Sawdust stoves are not a new phenomenon, but they are still quite popular today. Such units only increase their popularity among the population every year due to their significant advantages. The design features of devices operating on wood waste contribute to long-term combustion of fuel with maximum heat transfer. Heating with sawdust, a cheap and environmentally friendly material, allows you to save significantly by purchasing inexpensive raw materials for heating a private home.

Sawdust stoves, as they are also called, do an excellent job of heating greenhouses, workshops, service stations, garages and not very large residential premises . The manufacture of such common boilers can be done with your own hands without much difficulty by first viewing the drawings and studying the assembly process. As a starting material, you can use any available containers such as old metal barrels, pipes, gas cylinders, of course, without contents, and other similar containers. Before making a sawdust stove with your own hands, which you plan to heat in the cold season, we suggest that you familiarize yourself with the design and features of industrial equipment, and based on it, draw conclusions about what a wood chip boiler should be like and how to handle its assembly.

How does the combustion process occur in a sawdust stove?

If we compare this device with a standard design, then in no case should fuel be added to this stove during combustion.

It would be correct if you put pressed sawdust in the oven and until it burns completely, you should not open the oven. For prolonged combustion of fuel, in order to preserve heat in the room, you can reduce the combustion intensity. With a slow burning, the beginning of which will be in the center at the bottom, will gradually spread upward and to the sides, which will allow the sawdust to fall during the combustion process. Some stoves are quite capable of providing combustion for 8-10 hours.

Required video

In this video, the owner of a private house tells how to increase the combustion of sawdust in the stove:

Inexpensive or free sawdust is a good substitute for firewood or coal as a heating fuel. However, you should not burn them in direct combustion furnaces and boilers , due to the fact that they are intended for other types of fuel.

For such heat supply, they make sawdust burners with their own hands or order them from a specialist. The costs of purchasing or manufacturing such radiators will be justified within five to ten years if you have the opportunity to get sawdust for free or practically free.

What can a stove be made from?

There are no strict restrictions in this regard. You can go by what you have on hand. Everyone perfectly understands the shape that an ordinary cauldron has. Therefore, it is better to choose the rounded version. An ordinary two-hundred-liter barrel, a large-diameter pipe, a can, a gas cylinder and other items are suitable for this.

You can offer an option with a rectangular cross-section. In essence, we return to the potbelly stove, but this is not the same design. Because sawdust should be loaded into the combustion chamber from above, and not from the side, as is the case with a potbelly stove. After all, the fuel must be compacted or pressed. This is the whole trick of the long-burning stove.

What is this type of fuel made from?

The material for making fuel chips can be any wood, so most often this type of fuel is made from dry branches and various wastes that remain after processing or processing wood.

At the same time, the finished product retains all the features of the original wood, therefore such characteristics as:

- calorific value;

- ash content;

- specific resin content,

completely correspond to the trees from which the chips were obtained.

Because of this, pine chips are not suitable for modern automatic boilers, because the high resin content not only increases the ash content, but also leads to the appearance of deposits in the chimney and on the heat exchanger parts.

Between starting the boiler and heating the water to operating temperature, at least an hour passes, during which condensate containing a lot of resins settles from the hot smoke onto the cold pipes.

In addition, the calorific value of hard and heavy wood chips is always higher than that of light and soft wood chips. After all, the finished fuel only preserves the original characteristics of wood.

If the fuel is obtained from wood with bark, then its calorific value decreases, because this parameter of the bark is much lower than that of other parts of the tree, with the exception of needles and roots.

Fuel supply mechanism

Sawdust heating boilers operate autonomously. There are several basic fuel supply options. Typically, the receiver goes through a door to the outside of the house. Structurally, there is a screw transmission, which is connected to the hopper. After the storage facility is fully loaded, the transport unit begins operation, which transfers the chips to the mechanized department.

Storage in boilers:

- A hopper, the base of which is located at an angle, or cone-shaped with an additional screw-type mechanism fixed in the lower part. From it, fuel gradually flows into the firebox.

- A screw-type agitator attached to the bottom, due to the movement of which sawdust falls into the firebox.

In pyrolysis wood chip boilers, fuel is supplied gradually through screw mechanisms.

Automatic boilers for coal and wood chips

The design and principle of operation of these units is not much different from pellet ones. The screw conveyor in the same way supplies coal to the firebox at the command of the control unit, air injection and ignition work in the same way. The difference is in the design of the auger itself; for coal it is made more massive, and accordingly, the power of the electric motor is increased. In addition, a coal solid fuel boiler with automatic fuel supply requires fuel of a certain quality and humidity. This is due to the design features of the retort burner used in such heat generators.

Heating units that burn wood chips have one additional function in the feeder - wood chopping. After all, the length of the chips can be different and it is impossible to provide an auger for it. To make the chips the same size, a rotary chopper knife is built into the supply pipe between the hopper and the auger. Both the conveyor and the knife are driven by one powerful electric motor. Such products are offered by many European manufacturers, for example, the Austrian automatic solid fuel wood chip boiler FROLING.

A little about universal units. Their convenience is that if there is a shortage of any type of bulk fuel, you can switch to regular firewood at any time. For this purpose, the design provides an additional combustion chamber for storing wooden logs. Of course, the efficiency in this case is significantly reduced (from 90 to 80%), since the heater operates in the mode of a simple solid fuel boiler. One more circumstance should be noted: every manufacturer of automatic boilers is trying to expand the range of fuel burned by modernizing the supply system. Therefore, some products, in addition to pellets, can use coal dust, eco-peas and even seed husks. An example of this is the Polish universal boilers DEFRO DUO UNI.

Features of boiler operation

The most modern and reliable type of sawdust boilers are automated water heating systems. Their design consists of several main parts:

- fuel bunker;

- gas generator;

- hot water boiler - consists of a combustion chamber and a heat exchanger;

- automatic control system.

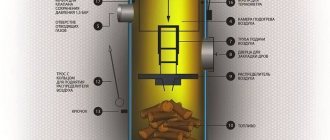

Modern sawdust boiler - device

The housing design includes the following elements:

- firebox;

- chimney;

- ash pan;

- heat distributor;

- coil;

- blower;

- sensors

Depending on the building design, it can be installed entirely inside, outside, or partially installed outside.

The automatic system is responsible for the following operations:

- feeding wood chips into the boiler;

- supply of hot air in the combustion chamber in accordance with the volume of fuel;

- temperature rise control;

- firefighting.

Among the imported boilers of a similar device, we can highlight the Austrian HARGASSNER. They are especially popular in Europe for heating hotels, houses, and office buildings.

A prominent representative of domestic boilers is BIO VULKAN produced. The main features of these devices:

Boiler BIO VULKAN – general device

- The firebox body is made of steel sheets and pipes, externally coated with heat-insulating material.

- The interior is lined with fireclay bricks, which increases the heating temperature.

- Sealed doors with a concrete body, large and heat resistant.

- Fans supply primary and secondary air to the firebox - this is necessary for combustion.

- The drum heat exchanger is protected from lime deposits by two-level water circulation.

These sawdust boilers have the highest efficiency, which is due to the installation of a five-pass heat exchanger on them. To burn fuel, a retort burner is used, which allows the use of wood waste with a fraction of up to 4 cm.

Subtleties of installing solid fuel boilers

The boiler piping scheme is adopted in accordance with the characteristics of the heated object.

You can implement it using one of the following options:

- boiler in an open heating system with natural circulation and radiators;

- boiler in a closed system with forced circulation and radiators;

- boiler with thermal accumulator in a closed forced system with radiators;

- boiler with thermal accumulator in a closed system with forced circulation and heated floors;

- boiler with radiators and heated floors as part of a forced circulation system.

The piping of a solid fuel boiler must be equipped with a safety system. The latter includes:

- heat accumulator or buffer tank;

- three-way valve for adding cold water;

- thermostat in the control system.

Solid fuel boiler safety group

Immediately before installing a solid fuel boiler, it is necessary to carry out a visual inspection and test firing in the open air for about 1 hour at maximum load of the combustion chamber.

According to the requirements of SNiP, after connecting the boiler, a hydraulic pressure test of the system should be carried out for 24 hours.

To do this you need:

- connect the water, open all taps and shut-off valves;

- increase the pressure in the system to 1.3 atm (with a control valve);

- make sure there are no leaks, especially at welded and threaded connections.

If the installation, piping and connection of the boiler are carried out correctly, there will be no pressure losses or coolant leaks. In this case, you can begin to inspect the boiler itself:

- checking the installation of grates and fireclay;

- setting the ignition valve to the extreme position to ensure optimal traction;

- checking the quality of installation of plugs, combustion chamber doors and other elements of the boiler design.

Connecting the boiler to a water heating system

Some home owners who have already installed a water heating system may wonder whether it is possible to connect such an economical sawdust stove to it. The answer is yes, and this does not require any special skills. You need to install a register by connecting the supply and return to it, which are connected to the central heating system. To improve heat transfer, a suitable option is to install a blower, a narrow pipe passing through the lid and the entire body instead of a cone.

So, for economical users who care about the environment, a long-smoldering sawdust stove is an excellent option for heating a greenhouse, cottage or small house. It is easy to make and install; it will bring warmth, tranquility and comfort to your home.

general information

The operating principle of such a heating device is significantly different from its stove “brothers”. The only thing that all stoves have in common is the generation of heat due to the combustion of wood hydrocarbons and heating the heating walls of the stove with hot air. Rocket pyrolysis, or slow combustion by supporting the smoldering of fuel in sawdust stoves, is an oxygen-limited mode that maintains the slow combustion of wood fuel.

Principle of operation

The main type of fuel is sawdust, shavings and other small waste from wood processing. The gas obtained during pyrolysis contains multi-element substances that are not entirely safe for humans: a mixture of hydrogen, carbon dioxide and methane, with the help of which heating surfaces are heated. Therefore, to avoid poisoning, you should carefully consider the installation of gas exhaust elements.

Is it necessary to insulate?

Foamed concrete has low thermal conductivity. But it’s still a stone material that needs additional insulation. It is always carried out strictly outside. If the width of the belt is less than the width of the wall, it is usually possible to still cladding the structure flush with the wall cladding. It is not very wise to use simple polystyrene foam - it is much more correct to use EPS; if you use mineral wool, be sure to leave a ventilation gap. Sometimes another situation arises:

- the width of the belt and wall is identical;

- finishing is completed;

- There is no gap between hardening and cladding.

Then the thermal protection is increased along the entire perimeter to the required height. If the house has 2 floors, and the reinforced belt is located at the interfloor level and after the second floor on the mauerlat, you will have to make 2 lines of insulation.

In the next video you will see the filling of an armored belt for a house made of aerated blocks.

Boiler Assembly Guide

Pellet boilers have a rather complex design. The instructions for assembling them will also be difficult and multi-step. For greater convenience, the assembly process of each main unit is considered separately. Buy or make the necessary elements, and then simply assemble them into a single system.

Burner

Burner

It is highly recommended to buy this element of a pellet boiler ready-made. The burner is where you will spend the most money.

Making a burner yourself is almost impossible for the reason that this part of the boiler is not simply a container for igniting loaded pellets, but a complex control and regulatory mechanism.

Pellet burners are equipped with special sensors and have several preset programs that allow you to achieve the most efficient fuel consumption and ensure the most efficient heating of your home.

Housing and heat exchanger

You can handle the assembly of the housing and the manufacture of the heat exchanger yourself. It is best to make the boiler body horizontal - with this placement of the unit, maximum heating efficiency is achieved.

It is recommended to use fireclay bricks to make the body. You simply assemble a kind of box without a top cover and place a heat exchanger in it with connected pipes and other elements. Brick is recommended for the reason that it accumulates heat much more efficiently than cast iron, steel sheets and other popular materials.

Fireclay brick

The heat exchanger of a pellet boiler is a system of pipes interconnected and connected to the heat supply pipes of a private house.

First step. Assemble a rectangular heat exchanger from square pipes. To do this, cut the pipes into pieces of the required length and weld them into a single structure.

Second step. Make holes in the profile that serves as a vertical post for connecting round pipes.

Third step. Prepare holes in the remaining front pipes for drainage and water connection pipes. Hot water will be discharged through the top hole, cold water will be supplied from below.

Use metal pipes with a length of 150 mm. Next, you can use polypropylene pipes. Be sure to install ball valves where the pipes connect to the boiler. Additionally, you can install filters if necessary.

Fourth step. Weld the back of the unit to its front and weld the side pipes.

At the same stage, select a convenient place to connect a chimney pipe with a diameter of 10 cm. At the bottom of the heating unit, provide a small chamber for collecting ash. Also, the design of a pellet boiler necessarily includes a firebox. More about him later.

Pellet boilers

Firebox

In the firebox, as already noted, pellets are stored and from here they are supplied to the burner.

First step. Prepare the necessary materials and equipment. You will need an auger with a diameter of 7.5 or 10 cm, an electric motor and a metal casing. You will connect the engine to the pellet burner control unit.

The function of a metal casing can be performed by any container of suitable volume with sufficiently thick walls.

Second step. Install the inlet pipe of your auger into the discharge mouth of the casing. Connect a corrugated plastic pipe to the other part of the auger to supply granular fuel to the burner.

In conclusion, all you have to do is assemble all the listed elements into a single structure. Do this and proceed to installing the boiler.

Manufacturing process

For manufacturing, you can use pipes, metal sheets (welded into cylinders) and barrels. One of the most budget-friendly and simplest options is a pipe stove.

Simple option

For manufacturing, you will need a pipe made of thick walls (minimum 4 mm) with a diameter of 40 cm. You can use a metal sheet of equal thickness, from which you need to weld a cylinder with the same diameter:

- Use a grinder to cut a hole for the chimney in a large pipe. The optimal distance is 100 mm from the top.

- Make the bottom. Cut a circle from a sheet about 0.6 cm thick, the diameter of which will correspond to the pipe. Weld the cut circle to the base, preferably using electric arc welding. Cut a 50 mm hole in the center of the bottom.

- Make perforation cuts on the pipe at a distance of 0.3–0.5 cm from one another, and weld it to the bottom. The length of the pipe should be 15–20 cm higher than the firebox.

- Cut the lid from a sheet of similar thickness to the bottom, only 2 cm larger in diameter. The edges must be bent tightly with a hammer along the entire diameter so that the lid fits tightly.

- Cut two holes in the center of the lid: for the chimney (according to the size of the selected pipe) and for the plug.

- To ensure the strength of the chimney, you need to weld the pipe on the inside and secure the chimney with clamps. Then they are sealed with heat-insulating material and tightly twisted with wire.

- Attach the legs. You can use corner pieces of the same height, which are welded to the base.

In addition to its advantages, this option also has serious disadvantages. Thus, the stove is only suitable for heating a small area; the walls become very hot, which eliminates the possibility of being at a close distance from it and the possibility of leaving it unattended.

Long burning boiler

The optimal material for such units is metal barrels, which can also be used as smokehouses:

- Cut off the top part of the barrel from which the lower chamber will be constructed.

- Make steel cylinders so that one fits perfectly into the other. Secure the lid to the upper (narrow) edge of the cylinder.

- Remove the bottom of the barrel and cut a circle of the appropriate diameter from thick steel. It is also used for the boiler lid.

- Make a 100 mm hole in the bottom for the combustion cone.

- Weld profile pipes inside the barrel. The height of the pipes should be slightly less than the height of the barrel so that the lid and tamping cone tightly cover the structure.

- Cut holes in the lid and cone for round pipes.

- Drill holes in the housing at the height of the pipes into which pipes for supplying water (cold and hot) and the chimney will be inserted.

- Construct an ignition chamber from the previously cut off part of the barrel. The door can be purchased or made from steel. You can provide traction using several holes that need to be drilled in the chamber.

If the boiler will be used for heating a living space, it is better to cover it with brick. It will be safer this way, and the heat will last longer.

How to calculate boiler power

To set the required boiler power, you need to know the size of the room it will serve, the degree of insulation of the house and the weather conditions of the area.

Complex thermal engineering calculations can be ordered from specialists, or you can make approximate calculations yourself.

To do this you will need to know the area of the house.

- For warm regions, 0.8 kW of power per 10 m2 is taken.

- In the middle zone - 1.2–1.4 kW per 10 m2.

- And in areas with frosty winters - 1.5 - 2 kW.

If the house is poorly insulated, add from 20 to 40% of the power.

For example, for a house of 90 m2 it is customary to install a boiler with a capacity of 9 kW, but if the home is located in the northern region, it is better to choose a boiler of 13 - 18 kW (90 x 1.5 or 90 x 2).

Operating principle and design of the furnace

A long-burning boiler differs from other solid fuel heating devices in that it is not combustion that occurs inside, but smoldering, which releases enough heat to provide one or two rooms. To create the smoldering process, the fuel is compacted so that a minimum of air remains between its particles, since oxygen increases the intensity of the process with enormous heat release.

In this case, fuel is quickly consumed and will need to be reloaded. Such boilers do not bring any savings, and excess heat will escape through the chimney and will not be used for its intended purpose. A long-burning boiler uses the energy released during smoldering and is equipped with a regulator that controls the flow of air. Smoldering in briquettes or sawdust forms “flue” gas, which releases a large amount of thermal energy when burned in the ignition chamber.

There are two furnace design options:

- In which furnace gas, as a result of fuel combustion, rises through compressed sawdust, entering the chimney.

- In which the stove gas from burning sawdust enters the external circuit, where it cools and is disposed of through the chimney.

- Standard long-burning boilers consist of the following main elements:

- A fuel tank (furnace) in which there is a damper that regulates the flow of primary air.

- Afterburner chambers with holes made through which secondary air enters.

- Chimney.

Types of stoves for different operating conditions

A rocket stove with a water circuit, brick or metal, can replace a boiler. The heat exchanger here is arranged in the upper part of the flame tube in the form of a surrounding water jacket. There are jumpers inside the jacket for more efficient heat transfer to the coolant. The design is extremely simple; it can heat households up to several tens of square meters.

A rocket stove for the garage can be made from an old pot-bellied gas cylinder or barrel. To do this, two holes are made in the selected container - one in the top lid and the other on the side surface. An L-shaped pipe is inserted inside. Having a little experience working with a welding machine, all work will take you a maximum of half an hour.

You can also make a rocket-type furnace described above from sections of square and metal pipe according to the drawing given.

Also suitable for heating a garage is the heating rocket stove “Ognivo – Khozyain”. This is a store-bought model made from aluminum corrugated pipe and ordinary sheet iron. It works in approximately the same way and allows you to warm a garage of up to 30 square meters. m.

There are no drawings of it in the public domain yet, so you can try to assemble the “Ognivo” stove with your own hands based on its photograph. You can also buy it on the manufacturer's website.

We have already said that to heat large households you will need a long-burning rocket stove with a water circuit. A small one-room household can be heated with a simpler stove and a stove bench - this way you will save space on furniture. It consists of the following nodes:

- Firebox with vertical loading - logs are placed in it;

- Afterburner is a horizontal section in front of the riser (flame tube), where pyrolysis combustion occurs;

- A riser with a hob is a vertical section with a metal body that transfers heat into the room;

- Horizontal channels - they heat the stove bench, after which the combustion products are sent into the chimney.

A rocket stove for heating a one-room house is coated with clay to create a flat and comfortable bed - here you can lay a mattress or a small blanket.

For camping use, the simplest rocket-type stoves made of metal pipes are used. They are compact, easy to light and extinguish, cool quickly and allow you to quickly prepare lunch in the open air. The main thing is not to overdo it with the amount of fuel loaded, so as not to burn the food with a high-temperature flame.

Design and operating principle

A long-burning stove does not look like a traditional potbelly stove, as we imagine it. In addition, it is not mass-produced by any manufacturer, and its design is entirely the achievement of various craftsmen. Most of all, the new potbelly stove resembles a round metal stove - a “slobozhanka”, but differs from it in the way it burns fuel. Sawdust is used as the latter, and here's why:

- heating with a potbelly stove powered by sawdust and wood chips will be inexpensive due to the availability of such fuel;

- compressed sawdust burns out for a long time; one load will last from 6 to 10 hours of operation of such a heat generator.

The stove has a vertical configuration and consists of two cylinders, the smaller one is installed inside the larger one. The simplest option is 2 barrels with a capacity of 200 and 100 liters. Under the small barrel, which acts as a combustion chamber, there is space for the ash box, which is removed through an opening in the lower part of the large barrel. To supply air to the firebox, the design of the potbelly stove provides a round hole made in the bottom of a small cylinder. It enters through the slightly open ash pan. The top of the housing is tightly closed with a lid, and a chimney pipe is installed on the side between two stiffening ribs.

There is no special wisdom in how long-burning potbelly stoves operate. First, a cone is inserted vertically through the open top cover into a round hole made in the bottom of the firebox. Then the combustion chamber is filled to the top with sawdust, which is compacted tightly. The cone is carefully removed, the top lid is closed and you can start igniting. To do this, take out the ash box, put wood chips, splinters, and small wood in it and set it on fire. The box is inserted into place without sliding it all the way in to leave a gap for air. Details of the process are shown in the video:

Under the influence of the draft created by the chimney, the compressed sawdust begins to slowly smolder, and the long-burning stove enters operating mode. Combustion products leaving the firebox heat the walls of the barrel and exit through the chimney pipe. This method of heat transfer makes it possible to remove a significant part of the heat from the flue gases, increasing the efficiency of the heat generator (efficiency) to 40-50%. In this case, the duration of work from one load can reach 10 hours, as mentioned above. In addition to these advantages, a sawdust stove has others:

- low cost of production;

- ease of installation, installation of a potbelly stove consists only of installing a chimney with satisfactory draft;

- low requirements for fuel quality;

- energy independence.

The disadvantage of a potbelly stove is that you cannot add fuel “on the go” until the previous portion of sawdust has completely burned out. Again, like any iron stove, the unit heats only the room in which it is located. But this drawback can be corrected by adding a water circuit and connecting it to several radiators located in other rooms. Then you will get complete heating with sawdust for a small private house or cottage.

Main advantages

The growing popularity of sawdust stoves is due to the impressive list of positive qualities of these heating devices:

- Long burning time (up to 18 hours);

- Autonomous operation that does not require supervisory actions;

- Lightweight and compact;

- High level of heat transfer;

- Mobility that does not require the construction of a concrete or brick base;

- Strength;

- Fire safety;

- Virtually waste-free fuel combustion;

- Ease of manufacture and low cost of materials.

The main function of sawdust stoves is heating, but they can also be adapted to heat water and cook food. The only drawback of the device is its short range.

Long-burning sawdust stove

A standard long-burning sawdust stove has a fairly simple and ergonomic design. The equipment includes the following structural elements:

- Chamber for loading fuel material.

- Blower for air supply.

- A chimney pipe equipped with a damper.

- Protective cover.

A minimum set of elements ensures rapid production of the furnace structure, and the finished furnace is economical, safe and reliable.

The distinctive features of such structures include the following:

- Combustion occurs from the top to the bottom of the firebox.

- The air distributor provides additional heat. The distribution unit is connected to a telescopic pipe, so as the fuel smolders, the press lowers to the bottom of the chamber under its own weight.

- The design does not require frequent ash removal.

- The draft level inside the stove is controlled using a valve. The fuel is ignited with the housing open, after which the air distributor and cover are installed.

- The controlled supply of the air mixture ensures proper smoldering of the fuel and good gas generation.

Factory analogues of furnaces are equipped with automatic control systems for the combustion process, fans and other devices. In addition, they ensure long-term maintenance of the optimal air heating temperature without additional fuel.

Features of using the oven

The operation of sawdust stoves has significant differences from traditional wood or coal devices. Fuel is loaded into a special fuel chamber, which is completely filled up to the chimney pipe. Thin branches, paper or rags soaked in a flammable mixture are laid on top of the sawdust mass. Next, the press is installed, and the chamber is closed with a lid.

After the combustion process begins, the damper remains motionless, and the device is warmed up until the next fuel supply.

Important! In a long-burning sawdust stove, you cannot add additional fuel in the middle of the process. The device does not open until the sawdust is completely burned.

The combustion process itself begins in the center of the embedded fuel mass, then moves to the circumference of the walls. As it smolders, the compressed sawdust significantly decreases in volume, which ensures a burning duration of up to 10 hours.

The heat transfer coefficient of a sawdust stove directly depends on the diameter and volume of the fuel chamber. Long and tapered designs provide accelerated heating, while large-diameter devices provide slow heating and high heat transfer.

Making a potbelly stove

Long-burning potbelly stoves are good because they are made from any available materials - these are various barrels, old capacious cans, pieces of large-diameter pipes or simply sheet metal. We chose sheet steel as the starting material - it is a more convenient material to process. You can adapt a barrel for this, but doing work in its internal volume is not very convenient.

All sizes are presented rather as guidelines, a kind of averaged best option. You, in turn, can deviate from the dimensions of the parts to create a stove that satisfies your specific wishes.

The design of a long-burning furnace is quite clear from the drawing presented above. Here are its main components:

- Combustion chamber - wood burns in it with the formation of pyrolysis gas;

- Afterburner – combustion of pyrolysis products occurs in it;

- Doors of the combustion chamber and ash pan - they are purchased in the store, but you can make them yourself;

- Chimney - in most cases it is a pipe with a diameter of 100-150 mm.

You can deviate from the drawing in one direction or another. But remember that as the size decreases, the burning time decreases and the power of the long-burning stove decreases.

The lower the power, the smaller the heated area. Therefore, it is best to provide a small reserve.

To make a long-burning stove like a potbelly stove, we need sheet steel with a thickness of at least 3 mm - this will ensure a long service life of the heating equipment. If the steel is thin, it will begin to burn through - after a couple of seasons, holes will form in it

Therefore, special attention is paid to the thickness of the steel. The optimal thickness is 3-5 mm

For our example, we will take the classic scheme of a potbelly stove, modify it and get at our disposal an effective wood-burning stove for a home. At the initial stage, we prepare the side sheets - in our drawing they have dimensions of 450x450 mm. Next, we make the lower walls, front and rear walls - their dimensions are 200x450 mm. As a result, we should get a rectangular box. But don’t rush to weld it together - there is a lot of work ahead.

First you need to make a base - this is the bottom wall and two side ones. We weld them together, weld the grate at a height of 80 mm from the bottom. Now we need to prepare the front wall of the long-term heating oven - we weld both doors into it, and then weld it to our structure.

We prepare two metal sheets measuring 200x370 mm. We weld the first of them to the front and side walls at a height of 160 mm from the top. Next, we prepare the back wall - we weld small metal tubes into it, which should fit into the space between the two inner sheets that form the afterburning chamber - secondary air will be supplied through them. Then we weld the back wall and a second metal sheet at a height of 80 from the top (welded to the side and rear walls).

The damper is used to regulate air flow. It is this that improves the efficiency and quality of traction.

Our DIY long-burning stove is almost ready - all that remains is to figure out the top cover. We make a hole in it with a diameter of 100 mm and weld a piece of pipe for the future chimney. Now it remains to find out whether you need a hob or not - it is also welded into the top cover. At the last stage, we install the lid in place and weld it - the stove is ready, now it can be installed on a non-combustible base, attached to the chimney and started.

When starting the long-burning stove presented above, let it burn, then cover the ash pit so that the wood barely smolders and the generation of pyrolysis gas begins.

Another interesting long-burning pyrolysis furnace is shown in the following figure. It is made from a barrel or a piece of large diameter pipe and is equipped with a suitable lid. In the lower part, at a distance of 80-100 mm from the bottom, a metal disk with a hole in the middle is welded. A door is welded between the disk and the bottom, on the side wall. The resulting space forms our firebox. We weld a chimney with a diameter of 70-100 mm in the upper part.

In terms of low cost of use, such a stove is a real gift, since there is no shortage of sawdust in a private home.

The resulting long-burning furnace receives heat by burning pyrolysis gases generated when heating sawdust. The sawdust itself is poured into the main volume, and to prevent it from spilling into the firebox, it is compacted using a wooden cone. When the stove starts, a fire is lit in the firebox, the cone is removed - after a while the unit will begin to produce heat.

Tools and materials

Homemade sawdust boiler

If you need a low-power boiler, then the firebox body is most often made on the basis of an old propane cylinder. There are two reasons: the metal is thick enough to last a long time, and its design allows you to easily make a firebox cover. In addition, an old cylinder is not difficult to find or buy. To make a more powerful model, you will need sheet steel at least 5 mm thick or some old large metal vessel.

Another product that you will need to buy is a chimney outlet at an angle of 90⁰, with a diameter of 89 x 4 mm or 107 x 4 mm. A thicker pipe wall will not be a hindrance. To seal the lid, you will need a sheet metal or strip 5 mm thick; a thinner steel sheet, but not less than 3 mm, can be used for the water jacket. To make a round weight, it is better to find metal 8–10 mm thick, an air pipe 40 or 50 mm in diameter. Squeegees with ready-made pipe threads are used as fittings for coolant supply.

Before making a sawdust boiler, you need to prepare the following basic tools and equipment:

- electric welding machine and electrodes;

- angle grinder with metal wheels;

- measuring instrument;

- hammer;

- mites;

- chisel;

- drill press or electric drill.

It will be more convenient to do all the work with an assistant.

Operating principle of sawdust stoves

Such a stove belongs to long-burning units, that is, the sawdust in it will not just burn, but smolder. This releases enough thermal energy to heat one or two small rooms. But in order to create a smoldering process, it is necessary to bring wood fuel to a dense state, when there is no air left between its particles.

Excess oxygen will cause the entire mass to begin to burn intensely, releasing a huge amount of heat. The fuel will quickly run out and you will have to load it again. In this case, you need to forget about saving, and the amount of energy released will be so large that its excess will be used for other purposes. That is, the efficiency decreases sharply.

This means that in order for the sawdust to burn for a long time and release heat evenly, they must be compacted well. Based on this principle, we will build a stove, or boiler, on sawdust.

Requirements for space heating devices

To heat with sawdust, it is necessary to use boilers and long-burning stoves that meet the following conditions :

- fuel combustion from top to bottom ;

- large surface area on the outside (important for stoves);

- large area of the heat exchanger or water jacket;

- large volume of firebox ;

- possibility of air supply to the combustion area.

Due to the smaller size of sawdust, they can be fed into the stove or boiler automatically, this further increases the time of independent operation of the radiator. Very often, to do this, an auger feed is used - a rotating auger lifts or lowers sawdust from the hopper and scatters it in the combustion zone.

When there is a lot of ash, the room heating device is stopped and cooled in order to clean it of ash and reload it with fuel.

Boilers and long-burning stoves of the Stropuva type (Russian analogue of Bubafonya) are perfect for heating with sawdust. These devices implement the principle of top combustion of wood , and air enters specifically into the combustion area.

Furnaces and smoldering boilers that run on sawdust can not only be purchased, but also made with your own hands. Homemade devices also fulfill the requirements described more for devices for heating a room.

Relevance and advantages of sawdust stoves

The modern world is increasingly aware of the threat of exhaustion of conventional fuels. In developed Western countries, especially in Europe, which is dependent on gas and oil supplies from other countries, there is an active search for alternative fuels. The search for heating devices capable of converting this fuel into thermal energy also remains relevant.

As a result of the work of engineering, a number of new models of furnaces were created. I would also like to say something about the sawdust stove.

Sawdust is still a waste fuel for our country today. Wood processing enterprises have not yet established their use for heating purposes. They prefer to dispose of them in some primitive way.

Therefore, creating a sawdust stove turns out to be extremely beneficial for the population, especially when it comes to heating a country house, garage, greenhouse or workshop.

Modified Furnaces

Long-burning furnaces are considered the most promising today. Most of them are pyrolysis or gas generator furnaces. In their design they have two combustion chambers. The first, lower chamber, is intended for loading fuel. Here, solid fuel with minimal access to oxygen is brought to a state of smoldering. Long-burning sawdust stoves have a lower chamber into which sawdust briquettes are placed. During smoldering, a large volume of flammable gas is released. This gas burns without residue in the upper chamber. It is the combustion gas that transfers its heat to the air flow circulating either in the outer casing of the furnace or in the tube system. This is how a sawdust stove quickly heats the air in the room to the temperature required by the user.

A combustion intensity control system is installed in the furnace damper. Thanks to it, for the first time among models of metal stoves, it becomes possible to regulate the temperature in the stove and in the room. Long-burning sawdust stoves can operate simultaneously on other types of solid fuel: wood chips, peat briquettes, firewood

The universal nature of heating devices especially attracts the attention of the population

For the most part, Butakov and Buleryan stoves are configured for working with sawdust. Unfortunately, Buleryan stoves are not cheap and can operate exclusively on briquetted fuel with a certain level of humidity (dryness). Butakov stoves have much more affordable prices.

We make ovens ourselves

Craftsmen who want an economical way to heat a country house, garage or workshop tend to use homemade sawdust stoves. In this case, the savings are double: there are no costs for purchasing expensive furnace equipment, and the costs for purchasing fuel (loose sawdust) are minimized.

On the World Wide Web, craftsmen post original diagrams of the furnace that they create on their own. In terms of its design, it is characterized by extreme simplicity, requiring a small amount of materials for production that are at hand

It is also important to provide the equipment with a chimney for a stove or boiler

And most importantly, fuel is loaded into it in bulk, without the cost of making briquettes and drying.

This is an ordinary round single-chamber potbelly stove, with an inserted cylinder for sawdust. As a rule, such a potbelly stove is used for summer cottages and non-residential premises. Before lighting the stove, the insert cylinder is removed and a core is inserted into its middle. Then layers of sawdust are laid around the core and compacted. The cylinder is placed in the body of the potbelly stove, the core is removed, and a space remains through which the air necessary for combustion enters the sawdust. Do-it-yourself sawdust stoves are made quite often, so the technology for its operation is well developed. Ignition is carried out from below, from the ash box. A stove fully loaded with sawdust can heat a room for 12 hours, or even more.

Suitable for any room

A homemade sawdust stove, like a Slobozhanka stove, can be used for full heating of a home or industrial premises, as well as for a home smokehouse. Thus, heating devices using alternative fuels are widely used by the population in order to reduce energy costs. In this, the enterprising population is ahead of the weakly responsive large manufacturers of heating devices. The prospects of using cheap fuels are being tested in practice very energetically and inventively.

Positive qualities of the stove

- Continuous operation on one load of fuel (10-20 hours, it all depends on the model).

- Autonomy of work (no need for regular human supervision).

- Relatively small dimensions and weight.

- The possibility of using different fuels (the boiler does not stop working on sawdust, coal, firewood, wood chips, pellets), which makes the selling price of heat supply significantly lower than other options.

- Does not require a foundation.

- It does not require constant kindling; prolonged downtime does not at all affect the durability and performance of the device, which is very convenient for a summer house or home outside the city.

- Maximum complete combustion of fuel and a small ash residue.

- The sawdust stove hardly smokes.

- It is very easy to do with your own hands from a simple steel barrel or other materials that are always at hand.

- Low price.

Pros and cons of the technique

The main advantages of using burning sawdust and wood chips as an energy source for the heating system are:

Naturally, such a system also has disadvantages. Among them, it is worth noting the difficulty of storing material that is highly flammable.

This problem is partially eliminated by pressing the fuel, however, sawdust still needs to be stored in a fairly spacious room.

Another disadvantage is the need for periodic cleaning of chimneys, which is due to the large amount of soot and ash generated during operation.

In general, the positive effect that the method of heating rooms with long-term burning of sawdust gives is much greater compared to some of its disadvantages. This means that such systems have a right to exist. And, moreover, over time they can supplant traditional heating options.

How sawdust burns

The combustion process of sawdust and firewood is different. If, when the latter are densely laid, air circulates freely between the logs, then in the case of even an uncompacted mass of sawdust, almost no additional air enters the combustion zone. Without air supply, the fire burns weakly and tends to die out. Of the total volume of loaded wood waste, only the top layer of 2-4 cm is involved in the process of constant combustion.

The cost of wood chips and small wood waste is 30 times cheaper than coal, 60 times cheaper than natural gas, and 3-4 times cheaper than firewood. And these figures take into account the preliminary grinding of large wood waste. It can be argued that even less efficient (in terms of power and fire temperature) combustion of sawdust, which requires an additional volume of material to obtain an equivalent amount of thermal energy, is considered a cheap option for heating.

The operating features of a solid fuel boiler using wood chips and sawdust significantly increase the heat transfer of the burned sawdust fuel, allowing it to be called economical.