- To what depth should the foundation be insulated?

- Equipment configuration

A fifth of all heat losses incurred by a heated building occur at the foundation. Freezing structures become moistened when they thaw, and moisture always tends to rise up through the capillaries. If somewhere there are areas with damaged waterproofing, water will certainly get to the walls - and this means dampness in the rooms, mold and other unpleasant consequences. In addition, cyclical freezing and thawing reduces the service life of reinforced concrete monoliths and masonry, so it is advisable to protect them from temperature changes. Let's look at how the foundation is insulated with polyurethane foam.

Characteristics of polyurethane foam

Plastic polymer masses, which are foamed to obtain a porous structure with a low thermal conductivity coefficient, are obtained on the basis of several types of polymers. Hence the common name - polystyrene foam. One of these polymers is polyurethane, which is used in construction both in the form of slabs (outwardly very similar to expanded polystyrene) and in the form of foam sprayed onto surfaces using special equipment.

Kinds

Slab insulation is much more convenient to use, since it does not require spraying equipment. In addition, PPU slabs can be used where foam cannot be used - for example, under a concrete floor laid on the ground. It is not used under slab foundations, because even with a higher density than EPS, its compressive strength is insufficient.

Slab and foam polyurethane

- In terms of other characteristics, polyurethane foam outperforms its main competitor and has a lot of advantages. This includes minimal moisture permeability and inertness to chemical influences. The degree of fire safety can be the same (flammability group G4), but due to the addition of fire retardants it can also be G1 (non-flammable).

- But most importantly, the thermal conductivity coefficient is only 0.028 W/m*C, which is 25-30% less than that of EPS. This means that the thermal insulation layer will be thinner to ensure the same thermal resistance, which compensates for the higher cost of the coating.

- Polyurethane in the form of foam is used to insulate external surfaces - or horizontal ones, but indoors. This coating is effective due to its seamlessness and is applied faster, but you have to pay for the services of specialists no less than the cost of the material itself.

- For this reason, the demand for work with spraying equipment is not too high, and manufacturers who have accumulated sufficient experience in the production of rigid polyurethane foam began to supply the market with the material in slab form. The owner of a private property can install it himself, and thereby save money. Accordingly, the demand for polyurethane foam insulation (the most effective compared to any other insulation) has increased significantly.

- The raw materials for polyurethane foam are materials with a cellular structure, homogeneous throughout the entire volume, polyisocyanate and polyol. The cells are closed, which ensures vapor tightness. The components are brought to a liquid state and poured into molds, where they are foamed. The mass expands, creating a certain pressure, and after 20-25 minutes it hardens.

Expert opinion Vitaly Kudryashov builder, aspiring author

Ask a Question

To expand the scope of application, manufacturers produce boards in a shell made of kraft paper or fiberglass, with one-sided or double-sided foil. In addition, these layers provide excellent protection from ultraviolet radiation and double the strength and service life of the slabs. To obtain thermal insulation coatings without through joints that would need to be sealed, PPU slabs are often produced with a quarter at the ends.

Advantages and disadvantages

Here's how you can briefly outline the list of advantages and disadvantages of polyurethane foam as insulation for the foundation:

| Advantages | Flaws |

| It does not absorb moisture, so it can come into contact with moisture-saturated soil without compromising its strength. | High price. One square meter costs at least 300 rubles. And the foundation tape needs to be insulated to a thickness of at least 100 mm - in two or three rows. It’s not difficult to calculate how much such pleasure will cost. |

| In fact, it is also a waterproofing material. | There is not enough compressive strength to insulate the base of a slab foundation. |

| During installation, you can create a seamless coating with sealed joints. | It interacts poorly with ultraviolet radiation - but being in the ground, it is protected from it. When insulating the basement part, the polystyrene foam is covered with finishing - plaster or hanging panels. |

| Resistant to aggressive salts dissolved in groundwater. | Susceptible to damage by rodents, for protection it is lined with geotextiles or covered with a PVC membrane. |

| The surface is not subject to cracking. | |

| It serves for a long time without changing its original properties. | |

| Withstands high loads without being damaged mechanically. | |

| The slab form makes it possible not only to insulate the walls, but also the floors of the basement, and this can be done in a short time. | |

| Compressive strength not less than 0.12 MPa. | |

| It is not afraid of temperature changes, and can work at 70 degrees, both above and below zero. | |

| Using the spraying method, you can insulate a foundation with a complex configuration and without seams. | |

| Long service life: for ordinary boards 20 years, for laminated boards - up to 60 years. | |

| Easy installation. | |

| Light weight. | |

| PPU is universal and can be used for both external and internal insulation. | |

| Fireproof, in the absence of open fire it goes out on its own. |

We insulate the PPU foundation

When the preparatory work is completed, you can begin to insulate the foundation. To do this, you need to use a special tool called a “spray gun”

In addition to this you will need:

Respirator.- Work or old clothes.

- Polyurethane foam.

- Protective glasses.

Due to the fact that the material itself is caustic, ordinary clothing cannot be used. In addition, it can be harmful if it gets into the eyes or respiratory tract.

After this, you should connect the cylinders to the sprayer and you can start. It is necessary to spray the insulation evenly from top to bottom, and at the same time go around the perimeter. In one approach, you cannot apply more than 4 cm of insulation in thickness. If greater thickness is required, do this in several approaches.

I would like to note that polyurethane foam can be sprayed onto small areas of the ground foundation, but their size should not be less than 0.5 meters. This is necessary to prevent wastewater from flowing behind the insulation layers, which can lead to rapid destruction of the insulation and create a pocket between the foundation and the building.

The process itself is simple and does not require special skills. It is only important to have good equipment that can evenly distribute the insulation over the surface. Polyurethane foam does not harden for a long time, usually a few minutes are enough, after which a new layer can be applied. But you cannot immediately fill the trench, since the material must “settle.”

When the polyurethane foam coating hardens, you can cover it on top with a layer of bitumen. This will improve the quality of the component and extend its service life. After this, you can dig a trench.

Interestingly, to protect this insulation from water, it is recommended to make a blind area, which is important for those areas where winters are very cold.

Next, finish the top part of the insulation along the frame. There are no requirements for operation, it is only important to protect the polyurethane foam from sewage and rain.

How to spray polyurethane foam

Due to their lower thermal conductivity, polyurethane foams have a huge advantage over expanded polystyrene foams. Although, since EPS is cheaper, there is always the opportunity to increase the thickness of the insulating layer. However, in some cases it is better when the thermal insulation is thinner, and this can be achieved by insulating the foundation by spraying polyurethane foam. For example - under hanging cladding.

Insulation of the base under the cladding

- This coating is very useful when it is necessary to insulate foundations with an intricate contour. In such cases, cutting and gluing the slabs is a hassle, and the many joints that are not always even are quite difficult and labor-intensive to seal. Foam insulation solves all problems at once. When the layer thickness does not exceed 2-3 cm, a large indentation is not required for cladding.

- The advantage of sprayed insulation over slab insulation is that when it is applied, no voids are formed between the base and the foam. This means that moisture cannot enter them, and visually undetectable cold bridges will not form. Foam can be applied to a base of any quality, even with a large number of differences, whereas for insulation with slabs they would first need to be leveled with cement glue.

- In general, in situations where the integrity of the insulation layer is difficult to control (especially on older buildings), it is better to use a spray method that will fill every hole and joint. Sprayed thermal insulation is also most relevant for buildings with a large foundation area (more than 100 m²).

- It is difficult to guarantee high-quality sealing of slabs in such areas, but in the case of foam insulation, the guarantee is one hundred percent. In addition, large volumes of work make it possible to get a discount of up to 15%, so it may well turn out that you will still win.

The savings are obtained not so much due to the cost of services and materials, but due to the reduced time frame for completing the work. Spraying is usually carried out by teams of two people, and in one work shift they can treat an area of up to 500 m². You don’t have to wait long for the foam to polymerize either (only a few hours). And time, as you know, is also money.

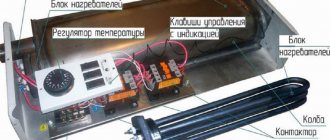

Equipment configuration

Sprayed insulation is mixed from two components. They are delivered to the facility in different containers: blue barrels contain polyol, red barrels contain isocyanate.

PPU system components

The installation, through which spraying is carried out, has the following equipment:

- A pressure compressor that provides the required pressure.

- A mixture preparation mechanism consisting of a pair of pumps and a remote control. With its help, the components are mixed and heated to the temperature specified by the manufacturer.

- Flexible pipeline with a dispensing gun and replaceable nozzles (differing in the type of spray torch).

- Technical silicone, which is used to lubricate the gun seating area.

- Equipment assembly tool.

- Protective clothing.

For normal operation, the compressor requires electricity, and not 220, but 380 volts. At new construction sites there is often no permanent network at all - and even if there is, it is not suitable for the operation of the spraying unit due to frequent power surges. Professional teams are also equipped with a diesel generator, although it is not included in the equipment package.

Expert opinion Vitaly Kudryashov builder, aspiring author

Ask a Question

Note: PU foam manufacturers offer consumers mini-kits for applying foam themselves. If you decide to purchase one, you will have to think about buying a generator.

Foam application

The final properties of the resulting thermal insulation coating depend on several factors: the proportions of the components; air temperature and the mixture itself; the pressure at which it is supplied; thermal conductivity of the base on which the foam is applied.

The application process generally looks like this:

- The base is cleaned of all types of dirt and loose areas. If necessary, wash and dry.

- Before applying foam, some specialists treat the surface of the foundation with waterproofing coating, usually bitumen. But in principle, this operation can be omitted, since the foam itself is an excellent waterproofing agent. But priming to reduce the absorbency of the base makes sense - this way less foam will be consumed.

- The mixture, liquefied due to heating, is applied to the surface in the form of a continuous coating, or it is filled into the cells of the sheathing installed under the hanging decorative material.

Expert opinion Vitaly Kudryashov builder, aspiring authorAsk a Question

When applying foam, experience is required: the mixture expands 100 times during the polymerization process, and in order to obtain a layer of the required thickness, this must be taken into account. A layer with a thickness of no more than 50 mm is considered normal. If this is not enough according to thermal resistance calculations, you will have to apply a second layer.

- Foam is applied to the foundation before backfilling is completed. If the structures of an already in use house are being insulated, the blind area must be dismantled, and the foundation strip or basement wall is exposed by 50 cm. Where the soil freezes slightly, only the above-ground part of the foundation and the soil around the perimeter can be insulated.

Insulation of the blind area

Subsequently, the strip, with polyurethane foam sprayed to a width of 80-100 cm, will be hidden under the covering of the blind area. It is very important to protect the already applied foam from ultraviolet radiation during polymerization, so the covering material must be taken care of in advance.

Let's get acquainted with special equipment - a foam generator

Equipment for mixing and applying polyurethane foam

Polyurethane foam is sprayed using special equipment. The PPU system can be a low or high pressure unit (for example, a “Foam” unit).

- Gear (or plunger) pumps inside the equipment provide the dosing principle. They are started by an electric motor.

- Raw materials flow from containers into a chamber where the components are mixed.

- The finished composition - polyurethane foam - is sprayed onto the surface through a gun. The remote control helps regulate the feed intensity.

The performance of the system is impressive: when working together, up to 1 thousand square meters can be insulated per day. meters (at least 350 liters per minute).

The choice of foam generator depends on the volume of construction. For small-sized ones, a low-pressure installation is sufficient. For large ones, a unit is needed that supplies and mixes components under a pressure of 260 atmospheres.

Before starting work, you should make sure that the equipment is in working order and that the required current is available: 220 W. Experts advise unprepared people to do a “control” spray. Thus, you can not only get ready for work, but also make sure the quality of the polyurethane foam (is the composition homogeneous).

Manufacturers and prices

Experts call the following companies the best producers of polyurethane foam:

BASF Polyurethanes GmbH. The German company is a leader in the production of polyurethanes. The product line also includes polyurethane foam. In Russia, together with OJSC Nizhnekamskneftekhim, they created the Elastokam enterprise to produce components for polyurethane foam.

Yantai Wanhua Polyurethanes Co., Ltd. Chinese manufacturer with a high-quality line of polyurethane foams.

SYNTHESIA INTERNACIONAL SLU The Spanish chemical company SYNTHESIA INTERNACIONAL SLU has been producing polyurethane foam since 2008. The products have found their buyers in many countries around the world, including Russia.

The price from all manufacturers is about $650 per 1 m3.

Step-by-step algorithm of actions

To evaluate the work and perform insulation yourself, you need to know the procedure.

If there is no one to help, you can purchase ready-made mixtures in cans with a spray gun, but the application process will be somewhat slower and more difficult.

The outer part of the base is cleaned, decaying areas are removed, and dried. Wear special clothing and protective equipment.

The solution is applied to a space of 1 * 1 m, completely filled, and proceed to the next sector. The steps are repeated until a complete overlap of the base is formed.

Then, you need to wait 30-40 minutes so that the applied polyurethane foam cools completely. You can immediately apply the next layer without waiting for the insulation to dry completely.

When polymerization is complete, excess foam is cut off and plaster is applied tightly. For external cladding, you can add color to the plaster, or finish it with brick, stone, or siding.

If the work was carried out on commercial buildings, to protect the material from ultraviolet radiation, you can paint the insulation with acrylic, silicate paint.

Is it possible to improve sound insulation?

The foam has sound insulation properties. This is affected by:

- The thickness of the applied insulation layer reflects the incoming noise.

- Elasticity absorbs vibration from sounds.

- The tightness of seams and cracks prevents noise from penetrating into the room.

But the foam in the cylinders does not have the same characteristics as the material sprayed through the equipment.

The only type of foam in cylinders that has good performance is MAXFORTE SoundFLEX.

Today, foam is widely used to insulate walls indoors and outdoors. It is used in attics and basements, attics and loggias. Insulation of pipelines and chimneys is carried out.

The material has many positive aspects and has good sound insulation properties. When using foam insulation, you should familiarize yourself with the application method and also think about the cladding.

Foam cost

If you buy a cylinder at retail, then on average you can pay 300-500 rubles per piece. But this type of insulation is rarely purchased separately. Usually its cost is included in the cost of work:

- polyurethane foam - about 100 rubles per linear meter;

- penoizol - 700−2000 rubles per cubic meter;

- polyurethane - 3000−5000 per cubic meter.

The price of the material also plays a big role in its selection. But you shouldn’t skimp on high-quality thermal insulation if you need to insulate your home for a long time for a comfortable stay.

Foam insulation is suitable for most walls , including panel, block and aerated concrete. Therefore, they can be safely used as insulation for apartments and private houses. What type of foam to choose is a purely personal matter for everyone. But first, it still doesn’t hurt to find out more about the selected composition, read reviews, and get advice from a salesperson at a hardware store. It is not recommended to use loose-fill insulation, which easily catches fire, unlike the foam fireproof version. And it is not the most convenient to use, the only exception being the floor surface.

Insulation with liquid foam is a better solution , because if desired, this procedure can be carried out independently, without the help of specialists. If you do everything correctly and are careful, you will be able to quickly insulate any surface that needs it.

Choice of insulation

The main problem that needs to be solved is the selection of the optimal thermal insulation material. What insulation is better to use? Nowadays, thermal insulation and waterproofing materials are presented very widely; you can choose any one your heart desires. However, experts do not recommend spraying; they advise taking a closer look at the two most popular options.

The first is polystyrene, which has become traditional, the second is polyurethane foam, which is quickly gaining popularity. These insulation materials differ in both characteristics and price, so choosing between them will not be easy. Thermal insulation of the foundation is the most important process, so there is no need to rush; you need to carefully study the advantages and disadvantages of each of these materials.

We take into account the features of the technology before starting work

Drawing diagram of applying polyurethane foam insulation to foundation walls.

The technology of spraying polyurethane foam is suitable not only for insulating the foundation, but also the base, walls, roofs and floors. If a basement is planned, both external and internal insulation is recommended. Masters of their craft offer interior work when it is not possible to work as a “sprayer” from the outside. External is done around the entire perimeter. A layer of 6 cm can be considered reliable.

PPU has its own temperature threshold - +5 C. Therefore, you should not plan work for late autumn and winter. It is not worthwhile to insulate with this building material during rain and strong winds (more than 5 km/h).

To carry out the work you will need raw materials and a foam generator. To thermally insulate the foundation, it is enough to choose rigid polyurethane foam (with a density of 32 kg/cubic m). Bitumen mastic is useful as additional waterproofing.

More information about the material

Now let’s figure out how to insulate the foundation of a house from the outside, what exactly is so good about polyurethane foam, and why it is optimally suited for treating the foundation. Here is a list of material characteristics:

- thermal conductivity coefficient: 0.025 W/mK (for comparison, for mineral wool this figure is 0.05-0.06);

- density: about 60 kg/m³;

- weight: about 1.7-1.8 kg in 1 “square” 3 cm thick;

- operating temperature range: from -100 to +100 degrees (for some brands it expands in both directions);

- durability: under normal operating conditions it can reach 40-50 years without significant loss of quality characteristics.

Now let's list the properties of polyurethane foam:

- absolute resistance to moisture - the material does not deteriorate even with constant direct contact (which is primarily important when treating the foundation walls of a house);

- neutrality in biological terms - fungus and mold do not appear on the material;

- significant soundproofing properties;

- fire resistance - the extruded material is difficult to burn even in its usual version, and the use of special additives makes it resistant to direct fire (on contact, a layer of coke is formed that prevents the spread of flame);

- reliability of the layer - over time, the applied polyurethane foam does not crumble or crack.

The first point is not just a marketing phrase from manufacturers. PU foam really tolerates long-term direct contact with moisture without any problems. Proof of this is, for example, the fact that the material is actively used in shipbuilding. This factor is extremely important when insulating the foundation walls of a house - since this part of the structure is almost always exposed to moisture, the blind area only slightly removes moisture. And due to the material’s resistance to liquids, additional waterproofing is, in fact, not necessary.

Stages of material application

We will consider both technologies, but we will pay more attention to sputtering.

First, let's list the general stages of work:

- The blind area is removed around the walls and a trench is dug with your own hands to the full depth of the foundation. Its width should be sufficient for comfortable work inside.

- The surface of the walls is cleaned of dirt, dust and remaining materials (if any) using metal and ordinary brushes.

- The integrity of the structure is checked.

- If there are cracks, plaster is used to seal them.

- The surface of the walls is primed (additional waterproofing will not be superfluous, despite all the advantages of the material).