The most important characteristic of a radiator is heat transfer (heat flow). The nominal heat flow is determined under standardized conditions: the difference between the average temperatures of the coolant in the radiator and the air in the heated room is 70 degrees C, the coolant flow through the radiator is 0.1 l/s at an atmospheric pressure of 760 mm Hg, the coolant is supplied from above down from different sides of the radiator. The heat transfer of one section of the RIFAR-B 500 radiator under normal conditions is 204 W.

The installation kit is purchased separately.

Radiators RIFAR 500: description, characteristics

The Russian buyer has already appreciated Rifar bimetallic radiators, and today this heating equipment is actively used and functions perfectly in many houses and apartments throughout Russia. The company took into account all the technical features of Russian heating systems and maximally adapted its products to their requirements.

Engineers of the Russian company RIFAR Base systematically monitor the systems used in order to expand the range, increase the range of standard sizes and new accessories. Tests are carried out for the performance of radiators at the maximum possible pressure of 30 atmospheres, which is significantly higher than the working one. This guarantees the normal operation of this equipment during operation even with high surges in heating networks. The inner surface of the radiators is covered with a special protective layer, and the outer surface is covered with powder paint, which protect the radiator from internal and external corrosion and damage.

Advantages of Rifar radiators

Rifar radiators are universally suitable for private and apartment buildings.

The obvious advantages of the Rifar b 500 radiator include versatility. It is installed in apartment buildings where centralized heating is used, and in private houses. However, in the latter case, you should not use an autonomous system. It would be much better to connect the radiator to a centralized heating system.

Temperature regulation is another plus, but for connection you will need to purchase a separate thermal head, thermal valve, radius thermostat, and thermal valve. For installation – 4 adapters, air vent valve, plug.

Considering the small internal volume of 1 section of the Rifar bimetal 500 0.136 kW radiator, low inertia is easily achieved. The small volume allows you to quickly heat the room and quickly cool it. This is appropriate if you need a higher temperature during the day and a lower temperature at night.

The polyurethane bushing is a part that connects the sections to each other, thanks to which tightness is achieved. In addition, laser welding of heating equipment contributes to tightness.

The solidity of the radiator allows installation without special adapters.

Beautiful design is also an advantage; the manufacturer allows the device to be painted in any desired color.

RIFAR Base product range

The Rifar company presents to the market three models of bimetallic radiators, different in design of the axial distance: 500, 350, 200 mm . All models vary in size, but are visually identical, making it possible to install this heating equipment in the same room with different height restrictions without disturbing the overall style.

Bimetallic Rifar models, depending on the number of sections and the level of heat transfer, have a number of configuration options. This makes it possible for the buyer to choose the right heating equipment of the required power and size for a specific room.

Products

The reliability of the intersection connection is achieved by milling the end of the collector for an O-ring gasket made of EPDM material. This technology of assembling a radiator from sections ensures the tightness of the intersection joint due to the formation of a locking connection. This connection is significantly more reliable than the conventional connection of collectors using a flat gasket, which is used in conventional bimetallic sectional radiators.

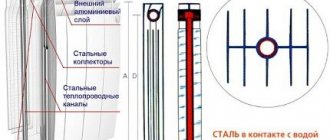

Each section of the RIFAR Base radiator consists of a steel pipe filled under high pressure with high-quality aluminum alloy, which has high strength and anti-corrosion properties. The resulting product with developed fins ensures effective heat transfer with a maximum safety margin.

In the production of radiators, RIFAR uses steel pipes of its own making from high-quality structural steel, which ensure high performance characteristics and corrosion resistance of the manufactured devices.

RIFAR Base radiators are presented in three models with center distances of 500, 350 and 200 mm.

The RIFAR Base 500 model is one of the most reliable and powerful among bimetallic radiators, which makes it a priority when choosing radiators for heating large and/or poorly insulated rooms. A wide range of models allows you to maintain a single style in rooms with different height restrictions in places where heating devices are installed. The advantage of the RIFAR Base 200 model is the closed rear surface of the section, which allows the device to be used in combination with panoramic glazing of windows.

RIFAR Base radiators are designed for use in open or closed water heating systems connected to external heating networks using dependent or independent circuits.

Radiators with the number of sections from 4 to 14 are mass-produced.

Radiators of the RIFAR Base Ventil modification are designed for bottom connection to the heating system and are used when installing modern heating systems with radiant wiring or modernizing traditional heating systems with hidden utilities.

To install radiators along rounded walls, unique radiators with a radius of curvature RIFAR Base Flex are produced.

Confirming the high design characteristics of its radiators and thanks to the quality control system operating at the enterprise, the RIFAR company establishes a warranty period for radiators of the Base model of 10 years, subject to compliance with installation and operating conditions; The service life of radiators is 25 years from the date of installation.

RIFAR Base radiators have passed mandatory certification for compliance with the requirements of GOST 31311-2005. All products are insured by SPAO INGOSSTRAKH.

Technical characteristics of one section

| Center distance, mm | Overall dimensions, mm | Nominal heat flow, W | Coolant volume, l | Weight, kg | ||

| height | width | depth | ||||

| 500 | 570 | 80 | 100 | 197 | 0,20 | 1,84 |

| 350 | 415 | 80 | 90 | 139 | 0,18 | 1,25 |

| 200 | 261 | 80 | 100 | 100 | 0,16 | 0,90 |

- Passport:

Base radiator passport (.pdf) 4.1 MB - Certificate:

General technical characteristics of RIFAR BASE 500

| Model | Distance between axles, mm | Dimensions, mm | Weight, kg | Nominal heat flow, W |

| RIFAR BASE 500*1 | 500 | 570 x 100 x 79 | 1,92 | 204 |

| RIFAR BASE 500*4 | 500 | 570 x 100 x 316 | 7,68 | 816 |

| RIFAR BASE 500*5 | 500 | 570 x 100 x 395 | 9,6 | 1020 |

| RIFAR BASE 500*6 | 500 | 570 x 100 x 474 | 11,52 | 1224 |

| RIFAR BASE 500*7 | 500 | 570 x 100 x 553 | 13,44 | 1428 |

| RIFAR BASE 500*8 | 500 | 570 x 100 x 632 | 15,36 | 1632 |

| RIFAR BASE 500*9 | 500 | 570 x 100 x 711 | 18,0 | 1836 |

| RIFAR BASE 500*10 | 500 | 570 x 100 x 790 | 19,20 | 2040 |

| RIFAR BASE 500*11 | 500 | 570 x 100 x 869 | 21,12 | 2156 |

| RIFAR BASE 500*12 | 500 | 570 x 100 x 948 | 23,04 | 2448 |

Performance characteristics:

- coolant surface temperature - up to 130 degrees

- nominal pressure (working) - 20 atmospheres

- test test - 30 atmospheres

- active use resource - 25 years

- Manufacturer's warranty - 10 years

A significant technical characteristic of RIFAR 500 is the high percentage of heat transfer, which can be determined under the following conditions:

- the temperature difference between the external environment and the coolant is 70 degrees

- atmospheric pressure - 760 mm Hg.

- coolant flow - 0.1 l/s

- The direction of movement of the coolant is from top to bottom on both sides

Dimensions of bimetallic radiators: width, depth and height of sections

The performance characteristics and dimensions of bimetallic radiators are the first thing you should pay attention to when choosing a suitable model . You need to start with the dimensions. It is recommended to install heating devices in niches under windows; in this case, effective protection is provided from cold air “penetrating” through cracks in the frames from the street. The device must be freely located in the niche and provide sufficient heat.

Characteristics of modern bimetallic radiators in terms of geometric parameters:

- The distance between vertical channels (center distance) in standard models is 200, 350 or 500 mm . It must be remembered that the center distance is the size between the inlet and outlet pipes, and not the height of the device. To determine the full height dimensions, you should “add” 40 mm to each side. With an interaxial distance of 200, the final height of the radiator will be 280 mm, with a distance between the vertical channels of 350 mm, the height of the device will be 430 mm, etc. All bimetallic devices have a standardized height range, but in practice you can find devices with center distances from 200 to 800 mm .

- The standard width of one section is 80 mm . The total width of the device is determined by multiplying the number of sections by the width of each.

- The depth of the sections ranges from 80 to 100 mm.

Sectional radiators

Each section of the bimetallic radiator consists of an internal steel part in the form of vertically arranged tubes, and aluminum plates are fixed on top, which provide an attractive appearance and serve as a source of heat transfer. The section is monolithic, the connections of individual segments are carried out by seamless welding using sealing materials. The inside of the steel core is coated with a thin layer of silver, which increases the product's resistance to corrosion and extends its service life. The aluminum body is located in such a way that it transfers heat to the external environment as much as possible, while the design is ergonomic and attractive, so the radiators look good in any interior.

In Rifar sectional radiators, the principle of energy conservation is implemented for the first time; the batteries can be equipped with heat sensors and thermostats, which reduces utility costs and allows you to achieve comfortable temperature conditions in the room.

ABOUT

The Russian one has been operating since 2002. During this time, it developed and adapted for sale modern heating radiators, which are used with great success throughout Russia and the CIS countries.

Not only Russian, but also foreign specialists and designers took part in the development of these products. The developments were aimed at creating a high-tech, economical and modern product that should not be inferior to European analogues. In addition, the Rifar batteries had to take into account the peculiarities of local climatic conditions and the requirements for functioning in Russian heating systems.

The production process of Rifar radiators

The result of the work is high-quality products with excellent characteristics, which are in great demand, growing from year to year.

Domestic radiators are reliable and fully justify the warranty period established by the manufacturer when operating in circuits connected to centralized heating. This is evidenced by numerous reviews from those who have installed such batteries in their apartment. There are practically no cases of complaints.

Capacity of the bimetallic radiator section

The main characteristics of bimetallic radiators include section capacity . This parameter directly depends on the center distance. For the most common 500 mm models, the section capacity is 0.3 liters of coolant .

In bimetallic heating radiators, the coolant circulates through steel cores - H-shaped welded structures, which consist of a lower and upper collector connected to each other by a heat conductor (vertical tube). Each manifold has two internally threaded side holes for connecting the sections using steel nipples. With this design, the coolant does not come into contact with aluminum parts, which increases the service life of the radiator. The steel cores of bimetallic devices use only round tubes, so the capacity of the sections of such devices is less than that of aluminum ones, in which the heat conductor has an oval cross-section.

Note that a round steel insert mounted inside a bimetallic radiator ensures long-term heat retention . Due to the relatively small volume of the section, thermal inertia is reduced, resulting in reduced costs for maintaining heat.

Thermal calculation - execution algorithm

The number of sections to be installed in heating radiators is calculated using a single algorithm. In our country, the following standard applies: to heat 10 square meters of area, a power of 1 kW is required. Most manufacturers in the technical parameters of their products show the maximum power that is provided by one section. Knowing this characteristic, you can calculate the required number of radiator components. To do this, use the following formula:

N = S*100/Q, where

- Q - passport indicator of the section,

- S - area of the heated room

- N is the required number of sections.

The typical block width is 80 mm. To create a sufficient level of heat in a room of 20 square meters, it is necessary to install a bimetallic radiator approximately 1 meter wide.

Technical characteristics of bimetallic

By the way, bimetal structures are also characterized by such a parameter as the section capacity. Thus, a unit with a center-to-center distance of 500 millimeters holds up to 0.3 liters of coolant.

An insert made of steel and mounted inside a bimetallic heating device ensures long-term heat storage. In addition, these embedded parts significantly reduce the volume of the section. This phenomenon has two variants of events: on the one hand, there is a decrease in thermal inertia, which, accordingly, leads to a reduction in the cost of maintaining heat, and on the other hand, narrowing of the channels can lead to rapid clogging of the heating network.

The structure of a bimetallic radiator.

A bimetallic heating radiator holds slightly less coolant in its sections than an aluminum one. But at the same time, a typical device from one of the manufacturers, with a width of 80 mm and a height of 350 mm, carries 1.6 liters of coolant. HE is able to heat an area of up to 14 square meters.

By the way, such bimetallic devices are 1.5-2 times heavier than aluminum ones.

Helpful tips when choosing

To choose the right Rifar radiator based on its operational parameters and appearance, you need to know important nuances:

- Bimetallic radiators are very similar in appearance to aluminum radiators, as they have the same shape and color. However, they differ greatly in price. The cost of aluminum batteries is much lower than bimetallic ones, since they are inferior in quality, service life and have limitations in operation.

- It is imperative to take into account the area and volume of the heated rooms - this is necessary in order to choose the most effective size and parameters of the batteries, and not overpay extra money.

Temperature and pressure requirements

When creating a heating system, parameters such as the temperature of the working medium and the pressure in the system are important.

The presence of a stainless steel insert does not have any effect on the appearance and dimensions of the heating device. But their use allows them to withstand significant pressure (up to forty atm.). It should be noted that testing of the heating network is carried out at a pressure of one and a half to two times higher than standard parameters.

Heating temperature chart

By the way, the maximum permissible temperature of the thermal environment can reach 100-110 degrees Celsius. This value is close to the parameters of the heat carrier entering the building from the centralized network. But it loses some of the energy when passing the point where the working environment circulating in the home network is heated.

Important! Before purchasing new heating devices, it is advisable to contact the office of the management company and request data on the operating and test parameters of pressure and temperature. This will help you make the right choice.

Sectional bimetallic heating radiators

Difference between Rifar Base and Monolith radiators

The most important difference between both lines of radiators is their design features. Rifar Base is a collapsible structure consisting of a different number of sections, the number of which depends on the calculated heating power. A monolith is a solid product with a predetermined heat capacity. The first can withstand pressure of hot water or antifreeze up to 30 atmospheres, the second - up to 150.

Thus, Rifar Base radiators can be used in apartments or offices, Monolith - in rooms of any purpose and thermal insulation. They are reliable, durable, easy to install, have a modern design and fully satisfy all consumer needs.

- Sectional models make it possible to complete the radiator with the required number of sections.

- For non-standard layouts, there are sectional models with a radius of curvature.

- If it is necessary to make a connection in a non-standard way, it is possible to select models with lower and upper types of coolant supply.

- All consumables supplied by Rifar are adapted for Russian engineering structures.

- Monolithic samples are ideal for installation in apartment buildings with frequent pressure drops in the heating system.

- Modern monolithic Rifar designs are suitable for all types of coolants.

- The reliability of the design and ease of installation have earned recognition among installation specialists, and the long service life allows you to forget about replacing the heating system for a long time.

The manufacturer values quality and works with reliable suppliers of its products, who can give a detailed description of each model and advise on any issues related to heat supply in the apartment.

Criterias of choice

1. The main criterion for choosing bimetallic radiators is the material they are made of:

the “filling” should be made exclusively of stainless steel or copper, and the body should be made of aluminum.

The fact is that if you do not go into these details when purchasing a device, there is a risk of purchasing a so-called semi-bimetallic battery, which is significantly inferior to the “original” in reliability and durability.

In such devices, vertical pipes can be made of stainless steel, and horizontal pipes of aluminum, or vice versa.

As a result, the radiator will show all the disadvantages inherent in purely aluminum models, such as: low resistance to temperature changes, fear of water hammer and pressure surges in the system, susceptibility to corrosion. In addition, the combination of two metals in the manufacture of the core causes another problem: due to the difference in temperature expansion of the materials in the connecting nodes, there is a high probability of leaks. It is impossible to distinguish semi-bimetallic radiators from real bimetallic ones by appearance.

Thanks to this similarity, they attract buyers with a lower price. By the way, the weight of the product will help you not to be deceived with your choice: a battery with an entirely steel core will be much heavier than one in which it is partially made of aluminum.

2. You should also pay attention to the pressure,

during which the device underwent pressure testing - it should be sufficient for the radiator to easily withstand peak loads in the heating system.

So, for installation in a centralized heating network, you can safely use batteries pressurized at a pressure of 35 atm. The maximum coolant temperature

for bimetallic radiators ranges from 90 to 135⁰С, depending on the model, while in reality the coolant in systems does not always heat up even to the standard 70⁰С.

Bimetallic radiators have a laconic design, have streamlined shapes and smooth lines of protrusions, they do not have parts that can cause injury. Color options - from dazzling white and ivory to noble gray and deep graphite

3. In quality products, the wall thickness of steel or copper pipes

should be at least 3–3.5 mm, and

the thickness of the shell fins

should be at least 1 mm, otherwise the radiator will have low mechanical strength and reduced heat transfer.

If, when you try to bend the edge with your fingers, it easily gives in to force, or even tends to crack, it means that a low-quality alloy was used for the casing, and the device can be damaged by any impact. To increase heat transfer, models of some brands are equipped with additional fins. 4. Experts recommend choosing sections with a width and depth of fins of at least 80 mm

- these are the optimal parameters for the greatest heat transfer effect.

Installing gaskets in the radiator

5. When purchasing a prefabricated sectional model, try to evaluate the quality of the mounting nipples and gaskets.

The first should be made of high-strength steel and have an impeccable thread (without scoring, distortions, etc.), and the second, usually made of rubber or silicone, should have medium hardness and good elasticity.

6. Important installation characteristics of the radiator - center distance

between the inlet and outlet openings (it can be 200, 300, 350, 500 and 800 mm), as well as

the connection diagrams to the heating network provided for by the design of the device.

We especially note that despite the simplicity of installation, which, by strictly following the instructions, the consumer can handle independently,

some manufacturers only allow professional installation of their equipment, stipulating this condition in the warranty documents.

Diagonal connection of a radiator

If calculations show that a room requires a radiator with ten or more sections (for example, it is located in an old house, or on the ground floor, or is simply large in size), then it is recommended to connect such a device according to a special diagram. Otherwise, due to the large length of the channel through which the coolant flows, the equipment will operate with reduced heat transfer. The problem is solved by diagonally connecting the upper inlet pipe to the lower outlet pipe, which makes it possible to achieve the calculated heating efficiency.

7. Pay attention to what coolants the radiator can operate on.

Some models allow the use of any liquid with varying degrees of chemical aggressiveness; others, in addition to water and antifreeze, also require the use of steam and oil, while others only need specially prepared water with a certain pH level.