When building a country house, heating organization becomes an important point. If there is no main gas pipeline, a diesel heating boiler for a private home will help solve the problem.

Diesel boiler - an alternative to gas heating Source nehomesdeaf.org

Diesel boiler

This type of heating device operates using liquid fuel (diesel). It features a simple design and low price. Refers to an autonomous heating system.

Installation of the device will go without problems, since there is no need to ask permission from higher authorities, as is the case with gas equipment. Both stove diesel fuel with additives and the usual substance of this option are used as fuel.

The diesel boiler is equipped with a combustion chamber. It can be of two types: open and closed chamber. It also consists of an ECU that controls the spark in the device for heat transfer, fuel combustion, pumping diesel fuel and the volume of the container.

Characteristics of work

A diesel fuel-powered device begins to function by heating the coolant, which in turn transports heat through circuits to devices for distributing warm air.

Like a gas appliance, diesel equipment consists of a special nozzle. It acts as a diesel fuel atomizer in the combustion chamber, thereby providing strong combustion of the composition with good thermal energy output.

- Substances are supplied to the container from the fuel equipment through pressure to warm up the room, which are distributed throughout the entire volume of the device.

- Next, the air is heated by mixing oxygen and fuel.

- It all ignites in the internal combustion chamber.

- Here, human participation is not required; the automatic heating system itself sets the rhythm of the diesel boiler.

Fuel container

Heating with diesel fuel involves storing fuel. Therefore, the issue of capacity for this purpose is also an important point. The first question is where to store this container. And regardless of whether the tank is located in the boiler room or near the house - in any case, there must be access to a refueling machine.

As stated in “Design of autonomous heat supply sources” (SP 41–104–2000), the capacity of the tank in the boiler room should not be more than 0.8 cubic meters. But such a volume is unlikely to be enough to fully heat the building.

Gas heating of a country house

Typically, users install containers of 2000-4000 liters, but the best option would be to install the container outside the living space.

So, you will not need to run a hose into the house when refueling; in the event of a fuel spill, this will add safety, and will also increase the area of the boiler room due to the lack of large tanks.

Diesel fuel containers

Those users who use diesel fuel to heat a country house usually install vertical tanks with a volume of 800-2000 liters; they are considered the most common. If necessary, a fuel storage facility is created on the basis of such tanks - the tanks are connected to each other by a fuel piping. Thanks to this, the period of operation of the boiler room at one gas station increases.

As for the material used to make tanks used to heat a country house with diesel fuel, they can be made of plastic, metal, or fiberglass. There are also tanks for underground storage of diesel fuel. If the volumes are small - do not exceed 2000 liters, then it is not necessary to bury the container in the ground. Remember that if you store the tank outside, it needs to be insulated to protect it from freezing.

Diesel fuel storage tank components

We also note that if your home heating with diesel fuel uses a tank outside the premises, then you should provide an additional pump to pump diesel fuel into the boiler room. In the boiler room, a small tank is made, about 200 liters, which will store fuel for some time.

Type of equipment

The diesel fuel boiler has the following variety:

- Equipment with a steel heat exchanger. It is distinguished by its inexpensive price and light weight;

- The device is made of cast iron heat exchanger. It has a number of positive features, such as a long service life with reliable, high-quality work.

It is important to know! Based on their application, liquid fuel boilers are divided into single-circuit and double-circuit devices. Equipment with one circuit is intended only for heating the room. A unit consisting of two heat transfer circuits is necessary for heating and heating the liquid to a hot state.

In addition

When choosing a diesel boiler, you should additionally pay attention to the presence of heat and sound insulation with an insulating layer. It helps improve the efficiency of the unit. Sound insulation will make using the equipment more comfortable.

Many modern models are equipped with additional functions in the form of various operating modes, programming capabilities and self-diagnosis. The presence of automation increases the cost of equipment; it has a positive effect on the ease of use and service life.

Thermal output of equipment

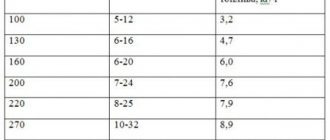

The use of a diesel unit for premises of various sizes depends on this feature. For small houses, low-power diesel equipment (11-200 kW) is used. They are represented by devices for creating all the amenities in a private household, filling it with heat and supplying the owner with hot water.

- Boilers with maximum thermal energy up to 1200 kW. Presented as a device for a replaceable burner. That is, these units are easily converted to gas equipment and vice versa to a diesel appliance as needed.

- Such boilers are of excellent quality with a long service life. Even if some part breaks, replacing it will not be difficult. Boilers are supplied as part of the body, insulation and automation. For such equipment, it would not be superfluous to purchase a gas burner.

Units with heat output up to 20,000 kW. Intended for industrial use. Used for all types of heating devices, from gas to diesel heating equipment.

Like the above-mentioned brother, they have a replaceable burner, which can change its purpose depending on the type of fuel in the device. Price and quality only confirm the versatility of this equipment.

Also, the main feature of the device is the acquisition of a different type of burner for it.

Boiler room plan, radiator locations, heating diagram

We have completed the basic calculations. Now you need to estimate the location of the boiler room, radiators, and fuel tanks on the house plan and from here calculate the need for pipes for heating distribution and the necessary fittings.

I recommend: How to properly arrange additional heating

We start from the location where the boiler is installed. It requires a room with an area of at least 6 m2 and a height of at least 2.5 m. The room must have supply and exhaust ventilation, and the walls and floors are made of fireproof materials.

A heating system plan is needed first of all to calculate the need for materials

The boiler must be placed so that there is a passage of at least a meter on the front side and on the sides. The boiler must be at least 4 m away from the fuel tank, or separated from it by a fireproof wall.

We will lay heating pipes from the boiler in two lines: supply and return.

In addition to the pipes, you will need valves, two for each radiator. Their task, if necessary, is to completely or partially shut off the coolant supply to the radiator. This is necessary to adjust heating or repair.

Various fittings will be required - elbows, tees, transitions from plastic to metal, etc.

The movement of the coolant (water or antifreeze) in the pipes will be ensured by a centrifugal circulation pump.

We reflect all this on the heating diagram, calculate what and how much is needed and go to the store.

Advantages and disadvantages

A diesel boiler for a private home has a number of both positive and negative features.

So, why is it worth purchasing this equipment:

- Independence from the heat transfer line;

- Availability of diesel fuel;

- Equipment automation;

- Simple connection of the device, independent of higher authorities;

- Easy installation of the boiler. An ordinary wall in the room is suitable for the chimney outlet;

- Affordable price.

Equipment disadvantages:

- To avoid discomfort in the house (smell and smoke from diesel fuel), additional space for the boiler room is necessary;

- Purchase of huge containers for fuel;

- Dependence on electricity;

- High price of diesel fuel.

Flaws

Now let’s look at the points that hold back buyers in their desire to purchase a diesel heating device:

- In the first place is the high price of fuel material. This makes using the equipment expensive. It is justified only by the absence of a gas pipeline near the land plot. Connecting gas communications from afar will be an even more expensive undertaking.

- Diesel fuel contains impurities that clog the nozzle and reduce pump performance. In this case, the installed cleaning filters quickly become clogged with paraffin. Without timely maintenance, the boiler will not operate at its full possible capacity with the same amount of fuel.

- The need for specially equipped fuel storage.

- The need for stable power supply. If situations with power outages are expected, it is better to acquire a stabilizer.

- Strong smell and noise require the installation of a separate isolated room or building.

- Thickening of the heating material under the influence of temperatures below +5⁰ C, which forces the pump to work in increased mode.

Cost of a diesel boiler

The price of diesel boilers depends on the region where the equipment was purchased. For example, in the Moscow region, the cost of this equipment starts from 28,000-30,000 rubles.

For this price they offer good options for boilers with a power of 16 kW and a fairly high efficiency. In this case, the equipment will be equipped with a floor-mounted installation with a heat exchanger made of steel material.

The unit will also be equipped with remote control via a remote control, overheating protection, self-diagnostics and a mode that prevents the device from freezing.

Operating rules

Since diesel boilers are a source of increased danger, their use has several requirements and restrictions. For smooth and safe operation of the installation, a number of measures must be observed.

Safety

It is important to regularly check the system for diesel leaks. The first switch-on should be carried out in the presence of a professional. If you find defects in the equipment or malfunctions in the operation of the unit, you should not resort to independent repairs.

If you find any boiler defects, you do not need to fix them yourself.

It is prohibited to allow children and persons who have not undergone detailed instructions to access the boilers.

Fuel should be stored in a safe room at some distance from the residential part of the house.

Rating of diesel boilers

Feedback from professionals and buyers about diesel boilers made it possible to highlight the line of the most popular equipment of this type.

Most purchased diesel equipment:

- Danvex B 30. Used for private households and small cottages. The device has burners with a sensor that operate using diesel fuel. Heat-resistant steel is used to create the equipment. The system is also equipped with a special ash pan, which serves as a place to collect combustion products. This device pleases with uninterrupted operation and its parts, which are replaced without significant damage to the budget;

- The Ferroli Atlas 47 device is a diesel equipment for heating large premises (more than 280 sq. meters). Features a long service life. It uses the air in the room to function. The system is floor-mounted, so installation of the device will not be difficult. The equipment is made of cast iron. And also the high power allows you to quickly heat the room, while the ease of control of the device is pleasing;

- Equipment made in Germany Buderus logano G 125 WS-25. It differs from other models in the simultaneous operation of burners and a universal control system. The device instantly heats the room. In this case, the equipment is configured manually, and then the device operates according to these settings. The unit operates silently and has electronic control, which is carried out by connecting to the device via a connector;

- Protherm Bison 50 NL. Represented by a boiler made of cast iron material. Excellent heating of large rooms with universal use. No cold is scary with him. At the same time, the work process is automatically controlled. The only negative is that the burner in this device must be purchased separately.

Calculation of heating radiators

Each room will need a heating radiator. Its size is determined at the rate of 100 W per 1 m2 of room area.

Since different types of radiators differ noticeably in power, we will select them when purchasing, but to get our bearings in advance, let’s estimate:

A “classic” cast iron radiator has a heat output of one section of approximately 150 W, that is, for a room three by five meters, you will need a radiator of - 15 m2 (we take into account not the boiler power, but the heat consumption for heating the building) 100 W: 150 W/ section = 10 sections.

For aluminum with its output of 200 W, 7.5 sections will be required. Rounding up, we get 8.

Photo of a diesel boiler

An important part of the system is the heat exchanger

Heat exchanger of a diesel boiler

The breakdown of the same burner is not as important as the current condition of the heat exchanger. Heating occurs inside this part of the boiler, and it is advisable to select the best material for it.

Heat exchangers are made of either steel or cast iron. And it would be better to use the second option, since cast iron is more resistant to condensation, as well as corrosion.

Heat exchangers can last up to 50 years, which is a very good investment. The same cannot be said about burners. These elements are not difficult to replace with the help of a household mechanic. And such repairs are cheap.

The only disadvantage of cast iron is that such material can be destroyed by local overheating. Steel, on the contrary, is destroyed due to the formation of condensate, in other words, during the “heating-cooling” processes.

Dual-circuit models

Double-circuit boiler

A double-circuit boiler is a design with two heat exchangers. It follows from this that one coolant is for heating, and the other is for hot water.

And there are also two subspecies for such options:

- Double-circuit with flow-through heater. Exactly what was described earlier.

- Double-circuit with built-in boiler. And it heats and supplies water for the entire house.

There are also differences related to traction:

- Natural. In this case, the combustion product, or rather its waste, comes out the old fashioned way, through the chimney.

- Forced. The firebox is a closed type, and exhaust gases are removed through the built-in chimney pipe.