Warm floors are an opportunity to provide maximum comfort in the home. Thanks to this system, you can easily control the temperature in the room and do not depend on central heating. But for this, installation must be carried out in full compliance with technology, and all materials must be correctly selected. One of the most important points is the installation of a protective top layer over the heating pipes. Having studied how and with what to fill a warm water floor, you can get to work.

How to fill a warm water floor

The essence of dry screed technology for heated floors

As the name implies, “dry” means a light system, without the addition of water and plasticizer.

A heated water floor is a fairly massive structure, and if you use a wet screed, the level of the floor itself increases. It is worth saying that not every room has the required ceiling height to compensate for the lost centimeters. In addition, a wet screed increases the load on the floors of the building. The weight of 1 m² of a heated floor with a concrete screed is 200-300 kg. It is clear that the weight of the structure in a room of 15-17 m² will be serious and not the weight of the house, much less apartments, are designed for such a load. Therefore, many users prefer dry screed.

Dry screed for heated floors can be made in two variations:

- wooden;

- polystyrene.

Based on what materials are used, the name and installation method are determined. In this case, strips and boards made of OSB, gypsum fiber board and chipboard act as the main support. But you can use any other tiled material. For a polystyrene system, the support layer is made of polystyrene boards. Insulating layers are laid directly on this base, in which there are grooves for installing water circuit pipes. The final coating here will be not a monolithic concrete slab, but a stacked structure made from gypsum fiber board sheets.

Mistakes you shouldn't make

When building with your own hands, a number of mistakes are made, which ultimately lead to problems:

- Savings on specialists to install water circuits (not everyone will be able to do this at the same level).

- Work before installation of the system is a mandatory process.

- Poor quality installation of damper tape.

- The rough screed is poured unevenly.

- Sloppy installation of the system, poor-quality fastening.

Many small mistakes occur when you fail to properly fill a heated floor. A plan for performing preparatory and installation work and studying professional tips will help you avoid mistakes. An estimate of waste is drawn up, which must be followed and not skimp on materials.

Concrete pouring serves as protection against damage to the water circuit. In order for it to serve for a long time, you need to follow all the rules. Precise laying of the heating circuit and high-quality screed determine the level of reliability and operation of the system.

How to properly lay a “semi-dry” concrete screed

In order for the concrete layer to be perfectly smooth, you need to position the beacons correctly. The distance between the beacons is left such that the one and a half meter rule can be used. That is, a distance of no more than 140 cm should be maintained between the beacons.

Types of beacons:

- Mortar beacons made of narrow ridges of cement-sand mortar (gypsum cannot be used). Not the most effective method, since the ridges must dry out, and this takes time. In addition, a rule can accidentally “knock down” such pointers.

- Lighthouses made of metal pipes. Pipes or other rigid profiles are strengthened at the required height. A day after laying the concrete, they are removed and the recesses are filled with mortar. Pipes are used several times for this purpose. The only condition is that they must be perfectly even. Both round and rectangular profiles are used.

Galvanized guides for plaster. The stronger the beacons, the better. The optimal size is 1-1.4 cm. After they have performed their function, they can be left in place or removed after the solution has set. Such beacons are disposable. If you have the skills, you can set them as evenly as possible. Strengthen with mortar, adjusting it to the level using a piece of tile or a brick fragment. The distance between the beacons is 40-50 cm. Sometimes they are installed on special supports that can be adjusted.

Dry screed for heated floors

A reduced concentration of water, introduced in limited quantities into the semi-dry mass, ensures accelerated hardening and a high degree of strength. The main ingredients of the composition for semi-dry base formation:

- Portland cement grade M400.

- Pre-screened coarse sand.

- Fiber fiber introduced in a volume of up to 800 grams per cubic meter of composition.

There are several types of screeds used when installing heated floors

Semi-dry screed for heated floors has many advantages:

- hardens much faster compared to concrete;

- has increased strength;

- acquires operational characteristics with minimal shrinkage;

- does not become covered with a network of cracks;

- resistant to sudden temperature fluctuations.

The disadvantages of a semi-dry composition include:

- Reduced plasticity, requiring significant effort when kneading.

- The need for reliable protection of the hardened mass from moisture absorption.

- The formation of cavities in the semi-dry mixture after laying, associated with uneven compaction.

A feature of Knauf brand dry mixtures used for water heating is that there is no need to use water to prepare the working composition. Enlarged, the “sandwich” consists of the following layers:

- protective polyethylene film that protects the composition from moisture;

- dry composition based on fine expanded clay up to 4 mm in size;

- sheet material forming the finishing coating.

The entire screed is made from dry materials, and it is quite possible to lay a heated floor on a dry screed. No special surface preparation is required for the dry expanded clay mixture. This makes it possible to quickly form a reliable base for protecting heating lines and installing a finishing coating. Advantages of the dry mixture:

- accelerated pace of foundation formation;

- installation of sheet covering after filling with expanded clay chips;

- absence of dirt at the work site;

- simplicity of backfilling, ease of independent implementation of activities;

- improved sound insulation;

- reliable heat retention;

- laying on various types of bases;

- compensation for surface differences;

- low dry weight;

- easy access to heated floor elements.

We invite you to familiarize yourself with the Electric boiler for heated floors in the bathhouse

Disadvantages of dry mix:

- long drying when wet;

- dust formation due to violation of installation technology;

- increased hygroscopicity.

For water and electric heated floors, a semi-dry method of forming a protective layer is used.

Semi-dry screed method. A small amount of water is used for production

It involves the use of the following components:

- Cement grade M300 and higher – 1 part.

- Coarse sand, cleared of impurities - 3 parts.

- Fiber, representing fiber, introduced in an amount of 400–600 g per 1 m³ of solution.

- Add water until the mixture reaches a slightly damp consistency.

The semi-dry composition has pros and cons. The positive aspects of using a semi-dry mixture are:

- accelerated hardening;

- increased strength characteristics;

- slight shrinkage;

- no cracks;

- resistance to temperature changes.

The disadvantages associated with the features of the laying technology include:

- the rigidity of the composition, which is problematic to stir;

- the need to protect the semi-dry mixture from moisture absorption;

- the presence of voids caused by uneven compaction.

Stages of work on semi-dry screed

Rice. 7. The process of laying semi-dry screed

Using the already mentioned example of semi-dry XPS screed, we will show the sequence and stages of the technological process

Installation of damping tape

It is laid along the entire perimeter of the walls and around columns. It is fixed using its own adhesive layer, or, if there is no such layer, with double-sided tape, foam adhesive or using a stapler (if the wall is plastered). If a waterproofing material (film, foil flooring, etc.) is laid on the subfloor or insulation, then the tape must be folded inside the room, overlapping with the horizontal surface.

Reinforcement

Reinforcing steel mesh is laid on a layer of insulation with overlapping sheets, which are connected with wire. The mesh should be located in the lower third of the screed, but not at the very bottom, but on top of the 1st layer. This height provides, on the one hand, a protective layer of concrete under the metal, and on the other, the ability to lay heated floor pipes using rows of cells as markings.

To do this, after filling the 1st layer and distributing the mixture, the mesh is lifted upward and only then the surface is compacted. When compacting, the mesh does not sink completely into the screed. It is clearly visible when laying pipes or cables.

Preparation of the solution

Since the setting time of the mixture is limited, it is necessary to prepare the solution exactly for laying one layer (bottom or top). Fiber fiber is added to water and then mixed. The consistency of the resulting mass should be similar in plasticity to snow when forming a conditional “snowball”, but water should not be released.

Laying the mixture

From the mortar pump, the screed mixture is supplied to the site in discrete portions into a special absorber receiver standing on a tripod. The mass that spills onto the floor from the damper is distributed around the room using shovels and rakes.

The main team forms the second (top) layer of semi-dry screed immediately after laying the pipes and preparing the second portion of the solution.

Seal

On small objects, compaction of the 1st layer is carried out by trampling. In large rooms, compaction can be done when filling with milling machines. Compaction of the top layer is performed directly during leveling with the rule.

Laying heated floors

When a team of concrete workers leaves the premises, specialists enter it to lay pipes or electric cables for the heated floor. Since this operation does not require a strictly flat plane, it can be started immediately after compaction, without waiting for it to dry - the end of the setting time of the solution is sufficient.

Formation of beacons

This is done after filling the 2nd layer of screed. Unlike wet technology, semi-dry technology does not involve the installation of metal beacons. Areas of compacted screed serve as beacons. Point areas are made using a laser axle builder. Then the master, combining these sites with a rule, creates linear beacons. These guide elements must be formed along the walls and along the centers of the largest spans. The distance between parallel beacons should not exceed the length of the rule.

Rice. 4. Work on semi-dry screed over EPS in a small room

Leveling and compacting the surface

It is carried out by the rule according to the formed beacons. During the operation, a single plane is ensured, all irregularities are cut off, and the entire leveling layer is given the required density.

Grout

Mechanical processing with rotary trowels is carried out during the initial setting of the screed, immediately after its leveling and compaction. The metal disk of the machine cuts off the slightest deviations from flatness and further compacts the concrete layer.

Strength gain

To extend the drying time, it is necessary to slow down the evaporation of moisture. To do this, the surface of the screed is covered with film and left for a period of 1 week to a month (depending on) the temperature in the room, the work plan and the planned type of finishing coating.

Tools and materials

In order for the work to start and proceed without distractions, you should consider preparing in advance not only the tools, but also the appropriate materials. As for the latter, the proportions of the semi-dry floor screed must be fully observed. The main quality of the finished base for the flooring will depend on the proportions.

Among the tools are a construction level or a water level. Laser levels are no less popular. But its cost puts some off. There is not always a desire to spend large amounts of money on a single task. A tape measure and various containers for mixing the solution and stirring using a drill with an appropriate attachment will also be useful. In addition, spatulas and trowels will be useful in the work.

Depending on the installation process of the semi-dry screed, any additional tools will depend. If the beacons are positioned and attached to the base using self-tapping screws with wire, then you do not need a screwdriver or wire cutters.

The semi-dry screed has proportions that are best looked at in the instructions for the purchased material. The cement mortar should be homogeneous and without unnecessary lumps. To avoid possible difficulties with mixing, there are enough dry mixes in the store chain, to which you only need to add a certain amount of water. True, here the proportions of liquid in relation to the mixture must be appropriate.

When making your own mortar for a semi-dry screed, buy the following in the store:

- 50 kg of cement. Its brand must be at least M-400.

- For this amount of cement you will need 200 kg of sand, with a fraction of no more than 0.8 mm.

- 30-40 liters of water. There is no need to rush about water. It is better to pour slightly less than the required amount, and only then add as much as needed. The main thing is that the solution does not turn out liquid.

- Plasticizer. It can be found in finished form in stores. Its amount will be insignificant, about 200 grams. Some experts advise adding regular liquid soap instead of an expensive additive. The elasticity of the screed will remain at a decent level.

- The thermal insulation layer is made of polystyrene foam boards.

- A special metal profile, called “beacon”, is used as beacons. Beacons, by the way, can be made in other ways, of which there are a huge number.

Ratio of concrete mixture components for floor screed

The construction mixture for forming a monolithic floor includes three main components: lime cement, coarse river or quarry purified sand, and clean water. To increase the workability of the mixture, various synthetic additives can be added to the solution, for example, to increase viscosity or plasticity, but a properly mixed solution and a consistent ratio of bulk and liquid materials give excellent results, and the solution perfectly levels and adheres to the prepared floor surface without purchasing additives that will cost a pretty penny.

Building materials markets sell ready-packaged dry concrete mixture for floor screed. Their advantage is that it is possible to more accurately dose the proportions of concrete for floor screed and pour the working surface faster. There is only one drawback of such dry mixtures: they cost 1.5-2 times more than a mixture prepared independently. Therefore, in order to save money (and in individual construction this goal is constantly pursued), when given the task of pouring a floor on the ground at a minimum cost of building materials, the solution is prepared with one’s own resources and resources. In this case, it is necessary to observe the following proportions of concrete for pouring the floor inside a residential or non-residential building (in weight or volumetric proportions):

- One part of cement TsEM I 32.5H PC (M 400) to three and a half parts of river or washed quarry sand, and 6/10 parts of industrial water;

- One part of Portland cement CEM I 42.5H PC (M 500) to four parts of river or quarry sand, and 7/10 parts of industrial water.

The ratio of grades M 400 and M 500 to other components of the composition When mixing concrete, the developer has to independently measure the volumes (weight) of bulk or liquid substances and mix them, so the result (ready-made solution) will be much cheaper than a factory-packaged mixture. For M 400 and M 500, the ratio of components given in the list above will correspond to the concrete grade M 150. A similar grade of concrete is used for the floor in a garage or in other unheated rooms with high humidity.

The solution that will be poured and used outdoors differs in composition and proportions from the solution for indoor use. Screed in open space is constantly exposed to changes in temperature, humidity, weathering, and solar radiation, so its mechanical properties should a priori be better.

High-strength concrete screed for self-leveling floors

| Portland cement, brand | Concrete mortar, brand | Portland cement|sand|crushed stone (weight, kg) | Portland cement|sand|crushed stone (volume, l) | Volume of solution from 10 liters of Portland cement |

| 400 | 100 | 1,0|4,0;6,0|7,0 | 10|41|61 | 78,0 |

| 500 | 1,0|5,0;8,0|8,1 | 10|53|71 | 90,0 | |

| 400 | 150 | 1,0|3,0;5,0|5,7 | 10|32|50 | 64,0 |

| 500 | 1,0|4,0;5,0|6,6 | 10|40|58 | 73,0 | |

| 400 | 200 | 1,0|2,0;8,0|4,8 | 10|25|42 | 54,0 |

| 500 | 1,0|3,0;5,0|5,6 | 10|32|49 | 62,0 | |

| 400 | 250 | 1,0|2,0;1,0|3,9 | 10|19|34 | 43,0 |

| 500 | 1,0|2,0;6,0|4,5 | 10|24|39 | 50,0 | |

| 400 | 300 | 1,0|1,0;9,0|3,7 | 10|17|32 | 41,0 |

| 500 | 1,0|2,0;4,0|4,3 | 10|22|37 | 47,0 | |

| 400 | 400 | 1,0|1,0;2,0|2,7 | 10|11|24 | 31,0 |

| 500 | 1,0|1,0;6,0|3,2 | 10|14|28 | 36,0 |

An example of a concrete structure that will be constantly exposed to all kinds of atmospheric influences on the street is a concrete blind area around the circumference of a house or garage. In this case, the grade of concrete for the garage foundation should be M 150 and consist of the proportions of the components given below.

Blind area around the house

The surface of the finished screed must be ironed with pure cement:

- One part of Portland cement brand CEM I 32.5H PC (M 400) to four parts of river or purified quarry sand, five and a half parts of crushed stone (marble, gravel or granite chips) and 9/10 parts of clean industrial water;

- One part of Portland cement CEM I 42.5H PC (M 500) to 4.1 parts of river or purified quarry sand, five and a half parts of crushed stone (marble, gravel or granite chips) and 7/10 parts of clean industrial water.

For screeds or floors on the ground that do not experience large mechanical and shock loads, marble, gravel or granite chips acting as crushed stone can be replaced with construction rubble: brick waste, furnace or blast furnace slag, waste ceramic building blocks, etc.

Why is only the M 150 brand recommended? It complies with SNiP 2.03.13-88, which states that for pouring concrete screeds, building materials with a compressive strength of ≥ 15 MPa or 150 kgf/cm2 should be used, and these indicators are only suitable for grade M 150.

Recommendations for designing floors SNiP 2.03.13-88

Composition of purchased solutions for installing screeds on warm water floors.

The composition of dry mortars for screeding is practically no different from homemade ones. Only we must understand that the proportions of cement and other components in it are accurate, and in the end you will receive a screed of the brand and quality declared by the manufacturer. The most interesting thing is that the granulated slag fraction, the quality of the sand, will be just as high as what you buy separately. Plasticizers are also selected by the manufacturer according to the established database and tests performed! umnyestroiteli.ru The thick-layer self-leveling screed “Glims” has proven itself well in this area. The thickness of which can reach 4 centimeters. This characteristic is irreplaceable when installing a warm water floor* and the base does not lose its primary characteristics than other screeds. It can be used even in rooms with high humidity. If the water floor line breaks, this screed compound will be able to hold water for a long period of time! And everyone should know this about the composition of screeds for warm water floors!

Screeds are divided into three types:

- Fine grinding fraction;

- Average grinding fraction;

- Large grinding fraction.

Screeds with a solution composition of medium and coarse grinding are suitable for monotilizing a water floor. Screeds with finely ground fractions are not used for pouring warm water floors! This is due to the fact that the layer of finely ground stitch solution cannot be made more than 1 centimeter. And in our case we need at least 2 cm.

https://youtube.com/watch?v=fY3jneItmIs

How to choose a floor screed?

Dry floor screed is selected according to the following parameters:

- Compressive and bending strength - the more, the better.

- Adhesion - the higher, the less chance of the screed detaching from the base.

- Curing time after pouring in hours.

- Consumption based on kilograms per square meter of filling with a layer of 1 mm.

- The composition of the screed is gypsum or cement, as well as the presence of additives.

- Cement brand and grain size in millimeters.

- Pot life is the time it takes for the solution to set in an open container.

You also need to look at the purpose of the composition (the proportions of the solution depend on it) and the type of work (internal or external). The color is usually grey.

How to make a floor screed correctly

Requirements for screeds

First of all, we note that the coating must be smooth and horizontal. A difference of 5 mm is allowed. Otherwise, the top finish may crack, sagging may appear, and heat will not be distributed evenly. Let's talk in more detail about other requirements.

Which material to choose

For warm water systems in residential buildings, the recommended grade of concrete is M150 or self-leveling compounds for creating heated floors. For a mortar made from a cement-sand mixture, you will need cement grade M500 or M400 and sand with a fraction of no more than 3 mm. If it is necessary to make the layer thinner than the recommended values, plasticizers, fiberglass or PVA glue are added to the mortar or concrete composition.

The recommended particle size in dry backfill is 5 mm. As for the filler, foamed vermiculite, expanded polystyrene or perlite is considered a more preferable option. They are lighter than expanded clay.

Instagram @shakirov1758

Instagram @housemaster63

Optimal screed thickness for a warm water floor

This indicator is important for any coating. Not only the quality of heating, but also the strength of the system as a whole depends on it. The thickness is chosen depending on several factors.

- Ceiling height.

- Pipe diameter.

- Type of laying mixture.

- Strength of floors.

The minimum height for residential premises is 3-3.5 cm. The maximum is 5-10 cm. Layers that are too high, especially the top one, prevent the room from warming up quickly and eat up the distance to the ceiling. In some apartments this will be very noticeable. If you make the coating too thin, the structure will become less durable and will retain less heat. On average, the best option is considered to be a finishing layer thickness of 7-8 cm, with 4-5 cm in the space above the pipes. For rough filling, 3-3.5 cm is enough.

The thickness of the dry coating should be such that there is no empty space between the backfill and the gypsum board sheets, and the heating circuits are located at a depth of at least 2 cm from the surface.

The video contains more detailed recommendations on choosing the maximum and minimum thickness.

Screed composition

Screed for heated floors can have a different composition; usually a mixture of sand and cement is used. Often crushed stone or expanded clay is added to the solution to save cement, as well as a plasticizer to improve properties. In this case, a concrete screed is obtained. The cement content in the mixture may vary, depending on the chosen floor covering.

If laminate, parquet, tiles or other heavy materials will be laid on the screed, then take 5 parts sand and 0.7 parts water to 1 part cement. When planning to lay light flooring, for example, linoleum, carpet, the ratio of cement, sand and water will be 1:4:0.7. When adding crushed stone to the mixture, adhere to the following proportion: 1 part cement, 3 parts sand and 5 parts crushed stone. The amount of water can reach half the mass of cement. Regardless of the composition of the mixture, it is recommended to add a plasticizer to the heated floor screed. It can be PVA glue. For 1 bag of cement you will need 1 kilogram of glue.

Screeding can be done easier and faster by using ready-made mixtures. How to use them is indicated in the instructions supplied with them.

conclusions

From a comparison of heating methods and types of screeds, the following conclusions can be drawn:

- It is permissible to heat cottages with electric heating cables; they fully provide the generally accepted thermal power of 100 W per m2 when laid in a snake pattern. To heat 100 m2 of area, 10 kW of electricity per hour will be consumed. With an average tariff of 3 rubles. per kW, daily expenses will be 720 rubles, monthly 21,600 rubles.

- However, these calculations do not take into account an important aspect. For water heating, double-circuit boilers are used, which simultaneously provide hot water supply or simply heat water in the warm season. When using electricity, you will need to install a boiler to heat water, which will lead to additional electricity consumption (minimum 400 kW per month for an average family).

If we compare wet with semi-dry screed in a cottage, the latter has the following undeniable advantages:

- It is immediately ready for laying any type of covering, while beacons need to be removed from a wet slab and the surface should be rubbed with cement laitance.

- The semi-dry method of installing screed in an apartment or house is fully automated and takes less time.

- It is cleaner due to the absence of wet processes; all dirty work is carried out outside.

- There is no cost item for lifting materials to the floor (more than 10 tons per 100 m2) and concrete mixers.

- A semi-dry screed for water-heated floors costs from 600 rubles in Moscow. per m2, and its price falls with increasing volumes. Also, its overall cost is lower than wet.

From the above it is easy to draw the final conclusion - water heating and semi-dry screed are the best option for heating individual houses.

How to fill with a “wet” screed

If a lot of water is added to the solution, you get a “wet” screed. The solution will be plastic.

The component ratios are as follows:

- When laying heated floors in a dry living space, an M200 solution using M500 cement is suitable. You will need 1 part cement, 3 parts sand and 1-1.4 parts water.

- When laying heated floors in a damp room (in a bathroom), you need an M200 solution based on M400 cement. Take 1 part cement, 2.5 parts sand and 1-1.4 parts water.

- In reality, the volume of liquid depends on the moisture level of the sand and the amount of dust in it. In this regard, water is added gradually, mixed and plasticity is controlled. The result should be a mixture similar to thick sour cream.

- The solution is leveled between the pipes and compacted, removing air bubbles.

The process of leveling the mixture is facilitated by a long rule and pre-placed beacons. The recesses are filled with the mixture and leveled again.

The screed is made from the screenings in the same way. But everything is done more carefully, more labor will be required. The advantage of the “wet” method is the plasticity of the solution, which is easy to level with a rule.

Mixtures for self-leveling floors

Let's look at what you can use to fill the heating elements and the floor underneath them.

Cement-sand mortar. Due to the presence of sand, the mixture has good plasticity and is easy to work with. The most suitable brand is M200. For heavy loads, stronger solutions are used: M250, M300. If the room is damp, then M400 cement is suitable. To strengthen the cement mixture, fiber can be added to the composition.

Proportions of mortar for screed (by weight):

- M200 - water/cement/sand - 0.48/1/2.8;

- M300 - water/cement/sand - 0.4/1/2.4.

Concrete from ASG. Cement mortar on a sand-gravel mixture is classic concrete. When installing heated floors, it can be used to fill the rough screed. The result is a strong and inexpensive base.

The consumption of materials for concrete grade M300 will be: 1/5.6 - for one kg of M400 cement take 5.6 kg of ASG (group 4 with a gravel content of 60-65%).

Concrete from screenings. Screening is fine-grained crushed stone that has been passed through a sieve (particle size up to 10 mm). It is added to the mixture instead of sand. Irregularities characteristic of screening particles help strengthen the screed. However, this also makes placing and grouting the concrete more difficult.

Foam concrete. A distinctive feature of foam concrete is the presence of a foaming agent in its composition. This makes the material cellular (it has a large number of closed pores). It has increased sound and heat insulation properties, weighs less than conventional concrete and demonstrates greater strength. If necessary, it can be easily drilled.

Expanded clay concrete. Expanded clay concrete is similar to a regular cement mixture, but instead of heavy crushed stone, expanded clay granules are added to it. Thanks to this, the material is warmer and lighter. But expanded clay concrete is fragile, and it cannot be used for pouring surfaces that will be actively used. Those. Expanded clay concrete is used for screeding under heated floors.

More details about the construction of a subfloor made of mortar with expanded clay are shown in the video tutorial.

Self-leveling mixtures (self-levelers). Self-leveling allows you to get a flat surface with less labor. Can be used both for pouring the base under heated floors and for the top screed on which the flooring will lie. This material costs a little more than others. You can use, for example, Ceresit CN 176, cement leveler Unis Horizon.

Gypsum solution. Not suitable for pouring floors!

The best manufacturers of plasticizers

Construction stores offer a fairly wide selection of various additives, so deciding which brand is best to choose is not so easy. To simplify this task, we offer you the highest quality formulations that are most popular today.

Sanpol (Ukraine)

The Ukrainian manufacturer produces liquid plasticizers that improve the thermophysical properties of the base for heated floors. In addition, the composition improves the resistance of the slab to mechanical damage.

The manufacturer's recommended proportion for mixing the solution is 0.2 liters of additive per 400 kg of cement. Such a liquid plasticizer costs about 140 rubles per liter.

ArmMix (Russia)

Another high-quality liquid plasticizer is offered by. The main advantage of this solution is that it increases the water resistance of the concrete coating by 4 steps, and this is an important advantage when installing water-heated floors. It is also worth noting the high frost resistance of the solution, thanks to which work can be carried out at sub-zero temperatures.

To mix, you need to mix 1 liter of ArmMix per 100 kg of cement. The cost of the additive is 100 rubles per 1 liter.

Warm floor HLV-75 (Ukraine)

Dry and liquid plasticizing compositions are suitable for self-installation of the base for warm, water and electric floors. For 100 kg of cement, about 0.5 kg of substance is consumed.

Unlike analogues, this composition does not slow down, but, on the contrary, accelerates the hardening process of concrete by 3 times. The plasticizer costs 620 rubles for 2 kg of dry mixture.

Rehau (Germany)

Despite the fact that the supplement from a renowned manufacturer costs 3,000 rubles per 10 kg, the products of this company are deservedly considered the best. Rehau plasticizers are available in both liquid and dry forms. In addition to its main characteristics, this composition is highly environmentally friendly, so when heated, it will not harm human health in any way.

The additive can significantly increase the thermal conductivity of the rough base for heating elements.

Superplasticizer S-3 (Russia)

The premium liquid additive is produced by analogy with the German plasticizer brand “Mighty 100”. The domestic composition is in no way inferior to the foreign “source” and is distinguished by the same high strength characteristics.

However, it is worth paying attention that this plasticizing component contains phenol, formaldehyde and naphthalene derivatives. Therefore, before using it, be sure to check with the seller at what temperatures the selected component will be safe for your health

The proportions of S-3 are almost the same as those of analogues - no more than 1.5-2 liters of plasticizer are used per 100 kg of cement. The cost of the additive is about 1,000 rubles per 10 liters.

If you wish, you can make the additive yourself, but it is worth considering that in this case the positive properties of the additive will be minimal.

Choice of plasticizer

Plasticizing additives are used together with other components of the solution: cement, water and various aggregates. When mixing this composition, a homogeneous concrete mixture is obtained.

The use of one or another plasticizer for the screed depends on the type of its device. In this regard, the following are highlighted:

- traditional screed, or as it is also called “wet”. This is a mixed mixture containing cement, water and sand in a component ratio of 1:3. Some craftsmen are inclined to believe that the traditional composition of concrete is not entirely suitable for installing a floor heating system. It cannot withstand temperature changes and collapses. This is why there are special plasticizing additives;

- semi-dry type of screed, has received good reviews and is most suitable for installing heated floors. When dry, it does not form air bubbles. The dry mixture is diluted to a liquid state with a small amount of liquid.

In any of these types of screed, it is advisable to use plasticizers to improve its technical parameters.

Since the solution is poured directly onto the pipes, the plasticizer should make it more plastic and thick, thus protecting the pipes from mechanical damage.

Types of plasticizer

In order for a warm water floor to be more effective, the density of the concrete used to fill the tubes must be high.

To do this, a plasticizer is added to it, which makes the solution elastic and gives it new properties:

- improved waterproofing;

- resistance to mechanical damage;

- increased plasticity;

- increase in service life;

- ability to withstand temperature changes.

This result is possible thanks to the substances that make up the additives:

- sulfuric acid,

- formaldehyde,

- purified phenol waste,

- defoamers,

- caustic soda and water.

By adding plastic fibers to its composition, additional reinforcement of the plasticizer occurs.

Each type of additive, in addition to increasing the strength of the concrete screed, also performs additional functions.

For example, one type helps to increase ductility, another is used to accelerate hardening, and the third is used to work at sub-zero temperatures.

Plasticizers for heated floors are produced in the form of:

- liquid solution;

- dry powder;

- antifreeze compounds;

- reinforcing polyamide fibers.

Liquid compositions are stirred in containers and poured into concrete mortar in a proportion of 1.5 liters per hundred kilograms of dry cement. The dry plasticizer is diluted in water in a ratio of 1:2 and then used in the same order as the liquid one.

The cost of plasticizing additives is affected by their consumption and technical parameters. When pouring 1 sq. m of heated floor, use from 0.4 to 1 liter of modifier. The use of cheaper additives, which have a higher consumption, will increase the total cost of installing a heated floor.

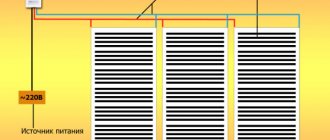

Pipe laying

A mounting grid is usually used to secure the pipes in place. This mesh is made of metal or plastic, has 100 mm cells and is laid out on top of the heat-insulating layer. Pipes are laid on this grid in accordance with the finished diagram, which later need to be secured with wire or special plastic clamps. The use of mesh increases the strength of the screed due to reinforcement, but at the same time increases the amount of labor costs.

Another option for attaching pipes involves the use of special polystyrene mats designed specifically for heated floors. Such material can simultaneously perform the function of thermal insulation and fixative. The outer side of the mats has projections into which pipes can be laid and fixed. Polystyrene mats are quite expensive, but they are also very easy to work with.

In any case, no matter what technology for laying heated floors under the screed is chosen, there are still a number of rules that must be followed when working. So, despite their flexibility, it is better not to bend the pipes too much. It is also not a good idea to step on pipes or drop heavy objects on them - if a pipe is damaged in at least one small area, it will have to be completely replaced.

Pipes for heated floors cannot be cut in advance. First you need to connect it to the supply manifold, then bring it to the return, and only then can it be cut off. It is not worth stretching pipes in order to save money, nor is it worth making one circuit out of several separate pipes - such operations will negatively affect the reliability of the assembled structure.

If a “snake” pattern is used for installation, then it is advisable to start laying pipes from an external wall or window - this will compensate for the decrease in temperature due to heat losses.

Spiral laying does not impose such a requirement, so the pipes can be placed in any convenient way. Date: September 25, 2022