It is difficult to imagine a bathhouse without a stove, because in addition to heating the room, it is also the key to comfort and pleasure from the bathing procedure.

It is easy to make a stove for a bathhouse with your own hands; it will function well and will not require a lot of money and time investment. The simplest model is a sauna stove made from a pipe with a large diameter. Its production does not require special experience and knowledge in this area.

Pros and cons of such ovens

The required properties for the material used in the manufacture of the furnace are heat resistance, strength, durability, and corrosion resistance. In addition, it must withstand sudden temperature changes and have good thermal conductivity.

The ferrous metal from which a thick-walled pipe with a diameter of 500-600 mm is made cannot be called completely corrosion-resistant. But it is precisely this type that is optimally suited for the independent production of a sauna stove, as it meets almost all of the requirements listed above.

Having a wall thickness of at least 8 mm, it makes the stove in the bathhouse quite heat-intensive, in which heat is retained when the fuel has already burned out. And the round cross-section inside it allows heat to spread efficiently.

The use of a round-shaped pipe for a stove in a bathhouse reduces the length of welding seams - these are the very first places for corrosion to form , and it is through them that carbon monoxide escapes. In addition, this option remains the cheapest, although prices for ferrous metal are rising.

The choice depends on the type of heating system

Before you start choosing pipes, you need to accurately determine the heating system you are going to install.

The type of heating installation completely determines the required type of pipes.

You should have a list of information about your system, which will list the following parameters:

- Type of heating system: natural or forced;

- Installation method: closed (inside the walls) or open;

- Two pressure values in the system: average and maximum;

- Two coolant temperature values: average and maximum;

- System configuration: complex or simple.

In accordance with these parameters, you will need to familiarize yourself with all the types and choose the best option for your heating system.

Types of furnaces - horizontal and vertical, features of choice, pros and cons

A self-assembled stove for a bathhouse made from a pipe, although it looks unpretentious, does an excellent job of heating the steam room. Available in vertical or horizontal form. The choice directly depends on the area of the steam room and on the desires of the owner.

Vertical

Externally, such a stove resembles a common potbelly stove, but differs in its design features. In addition to the firebox and the compartment where the stones are placed, there is a special tank where the water is heated. This type is ideal for a small bath.

The firebox and grate are located one above the other in steps, which makes it possible to save space. Therefore, this model is gaining popularity for installation in bathhouses.

However, it is worth noting that it is less effective, since the heat goes up and the walls do not have time to warm up. In addition, fuel burns faster in a vertical design. And the main disadvantage is the presence of a firebox and a compartment to enhance traction in the steam room of the bath.

Horizontal

The horizontal shape is recommended for bath rooms with a large area. Equipped with a compartment where stones are placed and a water tank. The firebox is more voluminous, and its doors and the vent are located at the end of the pipe; they often open into the room in front of the steam room, which speeds up the heating process. In addition, this arrangement is more convenient, since when lighting, there is no need to enter the steam room, and it does not cool down.

Unlike the vertical type, this type of heater requires more space, but since the firebox is longer and located at the bottom, this significantly increases the heating area and improves the natural exchange of warm air in the bathhouse. Therefore, experts recommend this particular model, if the bath area allows.

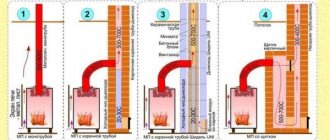

Regulatory requirements for the installation of chimneys

The rules for installing chimney ducts are regulated by a number of building regulations:

- SP 89.13330.2012 “Boiler installations”.

- SNiP 41-01-2003 “Heating, ventilation and air conditioning”.

- DBN V.2.5-20-2001 “Engineering equipment of buildings and structures. External networks and structures. Gas supply."

- NPB 252-98 “Heat generating devices operating on various types of fuel. Fire safety requirements. Test methods".

- GOST 9817-95 “Household appliances running on solid fuel. General technical conditions".

General requirements for the installation of a smoke exhaust system

In general, the basic rules are as follows:

- As a chimney, it is allowed to use pipes that are resistant to extremely high temperatures, moisture, and acidic environments formed when combustion products come into contact with condensate.

- Each heat generator is supplied with a separate smoke shaft.

- Combining ventilation and chimney circuits is not allowed.

- It is prohibited to install chimneys near gas pipes, electrical wiring and other utility networks.

- The position of the smoke exhaust circuit should be as vertical as possible. The average angle of inclination of the pipe should not exceed 30°.

- It is not prohibited to place some of the contours horizontally, but it should be taken into account that any deviation from the vertical reduces the traction force. Therefore, the number of horizontal outlets should not be more than 3, with a length of each no more than 1 m, and the total length of the chimney up to 2 m.

- The speed of the air flow in the smoke shaft with natural draft force should be in the range of 0.15-0.60 m/s.

- The parts of the chimney line must be hermetically joined, and the pipeline itself must be rigidly fixed to the wall. Any sagging must be eliminated.

- For periodic cleaning, the chimney must be equipped with an inspection hatch.

- The section of the smoke shaft that goes outside must be protected from atmospheric precipitation and also be equipped with a spark arrester.

- All structural elements of the building in contact with the smoke exhaust must be made of fire-resistant materials.

What we need - tools and materials

Before you start making your own sauna stove from a 530 pipe, you should prepare a place to work and stock up on the necessary tools:

- welding machine;

- grinder with different attachments;

- electric drill;

- metalworking tools;

- door handles;

- mortise tap;

- asbestos cord.

In addition to tools, you will need the following material:

- Thick-walled metal pipes for fireboxes and water tanks, having a diameter of 500 to 650, a wall thickness of 8-16 mm, and a length of 1.2 to 1.5 meters. Also the pipe through which carbon monoxide will escape, its diameter is 120 - 150, and the wall thickness is 2 - 4 mm.

- A steel pipe where the stones will be placed. The thickness of its walls is 5-8 mm, and the diameter is 350.

- Sheet metal, size 600 by 800 mm, having a thickness of 8 - 12.

- Hinged steel hinges.

- Water pipe - a small piece, suitable diameter ½ or ¾ inch, length 50 - 80 mm, and a ball valve with a similar thread.

- Metal reinforcing bars - 500 mm, diameter 12 - 18.

- Cement.

- Brick.

- Sand.

Cross-linked polyethylene (PEX pipes)

Cross-linked polyethylene

The production of pipes of this type occurs according to the principle of “polyethylene cross-linking”.

During the manufacturing process, different layers are superimposed on each other, which leads to the formation of additional bonds between the molecules of the materials.

Among the advantages of polyethylene are:

- High material density

- Resistance to elevated temperatures and high pressure. (Normal operating temperature is 90 degrees)

- “Memory effect” - if a pipe made of this material is heated and bent under temperature, after cooling it will retain its shape. This is especially true for installation.

- Pipe service life – up to 50 years

- Light weight, which does not create additional loads on supporting structures.

- Fittings and various threaded connections are used during assembly; you do not need any additional tools or equipment.

- Not subject to corrosion

Watch a video that will show the strength of this type:

Schemes and dimensions of vertical and horizontal furnaces

After choosing a model, before making a sauna stove with your own hands, a drawing is drawn; it must reflect all the parameters and configuration of the stove. A correctly drawn up drawing will not only facilitate the installation process, but also eliminate operational problems.

The diagram should show the main parts of the furnace. If this is your first time making a stove for a bathhouse, then it is better to use a ready-made diagram.

Horizontal model diagrams

It is the model in which the horizontal pipe is most often installed in bathhouses, if space allows.

Vertical furnace diagrams

As with a horizontal stove, a pipe with a diameter of 530 is also ideal for a vertical model.

An example of a drawing of a stove for a vertical bathhouse, which is easy to install yourself.

Video description

An example of a vertical stove with a closed, insulated heater is shown in the video:

Above the heater, a water compartment is fenced off with another horizontal spacer and equipped with a tap. Since the water in the “blackie” pipe quickly becomes red from rust, it is often replaced with a stainless steel tank.

Without special electrodes and skills in such work, it is difficult to qualitatively weld ferrous metal with stainless steel. It is better to buy a ready-made tank with a section of the chimney already installed in it and place it on the heater.

Tank for installation on a stove Source prom.st

If space allows, the water tank can be installed separately, connecting it to the firebox with a piece of pipe. One end of it is welded to the wall of the firebox, and the second open end is inserted into the tank, into the lower part of the side wall.

Assembling a horizontal model

The stove is made from a horizontal pipe for a bath, has a heater located on the outside, and the tank is mounted. The advantage of this device is that it has a compact size and a large firebox depth. In it, the fuel burns completely and, therefore, more heat enters the bathhouse.

The instructions for independently producing a horizontal stove for a bathhouse are as follows:

- You will need a 2-meter pipe with a diameter of 500 mm, which has thick walls; marks must be placed on it. To do this, it lies on a flat surface on its side, is fixed and, making an indentation of 1/3 of the diameter from the bottom, two lines are drawn on it in the horizontal direction, located parallel.

- A base for a round firebox is cut out of metal, the size equal to the length of the pipe, and the width corresponding to the distance between the lines.

A rectangular or square window is made in the middle of the circle, into which a grate must be mounted. Perhaps you can simply weld reinforcing bars in the form of a lattice to the bottom of the window.

- The base is inserted into the main pipe of the stove strictly according to the marks and fixed by welding inside it.

- Two blanks are made from a metal sheet with thick walls, so that their lower part serves as the legs of the device. And the width of the walls should be 20 mm greater than the diameter of the pipe. To give an aesthetic appearance, the front wall is rounded, but the back wall remains rectangular; a water tank will be mounted to it.

- On the front wall of the stove there is a window for the firebox and a compartment to enhance draft. The lower level of the firebox opening is located 0.03 meters up from the base of the firebox. And the upper edge of the blower is 0.01 meters lower than the container with stones.

- Doors are made from cut parts. They are welded to the front side of the stove with loops near the openings. Handles and latches are attached to them.

- Each end strip is attached to the base of the pipe and fixed with a weld seam over the entire area.

- To increase the heat transfer of the stove, it is recommended to install an additional chamber between the firebox windows and the chimney, in which the accumulated heat is transferred to the stone. You will need a 350 mm pipe, with a length of 0.35 - 0.45 meters. It needs to be cut in half horizontally. One edge is welded with a plug shaped like a semicircle.

- A hole is cut in the upper part of this device, slightly offset from the middle. The size of the opening should be equal to the diameter of the chimney. A 0.1 meter pipe is inserted into it to connect the chimney.

- At the top of the main structure, not far from the rear wall, a round hole measuring 150 mm is made. Next, the prepared dome is installed in the furnace pipe so that both openings are slightly offset in relation to each other. It is then welded to the main pipe.

- The final stage is a metal basket made from welded reinforcing bars around the additional chamber; it will hold the stones. And a water tank is attached to the wall at the back, and you can begin to test a sauna stove from a pipe that you assembled with your own hands.

Advice! Since the firebox and the window to enhance draft are brought into the room in front of the steam room, it is recommended to decorate the wall around the door with metal plates for protection.

Watch the video

eternal sauna stove

Which chimney is suitable for long-burning stoves

The smoke removal system directly affects the efficiency of Buleryan. A correctly selected and installed chimney in accordance with all the rules will provide optimal conditions for the functioning of all components of the stove. Several types of chimneys can be connected to a convection oven, which have different effects on its functionality.

Stainless steel sandwich pipe

One of the most popular and effective options. Characterized by the following performance qualities:

- The pipe is a three-layer structure. Inner tube made of stainless steel, resistant to acidic environments. The outer pipe is thinner, made of copper or stainless steel. The material of the outer layer is polished to a shine, giving the structure an attractive appearance. A layer of non-flammable insulation 3-10 mm thick is placed between the pipes (depending on the diameter of the product).

- The outer metal layer of the sandwich pipe does not heat above 40-50°C, which provides excellent fire-fighting properties.

- The multi-layer design minimizes condensation and provides good traction.

- Installation of a sandwich chimney is not particularly difficult due to the unique design of the pipes, which are simply inserted into each other.

With an external installation option, the chimney is securely attached to the wall, so the construction of a separate foundation is not required. Insulation of the outer pipe is also not required, since the insulation layer is already provided by the design.

Among the disadvantages of this chimney option, we note that the constant change of heating and cooling cycles over time leads to weakening of the fasteners and a decrease in tightness. The deficiency is easily eliminated by regular preventive examinations.

Ceramic chimney

More reliable and functional than a sandwich. There is practically no condensation in such a chimney, and a small amount of liquid does not in any way affect the performance of the heating system and is removed independently. The service life of such a chimney declared by leading manufacturers reaches 40-50 years.

The widespread use of ceramics is limited to the following points:

- Pipe material has a high cost.

- Installing a ceramic chimney is difficult and is unlikely to be within the capabilities of any homeowner.

- The blocks needed to protect the pipes will require additional processing - plastering or tiling.

The choice of this option is justified if the stove is installed thoroughly and for a long time. Relocating a ceramic chimney is an extremely costly and time-consuming undertaking. In this case, a sandwich is more suitable.

Single wall chimney

Classic single-wall metal pipes are the most budget option. This is where the advantages of such a chimney end.

There are many more disadvantages here:

- When laying the chimney externally, insulation will be required. The lack of thermal insulation is fraught with the formation of condensation and a decrease in draft.

- The internal surface of the chimney does not have a perfectly smooth structure, which contributes to the formation of soot accumulations.

- The pipe can heat up to high temperatures, which imposes serious restrictions in terms of fire safety.

- Relatively short service life. Depending on the intensity of use of the furnace, the pipes can last up to 10 years.

Note! The optimal thickness of products is considered to be 1 mm. Thick pipes will take too long to warm up, thin pipes will burn out quickly.

Not the most attractive appearance and low cost of products make the industrial sector, warehouses, etc. the main consumers of this option.

Brick chimney

Quite often, convection ovens are connected to an existing brick chimney. This option can be effective, but there are some nuances to consider.

A single-walled metal pipe is placed inside the brick channel, the furnace is connected to it using a special adapter.

Asbestos pipes

The least effective (albeit cheap) method of smoke removal. An asbestos chimney will allow large amounts of condensation to accumulate, and at high temperatures the material is susceptible to cracking. In addition, during operation, asbestos releases harmful chemical compounds. In some countries it is officially prohibited for use in residential premises.

Such pipes are often used for the installation of combined structures, in which the inner pipe is made of stainless steel and the outer pipe is made of asbestos.

Metal-plastic pipes

Metal-plastic

Heating pipes of this type have recently gained popularity among developers due to their numerous advantages and ease of use. The combination of metal and plastic gives pipes advantages over other types.

The inner walls are made of smooth polymer material, which prevents the appearance of sediment from water and protects them from corrosion. The average thickness of this layer is from 0.2 to 0.3 mm. This is usually highly elastic aluminum foil.

The steel outer layer provides additional protection against mechanical stress. The metal is protected by a layer of polypropylene.

The layers are connected using high-strength industrial adhesive with adhesion.

Among the advantages of metal-plastic are the following:

- Durable paint does not fade when exposed to direct sunlight.

- Easy to install and dismantle - the system is connected via press fittings without the use of special tools.

- Service life during normal operation is up to 50 years.

- Metal-plastic pipes are sold in coils, which eliminates the appearance of scraps during installation. You can “unwind” the desired length and cut as much as required.

- Protection against static electricity.

- Easy to repair - disconnect the fitting and replace the section of pipe that is not working properly.

- Pipes do not expand under the influence of temperatures - you can safely embed them into walls without fear of cracks.

There are undoubtedly many advantages. But there are also disadvantages:

- High cost - quality does not come cheap.

- Tapered fittings

- Not suitable for country summer houses - freezing of the coolant will lead to a rupture of the pipeline.

Options for connecting polymer pipes

Along with the main products, manufacturers offer original fitting systems, which guarantees their full compatibility with pipelines and the reliability of the connections made. Purchasing fittings and pipes for a water heating system from dubious manufacturers can cause various kinds of problems.

The following connection types exist:

- detachable when a threaded or collet connection is used;

- conditionally detachable or compression;

- one-piece - using press fittings.

Detachable and conditionally detachable

Threaded and compression methods allow you to repeatedly carry out operations of joining/uncoupling pipes with each other and with heating devices. The connection with compression fittings allows the connection to be disconnected, but the ferrule has to be changed. All threaded connections, i.e. the first two types should be easily accessible for maintenance and repair.

One-piece

The connection with press fittings is completely non-separable, due to which it has some advantages. For example, if the wiring is done using a hidden method, compression parts will not be suitable. In addition, one-piece fittings are stronger, more durable and do not require constant monitoring.

Press fitting.