of steel is installed. Two pipes are welded to it - one at the top for supply, the other at the bottom for return. It also has a rectangular hole through which heated gases will escape.

- The fifth row is laid. It is necessary to provide channels behind the side and rear walls of the boiler. Two small doors are installed on them to remove soot.

- A sixth row is formed, in which a hole is provided between the gaps made in the previous row. This is a suction channel to increase draft in a heating furnace. The door for the fuel chamber is also installed here.

- The wall is being laid out. It should be taken into account that fire-resistant bricks are laid around the door leading into the combustion chamber and above the fuel boiler.

- Cast iron stoves are being installed on which food can be cooked. A metal corner is attached to the entrance of the heating and cooking chamber.

- Chambers are formed, a channel is made on the back surface, and doors are installed.

- The facade of the cooking chamber in the 16th row is covered with a metal strip. And then it itself is covered by laying bricks on specially laid metal strips.

- A steam exhaust valve is installed to ventilate the furnace and an upper flue is formed.

- 35 rows are laid, on which the construction of the chimney begins.

Some people want to use a ready-made stove or fireplace, combining it with a water circuit. In this case, you will have to disassemble them almost to the ground in order to install the register.

Mayevsky crane

Material selection

Well-fired solid clay bricks are used to construct the furnace. It is possible to use ordinary building solid bricks made of clay, provided that the firebox is lined with refractory bricks. The masonry mortar is made from oily clay with the addition of fine sand.

The part of the chimney located above the roof level must be made of sand-lime brick with cement mortar. The temperature of the flue gases in this area of the chimney is already low, and exposure to heat and atmospheric moisture (as well as exposure to wind and precipitation) will quickly destroy the clay brick.

For the manufacture of doors, grates, and valves, finished cast iron products are used, produced at enterprises specializing in the production of such products.

How the system works

The simplest water circuit is with natural circulation of water flow. Its basis is a simple physical phenomenon: the expansion of liquids when they are heated. The unit that creates pressure is an expansion tank (a container for collecting water), installed in the attic or attic.

The water circuit is a closed system. The boiler heats the water in it and, expanding, it is directed through a pipe into a storage tank. The movement is carried out under pressure created by the cooled water constantly entering the boiler and passing through the entire system. Boiling water from the expansion tank is directed by gravity down through the pipes leading to the batteries. Having given off the heat, it returns to the tank and heats up again.

Installing a pump will help to significantly increase the pressure in the system and speed up the circulation of the coolant. At average outdoor temperatures, it can be turned off and the circuit will function on the natural movement of water. This will save you on your energy bills. Water enters the pump with the check valve closed. By turning it off (leaving it open), the entire volume of coolant is directed to bypass the pump.

Such a stove can be loaded not only with wood or coal. When using alternative fuels, it is possible to complicate the structure of the system by adding:

- granule storage tank;

- a mechanism that feeds pallets into the firebox (pneumatic or auger).

You can make the operation of the furnace easier by installing an automatic system for regulating its operation and forced ventilation.

Creating a heating wiring diagram

You can combine a stove with a water heating boiler and connect the circuit to the heating system using two schemes.

Open system

With an open system, the expansion tank is located at the highest point - in the attic; you can include a pump in the circuit

The coolant moves by gravity, so the installation of a circulation pump is required. It is placed on the bypass, reduces the temperature difference between the return and supply, increases the speed of water movement and the quality of heat transfer. Without electricity, the line will operate on the principle of gravity.

To organize it, you will need to increase the line and horizontal slopes in diameter. The open system is equipped with a 32 mm distribution manifold with a slope of 3 to 5 mm per linear meter. The expansion tank is located at the top; air enters it from the communications.

Closed system

The radiator network provides for forced movement of water. The thrust in this case is created by a pump. It also pumps up pressure from 1 bar for cold coolant. The membrane-type reservoir is located at the bottom. A shut-off valve is used to connect it to the main line. Safety devices (air vent, pressure gauge, drain valve) are required.

Masonry and brick

Stove maker is a profession that has been known since ancient times. Masters of masonry have always enjoyed special respect among all categories of the population. A qualified craftsman will create a unit such as a Russian water-heated stove, which will always have an evenly heated surface and excellent traction.

There are several main rules that must be followed by all specialists in this field:

- The combustion chamber must be made only from materials that are distinguished by their fire-resistant properties. If the fire escapes from the hearth, it can damage even ordinary brick or stone.

- When laying the walls of the stove, there is no need to skimp on materials. If the walls are laid with a quarter of a brick, this can significantly reduce the reliability of the entire structure.

- The tightness of the seams also requires special attention. If you leave even a small gap, carbon monoxide can then escape through it, and this can be very dangerous to human health.

Brick stoves with water heating today are modern equipment that will effectively heat your home.

https://youtube.com/watch?v=CZiTLx_zq5c

How to ensure optimal temperature conditions

When heating wooden houses with traditional stoves, obvious uneven heating is observed. The warmest areas in such a house are located in close proximity to the brick heater. It can get quite cool in the far corners. The multi-oven option is very expensive. In addition, this leads to a significant reduction in living space.

The most optimal solution is to use a combination of a brick stove with water heating. Many residents of our country already have similar experience, having managed to solve the problem of creating warmth and comfort in their homes. To do this, a conventional brick oven is equipped with a heat exchanger that looks like a coil. The place where it is installed is the firebox or the base of the chimney. Thanks to the heat generated, the water inside it begins to heat up, subsequently entering the radiator system. In this way, uniform heating of the home is achieved.

Advantages of a stove with a heating circuit:

- Efficiency and uniformity of heating. This is facilitated by the location of radiators in different rooms and the constant heating of the coolant.

- Absolute independence. These designs do not depend on the presence of gas and electricity in the house. In this case, the owners themselves choose the time and intensity of heating.

- Possibility of independent maintenance of heating systems. To carry out these simple activities, the presence of specialists is not required.

- Economical. Although such a system has to be started every day, due to the cheapness of fuel, the costs of its operation are quite small.

The weak point of such systems is their high fire hazard. For this reason, premises must be additionally equipped with fire protection. You should also take into account the fact that the heating device is static: it will not be possible to move it from place to place. A stove with a water jacket is capable of heating a small one-story house. If a building has a second floor, it is necessary to resort to the construction of another furnace, which results in considerable costs. Disadvantages of the system also include the need for constant human control.

Positive and negative aspects of stove heating in a private house

In most cases, stove heating is installed if necessary, in the absence of main natural gas. But heating with a stove has its advantages and disadvantages, which it would also be nice to know about.

What are the disadvantages?

Negative points include:

- It takes quite a long time to heat up the stove, and therefore the premises. This occurs due to prolonged heating of the walls and coolant in the system.

- Not very high efficiency of a brick building. To increase it, you have to build a higher chimney, make it a labyrinth type, so that the heat remains inside the structure longer.

- A brick stove occupies a fairly large area, but only on such a scale is it capable of heating several rooms at the same time.

- Unlike heating with natural gas, the stove must be supervised throughout its entire combustion, since brick options require constant addition of fuel. Long-burning cast iron stoves are an exception, since firewood is added once per burning session.

Positive points

Stove heating also has many positive qualities, which are often decisive in choosing it for installation in a private home.

If you have a cast iron stove

Cast iron models have average inertia and are not inferior in durability and strength to brickwork. Optimal conditions for burning firewood in them are achieved by tightly closing the fire door and the ash pan (fresh air is supplied in small portions or is shut off; in addition to firewood, pyrolysis combustion of flue gases occurs inside the sealed cast-iron firebox). Laying a new portion of firewood is carried out using special gloves, after carefully and smoothly opening the door and closing it the same way; the less the internal pressure fluctuates in such stoves, the better.

Installing a coil on a pipe

This is an excellent and fairly simple way to increase the efficiency of the stove. Flue gases heat the pipe to extremely high temperatures. The outer coil, like the inner one, helps reduce the temperature and somewhat cool the outer surfaces of the chimney. An external water heat exchanger is especially often installed on metal chimneys. This is an excellent auxiliary device for heating small spaces.

This heat exchanger has two pipes. The top one is connected to a pipe going to the storage tank, the bottom one is connected to the heating circuit. It is easy to make such a structure, as well as attach it to a pipe.

Preparation and selection of installation site

To begin, lay out all the materials in front of you. But we do this at the place where the stove is installed. We choose the latter like this. For maximum efficiency, the heat generator is mounted in the corner of the room so that the heat spreads across 2 walls and is not lost in 4 directions.

In this case, it is necessary to leave a small gap from the walls, equal to approximately 150 mm. If the stove is used in a country house, it is advisable to provide a chimney during its construction and run the upper section of the pipe through the roof.

There is no need to lay a foundation for our unit, because with the given parameters the weight will be small. If the stove is planned to be massive, then it is better to prepare a concrete base.