In Russia, in addition to two well-known disasters, four more await us all: spring with river floods, summer with heat and fires, autumn with a bountiful harvest and winter with snow and frost. The frost is no joke. He cleans out houses and apartments. To maintain comfort and coziness in a living space, you need to heat, heat and heat. But there is another way: insulate the building on all sides and heat it.

By studying the heat loss of various buildings using a thermal imager, heating scientists compiled a map of heat losses from various structural elements of the house (shown in the figure below). It shows that the main heat loss occurs through the floor, walls, windows and roof.

There is enough work on how to insulate walls, windows and floors on the StroyGuru website. For example, the last article “Insulating walls outside with mineral wool.” But no attention was paid at all to insulating the roof from the inside with mineral wool or other types of thermal insulation materials. We will correct the omission and consider in the material below all the nuances of roof thermal insulation with glass wool and wool based on basalt fibers.

Mineral wool for roofing - which one to choose

Mineral wool is traditionally considered the best insulation for pitched roofs, creating a thermal insulation layer above the attic. Experts recommend this material for roof insulation. Let's figure out why this happens, because polystyrene foam is cheaper. Also, mineral wool varies greatly in its properties - which one is better suited for the roof truss system?

What is the difference between mineral wool - expert opinions

If you listen to the opinions of experts, it is not difficult to notice that mineral wool is best combined with wooden structures. It allows steam to pass through itself well, and the wood in contact with it does not become damp.

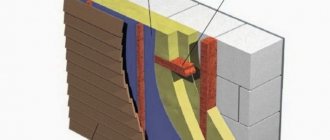

But this property requires the arrangement of steam regulation of the insulation layer - a vapor barrier on the room side, and ventilation on the street side, free movement of outside air through the vent. gap.

Mineral wool is resistant to fire and does not ignite, so it may not be separated from living rooms by fireproof shells. But at the same time, it is not environmentally friendly, so the vapor barrier and interior decoration also perform a protective function.

Various quality and characteristics

Mineral wool can vary greatly in physical characteristics, from heavy, durable (non-compressible) slabs to rolled soft material.

In this case, the specific gravity can be from 30 kg/m3 to 200 kg/m3. Fibers can be made from various minerals. Manufacturers often use cheap waste from large-scale industries in the form of slag. But basalt or quartz sand can be used...

- The fibers themselves can be long, large, form pliable mats, rolled materials, then the material is usually given the name glass wool.

- If the fiber is thin, brittle, dusty, and the slabs themselves are hard and fragile, then the insulation is more often called “rock wool”.

But what to choose for the roof?

Thermal conductivity and layer thickness

If you read the advertisement, you can learn from it about the excellent properties of mineral wool; sometimes an extremely low thermal conductivity coefficient is indicated, for example, 0.027 W/m*K, almost like air. In reality, due to moisture, the working value is much higher. For heavy dense samples, at least 0.05 W/m*K should be taken for calculations. For soft ones for the initial period of operation - 0.045 W/m*K, but later after shrinkage this coefficient increases.

In accordance with this, it is not difficult to calculate the thickness of the layer, guided by regulatory data on the resistance of structures to heat transfer. For a roof located somewhere in central Russia, where this value is about 4.5 m2 x °C/W, a mineral wool thickness of at least 20 cm will be required.

Mineral wool options

Meeting application technologies, and therefore consumer needs, manufacturers create mineral wool samples with special properties and new characteristics.

- Foil plates. Many people do not recommend using foil in the roof or shielding a house with metal. The existing natural electromagnetic background should not be disturbed. There is no need to interfere with the operation of radio devices.

- Plates with vapor barrier film. In principle, it is not bad to have an additional vapor barrier on each slab, but this will not negate the use of a solid membrane over the entire area of the insulating layer.

- Layers of different densities. The top layer of increased density (more than 80 kg/m3) is not ventilated under normal conditions in the ventilated façade system, while the main layer is lighter and heat-insulating. This option is the most preferable in many cases.

- Coating with superdiffusion film An option in which mineral wool is immediately supplied with vapor-permeable protection against blowing has its place, but is usually expensive...

Service life is the most important characteristic

Less dense slabs from unknown manufacturers quickly shrink, the layer shrinks, and the thermal insulation properties decrease down to 50-80% of the calculated ones. Over what period will this happen...

Well-known manufacturers indicate the expected service life of their mineral wool - up to 50 years. These figures refer to dense (elastic) samples that retain their shape and restore it when compressed. But the stated period has not been proven in practice and is not officially confirmed by government research.

Leaky and cheap samples, as a rule, are not standardized at all. Their lifespan will largely depend on the position in the structure and on the initial loads that determine the compressive forces.

Which mineral wool should not be used for roofing

The roof insulation technology involves placing mineral wool between the rafters. It is extremely important that there are no gaps or voids left - the insulation boards should be inserted sideways, with some pressure from the sides.

Also the most important indicator is the total mass, i.e. the specific gravity cannot be too large, the additional material should not create a significant load on the roof structures. But exact figures can only be determined in each specific case.

Accordingly, rigid and heavy samples are not suitable for roofing. As a rule, over 100 kg/m3 are not applicable in these cases.

What can be applied

But too soft, caking mineral wool samples are also not the best choice. Heat loss through the roof is usually the greatest. Therefore, the standards require that insulation of the greatest thickness be installed in this place, compared to other structures. Failure of insulation over such a large and important area will have a very significant impact on the overall energy losses of the house.

Therefore, experts recommend using special samples of mineral roofing designed for pitched roofs of private houses, and only from well-known manufacturers. The recommended density starts from 60 kg/m3.

Which manufacturers have been on the market for a long time?

Mineral fibers are created in large high-tech industries. The products are then supplied to companies that directly manufacture slabs from them for insulation of private houses. There, the fibers are glued together with a binder and formaldehyde (usually), compacted to the required values, etc.

Well-known brands under which mineral wool for roofs is sold:

- Knauf. The most famous brand in Russia and Europe selling mineral wool insulation. The technology for manufacturing fiberglass material has been given its own name, ECOSE Technology. The manufacturer claims that the products meet European quality standards.

- Ursa. Well-known samples have earned trust as elastic mats that restore their shape. They claim fiberglass of the highest quality; in some insulation options, the fibers are bonded together without the use of formaldehyde...

- Izover. Also a well-known brand in Russia, Ukraine, and the CIS, which has been distributing its products for quite a long time and very successfully, it has earned respect. It is also announced that mineral fibers will be created using a special technology, this time the secret meaning is contained in the abbreviation - TEL.

Preparatory work

The preparatory work for roof insulation has a peculiarity - it basically comes down to laying a one-sided vapor barrier membrane of type A or AM (builders call it “waterproofing”). The need for this type of work (vapor barrier) is shown in the material “Installing a vapor barrier with your own hands.”

Before laying the windproof membrane, it is necessary to ensure the integrity of the wooden roof structures (if they begin to rot, replace them), and then treat them with antiseptics and fire retardants.

In the process of fixing the membrane, several rules should be followed:

- There must be a ventilation gap between the membrane and the roofing finish. According to SNiP no less than 6 cm, in practice 4-5 cm;

- should be laid on the rafters, and not on the sheathing under the roof;

- air movement must be free over the entire surface of the roof slope. If ventilation is conditionally limited, i.e. exists for each gap between the rafters or slats (boards) separately, then in winter ice will certainly appear in certain places. This can be easily verified by those who have carried out thermal insulation work on their own;

- between the rafters the membrane should sag by about 1 cm. If pulled tightly, it can break under the influence of temperature fluctuations, like electrical wires during severe frost;

- secured with a stapler. The staples must be taped;

- laid with an overlap (15-20 cm);

- the seams are sealed with construction tape;

- If a finished roof is being insulated, the membrane can be installed using two technologies:

- with a smooth sheet at the bottom of the rafters, after which insulation is carried out in stages along a two-layer sheathing, where the first row is packed horizontally, the second, along the first, vertically;

- along the rafters, but going inside the rafter system. In this case, the insulation is laid between the rafters, using the technology of insulation from the inside without a finished roof.

Laying a windproof membrane when insulating a finished roof.

About the use of insulation

The general category of insulation, obtained by dividing the raw material into fibers, is usually called mineral wool.

The widespread use of inorganic insulators is associated with high heat and sound insulation properties:

- construction of engineering communications;

- to protect industrial equipment;

- in the field of construction.

Insulation of the roof of a building

The main advantages of mineral wool:

- There are completely no organic elements in the structure of the product, which allows the service life to be unlimited;

- does not burn - class NG, NPB 244-97;

- the material belongs to breathable insulation - the fibrous structure allows excess moisture vapor to pass through, air circulation is maintained;

- does not decompose or mold;

- does not attract insects and rodents;

- tolerates temperature fluctuations and exposure to aggressive environments.

Mineral wool is used in interior decoration in accordance with building codes (SNiP) and codes of practice. The vapor permeability of the material is especially important for insulation and sound insulation of wooden and stone structures. High performance properties of the best types of mineral wool and reasonable price are the main factors for consumer choice.

Ecowool

Relatively recently, a new insulation material has appeared on the construction market - ecowool. For its production, waste newspapers are used, which are pre-shredded and treated with fire retardants and antiseptics. At the same time, dangerous lead, which, according to many, is contained in newspapers, is completely excluded from ecowool.

The composition of the material fully complies with environmental requirements, even during the smoldering process and with a sharp change in temperature. This property makes ecowool more effective and profitable compared to mineral wool and expanded polystyrene.

But due to insufficient knowledge, insulation with this material is carried out only by specialized construction organizations.

Main types

The source material and manufacturing technology determine the future characteristics of the product and the type of mineral wool. Main groups by type of raw material:

- stone (basalt);

- slag (slag wool);

- fiberglass (glass wool).

Basalt mineral wool

The raw material for the manufacture of insulation is volcanic rock (basalt) or dolomite. The hardness and fine-grained nature of the material make it possible to produce super-thin (1-3 microns) fibers up to 5 cm long in the mineral wool structure. Due to the small number of ingredients, simple manufacturing technologies are used. The thermal conductivity of stone wool is the lowest among the main types of insulation.

Basalt fiber insulation

The advantages of this type are manifested in the following characteristics:

- compressive rigidity of the material - installation of vertical insulation sheets does not require supporting supports;

- chemical resistance;

- durability (service life up to 50 years);

- low hygroscopicity – optimal air humidity is maintained;

- high strength, elasticity;

- good sound absorption – high degree of sound insulation;

- fire resistance – up to 1000°C;

- environmental friendliness

Basalt wool can withstand loads when reinforcing and plastering the surface. Insulation sheets are placed inside the wall, as part of fire protection structures.

High performance qualities ensure the versatility of using basalt insulation.

Foiling stone wool enhances the thermal insulation properties of the product. When arranging the sheets, it is important to point the shiny surface towards the room.

Foil insulation

In operation, basalt mineral wool is more convenient in comparison with other types of insulation due to the fact that during production the fibers do not take on pointed shapes.

The disadvantages of the material include:

- dust formation during work - a mask or respirator is required;

- relatively high cost.

In practice, high demand in private construction for stone mineral wool remains due to the fact that:

- the quality of the slabs fully complies with the requirements for internal and external wall insulation;

- The labor intensity of the process is lower than when working with other types of mineral wool.

Slag wool

The raw material for the production of mineral wool is waste from the metallurgical industry - blast furnace slag. The cotton wool fibers obtained through processing are up to 16 mm in length, with a diameter of 4-12 microns - the smallest size due to the chemical composition and processing technology of raw materials.

Slag

The special properties of the material limit its use in private construction; insulation is more often used for thermal insulation of non-residential premises.

The advantages of slag wool include:

- Possibility of installation on round, shaped surfaces;

- high-quality sound insulation;

- fire resistance;

- durable operation - up to 50 years;

- high chemical and biological stability;

- low cost.

- low sintering and application temperatures;

- hygroscopicity – cannot be used for insulation of facades or water pipelines;

- exposure to temperature fluctuations - the quality of thermal insulation decreases;

- barbs during installation;

- the presence of phenol-formaldehyde resins, which are harmful to health;

- low vibration resistance - loads lead to subsidence of the material, increasing thermal conductivity;

- slag acidity – incompatibility with metals at high humidity.

The safe use of slag wool is recommended for insulating attics, basements, and non-residential buildings, since the material is inferior in quality and inconvenience to work to other types of insulation. Its use is wider at industrial facilities.

The products are characterized by the lowest rigidity (compression). The level of good thermal insulation is comparable to other types of mineral wool.

Glass wool

The production of fiberglass material is based on the use of up to 80% cullet and silicon rock as raw materials. The addition of sand, soda, limestone and other ingredients does not exceed 20%. The mixtures are melted and blown with centrifuges to obtain thin fibers approximately 5 cm long. The performance properties of the product are of a good level, but working with fiberglass material requires the use of protective equipment.

Installation of glass wool

The widespread use of glass wool, despite the large selection of alternative insulation materials, is based on certain advantages of the material:

- chemical resistance;

- insulation of uneven surface shapes;

- good sound absorption;

- vibration resistance;

- low thermal conductivity;

- fire safety;

- low price.

Significant disadvantages of the material are:

- high water absorption - vapor protection is needed;

- causticity;

- low heat resistance;

- the need for reliable insulation;

- service life up to 10 years, significantly shorter compared to other insulation materials.

Working with glass wool requires special care: enhanced protection of the organs of vision, respiratory tract, and skin.

The high fragility of the fibers carries the risk of particles getting into the lungs and mucous membranes, which causes severe irritation, swelling, and allergic reactions.

Working with glass wool

Characteristics of roll insulators

Insulation in the form of layers and mats, such as mineral wool, is extremely inconvenient for insulating pipes, exhaust shafts and large areas. In such cases, roll thermal insulation materials are used. They are flexible when laid and quickly return to their original shape. It is roll insulation materials that are convenient to use in order to wrap the required insulated surface. Due to their structure, rolled materials are resistant to temperature changes and can withstand both extremely high temperatures (up to 700-750 °C) and extremely low ones. At the same time, the insulation retains all its qualities. Despite all the positive aspects, you cannot be sure of the quality of thermal insulation, because it directly depends on class=”aligncenter” width=”596″ height=”283″[/img]

The best manufacturers

The comfort and safety of people in the room depends on the use of proper insulation. Leaders in the production of mineral wool strive to achieve a product combination of construction advantages, environmental friendliness of the product while maintaining an acceptable price for the product.

According to consumer reviews, the ranking of the best brands is as follows.

Danish company with factories in Russia. They produce stone wool with enhanced properties:

- fire safety - fibers can withstand temperatures up to 1000°C (standard 600°C);

- sound absorption – products are chosen for acoustic comfort;

- environmental friendliness;

- durability - maintains quality indicators during operation;

- thermal insulation.

In the production of basalt wool, the company identifies priority quality areas, which are:

- saving energy, including heat;

- environmental friendliness;

- soundproofing;

- fire safety.

The manufacturer does not allow counterfeits and realizes the advantages of stone wool in full.

The downside is the high price.

Facade insulation

The manufacturer produces two types of insulation: stone wool and fiberglass wool. This suits builders who need different materials according to the conditions of the objects being built. The best side of the product is the reduction in the “prickliness” of products while maintaining high characteristics of the main indicators.

The price-quality ratio of this company is one of the best on the mineral wool market.

Izover insulation

The products are represented by basalt mineral wool and fiberglass-based insulation.

An important factor was the specialized purpose of the products, reflected in the names:

- Acoustic partition;

- HEATWALL;

- WARM roofing, etc.

The environmentally friendly material is intended for construction work on the construction of residential buildings. The high price is the only drawback.

The low price of basalt products used for insulation of walls, facades, and roofs is attractive. Quality indicators meet standards. The disadvantage is a slight shedding of the material during work. A particularly popular area is finishing attics and pitched roofs with Izovol mineral wool. Mineral wool is fire resistant, environmentally friendly, and has good thermal insulation properties.

Necessary tools and calculation of material thickness for roof insulation with mineral wool

To insulate the roof structure you will need:

- Minvata. The volume of insulation is calculated based on the roof area. For multi-slope complex structures, you need to measure the length and width of the roof (slope compensation). For a completely flat roof, just multiply the length by the width of the structure and add up to 15% for trimming.

- Wooden beam 40×40 mm for arranging the sheathing. An aluminum profile can be used instead of timber, but working with wood is easier.

- Vapor barrier film. It is better to buy special membrane-type waterproofing.

- Fasteners (screws, nails, dowels, etc.).

- Hammer or professional screwdriver.

- Hammer, hacksaw (for wood).

- A sharp knife (when cutting mineral wool, the knife quickly becomes dull, so it is advisable to have a sharpening wheel).

- Glue. Large volumes of glue will be needed for pitched roofs, so in this case it is necessary to prevent the thermal insulation from slipping.

When choosing a board for rafters, you should take into account not only the design strength, but also the thickness of the mineral wool. For average climate zones, the thickness of the insulation for the roof of a residential building should be from 10 to 15 cm. For the northern regions, thicker mineral wool is needed.

Let’s take, for example, a structure with a required rafter height of 15 cm, where the thickness of the mineral wool will be 18 cm. In such a design, you need to add the height of the rafters to ensure the possibility of laying mineral wool between the beams, taking into account a 5 cm ventilation layer. To do this, you can lay boards of small thickness along the rafters (counter-lattice). This solution will allow you to properly insulate the roof of a residential building from the inside.

Consumer choice

In private construction, approximately 80% of the purchased insulation is basalt and stone mineral wool, which have universal quality characteristics. Slag and fiberglass wool are used more often in enterprises for thermal insulation of specific objects.

Reliable thermal insulation

In practice, which mineral wool is best for insulation needs to be decided taking into account a specific building, room, structure. When making design decisions, specialists calculate in advance what density of mineral wool is best to choose and how to use the material correctly.

Errors most often occur not because of the quality of the insulation, but because of its improper use. It is recommended to carefully study information from the manufacturer about the characteristics and properties of mineral wool, and features of use.

Sawdust

Insulating the attic roof with sawdust is not recommended due to the low performance characteristics of this material. The only advantage is the price. According to other criteria, sawdust is inferior to modern insulation.

- Relatively high thermal conductivity coefficient;

- Spontaneous changes in density under the influence of gravity, the likelihood of voids appearing in the roof structure;

- Combustible material. The effect is reduced when using a solution with gypsum, cement or lime;

- Rotten;

- Habitat for rodents and insects.

The best materials for insulating an attic are basalt wool and polyurethane foam. They have high thermal insulation properties, reduce noise levels and are harmless for use in residential areas.

Principles for choosing roof insulation

On our website we have already devoted quite a few articles to the principles of choosing various thermal insulation materials. In this material we will look in detail at which insulation to choose for the roof and we will look at the choice of insulation specifically in this section. Here are a few things to consider about your roof.

- Roof enclosing structures have increased requirements for thermal resistance. For example, in 2010 in Finland, the coefficient of such resistance for walls was 5.88 m2*C/W, and for the roof it was 11.11! Almost double the difference.

- The material on the roof is more exposed to moisture than others. And, as you know, water is the enemy of thermal insulation.

- Roof insulation is installed, in fact, according to the principle of ventilated facades. This means that it is not protected from fire, for example, by concrete or plaster elements. In this regard, the insulation itself must have increased fire resistance.

- And it doesn’t matter whether we are talking about a flat or pitched roof, the insulation area is quite high, so the cost of the material should be reasonable and fit organically into the estimate for building or renovating a house.

These are the basic general requirements for thermal insulation for a roof. However, you need to take into account the type of roof. [flat_ab id=”33"]

What are the advantages of roof insulation with mineral wool?

Let's figure out why high-quality roof insulation is necessary. Is it possible to do without this procedure? The first answer to this question is completely obvious: insulating the roof with mineral wool will save a large amount of money on heating the house. In addition, professional performance of such work extends the life of the roof structure.

The lack of high-quality roof insulation and normal waterproofing of the roof space leads to an acceleration of the processes of rotting of rafters and beams as a result of moisture penetration.

Roof repair is a very expensive undertaking. No one has the desire to do it every few years, therefore, it is necessary to carry out proper insulation and waterproofing of the roof. Special requirements for insulation are imposed in the presence of an attic floor.

Types of roofing and insulation for them

When choosing a material for insulating the roof of a house, the difference between the three types of roofing structures is important:

- Flat roof;

- Pitched roof (cold attic);

- Mansard roof (floor).

Each of the three types of roofs requires its own approach in choosing insulating materials.

A flat roof is most often used, which means that the thermal insulation of the roof must be rigid. For these purposes, extruded polystyrene foam is most often used, for example, penoplex or rigid mineral wool insulation. Typically, each manufacturer has special solutions for this type of roofing. Slabs with cuts allow you to create the desired slope and special gutters for discharging water. It is enough to lay such a layer of insulation correctly and the roof can be considered insulated.

You can insulate a pitched roof with a cold attic along the floor. However, in some cases, insulation is also inserted between the rafters. For these purposes, soft and elastic mineral wool slabs are most often used, which are inserted into the spacer. The attic floor is insulated with various materials, both sheet, bulk and sprayed.

An attic roof is essentially the walls of a room, but they are made not of concrete or brick, but of rafters and, for example, tiles. This design is more expensive than a separate, ordinary floor. Roof insulation for an attic roof must be environmentally friendly, because, in essence, we are talking about insulating the room from the inside. There are also increased fire safety requirements. In a separate article, we examined in detail the issue of using polystyrene foam in insulated attic roofs. Most often, such roofs are insulated with mineral wool.

conclusions

So, what is the best roof insulation? You can choose the option, like most, and use mineral wool. If we are talking about insulating the floor on the roof, pay attention to ecowool . When calculated, its cost is not that high. But this is an environmentally friendly material that is not afraid of rodents. And this is a big plus. We have given enough general considerations to help you choose insulation. However, no matter how correctly the chosen material is selected, when laying the insulator it is important to adhere to the installation rules, which we described separately.

As we found out, roof insulation can be not only buns with hot chocolate, but also at least 6 other good materials. Choose and let your roof be as warm as Carlson’s.

Is the most popular one suitable? - Styrofoam

It is worth mentioning that by foam plastic we mean both ordinary, white polystyrene foam (PSB-15) and extruded polystyrene foam, the density of which can reach 35-45 kg per cubic meter.

So, PSB-15 is not used for flat roofs. Although it is much cheaper, it can still be damaged when installing insulation by simply stepping on the sheet. In addition, the foam is made without a quarter. But, for example, penoplex has special grooves at the edges that are fastened together and create one indestructible layer of insulation on the plane.

The ceiling of a cold roof is often insulated with foam plastic in the frame when it is laid between the joists. For the same purposes, more moisture-resistant polystyrene foam is used, which, by the way, has much greater compressive strength.

The issue of using this material for a residential floor under the roof was discussed separately, and this is generally a whole topic.

Thermal insulation materials start with polystyrene foam. But, alas, it does not qualify for the title of best insulation for roofs. That's why they mentioned it at the very beginning. Further - more interesting. [f[flat_ab id=»34"]p>

Polymer thermal insulation materials

If there is no waterproofing film or diffusion membrane that protects the rafters from moisture accumulation during steam condensation, it is best to choose one of the polymer insulation materials.

Most often, a similar situation arises during the construction of a house in which a residential attic was not intended. That is why materials with extremely low permeability, such as polyurethane foams and expanded polystyrene, become the best option.

Such insulation perfectly protects not only from freezing of the structure or a decrease in room temperature, but also from constant exposure to moisture. They are harmless to humans, but require the creation of ventilation systems, as they interfere with normal air circulation.

Polyurethane foams

An interesting option for roof insulation is a material based on polyurethane foam. This insulation is applied by spraying, which ensures the absolute integrity of its layer without the formation of cold bridges.

In addition, this material does not require additional fastenings or fixation due to good adhesion to the base. To treat a roof of 100 square meters it will take no more than 4 to 8 hours, which significantly reduces the process of arranging the attic floor.

The thickness of such insulation to protect the attic compared to classic mineral wool can be reduced by 1.5 - 2 times and amounts to 80 - 100 mm. It is thanks to the integral structure of the applied layer, as well as the formation of absolutely closed air cavities, that polyurethane foam perfectly protects the room from heat loss.

Expanded polystyrene

In this case, both classic polystyrene foam and extruded polystyrene foam will cope perfectly with the task of insulation.

Both materials have excellent thermal insulation properties, but the extruded version is more reliable and durable. Its thermal conductivity is lower, so the effective layer is reduced to 80 mm.

The cost of polystyrene foam is lower, but taking into account the difference in the required amount of materials, the total costs remain approximately equal. The undeniable advantage of extruded polystyrene foam over polystyrene foam is its non-flammability.

Extruded polystyrene foam, unlike polystyrene foam, is not susceptible to rodents; its structure simply does not allow them to create their nests in the thickness of the material. Nevertheless, polystyrene foam still remains one of the most popular insulation materials.

The density of both types of expanded polystyrene is also selected in the range of 30 – 50 kg/m3 to prevent the weight of the structure. They are fastened using special disc-shaped dowels with large polymer caps.

Roofing classics - mineral wool

By mineral wool, people most often mean:

The latter is highly not recommended. The maximum where you can use insulation from waste from the metallurgical industry is not residential buildings of enterprises.

Stone wool is used for residential premises. Although it contains resins such as formaldehyde, their percentage is still insignificant, and moreover, it has undergone a polymerization process. This means that the resin has settled and is now in a solid state with a closed molecular structure.

For flat roofs, as already mentioned at the beginning, rigid mineral wool slabs with a density of 140-160 kg/m³ are used.

To insulate a pitched roof, soft slabs are inserted between the rafters, trimming them. The same slabs are inserted between the joists and covered with a protective coating on top in case of overlap. Mineral wool is most often used for roof insulation. This is due to its “breathable” structure. The fact is that any wooden structure must be well ventilated. And if polymer insulation is adjacent to it, this procedure becomes much more complicated. That's why they use cotton wool. In addition, cotton wool is a non-flammable material. Being in its essence a semblance of volcanic lava, cotton wool does not burn, it only melts, and even then at a huge temperature - above 1500 degrees.

However, the insulator is not without its disadvantages. It is associated with poor resistance to moisture. For example, if a cotton slab has a thermal conductivity coefficient of 0.036 W/m3 K, then when wet, this indicator can actually change by 2 times! And, as you know, the roof is a place where leaks can happen. In practice, this means that you will have to replace a section of thermal insulation that has become wet.

Over time, the mineral wool also crumbles, forming dust that can enter the room. Some people don’t like this material precisely for this feature.

The trick is “slabs in rolls”

Manufacturers are increasingly trying to simplify the installation of insulation. Nowadays, you can increasingly find a mineral wool form factor, which is called “slabs in a roll.” This material has sufficient density to fit well in the frame. In this case, it is enough to fix the roll in the upper part, between the rafters and roll it out at the bottom. For example, about Izover Profi, it is even stated that it does not need to be trimmed (it is clear that we are talking about a not very significant change in the width between the rafters), but simply press it in and the wool will take the desired shape. It is more convenient to use such rolls than to insulate using slabs. Installing slabs takes longer.

When deciding how to insulate the roof of a house, most owners or developers choose mineral wool [fla[flat_ab id=”35"]

Insulation of the roof of a private house with mineral wool: installation along the rafters and between them

Laying mineral wool between rafters

When insulating the roof internally, it is more convenient to place mineral wool between the rafters. This option will be available if the thickness of the thermal insulation is no greater than the width of the rafters. If the width of the mineral wool is greater than this parameter, then it is necessary to perform combined insulation of the slope.

Technology for laying mineral wool between rafter elements:

- The bottom surface of the rafters should be at the same height. A building level is used for checking. If different lumber was used to make the rafter legs, it is necessary to carry out work to bring the heights to the same value.

- To waterproof the insulation, a polyethylene film is used, which is laid on the rafters.

- The mineral wool needs to be cut into pieces of the required size. Thermal insulation is installed by surprise. To do this, the width of the mineral wool sections should be approximately 30 mm larger than the size of the gaps between the rafters. When laying mineral wool in two layers, installation must be done in such a way that the joints of the layers do not coincide.

- The membrane vapor barrier is being cut out. It is placed on top of mineral wool to protect the insulation from moist air. The vapor barrier membrane sheets are fixed along the entire slope perpendicular to the rafter elements. A construction stapler is used to secure the vapor barrier.

- A layer of waterproofing, mineral wool and vapor barrier can be covered with plywood, plasterboard, lining or other materials that can be decorated with decorative finishes.

Rafter installation

If the thermal insulation layer, which is necessary to insulate the roof, turns out to be thicker than the size of the gaps between the rafters, laying the mineral wool is carried out in two stages. First, thermal insulation is placed between the structural elements of the roof frame. After this, another layer of mineral wool is laid on top of the frame parts. To insulate a roof in this way, you will need a much larger amount of insulation. The roof will be more expensive, but heat loss through it will be minimal. This insulation option is used for heated attic rooms.

Main stages of work:

- The gaps between the rafter legs are measured. To do this you need to use a construction tape. After taking measurements, you need to cut the mineral wool into pieces, the width of which is 30 mm greater than the distance between the rafters.

- If you purchased roll insulation, then after cutting the mineral wool, you need to keep its pieces in an unfolded state for some time. Laying can be done after the material has completely straightened.

- The edges of the pieces of mineral wool must be tucked towards the center. In this state, they are placed between the rafters and carefully straightened.

- Using a stapler, you need to attach the vapor barrier sheets to the rafters. The vapor barrier membrane strips should be overlapped by 150 mm. This will protect the insulation from moisture entering through the joints of the vapor barrier sheets.

- Between the rafters it is necessary to fill slats (perpendicular to the rafter legs). The thickness of the slats should be 20 mm greater than the width of the mineral wool layer. The slats are filled at intervals equal to the size of the thermal insulation slab.

- The insulation must be placed between the slats so as to prevent the joints in different layers of mineral wool from matching.

- The slats that were stuffed to install roof insulation can act as a frame for attaching decorative cladding, which can be made of lining, plywood, plasterboard and other materials.

Bulk insulation for roofing

This type of insulating materials for the roof of a house attracts many people for three reasons:

- Low price;

- Environmental safety;

- Lack of interest in rodents.

It is immediately worth noting that the roof can be insulated using bulk thermal insulation materials only on the floor. They are poured into the frame. Therefore, the material is suitable for covering an attic. Most often used:

Sawdust itself is a fairly inexpensive material. Its advantage is its absolute naturalness. But there are two problems with using it:

Both solve in the same way. Adding lime to sawdust. Gypsum is also used to impart viscosity to the mass. It is added in an amount of no more than 5% by weight of sawdust. The resulting mass becomes viscous and is perfectly applied and keeps its shape.

Expanded clay is small crushed pebbles of different fractions (sizes). It is filled between the joists. Expanded clay is not afraid of either steam or rodents. In a sense, it is an ideal insulating material for roofing.

In addition, it is not quite expensive. We will talk in more detail about the use of this type of thermal insulation for roofing in a separate article. Here the mention was necessary to understand the general picture of possible insulation options.

Spraying and blowing

There are two main representatives in this family of roofing materials:

Polyurethane foam is one of the most effective thermal insulation materials. It is sprayed or blown in the form of white foam. To blow in polyurethane foam you need a special suit and a compressor. This material does not allow steam to pass through and you need to use a lathing to blow it in.

PPU is a synthetic material, ecowool is environmentally friendly. Both of these materials are rodent resistant and require special equipment to blow them out. A specially trained technician can apply polyurethane foam correctly.

Ecowool has been used in Western countries for about 50 years. This roof insulation came to the territory of the CIS relatively recently. Ecowool is a cellulose fiber and is made from waste paper. There are special machines for crushing raw materials and “cooking” such cotton wool. Using special pneumatic transport, the cotton wool is delivered to the blowing point, where, for example, it is placed between the lags.

Another obvious advantage of ecowool for roof insulation is that it is easy to blow into the narrow space between the rafters. Laying even rolls of mineral wool in this area is very problematic.

Algorithm of actions for insulating a roof with mineral wool

- Preparation for roof insulation work.

At this stage, it is necessary to prepare the roof surfaces that are to be insulated. It is necessary to inspect all roof elements to identify defects and clean them from dirt and dust. In addition, it is necessary to calculate the required amount of mineral wool and other materials. The minimum thickness of the thermal insulation layer should be 200 mm, and therefore, if you have thinner insulation, it will need to be laid in 2 layers.

- Waterproofing.

To protect the roof structure from moisture, it is necessary to lay overlapping waterproofing. A stapler is used to attach the waterproofing material. In this case, the joints need to be taped. For high-quality protection from moisture, there must be an air gap between the waterproofing membrane and the mineral wool, and the film itself must extend slightly onto the walls. To provide an air gap, a sheathing of wooden slats is placed over the membrane. In order for the roof to last as long as possible, all wooden structural elements must be treated with an antiseptic.

- Laying mineral wool.

Before laying the mineral wool, carefully cut pieces whose width is 50 mm greater than the gaps between the rafters. Laying should be done in such a way that the mineral wool fits as tightly as possible to the beams without forming gaps.

- Installation of vapor barrier.

After laying the mineral wool, you need to ensure its protection from the steam that comes from the interior. To solve this problem, a vapor barrier is installed from special foil materials, polyethylene or roofing felt. To ensure the tightness of the vapor barrier, it is necessary to ensure that the layers overlap and the seams of the vapor barrier are sealed. The foil insulating material is laid with the metallized side facing the inside of the building. To fix the vapor barrier, wooden slats are used, to which the sheathing is subsequently attached.

Polyurethane foam

Spraying polyurethane foam is a good way to insulate an attic. In addition, the material has the following properties:

- Excellent degree of thermal protection.

- Possibility of insulation without a frame and special fastenings.

- The absence of seams, which are always conductors of cold.

- Creating tightness in hard-to-reach places.

- No reaction with any roofing material, excellent resistance to moisture and vapor permeability.

- Good grip on any surface.

- Polyurethane foam is not afraid of rodents and insects, and is also not affected by mold and rot.

But polyurethane foam still has a drawback: it cannot be applied independently without special equipment.