Author: Yuriy Fedorovich Kolesnikov, thermal power engineer

The current global trend regarding garbage from private households is a complete ban on self-disposal. But a trend is not yet a law, and where there is already a law, they often turn a blind eye to it, as long as there is no visible harm to the environment. The reason is that the total greenhouse gas emissions from garbage trucks, according to all calculations, turn out to be greater than from garbage burned directly at the point of accumulation. Plus (for the economy and the environment - minus) capital investments and operating costs for special transport vehicles and a landfill (landfill) or waste plant. Therefore, a household waste incinerator (garden incinerator) is a produced and in demand product even where independent waste disposal is expressly prohibited . However, calculations and considerations of this kind are valid only on the condition that the concentration of foreign substances (except carbon dioxide and water vapor) in the emission of a household waste stove is not higher than that according to local environmental standards for household and household waste disposal enterprises. Let's see what the production of the high-tech age will delight us with here, and what we can do ourselves. Because everyday practice inexorably confirms that behind a high price there are sometimes not high and even primitive technologies.

Advantages and disadvantages of this design

Any stove, regardless of whether it is pyrolysis or a potbelly stove, has a number of advantages and disadvantages.

Advantages of a pyrolysis stove:

- almost complete combustion of fuel occurs, which burns for a long time, due to which high efficiency is achieved;

- very few harmful substances are released into the air after combustion: it is mainly steam and a little CO, so it is environmentally friendly;

- high efficiency, which reaches 85%, and if a Lachinyan pyrolysis stove is installed, then up to 95%;

- it is possible to regulate the combustion process, while the stove can operate from 5 to 100% of its power;

- it is possible to connect a heating circuit, which can be with either natural or forced circulation; in this case, Lachinyan’s pyrolysis stove will be able to heat not just one room, but the entire house, and you can also take water for household needs;

- it is possible to use different types of fuel: a pyrolysis stove can operate on both solid and liquid fuels;

- operates in automatic mode, human presence is only necessary for loading fuel, which is carried out depending on the model approximately once a day, and unloading ash once every 5-7 days.

But don’t think that this design has only advantages. It also has its disadvantages:

- quite large in size, especially if you want to make such a stove out of brick;

- it is necessary to provide a place for storing firewood, it must be protected from precipitation, since only dry firewood is needed;

- There is still a slight odor when burning garbage, so a high-quality and efficient ventilation system must be installed in the room;

- to increase the efficiency of the pyrolysis stove, it is necessary to install a fan, and if there is a water circuit, then a pump, and this requires an electrical network;

- Since the smoke temperature is quite low, condensation accumulates in the chimney. To collect it in the chimney, it is necessary to make a storage tank. The cross-section of the chimney must be large, and it must be insulated.

Industrial technology

Most of the old waste incineration plants are currently unprofitable and rely on subsidies. A modern horizontal thermal destruction incinerator (garbage boiler) is a complex, expensive, but payable 3-stage device on a large scale (above in the figure below). In the pyrolysis chamber, at a strictly fixed, relatively low temperature, light flammable gases are released. It is impossible to run effective high-temperature pyrolysis - the garbage is full of harmful rubbish, which should not get into the pyrolysis gases. For the same reason, combustion in the combustion chamber is also carried out at a lower temperature that is not optimal from an efficiency point of view.

The design of a modern industrial boiler for burning waste and the appearance of its household analogue

Pyrolysis gases enter the burner, which heats the afterburner; It is this that ensures proper operation of the boiler. Since garbage is a highly unstable source of combustible gases, the burner is fueled by natural fuel gas. In the afterburner, the temperature rises as much as possible, to 900-1000 degrees or more. Having heated the pyrolysis chamber as long as necessary, the flue gases, consisting only of CO2 and H2O, escape into the atmosphere, possibly passing through an economizer or hot water heat exchanger.

The ash goes for further processing - the content of elements such as palladium, iridium, and rare earth metals in it is higher than in natural deposits that are considered industrial. Recently, they have been trying to extract gold from garbage ash - it comes there with microchips flying into the trash. Next, the ash is purified from toxins and radionuclides (both are also valuable raw materials), and the harmless granular residue is used in construction, road work, etc.

Doesn't take out equipment...

Industrial-type horizontal incinerators are commercially available; Amateurs are also trying to build them “homemade” (below in the figure). But:

- Purchase prices - Mom, give birth to me back! 220,000 – 250,000 rub. for an economy class installation it is still cheap; however, with delivery within the region, installation (the foundation is the owner’s according to the manufacturer’s specifications), commissioning and start-up in operating mode. The main reason is complex, expensive (and energy-consuming) electromechanics, because in order for garbage to move from chamber to chamber, and ash to the ash pan, pallets with material must be shaken in a certain way all the time.

- Mechanical resource is limited: approx. Once every 3-5 years, a major overhaul of the boiler is required. The cost is about a third of a new unit.

- Fuel gas is needed to feed the burner. There is a monthly fee or the cost of receiving a one-time batch. In private household plots, gas - please, according to the house meter. There are no discounts or subsidies, because self-disposal of waste is not legalized.

- Ash from the boiler is not suitable for fertilizer, because contains a lot of harmful and dangerous substances. Again, it needs to be taken in for recycling. They do not pay for the accepted material - the deliverer needs to pay in order to take it, because, unlike mass household and industrial waste, the profitability of processing garbage ash from one farm is in no way guaranteed.

Note : most often, home craftsmen build horizontal incinerators based on the model of the Vesta Plus furnace, patented by engineer Mikhienko (Kazakhstan), see video:

Video: Vesta Plus waste incinerator

Horizontal stove made from a barrel with a pipe

The design of horizontal barrel stoves consists of a container turned on its side, standing on supports or legs. Such bases can be made in the form of trestles, vertical or inclined metal profiles, connected from below to a container in which waste is burned.

They are equipped with a door, a chimney and, sometimes, an ash removal system (an ash container and a grate). During one working cycle, such a device can burn up to 150 - 170 liters of waste.

A typical stove for burning garbage from a horizontal barrel is shown in the diagram:

Materials and tools

To create such a furnace, you will need the following consumables, tools and accessories:

- Empty barrel with a volume of 200 liters.

- Steel profile (5 meters).

- Metal rod (5 meters).

- Hinges for the door.

- Welded mesh (1 square meter).

- Wire (200 grams).

- Spark arrester.

- Tin pipe for the chimney (1.5 meters).

- Metal handle with wooden nozzle.

- Bolts, nuts - 6 pieces each.

- A jigsaw, several metal files.

- Self-tapping screws with large flat heads (20 - 25 pieces).

- Set of drills for metal.

- Angle grinder (grinder) with cutting and grinding wheels.

- Fireproof paint.

- Acetone or white spirit.

- Several brushes or a paint sprayer.

- Electric drill.

- Personal protective equipment for working with an angle grinder (goggles or mask, gloves).

- Measuring and marking tools (core or sharpening, tape measure, building level, square).

Step-by-step instruction

After preparing all the materials and tools, you can begin the actual production of components and assembly of the structure. How to make a stove for burning garbage from a horizontal barrel:

- First the door is cut out. To do this, using a marking tool, draw a straight line parallel to the diameter of the barrel and 10 centimeters from the edge. Using a grinder, a slot is made along the resulting chord. When performing this operation, you need to ensure that the cutting disc of the angle grinder does not cut through the side of the container. Next, using a drill with a diameter of 12 millimeters, a hole is made for the jigsaw file and the door itself is cut out. You cannot use a grinder for these purposes, as the disc will cut through the side surfaces of the barrel.

- Several holes are drilled in the lower part of the resulting door to allow air to enter, which is necessary during the combustion process.

- Using an emery disc and an angle grinder, the surface of the barrel is cleaned from rust and burrs. This is needed for the upcoming painting of the incinerator.

- A support post made in the form of goats is constructed from a metal profile. Profile sections 1 meter long are joined into two X-shaped crosses at an angle of 90 degrees using bolts and nuts. Next, they are connected using the fifth piece of the profile into a single whole.

- All structural elements are degreased using a solvent and, if desired, primed. Next, a layer of fireproof paint is applied. It is better to do this in 2-3 layers, waiting for it to dry after each painting.

- All elements that have dried after painting are assembled. The goats are tightened using bolts, nuts and washers. The barrel itself is secured to the trestles using the same self-tapping screws.

- Hinges and a handle are installed on the door using self-tapping screws and an electric drill (or screwdriver).

- A chimney hole is made in the body using a grinder, and not just a circle is cut out, but cuts are made in the form of petals. Then they bend back and the chimney itself will be fixed to them.

- Using self-tapping screws, the chimney is installed on the surface of the barrel and petals.

- At the bottom of the barrel, the grate is assembled and mounted.

- The back cover is installed using clamps and bolts.

- The oven is completely ready for use.

Ecological danger of MSZ

Toxic emissions, when released into the air, cause catastrophic harm to the environment. There has been an increase in cancer and allergic reactions among the population where waste incineration plants are located.

Environmentalists who oppose the construction of waste incineration plants have developed a map. It includes information on the location of existing and under construction waste incineration plants. The purpose of this map is to inform the population about all the risks of constructing such enterprises near populated areas.

- Even incinerators equipped with the most modern treatment plants are capable of releasing large amounts of heavy metals into the atmosphere.

- Incineration results in incomplete destruction of waste. They are transformed into harmful emissions that settle in adjacent areas.

- Dioxins present in all emissions from factories. When burned, they decompose and are then converted into new dioxins when temperatures change.

- Polychlorobenzenes have a significant impact on changes in human health.

- The release of mercury into the atmosphere is a big problem. It does not settle on cleaning filters and spreads over long distances.

At the end of the combustion, waste remains that needs to be disposed of, but unscrupulous owners of the incineration plant take it outside the city.

Old-style waste incinerators poison the atmosphere and people with harmful emissions.

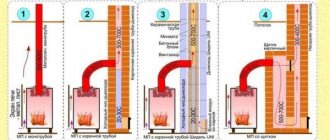

Types of pyrolysis furnaces

The following types of pyrolysis furnaces can be distinguished:

- Single-circuit devices. Single circuit furnaces have two combustion chambers that are separated by a fireproof partition.

- Dual-circuit devices. These gas generator furnaces have the same design, but they have an additional circuit that heats the liquid for hot water supply.

Also, based on the material used to make the heat exchanger, the following types of pyrolysis furnaces are distinguished:

- Devices with a cast iron heat exchanger. The service life is at least two decades, but the unit is sensitive to sudden temperature changes in the combustion chamber. In such aggressive conditions, a cast iron pyrolysis furnace gradually becomes unusable.

- Devices with a steel heat exchanger. Service life is at least 13 years. The equipment is susceptible to corrosion processes, but is not afraid of temperature changes.

A pyrolysis furnace with a water circuit is able to heat a small volume of liquid in a short period of time.

For property owners who do not want to purchase a pyrolysis combustion furnace in specialized stores, but to construct the device with their own hands, a mini pyrolysis furnace will come in handy. This is the same stove, but small in size, installed in garages, bathhouses or other small rooms.

The operating features of a mini pyrolysis oven are presented in the video.

Blueprints

Drawings with dimensions will help you make a simple or unusual container for recycling organic waste. We added some of them to the description and added a video, after watching which you can make a stove yourself.

Purchased models

The finished stove consists of a metal casing that prevents sparks from falling out during the combustion process. It is made of sheet metal with a minimum thickness of 3 mm. The body is covered with heat-resistant enamel, which prevents the development of corrosion. The dimensions of the finished models are relatively small. When cold, it can be easily transported from place to place or loaded into the trunk of a car.

There are grates inside the firebox. They look like gratings, most often made of cast iron. The combustion process occurs on the grates. Large debris remains here until it becomes ash. Grate bars are also needed for the flow of oxygen, which supports the combustion process.

There is a blower door at the bottom. When it is slightly open, air enters the firebox, enhancing the combustion process. Subsequently, you can rake out the ashes from here and use them as fertilizer.

The top cover will protect the fire from rain and bad weather. It limits the flame, preventing sparks from flying up or flying away. The design may have vertical loading of waste. In this case, the firebox door will not be on the body, but on the lid.

Materials for work

To build a long-burning brick pyrolysis furnace with our own hands, we will need the following materials:

- refractory ceramic bricks - 400 pcs; fireclay bricks - 100 pcs; sheet steel 6x1.5 m, thickness not less than 4 mm - 9 m2 cast iron grate of standard size - 3 pcs; concrete B12.5 - 0.12 m3 fan, power minimum - 300 W ;temperature regulator; door for the ash pit; door for the firebox; metal pipes; metal profile; ready-made high-temperature mixture for masonry - 470 kg; electrodes; high-temperature sensor.

Why build a waste incinerator?

Incineration is the most effective way to dispose of plant waste for owners of private houses and land.

There are several ways to burn unnecessary things:

- at the stake;

- in a suitable metal container, such as a garden barrel;

- in a special oven.

Of course, lighting an open fire is the least environmentally friendly and safe option. After all, gusts of wind can carry sparks and burning masses to the sides, which can cause a fire. In addition, the scorched and burnt earth under the ashes becomes “dead” for a long time.

From this point of view, putting waste for burning in an iron container is the safest, but it also has a number of disadvantages:

- used containers with fairly thin walls quickly burn out and become unusable;

- due to the lack of traction, a compressed mass of waste remains untouched by fire at the bottom;

- Flying sparks and burning pieces can also cause a fire.

So, with the burning of garbage, the owner of the house faces various pitfalls.

An acceptable solution is to burn waste in a special furnace that meets all fire safety requirements. You can also burn garbage in a barrel at your dacha.

Features of a homemade recycler

Homemade designs attract attention due to their simple maintenance and low cost. If you have a metal barrel, manufacturing costs can be minimal

To build such a stove, you can literally get by with a grinder, a drill and a hammer. However, it will not be possible to assemble a functional device at home.

Factory heat exchangers allow you to use the generated heat for cooking or heating your home. Such products have good build quality and attractive appearance. Some options are equipped with filtration systems, which reduce the level of harmful emissions into the atmosphere. The devices are more durable than a barrel, but their cost is quite high. Therefore, such a purchase for use in the country is not always justified.

The design of the stove must be made taking into account safety regulations. Before you start burning waste, you need to prepare fire extinguishing agents, such as water and sand.

For disposal, you should use garbage of organic origin, which, after burning, turns into ash and can be scattered in the garden as fertilizer.

Despite the fact that anyone can build such a stove, you need to know about the advantages and disadvantages of such a device.

The advantages include:

- the ability to move to any place on the site;

- compactness;

- no scorched soil.

Flaws:

- improper placement and lack of control can lead to fire;

- Frequent use contributes to metal burning and failure of the container.

Inorganic waste cannot be disposed of by burning. Such waste includes plastic, glass, metal, electronic circuit boards, and synthetics. It is strictly forbidden to burn aerosol cans of paints and other substances. Also, do not burn chipboard, various posters, or painted boards, since during the combustion process they release toxic substances. The exception is wood coated with water-based emulsion.

Before you begin recycling street waste, you should consider the following points:

1. The barrel must be located at a distance of 25 m from buildings, trees and bushes and 50 m from the forest. 2. There should be no dry grass, branches or other easily flammable materials nearby. 3. If there is a strong wind, you should not burn garbage. 4. Be sure to control the combustion process. 5. You need to prepare a sheet of metal to cover the tank.

What waste can be processed using pyrolysis

Note! MSW - municipal solid waste - different substances that cannot be reused in human household activities without treatment.

Solid waste is a mixture of substances of organic and inorganic origin that have different properties. In Russia, waste is not sorted. However, abroad, and in our country too, there is a tendency to reduce the share of food waste in garbage and increase the share of packaging materials: plastic, cardboard, paper. Studies have shown that approximately 30 percent by weight and 50 percent by volume of solid waste comes from packaging material. And 13 percent by weight and 30 percent by volume of packaging material falls on the share of plastic products, the vast majority of which are plastic tableware. The organic component of garbage is divided into:

- compostable (kitchen waste, sawdust, tree bark and branches, wood chips, old newspapers, cardboard);

- non-compostable (plastics, rubber, leather, discarded old tires, cables, viscous pasty waste such as motor oil, oil sludge, soil contaminated with fuels and lubricants).

Compostable and non-compostable components of waste are subjected to pyrolysis.

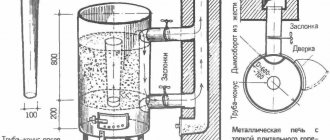

Homemade designs

The simplest smokeless furnace for burning waste is made from a metal barrel (the desired wall thickness is from 2 mm). A 200 liter container is suitable, not too rusty to ensure a long service life of the product. An alternative option is a piece of pipe with a diameter of 500 mm. They have thick walls (from 8 mm), which increases the weight of the structure and makes it more difficult to make holes. Although the system turns out to be stronger and more durable. To work with any workpiece you will need:

- drill or screwdriver;

- grinder - for removing the bottom or cutting out large holes in it;

- metal rods or finished grate;

- welding machine (optional);

- bricks or other material for the frame.

It will be enough to dig a hole (according to the diameter of the structure and a depth of 20-30 cm) above which, on legs made of bricks or other objects, the firebox will be placed. For better traction, holes with a diameter of 25 mm are made at the bottom of the body and above the stiffeners.

The garden stove can also be made in the form of a rectangular box. The combustion chamber is located at the bottom (side loading). To make this design you will need:

- blueprints;

- sheet steel, thickness from 2 mm (replaced with a rectangular tank if available);

- metal corners;

- welding machine;

- cutting tools.

A ready-made container is the optimal solution. But even in this case, you will need welding equipment to attach the lid hinges, chimney and other components. Making a hearth from scratch will take longer than turning a tank into a stove. First, steel parts of specified sizes are cut out, depending on the planned volumes of waste to be burned and the area of the selected area - some sellers offer to perform this procedure for the client. Places of future connections are cleared. For additional strength, the corners are fixed from the inside. They can reinforce all seams, but 4 elements at the joints of the sides are sufficient.

For the chimney, if provided, it is convenient to take a metal pipe of round, square or rectangular cross-section. The size is calculated based on the parameters of the firebox, but for a small stove a channel with a passage diameter of 80-100 mm is suitable. You can cover the chimney with thermal insulation and equip it with a filter with a spark catching function.

The energy generated is suitable for cooking or heating food. You should not barbecue over garbage coals. But its heat from an iron barrel is suitable for heating water; warm liquid is a necessary condition for dissolving a number of fertilizers and poisons. A large pan fits well into the hole without blocking the draft due to the perforation of the hearth body. The upper plane of the rectangular heat exchanger will turn into a full-fledged cooking surface.

A brick kiln is also used for recycling solid waste. Both the sauna hearth, which has received a second life, and a new design created specifically for the task are used. The bricks are placed without mortar, remaining in place due to their weight and rough surface. They line a barrel or create independent structures. Be sure to use fireproof blocks. Suitable for oven:

- Fireclay stone can withstand temperatures up to 1500°C, but only if the manufacturing conditions are met. Blocks overexposed in the oven lose their fire-resistant properties.

- Red brick - designed for heat up to 1000°C. Solid blocks are used for masonry.

- Graphite - intended for finishing the inner surface of the firebox. Depending on the composition, it can withstand up to 1600-1700°C.

Products made from red clay are the most affordable. Brick, due to the lower outside temperature, provides greater safety compared to bare metal. It opens up additional design possibilities, allowing you to make a two-chamber waste incineration furnace without welding and cutting tools - you just need to correctly design the arrangement of the blocks and then complete the drawing.

Additional items

Today, many ready-made designs are produced that have special additional components. They improve the performance of the equipment by adding a number of functions. For example, complex structures may have a chimney. It increases traction, so waste is burned faster and better. The design with a chimney is productive, so it is purchased if you need to burn large volumes of garbage. Even in wet weather, the recycling process will be fast.

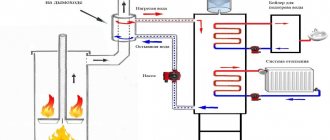

Another possible additional element may be the presence of a water heater in the design. The liquid is supplied through tubes that pass inside the firebox using a pump. Such a boiler is connected to radiators, using it in the cold season. These are volumetric furnaces designed to burn not only garbage, but also wood and coal.

Equipment with a boiler is used for a small country house. The inconvenience of such a system is the need to constantly throw garbage or firewood into the firebox. They burn out in 3-4 hours, and then you need to load solid fuel again. Fill the heating system with special antifreeze so that if the boiler stops, the coolant does not freeze and damage the pipes.

Some designs include smoke purification filters. The oven will be safe for the environment.

Some owners purchase designs with a burner on top. During the combustion of household waste, it will be possible to cook food and heat water. If you have a summer kitchen at your dacha, a model with a burner (or even 2 burners) would be the preferred option.

Typical design of a finished stove for a summer residence

A factory stove consists of a main body that prevents sparks from spreading during combustion. It is usually made from metal about 3 mm thick. The case is protected from corrosion by heat-resistant enamel. The dimensions of the finished models are small and can be carried.

As a rule, the firebox contains cast iron grates on which combustion occurs. The grates are necessary for the supply of oxygen. A door for the blower is installed at the bottom. If you open it slightly, air will enter the firebox and the combustion process will intensify. The lid on top protects from precipitation and prevents the spread of sparks.

Some designs provide for vertical loading, in which case the door for the firebox will be located on the lid.

Option for a stove combined with a boiler

Such models are installed in small country houses. The inconvenience of such a device is the need to regularly fill the firebox with garbage and wood. The heating system requires filling with a special antifreeze so that when the unit is stopped, the coolant does not freeze and, as a result, damage to the pipes occurs.

Additional items

Today, many ready-made designs are produced that have special additional components. They improve the performance of the equipment by adding a number of functions. For example, complex structures may have a chimney. It increases traction, so waste is burned faster and better. The design with a chimney is productive, so it is purchased if you need to burn large volumes of garbage. Even in wet weather, the recycling process will be fast.

Another possible additional element may be the presence of a water heater in the design. The liquid is supplied through tubes that pass inside the firebox using a pump. Such a boiler is connected to radiators, using it in the cold season. These are volumetric furnaces designed to burn not only garbage, but also wood and coal.

Equipment with a boiler is used for a small country house. The inconvenience of such a system is the need to constantly throw garbage or firewood into the firebox. They burn out in 3-4 hours, and then you need to load solid fuel again. Fill the heating system with special antifreeze so that if the boiler stops, the coolant does not freeze and damage the pipes.

Some designs include smoke purification filters. The oven will be safe for the environment.

Some owners purchase designs with a burner on top. During the combustion of household waste, it will be possible to cook food and heat water. If you have a summer kitchen at your dacha, a model with a burner (or even 2 burners) would be the preferred option.

Pros and cons of burning waste in a barrel stove

Each design has both its pros and cons. Of the general advantages and disadvantages, the following positive and negative points can be highlighted.

Pros:

- barrel-stoves are mobile and easy to move around the garden;

- allow you to avoid open fire;

- the strength of the fire can be controlled.

Minuses:

- constant exposure of the barrel to elevated temperatures leads to wear and tear of the structure;

- the use of barrel stoves even in your own garden plot is prohibited by law; constant use of them will most likely lead to the payment of fines;

- This method of disposal of garbage is not environmentally friendly, and also does not provide absolute fire safety.

Advantages and disadvantages of a long-burning stove

A pyrolysis furnace as a heating device has a number of advantages:

- Environmental Safety. Almost complete combustion of products without the formation of toxic smoke.

- Economical. Longer combustion requires less fuel.

- Possibility of connecting to a heating device with any type of circuit.

- Recycling. Instead of fuel, garbage is loaded into the unit.

- The efficiency is 85%. With low fuel consumption, the room is heated in a short period of time.

- Availability. It is possible to install the stove yourself without the help of specialists.

The main disadvantage of pyrolysis plants is their dependence on the alternating current network. Powerful units cannot provide themselves with sufficient thrust, so additional fans are built into them.

Today, pyrolysis is the most effective method of waste disposal. As a result of this process, no dangerous or harmful substances remain. Even storing pyrolysis waste does not harm the environment.

Safety regulations

- The process of burning waste is accompanied by a number of dangerous and harmful factors that can lead to fires, burns, and poisoning by combustion products. Such devices should be installed as far as possible from residential premises, on the border of the garden plot.

- When using them, it is necessary to take into account the direction of the wind; it should blow in the opposite direction from the buildings. During strong winds or hot dry weather, the operation of such stoves is extremely undesirable, as this can lead to a fire.

- When burning garbage, you should constantly monitor the process occurring inside the container. However, it is extremely undesirable for a person servicing such a device to be in the area where the smoke escapes. Children and pets should be protected from inhaling such smoke.

How does a waste incinerator work?

The kiln contains 7 layers of brickwork and has been in operation for 5 years. Before kindling, the ash pan must be cleaned; ignition takes no more than 5 minutes. A new portion of tops is loaded with a pitchfork at intervals of 5-10 minutes. Any pile of green tops, raspberry branches, gooseberries, and currants is burned in 20-40 minutes.

Three characteristic periods can be distinguished in the operation of the furnace:

• ignition of the firebox and its one-time loading with firewood;

• burning of wood and the contents of the barrel, which is accompanied by abundant smoke removal;

• combustion without smoke, only flames are visible, even when loading a portion of green tops or branches.

After each fire, I recommend covering the stove with a steel sheet to protect it from precipitation.

When dry leaves are burned, it feels like a rocket has been launched into the area. The neighbors like the operation of the stove, but refrain from repeating it. One of the passersby, standing by the fence for a long time, looked at the working stove, I invited him to come in and take a closer look, but refused: “No, if I come in, then I’ll want it too.”

Furnace design

Recycling ovens are a profitable option for biomass disposal. The destruction of waste in such devices makes it possible to obtain pressed wood briquettes for use in heating boilers. The operation of the installations is identical to the operation of household stoves, but there are differences in technical design. The furnace design includes the following elements:

- Loading hopper.

- Heat exchanger.

- Grate.

- Perforated glass.

- Smoke exhauster.

- Afterburner chamber.

Complete combustion without decay products helps improve the environmental situation.

Types of wood waste burning stoves

The models of stoves for recycling wood waste are varied. 3 manufacturers supply various incinerators to the domestic market:

- IZHTEL. Izhevsk manufacturer of incinerators produces furnace models with a loading hopper volume from 150 to 2100 kg. Productivity from 50 to 350 kg/hour.

- VOLKAN, HURIKAN. Stoves from Krasnodar manufacturer Eco-Spectrum. The volumes of VOLKAN loading tanks are FROM 150 to 2000 kg. HURIKAN bunkers - FROM 200 to 8000 kg.

- Progress (IS series). Incinerators from the St. Petersburg plant with a capacity of up to 350 kg/hour.

All models are equipped with afterburning chambers, control panels, and imported Italian-made burners (Lamboghini) with auto-ignition.

Classification

As mentioned earlier, there are a large number of specialized furnaces that are created to operate and burn a specific type of waste. They use some engineering features and technological solutions that not only simplify the process of burning materials, but also significantly reduce the cost of maintenance!

- Recycling and burning of hazardous waste. A medical waste incinerator is a fairly clear example of the type of device that handles hazardous materials. Medical waste poses biological and chemical hazards, so all items must be disposed of properly. In the working chamber, the temperature reaches 1200 degrees Celsius, which is quite enough to reduce the mass and volume of waste, destroy microbiological residues, as well as residues of pharmacological agents.

- Disposal and incineration of mixed waste and garbage. This type of device works with a wide range of materials, which explains its popularity. The average temperature in the chamber is about 1000 degrees. Thanks to the availability of modern engineering solutions, it is possible to achieve high energy efficiency.

- Disposal and burning of animal carcasses. The system is actively used on farms and other livestock farms. Average efficiency is about two tons of waste per hour. The stove has a rotating mechanism that ensures uniform combustion of objects, as well as a large number of air filters that allow you to clean the exhaust air from any impurities and sediments.

- Recycling and combustion of mixed waste (and garbage) with increased productivity. This type of model has the following technical characteristics: Volume of waste burned: about 350 kg per hour; The amount of energy released from combustion: not less than 6250 kcal/kg; Ash content indicators: 9.5%; Humidity: no more than 50%.

- Furnaces for burning phenol and formaldehyde generated during the production of plywood and chipboard. A fairly simple device that maintains elevated temperatures to eliminate phenol and formaldehyde compounds from materials. The furnace is a dual-circuit device, and elevated temperatures are achieved through active combustion of diesel fuel and natural gas.

- Furnace for thermal neutralization of liquid waste from the production of polypropylene (mineral oil containing TEAL and ATMER). Devices of this type are installed at oil refineries to neutralize oils and other substances that contain polypropylene. Despite the modern structure, the installation must be installed outside the work premises where the company personnel are located.

Garbage incinerator

This version of the stove for destroying garbage in the countryside is made from an ordinary metal barrel. It is noteworthy that there is absolutely no need to have any special knowledge or skills for this. Anyone can make such a stove. And first of all, it is necessary to prepare materials and tools for work.

What you will need in the process:

- grinder and two discs for it (for metal and emery);

- bolts and nuts (six pieces each);

- twenty self-tapping screws;

- spark arrester (with fasteners diameter 11.5 cm);

- paint with fire-resistant properties;

- paint brushes (can be replaced with a spray gun);

- meter of metal grating;

- degreaser;

- a pair of door hinges;

- one and a half meters of tin pipe (11.5 cm in diameter);

- wire (approximately 200 g);

- five-meter steel profile;

- five-meter steel rod;

- handle with wooden attachment;

- metal drill (diameter 1.2 cm);

- electric drill;

- jigsaw and metal saws.

Having completed the preparation, you can begin the main workflow. A garden waste oven is made in several specific steps.

Barrel processing

You need to mark a straight line on the bottom - it is to this that the door will be attached in the future. Then make a cut according to the marks using a grinder, being careful not to touch the sides.

Make a hole at one of the edges of the resulting cut.

It is extremely important that it is located as close as possible to the side of the barrel, as well as directly on the cut strip

From the intended point you will need to move further with a jigsaw. Insert the saw into the hole and carefully cut out the bottom. Do not touch the upper part (the one above the cut). You need to move as close to the walls as possible.

It is necessary to make several holes in the resulting door - it is through them that air will flow. You can do them at will.

If necessary, clean the barrel from old paint or rust using a grinder with an emery attachment.

Place the door, securing it with hinges, and install the handles. For reliability, you can use self-tapping screws and a screwdriver.

Goats

To make a trestle you will need five sheets of metal profile. The goats will be made up of a pair of crosses, fastened together by a rod.

The profile must be connected at a right angle. To do this, you need to make two holes in each and tighten them with bolts.

The next step is degreasing and painting the barrel. We must not forget about goats.

It is advisable to handle goats disassembled. You need to apply the paint in several layers, each time waiting for it to dry.

A day after dyeing, you can collect the goats. Don't forget to put washers under the nuts. Tightly tighten all parts of the structure. The resulting strength should be sufficient for a metal barrel with an additional load in the form of debris.

Smoke exhaust

To make a hole for the smoke to escape, you need to draw a circle with a diameter of 11.5 cm at the top of the barrel. Cut the circle into slices, like a cake. There should be about ten elements in total. Bend the slices vertically upward.

Place the chimney pipe so that all the pieces fall inside. Then secure the pipe at several points with self-tapping screws for reliability.

Install the grate. Do everything as in the picture.

Place the cover - you can secure it with clamps or bolts.

The DIY waste incinerator is ready and you can start using it now.

Manufacturing options

There are several options for such designs. A waste incinerator for a summer house or personal plot can be made from:

- Metal barrel.

- Used gas cylinder.

- Trimming large diameter steel pipe.

- Concrete well ring.

- Bricks.

The most popular and widespread, due to the ease of manufacture and cost-effectiveness of such structures, are stoves made from old iron barrels. According to their orientation in space, they can be either vertical or horizontal. Below is a photo of a horizontal waste incinerator.

When starting to design such a stove, you should think about where it will be located on your personal plot. There is no need to place it in front of the facade of the building, this will spoil the overall appearance of the local area. A garden stove made from a barrel for burning garbage is an auxiliary unit; it is better to place it in the backyard of the site, closer to the forest or fence, away from the eyes of neighbors and passers-by.

Waste incineration barrel

Why is such a barrel needed?

The barrel is ideal for recycling garbage, dry grass, branches and much more. It moves easily thanks to the wheels mounted on the barrel.

Characteristics:

diameter 600 mm,

height 1000 mm

| Waste disposal barrel | 3900,00 |

The burning of waste in dachas, garden plots and areas adjacent to private houses is regulated by clause 218 of the Fire Regulations of the Russian Federation, article 20.4 of the Code of Administrative Offenses of the Russian Federation and the order of the Ministry of Emergency Situations of January 26, 2022.

We will set up a place for burning

- an open fire can be lit in a pit with a depth of at least 30 cm and a diameter of no more than 1 m;

- the fire must be 50 m away from all buildings, 100 m from coniferous forests, and 30 m from deciduous forests;

- the area on which the fire is located must be cleared 10 m from dry branches, logging residues, dry grass and other flammable materials;

- a mineralized fire protection strip with a width of at least 40 cm should run along the edge of the site;

- the site must have the necessary tools and materials to extinguish the fire;

- the person controlling the fire must remain on the site until the end of the fire (smoldering).

- We invite a representative of the fire inspectorate for approval

- After burning, you need to fill the area or container with water or cover it with sand until the burning/smoldering stops completely.

We burn garbage in a closed container (barrel, stove)

- the waste incineration container must be 25 m away from all buildings, 50 m from coniferous forests, and 15 m from deciduous forests;

- the area on which the container is located must be cleared 5 m of dry branches, logging residues, dry grass and other flammable materials;

- there is no need to create a firebreak;

- There should be a metal sheet next to the container that can cover it from above and limit the access of air to the fire;

- the person controlling the fire must remain on the site until the end of the fire (smoldering).

- We invite a representative of the fire inspectorate for approval

- After burning, you need to fill the area or container with water or cover it with sand until the burning/smoldering stops completely.

Important: in private areas, open fires are allowed within a radius of 5 meters from buildings. Fines

Fines

- An individual for violating the law will be fined from 1000 to 1500 rubles

- Official (chairman of a garden cooperative) - in the amount from 6,000 to 15,000 rubles

- Legal entity (garden cooperative) – from 150,000 to 200,000 rubles.

If improper burning of waste results in harm to the environment, people or property, a fine alone will not do, and a criminal case may be opened.

FORBIDDEN! Burn tires, bags, plastic bottles, film and other artificial materials.

Pipe 1 meter long with umbrella + 1490.00 rubles

Calculation of parameters

When designing a furnace, they strive to solve the main problem - to provide the required power. It will depend on the amount of fuel, so you need to correctly calculate the volume of the firebox. This can be done using a simplified method.

We set the required power

Suppose, based on the results of the heat loss calculation, it turns out that 10 kW of heat is required to heat the room at the lowest outside temperature.

We determine the required furnace power in normal (flame) combustion mode

It is known that in the gas generation mode the furnace power is 10-30% of that which develops in the flame combustion mode. Consequently, to obtain 10 kW with gas generation, the unit, when burning with a flame, must develop a power of W = 10 / 0.3 = 33.3 kW (we assume a 30 percent power ratio).

We choose the least energy-intensive fuel of all types that are supposed to be used

Here, for example, is data on the calorific value of some types of wood:

- beech: 15.5 MJ/kg;

- birch: 16.5 MJ/kg;

- aspen: 18.2 MJ/kg;

- oak: 20 MJ/kg.

Of all the listed species, beech gives the least heat, so we will focus on it.

We determine the volume of fuel reserve that can provide the required power

It should be taken into account that a portion of firewood burns in flame mode in approximately 4500 s. Therefore, during this time it should provide the following amount of heat: Q = 33.3*1000*4500 = 149.85 MJ.

Let's calculate the required mass of fuel, taking into account that it burns only 80% completely, and the efficiency of a homemade stove is approximately 50%:

M = 149.85 / (15.5*0.8*0.5) = 24.17 kg.

Knowing that the density of dry beech is 620 kg/m3, let’s convert the resulting mass value into volume: V = 24.17 / 620 = 0.039 m3 = 39 liters.

Determining the volume of the firebox

It should be taken into account that the furnace load factor is on average 0.63. Thus, it should have a volume: Vt = 39/0.63 = 61.9 l.

Therefore, the required volume of the firebox can be taken as 62 liters. Its length should be taken equal to 0.5 m - so that sufficiently long logs can be laid. Other sizes are optional. For example, the width can be 300 mm, then the height should be 413 mm (0.3 * 0.413 * 0.5 = 0.062 m3).

Horizontal barrel with chimney pipe: preparatory measures, step-by-step work process

Materials, available tools that will be needed:

- barrel;

- pipe (diameter up to 150 mm);

- metal corners;

- loops, 2 pcs.;

- fasteners (nuts, bolts, metal screws).

Tools:

- electric drill;

- Angle grinder or “grinder”;

- screwdriver;

- welding machine.

At the preparatory stage, the metal surfaces of the container are cleaned of paint residues. This can be done with a wire brush. Instructions:

- A simple design diagram is drawn up.

- Part of the lid is cut off. Leave 10-15 cm of metal where the pipe will be located in the future.

- The hinges are fixed, they connect the lid and the barrel.

- Make a hole in the solid part of the end section of the barrel - 100-150 mm (depending on the size of the pipe). For fastening, use a welding machine; if you don’t have one at hand, standard fasteners will do.

- A rectangular hole is made in the lower part on one side. Thanks to it, air draft will be ensured.

- A grate is made for installation inside the oven. It would be correct to use metal rods for this. First, a ring is formed, then the longitudinal elements are welded. But this is painstaking work. You can weld metal corners and any heat-resistant structural elements (small profile pipes, corners, plates, etc.) to them.

Horizontal barrel