Heating by furnaces with heat exchangers

Stoves with heat exchangers are an alternative option to conventional heaters, which provide space heating, hot water supply and steam generation.

Heating in a bathhouse from a stove heat exchanger can be organized both for the main premises - steam room and washing room, and for auxiliary ones - dressing room, relaxation room, billiard room, shower room, swimming pool.

At the design stage of heating equipment with a heat exchanger, the following data is taken into account:

- dimensions of the building and area of premises;

- design features of the furnace;

- weight of heating equipment;

- number of heat exchangers;

- coolant volume;

- length and diameter of the chimney pipe.

The following options for connecting heating equipment using pipes are possible:

- to the expansion tank for hot water supply in the washing compartment;

- to heating radiators installed in functional rooms;

- to hot water supply and water heating system in the main premises of the bathhouse and residential building.

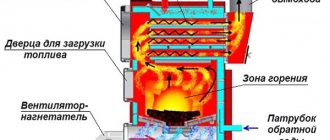

Heating stoves are equipped with internal and external heat exchangers. The internal element is located in the firebox, the external element is located around the chimney pipe.

Basic installation methods

The heat exchanger can operate in two different modes. They have distinctive features consisting in the uniqueness of the process of transferring thermal energy from the emitted smoke to the internal pipe of the register.

In the first case, the heat exchanger for a sauna stove on a chimney has a modification in the form of an external container with water. When boiling, water condenses on the heat exchanger tube and thus heats the structure itself. The temperature on the surface of the tube will not exceed 100 degrees Celsius, which corresponds to the boiling point of water. The water container itself will take a long time to warm up.

In the second case, the condensed steam does not affect the heat exchanger structure. The heat flow moves through the pipe unhindered, and the water heats up much faster. To understand the technology of the process by which heating occurs in a bathhouse from a heat exchanger, you can see how the process of heating water occurs in an ordinary pan on the burner of a home stove.

It is not difficult to notice that right up to the moment of boiling, moisture condenses on the walls of the pan and flows onto the surface of the stove. Accordingly, when arranging a heat exchanger using the second method, it is necessary to ensure that the pipe has a large wall thickness, which will significantly reduce the degree of condensate formation.

How to make heating in a bathhouse

Heating in the bathhouse is necessary to provide convenience.

One type of heating is automatic. Separate heating can be provided by electric convectors or electric boilers, as well as gas boilers. All of them can work offline. You can set it so that the room temperature is slightly above zero. This will prevent water from draining from the toilet tank, pipes, or electric boiler.

There is a minus in this system. Since it is autonomous, you may not notice that a failure has occurred and the temperature may drop below zero. Therefore, you need to install a temperature sensor with a signal.

How to install heating in a bathhouse from home

You can install both gas or electric boilers and stone or metal stoves. But these are all quite complex structures.

To heat a bathhouse from home, you can lay a heating main there. Install radiators in the house. Such a system will operate from heating in the house.

Heating a bathhouse from a sauna stove

The easiest heating method to manufacture, operate and maintain is heating a bathhouse from a sauna stove. The stove is installed directly in the steam room, and the firebox is installed in the dressing room.

Brick kilns maintain temperature for a very long time, but they must be heated for at least 5 hours. And it takes even longer to heat a bathhouse in winter.

High cost is another disadvantage. It is very difficult to build such a stove yourself. The help of an experienced stove maker is needed.

Heating the dressing room from a sauna stove

In most cases, a classic sauna is heated with one heat source. The stove is installed in the steam room so that all rooms can be heated. A tank of water is placed near the washing room.

It is very important that each element of the stove is made of refractory material. Therefore, it must be built from bricks

Such an oven will take up a lot of space and be large.

The ideal option would be a stove with a tank and an open heater. The firebox is equipped with a register, the lower edge of which is located 50 cm above the register. It will prevent premature boiling of water.

Is it possible to make heating from a tank?

To install a heating system from a tank, you need to know its operating specifics and operating rules. It is necessary to take into account the volume of the room and power consumption.

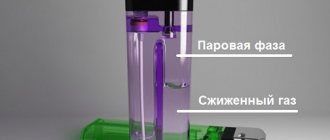

There are mounted and built-in tanks. There are also set-up tanks - a container of water is placed on top of a heated oven.

Comment! You can use the already created heat: a tank is hung on the chimney, the water is heated, and the temperature there can reach 500 degrees.

These methods do not supply hot water to the shower. Remote water tanks can do this. The heat exchanger is placed in the furnace, and a tank is hung next to it or in the attic. The system is connected by pipes through which water will flow. Thanks to the heat exchanger, it is heated and supplied to the shower through the tank. This heating system is simple and effective.

Overhead tanks are sealed containers with a lid and a tap for draining water. Attached to the wall using metal hooks. Made from stainless steel.

Attached water tank - an inclined pipe sealed at the end is welded into the furnace. The other end is at the bottom of the tank. Cold water rises through an inclined pipe, where it is heated to a boil. Hot air bubbles transfer heat.

How to make heating in a log bath

Three types of heating are installed in wooden houses: water, electric and air. Each has pros and cons.

The most popular type of log heating is water.

Pros:

- Economical.

- High heat capacity.

Minuses:

- Difficult to install.

- The need to constantly monitor the heat generator.

- In winter, be sure to drain the water from the heating system.

Such heating systems are:

- with bottom or top wiring;

- passing or dead-end;

- single-pipe or double-pipe;

- vertical and horizontal;

- with a pump or natural movement of water.

Two-pipe systems are less aesthetically pleasing than single-pipe systems.

Electric heating has several advantages:

- The heat supply level is easily adjusted.

- Small dimensions of heating devices.

- The heating is environmentally friendly and silent.

Air heating has only one advantage - high penetrating power.

But there are many more disadvantages:

- large stoves and fireplaces;

- very low heat transfer;

- uneven distribution of air in the room;

- expensive heating systems.

Before installing systems, you should weigh the advantages and disadvantages and possibly consult with a specialist in the industry.

Heating in a bathhouse is the most important thing that needs to be paid attention to during construction. The bathhouse is one of the best relaxation places where you can have a pleasant time with family or friends. If it is warm and cozy there, then you will rest in body and soul

If it is warm and cozy there, then you will relax your soul and body.

Heater location

Usually the bathhouse is heated using one heat source. For a house next to which a unique bath complex is built (with a dressing room, steam room, swimming pool, relaxation room, room for playing billiards), a generally accepted heating system is required.

If heating is designed for a classic bath, then the stove is positioned so that it can be used to warm up each room. A tank of water is allocated a place near the washing room.

The ideal is a “through” arrangement of the furnace. The firebox door can be opened while in the dressing room. The stove itself will be located in the steam room, and the water tank will be located in the wash room.

It is important that each of the combustible elements of the furnace structure is protected from fire-resistant material. To comply with this, you can build a heater out of brick, but it will have large dimensions and take up a lot of space

A practical option is to build a stove, the design of which includes a tank and an open heater. The firebox for heating water is equipped with a register, which will prevent premature boiling of water, during which the unheated bath is filled with damp steam

Heating a bathhouse in this way requires observing an important nuance - the bottom edge of the tank should be 50 cm above the register

Date: September 25, 2022

Heating by stove-stove

For small baths, a traditional heater remains a viable heating option. In this case, it is enough to purchase or manufacture a heating unit of the required power.

Calculation of equipment power is determined by the formula: 1 kW of power per 1 sq. m of premises. To ensure a comfortable stay for visitors in the steam room, a thermal power reserve of 35 to 55% is additionally taken into account.

The popularity of the heating heater is explained by the following advantages:

- ease of installation and maintenance;

- accessibility of operation;

- using available fuel.

When giving preference to a sauna stove, do not forget about some of the disadvantages of the device:

- impressive dimensions and weight;

- inability to automate the process of heating rooms;

- high fire hazard;

- formation of fuel combustion products.

Modern heaters operate on wood, electricity, liquid and gaseous fuel. The choice of the appropriate option depends on the financial capabilities and technical capabilities of the equipment.

To ensure effective heating of the room, heating the bath from the stove in the steam room is done as follows: the firebox is placed in the dressing room, the heater is in the steam room, and the tank with warm water is in the washing compartment.

When is protection needed at all?

The need to install protective casings and screens does not always arise. If a fire-safe distance is maintained between the stove and the nearest flammable surface, additional protection is not needed. At this distance, the IR rays are scattered, weakened, and the amount of them that the wooden wall receives can no longer lead to damage.

It is believed that the safe distance from the wall to the brick stove (quarter-brick laying) is at least 0.32 m, from the wall to the metal stove (not lined) - at least 1 m. For a metal stove lined from the inside with brick or fireclay, the distance decreases to 0.7 m.

Thus, maintaining fire safety distances is more possible in large baths, where the issue of saving space is not relevant. In family steam rooms, where every centimeter of space counts, installing a stove 0.3-1 m from the nearest walls is impractical. In this case, the safety distances established by the standards must be reduced using screens and casings.

Gas heating

The implementation of such a heating system has several options.

- Firstly, as I wrote above, it is possible to install a “classic” heater, in which a gas burner will be used instead of firewood.

- Secondly, you can use a standard gas boiler (the same as in residential buildings). But in this case, you will have to take care of the equipment of heating systems (installation of heating radiators, laying pipes, connecting a gas-carrying pipe to the bathhouse or a cylinder connection system).

- Thirdly, there is the possibility of installing heating from the house. In essence, this is the same option as the previous one, but with its own characteristics and disadvantages. A separate heating main is laid from the boiler used to heat the house to the bathhouse. This option is very convenient if your steam room is adjacent to the house or is very close to it.

Gas heating baths

If the distance to the bathhouse is relatively large, then in order to use this system in winter it is necessary to bury the heating main below the freezing level of the soil and insulate it well. This will prevent the possibility of defrosting and help reduce heat loss.

True, the undoubted advantage of this option is the complete elimination of the problem of maintaining a constant positive temperature in the bathhouse. In addition, you can do all the necessary work (if you have a certain skill) with your own hands.

Vodyanoye

Water heating is rightfully considered one of the most convenient and effective methods of heating. In such a situation, there are also several options for manufacturing a system, which in any case will be powered from a furnace with a water circuit.

Fortunately, today in specialized stores you can easily select stoves that are ready for installation, equipped with a heat exchanger. This greatly simplifies the task of any builder of his own bathhouse. And now directly about the options.

Water heated floors

- External heating. It is done very simply and, in fact, is arranged in the same way as a brownie. Pipes located along the walls are connected to the furnace. Depending on the area of your bathhouse, a certain number of heating radiators are connected to the pipes. Hot water passing through them heats the structure and, when cooled, returns back to the boiler.

- Water heated floor. The principle of its operation is the same as in the first option. The only difference is that the pipes are hidden in the floor, which was previously insulated (I wrote about insulating floors in a bathhouse in more detail in other articles). This design is considered non-separable (although, of course, there would be a desire to break everything), and therefore requires a very careful approach to the procedure for its manufacture. In this case, I would recommend seeking help from specialists.

https://youtube.com/watch?v=GO5dAde3rQA

Homemade boiler for a bath

You can build a boiler for heating a bathhouse with your own hands. You need a pipe of a certain diameter, a welding machine and a grinder.

You can do . For this, it is very convenient to use sections of thick-walled pipe. The best option is a piece with a diameter of 51 cm and a length of 100 cm. Such a boiler, even in a very cold winter, can heat not only the steam room itself, but also other rooms.

Prepare the following tools for work:

- electric welding machine;

- “grinder” with metal circles;

- pipe of suitable length and diameter.

The selected section of thick-walled pipe will serve as the body of the future boiler. Inside the housing, 3 supports should be welded parallel to the ground at 3 different levels. These supports are made from ordinary reinforcement bars 30 cm long and 14 mm in diameter.

The lower support will make it possible to install the bottom of the heating unit. The height of the second support is selected in accordance with the size of the blower door installed in the boiler. The third support will be installed at a distance of about 20 cm from the top of the unit base.

To construct the bottom of the boiler, a solid metal circle with a thickness of at least 4 mm is used. Grate bars can be made from a metal circle with slots. Choose a circle as thick as possible, then the lid can also be used as a support for stones. The lid is made of a metal circle with a thickness of at least 5 mm. A hole should be made in the cover, which will be used to attach the adapter ring of the chimney pipe.

The system for placing supports under the partitions implies their location one above the other. Stove and blower doors are installed in the hole for the box, which must be cut in the side of the pipe from the very bottom.

The depth of the box should be selected in accordance with the thickness of the wall that will be used to make the boiler firebox. A partition installed inside the box is necessary to separate the combustion and ash compartments. The level of this partition must coincide with the grate partition installed in the inside of the boiler.

The installation procedure is as follows. First, the box is welded, after which the bottom, grate and top cover are inserted into the boiler body

When performing work indoors, you need to pay attention to the fact that the box passing through the wall goes into the furnace room or outside, and not into the dressing room

At the next stage, a chimney is installed and stones are placed on the top cover of the boiler. The boiler is directly installed on a special foundation. you can organize such heating with your own hands.

Requirements for the manufacture of the structure

It is important to make gaps where the pipe passes through the holes.

When preparing to build a chimney, you need to familiarize yourself with the standards that the chimney must comply with:

- If the pipe comes out of the roof at a distance of one and a half meters from the ridge, then it makes more sense to mount the structure at a height of 50 cm above the very top part of the roof;

- When the distance between the ridge and the chimney is at least one and a half and no more than three meters, it is more advisable to install the chimney at the same level as the roof deck;

- If the ridge and pipe are more than 3 meters apart from each other, the chimney should be mounted above the dotted line, which is conventionally drawn horizontally from the highest point of the roof at an angle of 10 degrees;

- Only 1 meter of chimney should go out from the flat roof;

- The chimney, located one and a half meters above the roof, is certainly secured with guy wires.

Water and infrared floor installation

Gas boiler diagram.

A water heated floor is a pipe system located between the base of the floor and its subfloor. The pipes are laid in loops over the entire floor area, a separate circuit is made for each room, the flow of coolant is regulated by taps that are installed on each circuit. Coolant circulation is carried out by pumps. Boilers (wood, gas, electric) are used to heat the coolant. When installing a water floor with your own hands, you must take into account the possibility of heat leakage through the base of the floor; to prevent this from happening, the pipes are laid on a heat insulator with aluminum foil.

An infrared heated floor is a film with radiating elements or a heating mat made of carbon rods. In rooms with high humidity, which is what a bathhouse is, it is better to use heating mats. Infrared radiation from the floor heats surrounding objects, which transfer their energy to the air in the room.

This heating method is more efficient than convection heating, and therefore the energy consumption for heating is significantly lower than that of an electric convector. Installing an infrared floor with your own hands is easier than installing a water floor. Waterproofing is laid on a dry and clean base, then a substrate on which a system of heating mats is mounted. During installation, it is necessary to take into account all the nuances specified in the manufacturer’s instructions.

Convectors, heating a bathhouse from a residential building The easiest way to heat a bathhouse is to use electric convectors. To feel at home in the bathhouse, just connect the convector to the network. However, this heating method requires significant energy consumption. Gas convectors are more complex devices; for their operation, it is necessary to install a gas and air supply system into a special chamber where the gas is burned, and to ensure the removal of combustion products. It is not possible to install such heating with your own hands; specialists must work with gas equipment. The installation of these devices is justified in production facilities, warehouses or garages. They are not suitable for a home or bathhouse.

https://youtube.com/watch?v=v0vbA44F-Tc

If the home is heated with liquid energy, then the bathhouse can be easily connected to the heating system of the living space. Radiators are installed in the bathhouse and connected by pipes. The pipes are removed, insulated and laid in a trench; the depth of the trench should be below the freezing level of the soil. Next, we bring the pipes into the house and make a connection with the heating circuit. That is, another room appears near the house. But before you do such heating, you need to make sure that the boiler power is sufficient.

Principle of operation

The device is a pipeline with a coolant inside, which is powered by a sauna stove heated with wood or other fuel. The stove must be converted to heat underfloor heating.

After ignition, it warms up the system, full heating is achieved by the time the steam room is ready. Water circulates using an installed pump; it is included in the mixing unit. Warm pipes heat up the screed and flooring, which in turn transfers it to the room.

Electrical

And finally, let’s look at several ways to use electricity to heat a bathhouse. I’ll say right away: take care of the electrics in this case. Since the load on thermal electrical appliances is large, the quality of the electrical wiring should not be in doubt. Consider the total load, wire cross-section, wiring diagram and quality of electrical work.

Electric heating

Firstly, your room can be heated using an electric heater. True, in this case you will have to take care of heating the water in the shower in advance (for example, by installing a direct or indirect heating boiler). This type of heater does not require additional arrangement of the chimney and is considered environmentally friendly.

Secondly, the bathhouse (in particular the relaxation room) can be heated using electric convectors placed on the walls.

Well, thirdly, infrared film can come to your aid - the newest type of heater, which allows you to easily and quickly create warm floors both in the house and in the bathhouse. Detailed technology for installing heated floors is discussed in other articles.

Please note that the installation of heated floors is possible without the use of infrared film, but by laying electric heating cables. They are used both in underfloor heating systems and for heating water pipes.

It is quite possible to use infrared heaters as an additional source of heat. I hung it on the ceiling and forgot about it.

Infrared heaters

Using electricity to heat a bath undoubtedly has its advantages. You can safely use all the structural elements (heater, heated floor, boiler) at any time all year round. At the same time, you don’t have to worry about fuel or worry about pipes freezing. The only serious drawback can be considered the high energy consumption.

Mixed

In the case when you do not often use the bathhouse (especially in winter, rarely coming to the dacha), then the most optimal option would be a mixed heating device. For example, a stove is installed and electric heating is installed. If you decide to take a shower, rest or “stretch”, use electricity. If you decide to take a steam bath “like an adult”, turn on the stove thoroughly.

Remember. Whatever the heating in the bathhouse, if you do not use it constantly in winter, then be sure to drain the water from boilers, water heaters, pipes, toilet tank (if there is one), etc. This is guaranteed to protect them from damage, and you from unnecessary headaches.

Heated floor control unit

Several alternative options

Despite the fact that the options described above are the most popular and considered optimal, I decided to briefly mention some alternatives. In fact, they are varieties of stove heating, but have their own characteristics.

For example, if you have such capabilities, then you can install a diesel fuel boiler in your bathhouse. But this option requires a separate room (diesel fuel does not smell much), and you need to think about fuel storage.

There are also pyrolysis heating boilers. The undoubted advantage of such a boiler can be considered a very long, almost complete combustion of fuel. The disadvantage is the high cost and difficulty of operation (for example, raw wood does not burn in it).

It is also possible to use long-term combustion boilers, capable of burning a separate batch of fuel for up to 5 days, maintaining the desired temperature. There are even options for high-quality graded coal. But this is rather an “industrial” option, which is not suitable for a good traditional bath.

This is where I will finish the review of methods for heating a bath. Which heating is better is up to you to decide, focusing on your needs and capabilities. The main thing is that the rooms are warm and comfortable. Thank you for reading to the end. Until next time, see you on the pages of other articles. Bye!

Wisdom Quote: There are no dark times, only dark people (Roland Romain).

Some useful tips for installing a sauna stove

Heating system installation diagram.

Since a bathhouse usually has three rooms: a dressing room, a steam room and a wash room, the best option when installing a stove with your own hands is the option in which the firebox is in the dressing room, the heater is in the steam room, and a container with heated water is in the wash room. Existing models with a side-mounted heater will provide just such a configuration of the heating elements of the stove.

When building walls in a bathhouse, flammable materials (wood, insulation) are very often used, so when installing a sauna stove with your own hands, one should not forget about fire safety. Fireproof material is laid between the walls and the stove. The stove is installed on a steel sheet with non-flammable thermal insulation, and if it is heated with wood, then the same thermally insulated sheet is required in front of the fire door. The pipe is discharged through a ceiling device made of sheet steel and having a hole of the appropriate diameter. The stove is installed before finishing work begins.

A steel heater warms up the room very quickly, but requires constant burning, since it has practically no ability to accumulate heat. The heat from this type of heater is intense; ventilation will be needed to create more comfortable conditions.

A sauna stove made of brick has a number of advantages. Thick brick walls accumulate heat, gradually releasing it to the room. The process of heating the bath takes a long time, but the heat lasts a long time and there is no need for continuous burning. Making a brick heater with your own hands is difficult even if you have some construction skills. It is better to entrust the masonry to a qualified stove builder, but you can make a foundation of reinforced concrete for the stove on your own.

Construction of a brick stove

The main problem that arises when installing a brick heater is the massiveness of the structure. This requires the construction of a reinforced concrete foundation. For those who do not have experience in building sauna stoves with their own hands, the following tips may be useful.

If you put a thick layer of mortar between the brick joints, then under the influence of high temperatures it will begin to collapse and the heater will become leaky. On the contrary, a thin layer of mortar between the brick joints will negatively affect the life of the structure.

Each vertical layer of masonry must be covered with a top brick. It is advisable to make the ceilings in half a brick.

https://youtube.com/watch?v=cJLIxnSHc68

There are other nuances. So, if cut bricks are used, then the whole side should be turned inside the furnace. To ensure uniform linear expansion, cast iron elements are installed with a gap. To secure the upper part of the stove door, it is better to use a metal clamp.

Operating principle of the furnace

Let's talk a little about how the bathhouse heating system will transfer heat to the outside. If the heat radiation is at its maximum, you risk overheating or getting burned. Also, excess heat negatively affects the condition of the skin. To ensure comfortable conditions in the bathhouse, the stove must release heat using the principle of convection. Hot air comes from the oven and cooled air is supplied.

To achieve this result, the temperature of the furnace walls will be lower. But build the walls of the bathhouse from materials that will reflect infrared rays as much as possible. Heat accumulates well in the wall and in the stone backfill. In order for the stove to give off heat for as long as possible, build its walls thicker.

Combined heating system for bathhouse and home

If a residential building is connected to a central heating system, it is recommended to install auxiliary equipment for heating the bath.

Thus, the heating main from the house to the bathhouse is a practical and economical way to heat residential and functional premises.

In this case, the connection of the bathhouse to the heating system from the house is carried out through insulated pipes laid underground. In the bathhouse they are connected to heating radiators or convectors installed in all functional rooms. A sauna stove is used to heat the steam room and washing compartment.

At a short distance from the heating equipment installed in the house to the bathhouse, heat losses in such a system are insignificant.

In this case, the heating main of a residential building can be used for additional heating of the bathhouse, helping to maintain a comfortable temperature regime in winter. This will prevent possible freezing of sewer and water pipes and buildings.

The choice of a suitable heating system depends on the design features of the bathhouse and the financial capabilities of the owner.

Some owners prefer traditional electric or wood-burning heaters, which provide soft and even heating of the premises. Others choose combination systems or advanced heating technologies.

But if you know how to make heating in a bathhouse, following the rules and recommendations, the operation of the building is possible throughout the year under any climatic conditions.

Furnace air heating

Let us briefly consider this type of heating (warming up) of a bath. In fact, this option is considered the most common and most convenient. It is ideal for small spaces used directly for bathing procedures.

A good heater will be able to easily heat the entire bathhouse, and will not require the installation of an additional heat source and additional cash costs. Previously, to equip a good sauna stove, you had to find a professional mason or show good imagination to make it using scrap materials (what kind of stoves were invented).

Now everything is much simpler. You can easily purchase a ready-made product in almost any specialized store. Moreover, the installation of such heaters is quite simple and does not require any specific conditions.

The only thing you should pay special attention to when purchasing it is power (usually indicated in the product passport)

It is recommended to proceed from the calculation of 1 kW of power per 1 square meter of heated room. At the same time, in order to achieve maximum comfort and use the bathhouse at extreme drops in outside temperatures, it is worth taking into account when purchasing a power reserve, up to 30-50% exceeding your calculations. Here's an article about more detailed choices.

This type of heating also has another positive side. Most stoves of this type are heated with wood, which forms a unique psychological picture and allows true bathhouse lovers to preserve the tradition laid down by our ancestors.

By the way, the well-known company Teplodar recently released a new model of stove-fireplace called Siesta. She quickly gained authority among her “bathhouse brethren.” And this is no coincidence, since it is heated from the adjacent room, thereby simultaneously heating both the steam room and the relaxation room. Agree, it’s very convenient.

Naturally, there are options for heaters that use electricity, gas and even liquid fuel for heating. Well, here, I’ll tell you, everything is an acquired taste and depends on your capabilities and preferences.

https://youtube.com/watch?v=Waxg6VSKkXQ

Choice

What are the characteristics of gas stoves intended for baths?

Stones

The traditional stove for a Russian bath - a heater - is distinguished by a large number of round stones placed in a tray. The tray is located above the firebox and, after lighting the stove, heats up quite quickly; the stones heat up to temperatures of 200 degrees or more.

They perform a dual function:

- By accumulating heat, the stones maintain a high temperature in the steam room after the wood burns out.

- The very name “steam room” implies the presence of steam. The traditional mode for a Russian bath is 60 degrees with very high humidity. To add steam, just splash water from a ladle onto the stones.

Gas heater Ermak.

If you are a fan of the Russian bathhouse, a heater is your obvious choice. If you want to use a sauna with high temperatures and minimal humidity, you don't need stones. Heat accumulation in the case of gas, you understand, is of no value.

Water tank location

It may be located in the stove body or around the chimney. In the first case, the heat source for heating water is the burner flame, in the second - combustion products. In the author’s humble opinion, the second option is preferable: the tank additionally cools the combustion products, increasing the efficiency of the device.

Gas stoves

If you use bottled gas, a stove that combines two types of fuel would be an excellent solution for you. When the cylinder runs out, you can light the stove with wood.

Burner

Often it is purchased separately.

What should you pay attention to when purchasing?

- With a steam room volume of 18 m3, the reasonable maximum gas consumption by the burner is 1.5 m3 per hour. It is easy to recalculate the required productivity for your volume.

- The registration certificate and markings must be present. Automatic shutdown when the flame goes out is mandatory (in fact, now it is available almost everywhere).

- Any damage, even seemingly uncritical, puts an end to the device. Big and fat. We are talking about people's lives and health.

Domestic burner Teplofor.