Types and designs of shields

According to the internal structure, these structures are of 2 types:

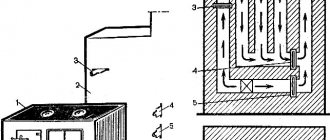

- channel: in the body of the shield there is a developed network of gas ducts, which consists of several vertical channels connected to each other. Before exiting, the gases make a tortuous path along these passages, intensely giving off heat;

- bell-shaped: such a shield for a cast-iron stove or stove has one or two chambers with horizontal arches, where hot gases are retained until they cool down. Only after this can they enter the vertical channel and go down the chimney.

Duct-type heaters are structurally simpler, and therefore easier to fold. Bell shields are more efficient in terms of heat removal, but their design is much more complicated. It is not recommended for beginners to undertake their construction; the hand of a master is needed here. For independent construction, we present you with drawings and sections of a simple duct-type heating panel with three vertical gas ducts:

In order for our heating and cooking stove to be used in the summer for cooking, the design provides for switching the smoke circulation to the summer mode. The transition is carried out using three valves built into the gas ducts. In addition, in the upper part of the structure there is an exhaust ventilation shaft to organize air exchange in the room. To avoid the draft tipping over in strong winds, a grate with a check valve is installed at the shaft exit.

The following diagram shown below shows a metal cooktop with a bell-type heating hood. As you can see, here the gases, after leaving the furnace firebox, enter a chamber with a vault, from which 2 channels lead.

Since the only way to move from the chamber is downward, high-temperature combustion products are retained under the roof until they cool down. Then they become heavier and, according to the law of convection, leave the chamber space. In this case, to increase efficiency, the furnace with a heating shield is equipped with tubular heaters located inside the flues.

Device designs

The designs of heating panels are divided into two large categories: they can be thick or thin-walled.

About wall thickness

- Thick-walled panels are laid in half a brick. They must be warmed up well beforehand. When a hob with a heating shield is used constantly, such a device is advisable. Among other things, thick-walled structures are preferable from a fire safety point of view.

- A thin-walled heating shield is placed in a quarter of a brick. To meet fire safety requirements, such structures are often covered with metal casings.

- The surface of the walls can be plastered, tiled with tiles, or, after opening the joints, left unfinished. The fireplace stove with heating panel should be covered during its installation.

- The devices can operate in two operating modes – winter and summer. In the first of them the structure is heated completely, in the second it is partially heated.

Basic operating diagrams

Based on the principle of operation, there are two types of devices.

Duct shields

- Inside such a device there is a kind of labyrinth of chimneys, which have the same cross-section.

- When such heating panels are installed, they can be arranged in both horizontal and vertical partitions.

- The combustion products release thermal energy to the walls during their uniform movement along the entire length of the channels.

- In duct type devices, jumpers are often installed that bypass the chimney. They are fenced off with partitions. This is necessary so that in the summer the cooking stove does not heat the room.

In fireplace stoves, jumpers are not needed, because they are equipped with shields for greater heat transfer. A device for a powerful metal unit, for example, for Bavaria (thermal power 14 kW), should not be made without such a jumper. (See also the article Biofuel for fireplaces: features.)

Bell devices

A bell-type heating shield consists of one or more cavities that are connected by chimneys. The exit and entrance of the channel in all caps is made much lower than the top of its plane.

Why is this necessary? Heated air and furnace gases always flow upward. Having penetrated the bell, the gases will be located there until they cool. When they give up their heat, they will be displaced by a new portion of heated combustion products, and they will flow down the chimney into the street.

Features of the implementation of the shield scheme

- In addition to rectangular devices, when there is little space in the room, a corner shield is often installed. In addition to the fact that this design saves useful volume, due to the larger heat exchange area, it releases more energy.

- If you equip the shield with a separate firebox, it will be transformed from an additional element of the stove into a full-fledged heating equipment.

- You need your own fuel chamber so that you don’t need to heat up the cooking stove. (See also the article Heating a private house with wood: features.)

https://youtube.com/watch?v=YiJRfgw9s90

How to make a heating shield for a metal stove with your own hands

Today, stores offer a huge selection of all kinds of heat-storage structures, but making a shield with your own hands is not at all difficult.

To build a shield with our own hands, we will need the following tools:

- pick;

- ruler;

- roulette;

- plumb lines;

- square;

- cord;

- hammer;

- combination trowel.

The following materials will be needed:

- refractory bricks (the quantity must be selected in accordance with the size of the heating shield you want);

- clay;

- sand;

- waterproofing roofing felt;

- special cleaning doors;

- grate for ventilation;

- several smoke bridges.

Selection of materials

If you decide to build a shield with your own hands, then it is best to do it from high-quality ordinary brick. It is advisable to use smooth material without chips. The wall thickness, ideally, should be half a brick. This size is considered the most optimal and efficient when using a stove, since this thickness ensures the fastest heating and fastest cooling of the shield. The brick must be hollow. It should be noted that correctly laid brick increases the efficiency of the furnace by 35 percent!

Disadvantages of metal cooking stoves and how to fix them

Change in the efficiency of a metal furnace when using a shield.

- The compact dimensions of metal stoves also have a drawback - the air heat exchange surface is too small.

- In addition, gaseous combustion products have a very high temperature - from +300° degrees or more. Therefore, you have to think about fire safety and thermally insulate the chimney.

- As is known, the efficiency of stoves is inversely proportional to the temperature of the exhaust combustion waste. To prepare food, cooking units do not use all the generated thermal energy.

- In addition, such stoves usually have short chimney ducts. Therefore, they also absorb some heat.

- Such heat losses are irrational from any point of view. There is a need to minimize them. One of the most common ways to reduce the energy losses of a furnace is to equip the unit with a heating panel yourself.

What is the device

- The shield is a small brick wall attached to the stove, inside of which there is a developed chimney system.

- Such devices are almost never made with a firebox. The shield heats up thanks to the gases removed from the stove. Structurally, the wall is not capable of releasing much heat into the environment.

A shield with a firebox.

- There are more complex and convenient designs, the price of which is higher. They are equipped with their own small fireboxes. You can make them independent of the hob and attach them, for example, to stoves with a fireplace.

- Brick has good thermal conductivity, and most importantly, high heat capacity. Warming up when lighting the stove or cooking, it gives off heat to the room for several hours. This way you can get an analogue of a brick stove. Only simpler in design and for less money.

Why is it needed?

The heating panel is a heat exchanger attached to the stove, made of brick. It is sometimes called the riser or furnace casing. Passing through it, hot flue gases heat the walls, which retain heat for a long time and transfer it to the surrounding air. The heat shield for a metal furnace increases the efficiency of the furnace and has the following advantages:

- Heats up the house much faster.

- Easy to do yourself.

- Allows the stove to store heat for a long time.

Manufacturing a heating shield for a metal stove allows its parameters to be brought closer to those of a brick stove. This design maintains the temperature required for high-quality heating of the room for a long time and allows saving fuel consumption. Its construction is the best option, combining the advantages of a metal stove and a brick stove.

Types of coarse stoves

Hruba (or rude) is one of the variants of the Russian-Dutch oven. Appearing in Russia more than 200 years ago, “Dutch” units have established themselves as an economical and reliable heating unit that takes up little space in the house. However, domestic stove makers, having decided to expand the functionality of the existing design, also added a stove bench to it. The original model underwent significant changes: the height and location of the beds were constantly changing, the materials were improved, the rough began to perform not only heating and cooking functions, but also to decorate the house, playing the role of a kind of fireplace.

Deciding whether the house needs a rough one, or whether it’s worth taking a closer look at another option, can only be done after carefully weighing all the pros and cons of the design in question.

- Roughly easier to build than most known duct power furnaces. This can be done both during the process of building a house, and in an already landscaped room. No large-scale construction work or alterations are required;

- the costs of materials are “affordable” for almost anyone;

- the stove is easy to use, compact and takes up little space;

- its appearance depends on the taste of the owner, who, at his own discretion, selects the shape and size of the bricks, the colors of the plaster and the design of the component elements;

- Thanks to the installed hob, it is easy to cook on the griddle.

The thermal efficiency of such a stove is extremely low: it can warm up a room with only an area. If the owner certainly wants to use a rough stove to heat a larger room, he will be unpleasantly surprised by the amount of kindling material consumed.

The addition of a heated bed is another plus of the rough bed. But this option is only possible when heating with wood. The coal heats the surface of the bed too much.

Types of acceptable structures:

Attaching a shield to the outside allows you to give the stove a more decorative look, making it look like a fireplace. If the work is done carefully, using tiles or decorative ceramic tiles, such a stove will give the room a special charm. But this will be a very expensive job: both in terms of the efforts involved and in terms of the volume of materials. Such a stove is more difficult and difficult to build; a foundation is required. Both wood (up to and coal) are suitable as heating materials. However, the thermal power of such a unit is much greater than that of a stove with a built-in shield.

With built-in shield

Outwardly, it looks like a regular hob. Such a unit is easier to build, and materials are spent several times less compared to the first option. This is a compact stove of small size, the amount of thermal energy of which is limited. Therefore, this option is only suitable for rooms in which they live from spring to autumn, and are visited occasionally in winter. The log can be built without a foundation, but the load-bearing capacity of the floor must be from 500 kgf/sq.m.

Advantages

Despite the fact that the modern world involves the use of high-tech devices and buildings, a simple heating panel does not lose its popularity. According to the basic principle, not only stoves are built in private homes, but also fireplaces are created, which are both a heating and a decorative element of the home.

It is important! By choosing the right type of heat shield, you can profitably save time and money that would have been spent on creating a full-fledged classic stove. In this case, it is important to take into account the size of the room, surface requirements, expected duration of use, etc.

The masonry of a simple shield is much lighter than stove masonry; in addition, in some cases, the structure warms the room much better and retains heat for a long period of time.

In addition to the above positive aspects, there is one more, no less important. The compactness of the shield provides great opportunities in large and small rooms. If installed correctly, you won't have to worry about any problems that might arise with the stove. The designs are mostly simple and will be understandable even to beginners in this matter. The main thing is to choose high-quality materials and carefully study the instructions.

The compact shield will fit perfectly into the interior of any room

You can even cook on such a surface later, since it is possible to equip the cast-iron surface with special burners. There are many more advantages than disadvantages, and an equally important aspect of the issue is the ease of self-distribution. You can make such a design yourself, the main thing is not to try to do it yourself, since any mistake can cause significant harm in the future.

Parameter calculations

The size of the chimney for a brick stove should remain the same along its entire length; its optimal value is selected depending on the dimensions of the heating device.

Sectional size

Suitable device parameters depend on the combustion chamber and furnace power. The inner walls need to be made smooth without sagging mortar or protrusions, then they will remain clean longer.

Most often, brick chimneys of square and rectangular cross-section are used; their masonry is made of 4, 5 or 6 bricks; when calculating the cross-section, one side of the structure is multiplied by the second. The standard dimensions are considered to be: 12.5 × 25 cm. The calculation is carried out according to the internal chimney channel. The indicated parameters refer to a masonry of 4 bricks, the cross-sectional area is 156.25 cm2.

When calculating a cross-section of five bricks, the result is a value equal to 312.5 cm2, and with six - 625 cm2.

When installing a brick chimney on a metal stove, you need to connect its square section to the round outlet hole of the stove. So, for a chimney cross-section with an area of 156.25 cm2, a round pipe with a diameter of 130 mm is suitable, its area is 133 cm2, the next parameter of 150 mm has a greater value than the declared one.

When calculating a circular cross-section, the required radius is taken into account, the area is calculated using the school formula:

S = π×R2, where the number π=3.14

Knowing the diameter of the pipe, you can easily determine the desired parameter.

Calculation depending on power

The internal channel depends on the optimal ratio of pipe sizes and the power of the heating device. Among the guidelines for choosing a suitable section, the size of the opening provided for the blower door is highlighted. The pipe size should be smaller than the hole for the door.

If, when calculating, we take into account the productivity of the furnace, then we can select the cross-section from the tabular data, but they do not take into account the thickness of the seams; they range from 6 to 10 mm.

| Power, kW | Pipe cross-section, in millimeters |

| 3,5 | 130×130 |

| 3,5÷5,2 | 130×190 |

| 5,2÷7,0 | 130×260 |

| 7,0 | 190×260 |

Chimney height

When calculating this parameter, you need to pay attention to the following features:

- if a highly flammable type is used as a roofing material, the chimney must rise above the roof by at least 1.5 meters;

- the height difference between the top point of the head and the grate should not be less than 5 meters;

- if there is a high building near the house, then the pipe should be 0.5 meters higher than its extreme point;

- on roofs with non-combustible coating, the minimum distance to the top of the pipe should be 0.5 meters.

When calculating the height of the pipe, the size of the firebox and the cross-section of the chimney are taken into account. So, if the total area of the combustion window is 0.35 m2, and the cross-sectional area of the channel is 0.04 m2, then a height of 7 meters is suitable for these parameters. To make calculations with other parameters, you need to establish this dependence and select the height.

The height of the chimney pipe affects the draft, so this size of a brick chimney pipe should not be less than 5 meters, otherwise turbulence may begin and all the soot will go inside the house.

How to correctly position the pipe from the roof ridge is shown in the photo below:

What devices is the shield used for?

The two most popular situations:

- Purchasing a metal stove, which is also considered a fireplace.

- Application of a brick hob.

Also, a brick panel is popular among residents of cottages in which Swedish Zhirnov stoves are installed. From the outside, they may resemble a fireplace, but structurally they consist of a combustion chamber and an electric stove: a significant part of the heat is spent on heating, a small part - on cooking.

Fehringer ovens are also often equipped with a brick wall, which makes it possible to increase their productivity.

If the heating panel

for a stove made of metal or a brick stove is not used, then the heat obtained from the combustion of fuel literally flies into the chimney. And if it is present, the heat is retained, which makes it possible to heat the room.

Stove with panel for heating the room

The heat shield, which looks like a thick brick wall, can be compared to a gas-air heat exchanger, which is attached to any furnace in order to increase its operating efficiency. Gas flows, under the influence of the draft of the chimney, move through horizontal and vertical channels in the middle of the wall.

The working principle of this device is based on the extraction of heat from smoke gases. As a result, the brick structure heats itself and then heats the air in the room. Due to the heat capacity of the material, the wall cools for a long time and continues to give off heat after the fuel burns out.

Basically a shield

is not equipped with its own firebox, playing the role of only an additional element. But sometimes the system provides for the presence of a firebox.

The role played by the brick shield is especially important. This device makes it possible to increase the efficiency of air heating when operating stoves of various types:

- steel stove-fireplace;

- heaters;

- a simple potbelly stove, the efficiency of which is usually no more than 30-40%.

When using a brick wall with air channels in the middle, you get the opportunity to reduce the consumption of firewood many times, providing the necessary heat supply to the room.

Disclaimer

It’s worth mentioning right away: the author is not an experienced stove maker.

The purpose of writing this article is to introduce the owners of country houses to a new concept, a way to dramatically increase the efficiency of a conventional Shvedka-type heating and cooking stove and make their home warmer at minimal cost. Judging by the information dug up during the writing of the article, these are very friendly and helpful people, which is not typical for the RuNet. You can receive an accurate and comprehensive answer to a specific question asked in the forum.

They will be happy to tell you the details of how heating panels are installed - the order, the size of the panel specifically for your home, the recommended type of panel and the thickness of its walls. The reason that discussion of any topic does not turn into throwing banana peels at each other is simple: stove makers are mature, experienced people. Finding out which of them is wiser and more experienced is simply not interesting to them.

Participants in furnace forums are, as a rule, middle-aged and sensible people who willingly share their knowledge.

Requirements for installing a brick kiln

First of all, it is important to decide on the installation location of the unit at the stage of pouring the general foundation of the building. Brick units will require a separate base for them.

And it’s better to do it right away. Otherwise, you will need to tear down the floors and make a pile foundation with a concrete slab.

The best option for installation is the kitchen. This design can be made small in size or a Russian stove with a stove bench can be laid out. The choice depends on the size of the room and financial capabilities

When pouring the slab, it is important to take into account the increase in size by 150 mm on each side of the furnace walls. But you will need to take into account the dimensions of the brick chimney and make a foundation for it

A brick stove for a summer residence is the best option if the dimensions of the kitchen and its constant use allow. During long breaks and the heater being in a damp, unheated room, cracks may form in the solution. The stove will need to be heated, after finding the place where the smoke passes, cover it with a solution of fireclay clay.

Tips: proper ordering

The technology for creating stoves for the home differs from traditional ones. Laying rows without using mortar, according to the order, is often used. To give the desired shape, the brick is hewn and trimmed. The dimensions of the stove are smaller than the walls of the house, and before construction, carefully measure the diagonals. Make a control measurement every 4 rows. This is convenient to do with the help of a stretched cord and rules.

Using a ready-made solution will help significantly save time. You will not need to soak the clay for 2 days, strain through a sieve, and knead to the required consistency. To prevent rapid drying, the brick is pre-moistened with water. The absence of rectangular ledges in the design will help save on operating costs. During laying, control the thickness of the joints and remove excess mortar. When building a furnace, different materials are used and different solutions are used to join them. Fireclay bricks are not combined with clay bricks; ovens, cast iron and steel plates, rods, water tanks, gratings are not embedded in the masonry. This is due to different expansion rates of materials at the time of heating.

Seventh row of the heating panel.

The sixth and seventh rows of the shield.

With the seventh row we block the first horizontal channel.

If you look carefully, you can see that the dressing is broken in this row.

I released all the bricks that block the channel by pushing them towards the slab.

When the slab frame is installed, it will cover all these bricks, so bandaging can be neglected here.

I have a flue gas inlet from the stove into the shield on the left, which means I make the exit from the first horizontal channel into the second on the left side of the shield.

Please note that I made the height of the first horizontal channel and the width of the exit from it the size of a brick. This will prevent the shield from overheating in this place and will allow gases to enter the subsequent channel at a higher speed. Gas flow rate is very important for a stove with a duct smoke circulation system

The gas flow rate is very important for a stove with a duct smoke circulation system.

The speed should be sufficient but not too fast, then the stove will heat well and at the same time accumulate heat better.

Do-it-yourself stove laying with oven and stove: main stages

After creating the drawings, you can begin the main work. Masonry requires certain skills and knowledge. It is better to entrust the work to an experienced stove-maker.

Stages of laying a stove with a stove:

- Monolithic masonry should be made on the first row. Solid brick is used for the edges. You can put halves in the middle.

- On the third and fifth rows there is a compartment for the ash pan. At the fifth stage, an overlap is made between the firebox and the ash collection chamber. Drying is also done.

- Starting from the sixth row, you can equip the stove from the inside. On the seventh row, a grate and firebox doors are installed.

- The eighth, ninth and tenth rows are allocated to the firebox. This is where the dryer box is made. Steel strips are installed on the eleventh row. You will need to leave room for the chimney.

- The slab is formed on the twelfth row. On the thirteenth row you can install a stove. Next, a water heating structure is installed that covers the chimney. It is laid starting from the fourteenth row.

Gradually the stove is ready. But the masonry itself has a lot of nuances and it’s quite difficult to do everything correctly. Certain dimensions and slopes must be observed.

Which brick stove to choose for your dacha?

The choice of stove design determines the size and type of room. Large cottages will require a massive stove structure with thick walls, which will take a long time to heat up, but at the same time be able to maintain the temperature for a long time. Building such a stove is not an easy task. This will require some experience and knowledge.

But even a beginner can handle a small stove for heating a small dacha if you strictly follow the diagram and do not change the laying rules.

small ovens

The first place in the popularity of heating and cooking stoves is worthily taken by the Swede, which enjoys well-deserved love and respect among Russian stove makers.

This design is a compact, ergonomic shape with a small cooking surface and a three-channel chamber. It is ideal for a small cottage, the length ranges from 880 to 1250 mm.

For the location of such a stove, the place most often chosen is between the kitchen and the living room. Thus, the stove performs a double function: it serves for cooking and decorates the living room with a fireplace.

Today you can find hundreds of different layouts for laying a Swedish stove with a hob on the Internet, so it won’t be difficult to implement it for your dacha. Many stove makers have added additional options to the standard masonry scheme, so each design is called by the name of its creator: the Buslaev, Kuznetsov stove, etc. But the principle of operation in them is the same.

Traditionally, a Russian stove can be called a bulky, massive structure, which is decorated not only with a hob with an oven, but also with a spacious bench.

Stove with bench

This stove is not only a functional device for cooking, but also a place for relaxation. It allows you to warm up the room well, retaining heat for a long time, and has a beneficial effect on the human body, thanks to which the owners of such stoves are less susceptible to colds.

The building usually has two fireboxes (main and additional). Thanks to the special design of the oven, heating is carried out evenly, from bottom to top. Any solid fuel is suitable for kindling, and there are no particularly strict requirements for the materials for laying a Russian stove.

A special place among small heating and cooking stoves is occupied by the little V.A. Potapova, created by a famous engineer at the beginning of the 20th century. To lay it, you need only 211 bricks, and the dimensions of the stove are only 630 * 510 mm.

Moreover, this little thing contains a single-burner stove, a small oven for baking and a hood. This type of stove would be an excellent solution for a small garden house or one-room cottage.

In this article, we invite you to study the rules and main points of laying a small heating and cooking stove.

Cooking oven order

Operating principle

Most often, in Russian country houses, potbelly stoves and Zhirnov stoves are used, which are compact heating units of the “Swedish” type. This stove is easy to set up, heats up quickly and does not require special care during operation. It is ideal for small country houses. Its disadvantage is the inability to switch to summer mode.

Several types of arrangement of such a furnace are best known, but despite the distinctive nuances, they are united by the following characteristics: the furnace power reaches 3.5 kW; there are 4 hoods in the cooking chamber and the chimney pipe does not exceed the dimensions of 270x140 mm.

The operating principle of the stove is based on direct-flow operation of the heating panel. As a result, only a small part of the heat is spent on cooking, and the rest is spent on heating the room.

For beauty, the shield can be decorated with plaster, tiles or left brick.

Features of stove heating

Stove heating has a number of advantages, thanks to which wood-burning brick stoves have not lost their popularity for several centuries. The most important advantage is the ability of the ceramic bricks from which the stoves are made to accumulate and release heat for a long time.

At the same time, radiant energy useful for the human body is released into the space, giving a feeling of warmth and comfort. With regular heating during the cold season, the house is always warm and dry, and natural ventilation is formed due to the stove draft. In hot weather, the stove, on the contrary, cools the rooms by removing excess heat into the ground and air through the foundation and chimney.

In addition to creating a comfortable microclimate, a brick oven can provide additional functions, the availability of which depends on the design:

- cooking - boiling, frying, stewing and baking;

- drying clothes, shoes, food;

- heating beds for sleeping;

- opportunity to admire the open flame.

Furnaces that provide several functions are called combined. These types of stoves include heating and cooking stoves, fireplace stoves, as well as several popular basic models, including the Russian stove.

Stove heating also has disadvantages, including the inability to effectively heat remote rooms. Therefore, in large houses, they usually install several stoves with separate or combined chimneys or combine stove heating with other types of heating.

In compact houses consisting of one or several rooms, the stove is usually located in the center, so that its walls are located in all rooms. The hob and oven are placed on the kitchen side, the stove bench is in the bedroom or nursery, and the open fireplace is in the living room or dining room.

Water heated floor system

A distinctive feature of heated floors is that they do not have external heating structures, and the system itself accumulates and radiates the resulting heat.

With proper heat distribution over the surface of the flooring, you can save 30% or more on coolant consumption.

The floor heating system can be represented by one of the following types: water, electric, film, rod or electric water. The latter is considered an innovation, but due to a wide range of advantages, it has already managed to win many fans

To rationally use the floor heating system, let's consider additional ways to help save:

- The length of the liquid circuit does not exceed 70 m. When choosing the optimal pitch for laying pipes, the coolant is transported with virtually no losses.

- Mixing hot and cold flows. The use of return water makes it possible to waste less energy from the boiler.

- Drawing up a detailed layout of the circuit with precise calculation of the step. Preliminary distribution of furniture positions will allow you to save on consumables, and, accordingly, on the circuit itself.

- When the system reaches maximum temperature, reduce the temperature by 20 °C. This action will help save 13% of the coolant.

In order to get the best result, you must strictly adhere to the installation technology. The heating mechanism of such a system consists of several layers, each of them has its own function.

The installation of a heating system using underfloor heating is carried out in stages. Work on each of them will take a certain time, for example, after pouring, subsequent work can only begin after 2-4 weeks

High-quality heating of the room by laying liquid heated floors is organized in several stages:

- Waterproofing. This layer eliminates the appearance of products resulting from condensation. Even polyethylene film can be used for the substrate.

- Thermal insulation. The main task is to eliminate heat leakage into the lower part. In most cases, sheet insulation is used. The thickness should be selected based on the conditions of the room - whether there is a basement or ground floor in the house. The colder the climate, the thicker the insulation.

- Foil or heat-reflecting element. Foil film that promotes maximum redirection of heat flow to the top. Laying this material allows you to save up to 5% on coolant consumption.

- Pipe installation. The main structure of the entire mechanism. Heated liquid moves through the pipes. If, when laying a heated floor, you choose the correct pitch between the turns of pipes, this will enable efficient heating with the least amount of heat resources.

- Screed. Provided that all previous layers were laid on a flat surface, the thickness of the screed will be minimal - 3.5 cm. A fill of ordinary cement-sand mixture, 50 mm thick, is often used. The thermal conductivity of such a material is 0.4 W/(m*K).

- Flooring. The liquid floor allows the installation of any material. Nevertheless, ceramic tiles have the best characteristics, namely thermal conductivity and maximum efficiency.

The installation technology involves the initial arrangement of the collector unit. Only after this can you begin laying the individual layers of the system.

Stages of work

Before starting work, you must purchase a pick, plumb lines, a ruler, a level, a tape measure and a square, a cord, a hammer and a combination trowel, which is used to remove excess mortar.

The material for constructing a standard heating panel and fittings will require fire bricks (about 310 pieces), about 6 buckets of clay and about 4 buckets of sand, 1.5 meters of waterproofing roofing felt, 3 special cleaning doors, a 20-centimeter grille for ventilation and 3 pieces of valves (smoke) measuring 13x13 cm.

As mentioned above, the shields are erected on the foundation. Therefore, the process begins with the arrangement and waterproofing of the base.

Construction of the foundation

The solution in the foundation is leveled using a level, without reaching approximately 10 cm from the floor. A brick is placed on the dried layer, the base of the structure is treated with waterproofing material, and the outline of the unit is outlined. Then a second layer of brick is laid, finally comparing it with the floor level.

The basic algorithm for laying the foundation is the same for arranging a heating panel of any configuration.

Laying a shield without an autonomous firebox

Row 1 – completely lined with bricks. The 2nd and 3rd rows are laid following the order. At the level of the 4th row, 2 clearings are installed and a window is left among the bricks for further connection with the shield. On the 5th row, the same work is done, but attention is also paid to bandaging the seams of the stove. The 6th row is placed, not forgetting to leave 2 channels.

- Starting from the 7th, including all remaining odd rows (up to the 25th), lay out the bricks in order, leaving 3 channels.

- Starting from the 8th and including all even rows, they act strictly according to the order scheme.

- At the level of the 10th, 11th, 17th, 23rd and 24th rows, a different masonry is used, which ensures a stronger connection of seams.

- In the 10th, 18th and 24th rows, do not forget to put the valve on the right.

- At the level of the 21st and 22nd layers, a samovar is installed, which will be blocked on the 27th row, which combines the 2 left channels into one common one.

- A reliable latch is placed on the 28th layer, and the 29th is laid out in accordance with the order, not forgetting about the dressing.

- On the 30th row, the channel on the left is blocked, and the valve is reinstalled.

- The 31st and 32nd rows should provide ligation of seams and overlap with a thickness of 3 rows.

- The levels of the 33rd, 34th and 35th layers are laid based on the order, and on the final - 36th row, care must be taken to leave channels (ventilation with smoke).

Arrangement of the shield with an autonomous firebox

This scheme is more complex and provides for the possibility of separate combustion of the shield and the stove. Here you will also need much more material than with a simplified version of the shield.

After the foundation is securely installed, the first two layers are laid, following the ordering pattern. 3rd row - similar, but with an ash pan, which is needed for the firebox.

https://youtube.com/watch?v=nj24EqaYTEw

- The 4th layer is quite important: 2 valves are installed here (for winter and summer), as well as doors (blowing and cleaning) in the amount of 4 pieces. Similarly on the 5th row, but here they additionally bandage the seams.

- On the 6th level they install an oven with a water-heating box, and also reduce the size of the channels and block the doors.

- On the 8th layer, doors are installed: a large one for the stove and a small one for the shield.

- The 9th and 10th rows are laid according to the diagram, but on the 10th row a steel seal is laid over the oven structure.

- On the 11th row, the upper edge of the oven is smeared with clay, and the doors are also blocked.

- The final row is the 12th, serves to strengthen the frame and install cast iron flooring.

The need to heat rooms around the clock prompted the creation, instead of a standard potbelly stove, of a highly efficient heating panel that has excellent heat capacity and guarantees comfort both when preparing food and when staying in the room.

In kitchen wood stoves, most of the heat energy literally goes up the chimney, and only a small amount of heat is used to heat the stove. To trap hot gases and use them to heat your home, you need a heating panel - a brick wall with smoke circulation channels inside. A heating and cooking stove with a shield is ideal for a summer house and summer kitchen - it does not take up much space, effectively heats the room and can operate in winter and summer modes.

How to lay out a panel with an autonomous firebox

What does it look like

The shield can work in both summer and winter smoke circulation systems, allowing you to heat either the stove or the shield separately.

Important! Before starting the main masonry, you should build a strong, high-quality foundation with waterproofing (you can use roofing felt).

Features of masonry

The arrangement of the heating panel in this design has its own characteristics (the diagram can be found on the Internet by asking the appropriate request). In general terms the process looks like this:

- The 1st and 2nd rows are laid out in accordance with the order.

- In the 3rd row it is necessary to leave an ash pan under the firebox.

- 4th row: two valves are installed (one for summer operation, the other for winter) and four doors (two blower doors + two cleanout doors with brick linings inside).

- Row 5 is similar to the fourth (bandaging the seams is observed).

- Row 6: all channels are reduced, all doors overlap. An oven and a hot water box are installed.

- In the 7th row, two grates are laid (one for the firebox of the stove, the other for the firebox of the panel). The bricks on both sides of the gratings are crowded together. The long channel on the left overlaps to create two short channels.

- In the 8th row (placed in order) firebox doors are installed (one smaller for the firebox of the shield, the other larger for the firebox of the stove).

- The 9th row is placed according to the scheme, as well as the 10th, but in it a steel strip is placed above the oven.

- Row 11: the doors overlap, the top of the oven is greased with clay solution. To the right of the water-heating box, the channel is closed with a brick, to the left it remains unblocked.

- In the 12th row, cast iron flooring is laid, and a frame of steel corners is strengthened around the slab. This row is the final one in laying the slab.

Other orders are the laying of the shield (see diagram).

- In the 16th row it is necessary to cut off the brick on the right at the second channel.

- At 19, a valve is installed that closes the pipe (from this to row 25 inclusive, five are formed from the three existing channels).

- In the 22nd row a samovar is placed, then in subsequent rows there remains one channel - a pipe, and the shield is covered with masonry in three rows.

- In the 31st row, the pipe channel is widened by cutting off the brick.

- A ventilation grille is installed in rows 32 and 33 (a separate channel is created for this).

Important! Watch the thickness of the seams - it should not exceed 3-5 mm.

Dimensions to consider:

- Length – 1400 mm.

- Width – 1020 mm.

- Height - 2170 mm.

- Weight - 2800 kg.

- The length of the steel strip above the oven is 550 mm.

Classification

As a rule, the shield operates from hot gases emitted by the stove's hob. But in some cases, an individual firebox can be built into it.

The result is a design in which the heat circulation does not depend in any way on the plate.

By wall thickness

Shields are of the following types:

- with thick walls (laid in half brick);

- with thin walls (laid in ¼ of a brick).

The option with thick walls is advantageous in terms of low flammability and if the stove is expected to operate for a long time.

The second option requires stricter compliance with fire safety rules, since the structure is heated not partially, but completely. In addition, these panels are laid on a waterproofed foundation. And if they decide to decorate them with tiles, then this must be done during the construction process. Such furnaces must be equipped with a metal shell - a casing.

The heating panel must be adjusted differently to operate in summer and winter. This allows you to use only the cooking surface of the stove in hot weather without heating the walls, and in winter to achieve the maximum possible heating. The principle of operation looks like this: in the summer version, the smoke passages are blocked by a valve, as a result of which only the stove is heated, and in the winter, the valve is moved back, which gives an impetus to heating the entire surface of the shield.

By design

Also, depending on the design and installation features, shields can be:

- Bell type. This unit consists of 2 vertical brick surfaces connected by channels. Once inside the special hood, the heated air is retained there and effectively heats the room.

- Channel type. It involves the operation of a winding chimney with a metal pipe of the same diameter. In this case, jumpers must be installed to prevent the entire surface from heating up in the summer.

Basically, the shields have a straight configuration, but sometimes they can be angular.

Masonry algorithm

The construction of a heating panel begins with laying and waterproofing the foundation. The solution in the foundation is leveled using a level, leaving 10 centimeters to the floor level. A brick and a sheet of waterproofing material (as a rule, roofing material is used) are laid on the dried layer, and the edge of the structure is marked. Then a second layer of brick is laid, finally comparing it with the floor level. The sequence of foundation construction is the same for all types of heat storage panels. The sequence of laying next to each other is as follows:

1 row is completely laid with bricks; 2 are laid out following the cover; Row 3 is built in the same way as row 2; In the 4th row, cleanings are installed and a window is left that will serve as a connecting channel; Row 5 is laid according to type 4, you should pay attention to the seams; In the 6th row two channels are left; Starting from the 7th row to the 25th, all bricks should be laid in order. At the level of the 10th, 11th, 17th, 23rd and 24th rows, a different masonry is used, this ensures a stronger connection of the seams; In rows 10, 18 and 24 it is necessary to install a smoke damper on the right; At the level of 21 and 22 layers, a samovar is installed, which will be blocked on the 27th row, which combines the 2 left channels into one common one. On the 28th row you need to put another jumper, and 29 is laid out in accordance with the order. On the 30th row, the channel on the left is blocked, and the valve is reinstalled. On layers 31 and 32, it is necessary to ensure overlap and dressing of seams; Levels 33, 34 and 35 rows are laid based on the order, and on the final layer 36, care must be taken to leave channels (ventilation with smoke).

So. We figured out what a heating shield for a metal stove is and installed it with our own hands.

Construction of a kitchen stove with a shield with your own hands

Using the instructions drawn up by professional stove makers, you can start building a summer cottage fireplace on your own. For beginners, we recommend that you first study all the intricacies of stove masonry and mortar preparation.

Budget heating and cooking stove

Exterior view of a country stove with a stove and a shield

This simple model works in winter and summer modes. In the summer, the shield channels are closed with a valve located in row 7, and hot gases are released directly into the pipe. For construction you need the following materials and stove equipment:

- 290 pieces of red ceramic bricks;

- grate bars 24*25 cm;

- combustion door 25*18 cm;

- blower door 13*13 cm;

- kitchen cast iron stove with burners 72*29 cm;

- three valves 13*13 cm.

Layout diagram of the first nine rows

A simple stove with a shield at the end

The shield is placed not only on the side, but also at the end of the structure. This option is considered the simplest and is ideal for a summer kitchen or a small country house. The model presented in the first diagram does not have a blower; it works on the “Dutch” principle - air enters the combustion chamber only through the cracks in the door. If necessary, the height of the riser can be easily increased or decreased by adding or reducing several rows. Through holes under the stove - trenches - increase thermal efficiency and increase fire safety.

Furnace with end shield: 1 – shield, 2 – sheets, 3 – plate

Section of a dacha hearth and the principle of gas movement

Order diagram of a heating and cooking furnace

Based on this simplest model, an improved design with a grate and a blower was developed. In this scheme, the first continuous row is laid directly on the foundation.

Improved model with blower

Arranging with a blower and grate

To build one of these modifications you need to purchase:

- 220 pieces of red brick;

- combustion door 21*25 cm (for a model without a blower with holes);

- plate 41*71 cm;

- valves 13*13 cm;

- grate and blower door (only for the second option).

Based on the same scheme, a kitchen assistant with a water heating tank and an oven was also developed.

Kitchen stove with hot water tank

Modification with an oven instead of a tank

Attaching a shield to a metal furnace

Modern heating and cooking stoves made of cast iron and steel can also be made more efficient by attaching a brick shield to them. This simple move will allow you to add a heating wall to the convection oven and reduce fuel consumption. Construction in this case comes down to laying a riser with smoke circulation, to which the chimney of a metal heat generator is connected. If there are two rooms in the house, then the heating panel is installed in the wall between them.

Cast iron wood stove with brick backsplash

More complex designs of heating and cooking stoves with a shield include a stove bench, a drying chamber, an additional firebox and other details that make the home functional and comfortable. However, each additional module increases the weight of the building and fuel consumption. We recommend that you coordinate any selected project with a specialist in order to finalize it to suit the needs of a particular home.