Comfortable living is ensured not only by the availability of utilities and the design of the premises. It is important to protect the house from heat loss, which is important during the cold season. Doors and windows are powerful sources of cold air entering the home. There are several ways to keep your room warm.

Replace doors with energy-saving designs. This is not cheap and involves related operations to design slopes, install platbands, etc. In many cases, it is possible to solve this problem in affordable ways without significant costs. One of the traditional insulation materials is felt door seal, which has both disadvantages and advantages.

Advantages of felt seals

Today, manufacturers offer a new generation of materials that are easy to install and affordable. The share of felt products is decreasing, but it is too early to abandon their use, since they have a number of special qualities:

- Wear resistance. Natural fibers can withstand significant physical stress without deteriorating.

- Life time. Unlike rubber and foam seals, felt does not contain volatile substances, the content of which steadily decreases during operation. This leads to destruction of the material and requires replacement. Felt seals do not lose their properties for many years.

- Soundproofing. The material absorbs vibrations. Both outside noise and the sounds of the door in contact with the frame are dampened.

- Environmental friendliness. Only natural raw materials are used in production. There is no release of substances harmful to health.

- Fire safety. The density of wool fibers and their quality are such that combustion is impossible under normal conditions.

Ready-made felt seal for doors

Production

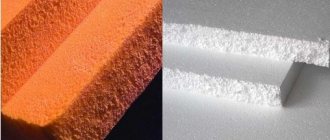

Felt is made using sheep wool. The production technology includes the process of felting raw materials, due to which the fibers are twisted together, forming a dense fabric. Felt fabric is produced both in rolls and slabs. In addition, felt can have different colors and technical characteristics, which can be selected according to certain criteria.

Photo: Felt with a rubberized layer.

Modern felt manufacturing technologies allow the use of synthetic fibers, which have characteristics similar to woolen material. Synthetic felt is distinguished by its strength and durability, while the insulation parameters remain the same.

Disadvantages of felt seals

Previously, felt was used everywhere as insulation and sealant. It was considered the best material for these purposes. Why is this method of protecting your home from the cold inferior? Despite the fact that the user qualities of felt are not in doubt, there are also disadvantages:

- Price. Production refers to traditional technologies with a centuries-old history. Felt is made from natural wool. During hydrothermal treatment, fibers are pressed into sheet or roll material. The cost of raw materials and labor create a price that is higher than synthetic fiber of similar size.

- Difficult to install. It is difficult to find a felt seal that satisfies most requirements on sale. All operations require an individual approach and qualifications. The range of felt materials is limited. You need to independently cut the strips of the required width and choose the method of fixation.

Rolled felt

- Attractive to moths and mice. Unlike microorganisms and mold, which do not live in felt, rodents and some types of insects like the material. Moths perceive felt as a food product, and mice insulate their minks with it.

Attention! When purchasing, you should carefully read the information about the product on the packaging or in accompanying documents. Natural felt is 100% wool. There are materials on sale with a similar name, but they cannot be considered as such. In cases where the percentage of natural fiber content is indicated in the composition, and even more so when it is absent there.

Laying the covering

Today there are two main methods of laying carpets - rolled and pieced. Installation in this case is carried out either on a base or on a cork substrate. Thus, carpet flooring will last several times longer. In most cases, installation is done using special nails or adhesives that fix the material to the base using a “gripper” (a strip of wood).

The coating is secured with double-sided tape, as a result of which further replacement does not present any difficulties. Along the perimeter, the carpet for the floor is fixed with a plinth.

Advice. Once every six months, it is advisable to treat the carpet with special products designed to clean the coating.

Which floor carpet you choose depends only on your requirements and operating conditions. As mentioned above, it is advisable to select a suitable option for each room before preparing the walls for wallpaper. There are no special requirements for the base, which is why carpet has become so widespread.

- 5

- 4

- 3

- 2

- 1

Types of felt seals

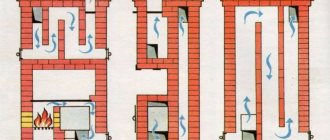

The production of the material is localized in regions that traditionally produce wool products. Classic technology is rooted in the distant past and has secrets. Not all developed countries know how to make felt. In Russia, production secrets have not been lost, and the products enjoy well-deserved respect. Despite the fact that the manufacturing process is traditional, the quality of the products is regulated by state standards. The consumer can choose the desired felt from the following types:

- GOST 288-72. Fine-wool technical felt. Inclusion of synthetic substances is allowed. Its main application is in technology. Gaskets and seals made of this material are used in mechanical engineering;

- GOST 6308-71. Semi-coarse technical felt. Excellent wear resistance. Used in mechanical engineering and in small quantities in construction;

- GOST 6418-81. Coarse wool technical felt. Used in many areas of economic activity. From mechanical engineering to construction;

- GOST 16221-79. This type of felt is called yurt. The name corresponds to the purpose of the material. Available in the form of rectangular cavities. There is no single standard. Allowed length is from 2 to 6 m, and width is from 1.4 to 2 m;

- Felt. It is used for technical purposes and in the production of household items and clothing. Expensive type of felt. Produced in thicknesses from 2 to 10 mm. Felt padding is made from old items such as hats or anti-shock layers removed from packaging and is used to transport fragile, valuable instruments and devices.

Automotive soundproofing felt

Any felt is used as a door seal. The minimum required thickness should be taken into account. The dynamic compression coefficient of felt is limited. For this reason, the difference in gap width should not exceed 2-3 mm. Otherwise, the door leaf rebate will not be airtight, the seal will be partial and the protection will not be effective.

Advice! If the width of the gap is uneven, you can pre-fill places with a large gap with pieces of felt of the required thickness. It is easy to cut lengthwise. After preliminary leveling, the finishing felt strip is installed. Another option involves installing a felt seal with the end side relative to the plane of the door. In this case, it is effective to form a roller.

Energy-saving finishing of balconies and loggias

Insulation of plastic windows and doors consists of gluing a strip of rubber or foam rubber seal, which prevents cold air from entering the apartment.

What is a self-adhesive seal?

Installation of sealing tape on a plastic base

This is a finishing option in the form of a tape, which is installed around the perimeter of the frame and door leaf or window opening. It can also be used for energy-saving cladding of metal or wood structures.

Insulation of the loggia can also be done by installing self-adhesive tape at the joints and cracks in the decorative finish. The seal is available in the form of a self-adhesive tape or as a rubber mortise tape finishing energy-saving material.

Adhesive-based seals come in the form of a roll of foam rubber and can have a different profile and an adhesive base, which is protected by a paper lining.

You can use a special roller for high-quality installation of the sealing tape

Installation recommendations:

To ensure high-quality thermal insulation, it is necessary to correctly select the width of the profile, which should completely cover the gap, but not interfere with the tight closing of the doors; The mortise seal is also made from foam rubber, but based on durable and rigid plastic

This ensures fastening strength, but it is important that the canvas and the box have a special groove for installing the seal; All modern models of plastic and metal structures are equipped with a special groove for mounting a seal, which can be replaced or installed with your own hands.

When do you need to insulate?

Wood has low thermal conductivity, but the disadvantage of the material is its response to changes in humidity and temperature. The door block dries out, swells, warps and even cracks. There are three main reasons signaling the urgent need to insulate a wooden door in a country house:

- Formation of gaps between the frame and the ends of the opening walls . Initially, during installation work, all gaps are foamed. Foam is a good insulator, but over time it loses its properties. Destruction occurs faster on the street side if platbands are not installed. Foam deteriorates from exposure to the sun. Another cause of cracks is the misalignment of the bowl.

- Formation of gaps between the frame and the sash . The most common defect in a wooden entrance door occurs due to poor wood, poor-quality installation and long-term use. Often the owner himself becomes the culprit when he trims the swollen sash so that it closes better. After drying, the product decreases in size and a gap forms.

- Wear of insulation. Each thermal insulation material is selected taking into account operational requirements. If they were not initially followed, the incorrectly selected insulation loses its effectiveness. For example, mineral wool quickly cakes, and due to dampness it decreases in volume. Any old wooden door, as well as a thin leaf, needs to be insulated.

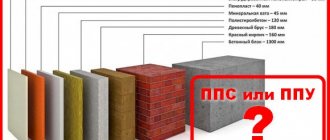

Which insulation is better to choose?

To make an insulated wooden door with your own hands, you will need thermal insulation material, as well as material for the top decorative finish. The gaps are sealed with a sealant. When the question arises of how to insulate a wooden door in a private house, pay attention to the following materials:

- polystyrene foam as internal insulation for wooden entrance doors. The slabs can be sheathed on the side of the room.

- Foam rubber is considered the most common insulation material, which is covered with artificial leather on top. Porous material allows you to create a volume effect. Foam rubber loses over time and crumbles into crumbs.

- Mineral wool does not burn, has good thermal insulation properties, but quickly cakes. When exposed to dampness, it accumulates moisture. Under the weight it slides off a vertical surface.

- Foamed polyethylene - isolon has a structure similar to foam rubber. The material has better thermal insulation properties and a longer service life. Isolon does not tolerate long-term exposure to direct sunlight.

- Polyurethane foam is applied by spraying, firmly adheres to the wood, and penetrates into all cracks. The disadvantage is the impossibility of performing work without special equipment.

- Expanded polystyrene resembles polystyrene foam, but has improved characteristics. The material has self-extinguishing properties when exposed to open fire.

When choosing insulation for the doors of a wooden house, it is important to consider the thickness of the material. Thick layers will weigh down the sash and create an obstacle to normal closing. Thin is useless. You need to find a middle ground between these two parameters.

Types of seals for door frames

In addition to thermal insulation, you will need a sealant to seal the cracks around the perimeter of the canvas. It is a tape that differs in thickness and material:

- The foam strip is fixed using an adhesive base. The seal wears out quickly during the season.

- The silicone strip is resistant to dampness and elastic. Over time, it begins to stick and tear into pieces.

- The rubber seal for wooden doors will last for many years. The tape is resistant to wear, dampness, and mechanical stress.

- Thermoplastic is the best in terms of wear resistance, but is difficult to install.

- The polyurethane strip is glued due to the adhesive base. The characteristics are not inferior to a rubber seal.

Thermal insulation cannot be done without decorative finishing. Usually the insulation is covered with artificial leather. Fixed with furniture nails with a wide decorative head. On the inside, the canvas is sheathed with laminated MDF panels. Genuine leather trim looks beautiful, but the material is very expensive.

Criteria for choosing building materials

If you carry out insulation yourself, it is preferable to purchase a self-adhesive version. Craftsmen advise having foam rubber or felt available. Using them is not difficult. A sash equipped with this gasket can be closed without any effort. The sealing material – rubber is characterized by high wear resistance.

Soft rectangular, tubular rubber seals are also in demand. Their service life is 5-7 years. They protect the room from odors and extraneous noise. The thermoplastic-based profile is resistant to temperature changes.

Craftsmen focus on the choice of filler for insulating the sash and the space around the frame. This process must be conscious, as it is difficult to change them

When choosing, you need to pay attention to the thermal conductivity coefficient. It determines how the material will handle heat retention. For wooden products, thin fillers are a good option. The use of soft insulation greatly simplifies the work. Its advantage is that it covers the surface with a reserve and shrinks as much as necessary

It is important to measure the thickness and dimensions of individual structural elements with increased accuracy

How to insulate a wooden door?

The insulation of a wooden door begins with preparatory work :

- weakened hinges are secured with new elongated screws;

- if thick, heavy insulation is used, install an additional loop;

- eliminate box distortions and fabric defects;

- check the condition of the seal around the perimeter of the door frame at the junction with the walls;

- replace broken fittings: lock, handles, peephole, latch.

After all defects have been eliminated, installation of insulation on wooden entrance doors begins.

a vapor barrier necessary when insulating wooden doors? When arranging the installation seams of the door block - it is necessary. The gap between the box and the wall is sealed with foam. To prevent the thermal insulation from deteriorating, the seam is covered from the street with PSUL tape. From the room side, the foam is destroyed by vapors. For protection, the seam is sealed with vapor barrier tape. A vapor barrier may be required for the product if it is installed in a damp room and mineral wool serves as thermal insulation.

Tool

It is impossible to get the job done without the right set of tools. To create insulated wooden entrance doors you will need:

- Tape measure and pencil;

- Stationery knife;

- Hacksaw;

- Hammer;

- Screwdriver;

- A flat rod or metal meter;

- Mounting tool or nail puller;

- Construction stapler.

If necessary, this set can be expanded, but for most operations it will be quite sufficient. It should be noted that a hacksaw can easily be replaced with an electric jigsaw. This tool allows you to get the job done with the same quality, but much faster. And if there is no screwdriver in the house, then you can take a simple drill. The main thing is that it has a reverse, which will allow you to unscrew any self-tapping screw or screw if necessary.

In addition to the tools, it is necessary to prepare the covering material. For most door panels, it will be enough to use leatherette, which has an attractive appearance. This material has good characteristics and wear resistance, so the canvas will not need to be repaired for a long time.

And if you like to do everything with your own hands, then we recommend you instructions on how to make a wooden entrance door.

When the door is outside the frame, all existing elements must be removed from it. The hinges, handles, peephole and lock are carefully unscrewed and put aside. If the door is not made only of wood, then it is necessary to remove the sheet of inner lining to gain access to the interior of the door leaf.

Installation of double doors

A good way to insulate your home is to install a double entry door. Due to the formation of an air space separating the room from the street, heat is retained. The disadvantage of this design is the reduction in space.

A threshold is set for the indoor unit. Insulation is additionally laid on the slopes between the doors. There are designs where two doors are hinged on one deep frame.

When insulating entrance doors, you must remember that moisture affects the canvas from the street side. Treatment with impregnation, painting with paint or varnish will help protect against dampness as much as possible. Drying oil creates good waterproofing.

Felt comes in rolls and sheets.

In one of the earlier articles, we introduced you to how to insulate a bathroom. Today we will talk about a very old, but, unfortunately, insulation made from natural sheep wool, which has lost its popularity - felt. This material is ideal for insulating doors, window and door frames, and the crowns of log houses. But if you want to completely isolate your house with it, you will encounter many problems, solutions for which are extremely difficult to find. “There are no hopeless situations,” said the notorious Baron Munchausen, but despite this, there is still no developed clear method for insulating walls with felt.

We solve the problem comprehensively

Proper layout of the premises is also important.

Many people, having spent good money on complete insulation of their bathhouse, suddenly discover that for some reason the desired insulation does not occur. Yes, it’s warmer, but where is the promised bliss, and why are there drafts across the floor?

The answer usually lies on the surface and whistles with pleasure - the door, the ordinary door to the bathhouse becomes the cause of this final inconvenience.

The solution to this problem can be very simple, or it can be a little more complicated, namely:

- Insulation of the door leaf itself;

- Insulation and sealing of joints where the door meets the jamb;

- Installation of thermal curtain;

- Installation of a second door.

Today we will go through all the points and be sure to solve two basic questions: how to insulate the door to the bathhouse and how to insulate the door to the bathhouse.

Let's get busy with the canvas

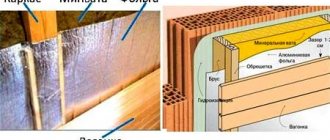

Photo of foamed polyethylene foil.

Any carpenter will tell you that it is not advisable to make the door structure heavier; moreover, this is fraught with distortions, and considering where the door is located (meaning in a bathhouse), then making it heavier is a completely unnecessary undertaking.

Therefore, in this section we solve the problems:

- Which insulation to choose so that it does not absorb moisture, can withstand low temperatures and is not very heavy;

- How to layer this insulation onto the door leaf.

We will not transmit the entire flow of information that the Internet is replete with about insulating fabric; we present a very simple method and its rationale:

As door leaf insulation, we offer you polyethylene foam with a foil layer. The material itself is quite resistant to cold weather, has the invaluable advantage of being wind and moisture impermeable, in addition, the foil layer will return heat flows back to the bathhouse. And the weight of the material will be slightly more than the total mass of the paint and varnish impregnation layers. The hinges will not experience a large load and the canvas will not move.

Regular door covering with this material.

From canvas to jamb

After insulating the door leaf, let's work on the jamb

The simplest thing is to trim the inner perimeter of the jamb with the door tightly closed (and note, already insulated)

In the old days, the most popular insulation for the front door was felt, but now you can use any other method. Basic requirements for the material: it must be soft enough, and at the same time fit tightly to the door leaf, thus preventing the access of air, and also not lose its qualities when in contact with water, not cake or tear.

The technology has not changed:

- The insulation is cut into thin narrow strips at least 5 cm wide;

- A 20x20 mm strip is marked and sawed off in such a way as to completely and tightly cover the internal perimeter of the jamb (taking into account the thickness of the insulation itself);

- The insulation is folded in half and installed with a fold to the door leaf as close to it as possible, pressed and fixed with a strip to the jamb;

- Thus, the entire perimeter of the doorway is covered.

Full guarantee

If you already want to get a full guarantee of protection from the cold, then you can finish insulating the door to the bathhouse by using a curtain made of dense material. You don't need instructions to cut and make the curtain. We chose the material, cut it, cut it, stitched the edges, thought out the fastening system and hung it. In this case, the fastening system can be under the rings on the pipe, simply overlapping the valve and stitching the valve under the pipe, or you can even make a cloth for clothespins (clothespin fastenings). There is also a simple way to attach between two planks. Therefore, we do not limit you in fastening and choice of material.

A few words about the second door

That's the point.

The second door is a method that has been tested and proven to be positive. Place your bet. To implement this, it is necessary to either install a jamb in which it will be technically possible to install two doors, while the adjustment of the two panels must be carried out before installation in the opening, which sometimes requires financial costs, time, and the warm season.

You can install an additional jamb and canvas to the existing ones, but you need to think about fixing the new structure to the existing one. A positive quality of the second door is the layer of air, which plays a buffer role and prevents the cold from quietly passing into the dressing room.

What kind of felt insulation for doors is there?

What a pity that this excellent, natural material with excellent characteristics is almost forgotten. Today, felt is used to insulate doors and window openings. In ordinary houses, this is where it ends, but if we are talking about wooden structures or a bathhouse from a log house (timber), then it is also used as inter-crown insulation and for caulking cracks. And probably no one even knows that felt insulation comes in different forms:

- technical fine-haired – manufactured in accordance with GOST No. 288-72;

- technical semi-coarse wool – manufactured in accordance with GOST No. 6308-71;

- technical coarse-haired – manufactured in accordance with GOST No. 6418-81;

- yurt - manufactured in accordance with GOST No. 16221-79;

- fert - made from the finest fibers of six rabbits and goats.

Felt insulation has a fairly low thermal conductivity, the coefficient is 0.03-0.07 W/m*K and depends on the density of the material. The latter varies in the range from 10 to 400 kg/m. cube

The material is produced both in panels and in rolls. The dimensions of the panels are 2000 x 2000 mm, rolls are up to 1800 mm wide and up to 200 m long. It is made from both natural and synthetic raw materials. Synthetics are already a trend of modernity; you shouldn’t take them seriously, but natural materials deserve attention.

This is a crown seal made of 15% felt.

How to insulate a bathhouse door with felt

Most often, felt is used to insulate door and window frames, as well as for external door insulation. The fact that the material is environmentally friendly and that it breathes allows it to be used even in baths at high temperatures and humidity. Let's look at insulating a bathhouse door with felt from two angles. The first will be the insulation of the box.

This technique is applicable for both entrance doors and the entrance to the steam room. In both cases, insulation for felt doors is laid around the perimeter of the frame at the junction with the movable part. To do this you need:

- roll the felt into a small roll;

- on the side where the edge is visible, the roll is laid around the perimeter of the box;

- fastened with nails or a stapler.

No additional protection is needed. If you need to insulate the front door with felt, then you need to take the panel and secure it to the outside. Then, using furniture nails with beautiful caps, fasten the material you like (usually a leather substitute) over the insulation. The main thing is that the finish is resistant to atmospheric aggression.

A two-pipe heating scheme for a two-story house can be either vertical or horizontal. At the same time, there may also be several methods for laying out horizontal contours for each floor. Some of them: hitching, dead-end, collector.

Heating a country house is somewhat different from the main home. You can read about the best way to heat your dacha in winter in this article.

Option #3. We seal the doorway using rollers

It may happen that it will not be possible to remove the door leaf from the hinges. In such cases, for insulation (if, for example, cold weather has already set in), you can use the same roller. To significantly increase the thermal insulation properties of the structure, nail it directly to the door frame.

This must be done according to the same scheme as discussed above.

It is only important that the location of the roller be calculated as accurately as possible, so that the door leaf adjoins it when closed

Attention! It is strictly not recommended to nail this roller to the threshold, otherwise the latter will soon become unusable. The best option is to attach it to the lower end of the canvas

As a conclusion

So we looked at the main ways to insulate a wooden entrance door. Of course, not all of the described methods give a 100% effect, and each of them also has its own disadvantages. However, if you have not previously purchased insulated doors, then this is the only way to spend the cold winter in warmth and comfort. Now you know how everything needs to be done, so get to work. Good luck!

Where else is felt insulation used?

Felt-based linoleum - insulation and sound insulation.

In addition to the purposes described above, this material can be used for thermal insulation:

The methods, of course, are rarely used, but are still discussed on forums. Although felt for floor insulation is very often used as a backing for linoleum. When considering the hypothetical possibility of laying insulation under finishing materials, for example, insulating walls with foam plastic, you need to immediately eliminate possible problems:

- moisture – although the material does not absorb moisture well, it still happens;

- moth - you need to saturate the material with some means, but then you can forget about environmental friendliness;

- rodents will not miss the chance to steal soft bedding into their hole.

As you can see, using felt for wall insulation is quite problematic, and the price is high. It is sold by weight and costs from 200 rubles per kilo, depending on density. Such insulation will cost almost gold. Felt sealing is suitable for local thermal insulation, but even the technology has not been developed for insulating large areas. What to do in a situation where you don’t even have anyone to turn to for practical advice? You won’t find any practitioners on this issue on the forums during the day - only theorists and those are skeptical.

Insulating a house with felt is a harsh reality

Despite all the positive aspects of this material, comprehensive insulation of a house with felt is not possible for a number of reasons:

- it absorbs moisture;

- there are moths in it;

- mice feel great in it;

- it's too expensive;

- There is no methodology for such work.

You can talk about how to insulate a door with felt from two sides:

- insulation of the box (joints);

- comprehensive insulation on the outside.

This material is also used for caulking inter-crown cracks. In addition, felt insulation for the walls of wooden houses is used as a gasket between logs (beams) during the installation of the structure. It can be used both in pure form and as part of other materials (jute). It is better to abandon attempts to completely insulate the walls of any buildings from any materials. Yes, there is strong felt for yurts that has high insulating qualities, but it still won’t work. It is not designed to be enclosed by the body of the walls, because you are not going to insulate without finishing. Felt floor insulation is used quite widely, but only as a backing for linoleum. It is not used for laminate.

Metal

Metal ones are much easier to insulate. All work is carried out in the space between the doors. If there was standard insulation there, it should be removed. Select the required material and place it in special openings for insulation. The process is quite simple and does not require much effort.

How to insulate a metal door using polystyrene foam?

The question of how and with what to insulate Chinese doors is asked by almost everyone who has installed it. Basically, for the production of iron sheets, several sheets of metal are used, fastened together. To provide additional insulation, the cavity inside needs to be filled.

The size of the foam must correspond to the size of the openings

Algorithm for insulation:

- Removing door parameters. Before insulating an iron door, you need to cut out a fiberboard sheet to cover the foam.

- Make holes for the door peephole and handle, having previously marked their location and dimensions on the canvas.

- Trying on a fiberboard frame (marks made must match).

- Cutting foam sheets with a sharp knife. The finished material should be attached to the inside of the door. This must be done by gluing it with silicone applied to the entire surface.

- Covering the insulation with a fiberboard sheet, which should subsequently be secured to the door using self-tapping screws.

To avoid frostbite and cold accumulation in the stiffener, you need to fill the void of this tube with polyurethane foam, having previously drilled a hole in it.