SHARE ON SOCIAL NETWORKS

FacebookTwitterOkGoogle+PinterestVk

A profitable option for supplying heating to the room and providing hot water is a waste oil boiler. The device is characterized by a simple design, which allows you to make it yourself. This will help you save additional money. If this possibility is excluded, you can purchase a boiler for factory assembly testing. Currently, the product range is presented in a wide variety.

The boiler can use different types of waste oil, which is characterized by an abundance of various impurities

What is a waste oil boiler?

Today, heating equipment that operates during mining is very popular. This is due to a number of distinctive advantages of the device. First of all, this is the low cost of installation and the availability of fuel, which can be purchased for a nominal fee. Exhaust heating does not require the use of resources in the form of electricity and gas, which makes it economically profitable.

Despite its many advantages, the boiler during development also has its disadvantages

Important! Recycling waste products in full has a beneficial effect on the environment, eliminating the disposal of oil and its release onto the ground and into water bodies.

When the boiler is set up correctly, the waste oil is burned completely, which prevents the formation of toxic combustion products. The device consists of a minimum number of parts, which can be seen in boiler diagrams. This increases the reliability and durability of the structure. It does not take much time to heat up the boiler. Forced convection helps to quickly increase the temperature in the room.

Despite its many advantages, the boiler during testing also has disadvantages. When the device operates, moisture evaporates from the air and oxygen is burned, which negatively affects human health. Therefore, the boiler should be located in a non-residential area with a good ventilation system. Devices during mining quickly become dirty. This especially applies to the plasma bowl and chimney.

For such a boiler, different types of waste oil can be used, which is characterized by an abundance of various impurities. Therefore, to ensure a long period of operation of the device, a filter should be installed in the place where oil is supplied to the boiler, which must be changed as it becomes dirty.

The waste oil boiler should be located in a non-residential area with a good ventilation system

Strapping. Duplicating the furnace during mining with an electric unit

Before connecting the boiler, you should consider not only the installation method and placement points for additional devices and shut-off and control valves, but also the method of venting the chimney to the outside. If it passes through a ceiling built using flammable materials, then a metal pencil case with twice the diameter is installed in it. The free space between the pipes is filled with asbestos or other non-flammable material with good thermal insulation properties.

Considering the high danger of heating with liquid fuel, it is best to install the boiler in a separate room with good ventilation. The podium for the unit is concreted or covered with a metal sheet that will protrude beyond its contours by at least 1 meter. After installation, the boiler is leveled plumb and only after that the connection begins.

The simplest way to connect a boiler is to integrate it into a gravity heating system. Despite its simplicity, its reliability is very high, since in this case there is no need for a circulation pump and automation devices. However, the use of additional equipment makes it possible to speed up the delivery of coolant to consumers and equalize the temperature at all points of the system, which saves fuel and increases comfort. For these purposes, a centrifugal pump and a membrane-type expansion tank are installed on the return line just before the entrance to the boiler. It is necessary to ensure that the system does not depressurize when temperature and pressure increase. A pressure line is connected to the upper branch pipe, and to regulate the temperature of consumers, a thermostatic head or other control device (three-way valve, valve to reduce the cross-section of the supply pipe, etc.) is installed in front of each radiator. To remove air plugs, an air vent is installed at the top of the system.

Piping diagram for a boiler running on waste oil

The piping of a unit operating in mining requires taking into account the inertia of this type of equipment. In other words, the change in coolant temperature occurs gradually, so the unit must be equipped with a safety valve . It will allow you to relieve pressure when it rises to a critical level. A good way to protect and equalize the temperature is to connect an indirect heating water heater in series. It will serve as a buffer that will take on excess heat in case of excessive temperature rise.

When connecting the boiler, shut-off valves are installed on the return and supply lines. This will make it possible to remove the unit for repair without the need to remove coolant from the system.

When they want to insure themselves in case of a shortage of used oil, an electric boiler is installed next to the homemade boiler. You can connect an additional unit in two ways - in series or in parallel. The advantage of the first method is that the coolant heated using a flame bowl will flow into an electric boiler, which can be set to a certain response temperature. When the burner flame decreases, it will turn on and increase the water temperature to the desired value. The disadvantage of this method is the increase in the length of the line, as well as the complete inoperability of the system in the event of dismantling one of the boilers for repairs.

Parallel activation implies independent operation of two heating units and is characterized by the absence of these disadvantages. Unfortunately, this method is not without its drawbacks, one of which is the need to install a hydraulic switch and accurately coordinate the operating mode and supply of the return line. In addition, when connected in parallel, there will be much more fittings, pipes and fittings, which will certainly lead to an increase in cost and complexity of installation.

Despite all the disadvantages, in any case, the inclusion of boilers in a cascade helps to increase the reliability of the system. If we take into account that one of the units will periodically or regularly operate on used motor oil, then this will also allow you to save a lot of money.

How does an exhaust boiler work?

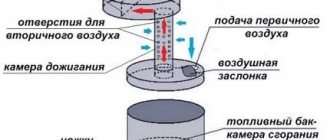

Boilers for a private home using waste oil, as well as for a garage, workshop or industrial premises, have a simple design. They consist of two chamber compartments: an evaporation chamber and a combustion chamber. In the first compartment, the process of preparing used oil for combustion is carried out. In the second, it is burned. The principle of operation of the device is as follows.

From a container with used oil, the pump supplies the substance to the evaporation chamber, which is located in the lower part of the device. It maintains the required temperature, sufficient for heating and subsequent evaporation of the waste. Oil vapor rises to the upper zone of the housing, where the combustion chamber is located. It is additionally equipped with an air duct in the form of a pipe with holes. Using a fan, air is supplied through an air duct into the chamber, where it is mixed with oil vapor. The resulting mixture burns without a residue.

The heat exchanger distributes the resulting heat. The resulting combustion products enter the chimney. A mandatory process is preheating of the waste. Oil contains many impurities; under the influence of a certain temperature, the substance decomposes into simple carbons, which are subsequently burned. As a result, water vapor, nitrogen and gas are formed, which are harmless to the body.

Waste oil boilers have a simple design

Complete oxidation of carbohydrates is possible only at a temperature of 600 °C. If this value is not observed, the combustion process produces many toxic substances that are extremely dangerous to human health.

Device

Such a boiler is identical in design to all other liquid fuel heating devices and consists of :

- combustion chambers (furnaces);

- nozzles;

- water jacket;

- heat exchanger;

- housings;

- fuel equipment.

The firebox is surrounded on all sides by a water jacket, which takes away the heat generated by the fuel and spends it on heating the coolant (water or antifreeze).

At the bottom of the firebox there is a nozzle that sprays liquid fuel and mixes it with air, thus forming an air-fuel mixture. There are also models without a nozzle ; in them, this role is played by various burners that heat and burn waste oil.

After combustion of the mixture, hot flue gases are formed, which pass through the heat exchanger, heating the water for hot water supply.

In many models of such boilers, the heat exchanger, or water circuit, operates in parallel with the water jacket, increasing the efficiency of the heating device, but when operating at low power, this reduces the temperature of the flue gases and leads to the appearance of condensation in the chimney.

The fuel equipment supplies exhaust gas to the nozzle, and after the water jacket warms up to a certain level, it stops supplying, thus ensuring temperature stability in the house .

Often in boilers, fuel equipment and a nozzle are combined into one device. The housing insulates the water jacket, so accidental touching the boiler does not cause burns.

Types of waste oil boilers

There are three options for waste oil boilers: water heating, heating and domestic. The first option is an alternative to a modern boiler. Having a platform design, the device heats up the flat surface where the water tank is located. A small pump is installed at the outlet of the tank, which regulates the pressure in the system.

Important! It is very difficult to change the temperature of the water, so if necessary, it is recommended to dilute it with cold water.

For water heating boilers using waste oil, a water tank with a volume of no more than 140 liters is used. It heats up within 2 hours, which is several times faster than the operating speed of a modern electric boiler. An oil water heater can operate in two modes: fast and wick. The first option is used to heat completely cold water. The wick mode allows the water in the container to be heated. However, this will require a large amount of fuel resource.

There are three options for waste oil boilers: water heating, heating and domestic

Important! Oil water heaters during mining are installed in basements, since they are non-transportable.

Domestic boilers are considered the ideal solution for country houses. They have a built-in gas purification mechanism, which contributes to the operation of the device without smoke. Such devices are mobile structures, which will allow them to be moved to any place without affecting the functionality of the product. This multifunctional device allows you not only to heat the room, but also to heat food. The unit can be used outdoors or while traveling.

Automation for waste oil boilers can perform various functions. Here you can set up control over the heating of the coolant and the air temperature in the room. Such devices are installed on the floor. Their cost depends on the functional features of the device.

Due to the compact size of the hot water boiler, it is convenient to install it in the boiler room

Characteristics of a waste oil heating boiler

The waste oil heating boiler must be located in a non-residential area. As a rule, to heat a house it is installed in a special extension. Despite the fact that modern devices are equipped with an improved filtration unit, during operation they emit an unpleasant odor of machine oil.

The inside of the unit is equipped with a heating unit with a water tube and a hydraulic pump. The last element can operate from the electrical network or from the energy generated by the device itself. Using a hydraulic pump, the coolant circulates in the circuit in the form of ordinary water.

The principle of operation of the device is as follows. In the combustion chamber, oil vapors and air masses, which enter under the influence of a ventilated compressor, are oxidized. The fire level is regulated using a hose with a valve. The ventilation device is the only movable element, as a result of which it may fail.

Such boilers are characterized by high performance and the ability to maintain room temperature for a long time. The fuel container is located on the floor, and the air heater can be mounted on the wall or ceiling.

The internal part of the boiler block is equipped with a heating unit with a water tube and a hydraulic pump

Subtleties of the process of creating a boiler for testing with your own hands

The most important component of the fuel combustion process is the preheating of the waste. This will allow the heavy substance to oxidize into light components. This result can be achieved by creating a thick-walled hot metal bowl into which the waste will be fed in drops.

When oil hits hot metal, the substance turns into vapor, which is discharged into the combustion chamber. There they must mix with air for better combustion, for which an air duct is used. It is equipped with an impeller, thanks to which the flow swirls, which contributes to a long stay of the oil-air mixture in the combustion chamber. Only in this case will the fuel burn completely.

To carry out the heating process of the evaporation bowl, a wick soaked in fuel should be placed in it. Next, a little diesel or gasoline is added and ignition is performed. When the metal heats up to the desired temperature, oil is supplied. This process is simple but very dangerous. Therefore, it is important to properly organize the flow of the substance into the nozzle for a waste oil boiler.

When oil hits hot metal, the substance turns into vapor, which is discharged into the combustion chamber

If the oil flows in a stream, the fuel will not have time to burn. As a result, toxic components are formed that are hazardous to human health. To achieve efficient combustion without smoke, a drip supply of fuel should be arranged. To do this, a hose is used, at one end of which a filter is installed. It is better to use a full filtration automotive oil element. Then a fragment of a medical dropper with a wheel-regulator is put on the hose. The element is fixed to the fitting. The oil from the dropper is directed into a funnel, which is connected to a pipe. It supplies fuel to the combustion bowl.

Pros and cons of heating by working off

Here are the pros and cons of using waste water heating:

pros:

- minimal fuel costs;

- the ability to convert the boiler to other types of liquid fuel or gas by replacing the nozzle;

- the exhaust burner can be inserted into any air or water heating boiler, originally designed to operate on liquid or gaseous fuel;

- with proper burner settings, waste oil products burn with minimal release of harmful substances;

- the ability to get rid of accumulated waste without expensive disposal.

Minuses:

- the combustion chamber must be frequently cleaned of soot;

- fuel must be stored next to the boiler;

- before burning, the waste must be heated to a temperature of 60–100 degrees;

- When fuel burns, a lot of slag is formed;

- any violation of the correct adjustment of the burner increases the toxicity of the smoke;

- any violation of the draft or nozzle settings leads to the appearance of a strong unpleasant odor and the room is filled with toxic smoke;

- even in devices with a working burner, there is a high probability of fuel spillage, which can lead to a fire;

- If water or brake fluid gets into the exhaust, the injectors often become clogged, which is why you have to clean them.

Making your own waste oil boiler with a water circuit

Based on studying the boiler drawing with your own hands using waste oil, the following necessary materials and tools are prepared:

- sheet of metal 4 mm thick for a tank or pipe with a diameter of 500 mm;

- pipes with a cross section of 200 mm;

- sheet metal 6 mm thick to create a cover;

- metal plates 3 mm thick;

- a piece of pipe for installing a chimney;

- oil supply pump;

- fan;

To make your own waste oil boiler with a water circuit, you need to know its components

- steel adapters;

- heat-resistant sealant;

- metal corner for supports;

- grinders with cutting wheel;

- drills;

- hammer;

- set of keys;

- welding machine with electrodes.

Helpful advice! To make it easier to create a homemade boiler for mining, you can use ready-made barrels for oxygen or propane.

The boiler body is conventionally divided into two parts. The heating radiator will be located at the bottom, and the water jacket will be at the top.

The process of making a boiler with your own hands using waste oil begins with the manufacture of an internal tank in the form of a container with a water jacket, a channel for oxygen supply and an oil pipe.

The boiler body is conventionally divided into two parts: radiator and water jacket

The dimensions of the tank elements are marked on a sheet of metal according to the drawing of the waste oil boiler. All parts are connected by welding. At the bottom of the housing there is a door for removing the bowl and igniting the oil. To speed up the process, the body can be made from a fragment of a pipe with a diameter of 500 mm and a length of 1 m.

Two round-shaped elements are cut out of metal plates, which will serve as the bottom and cover of the case. A round hole is made in the upper part, the size corresponding to the diameter of the perforated pipe into which it is inserted and welded. The body is covered with two plates by welding. Legs made of reinforcing bars are attached to its bottom.

The upper tank is made in a similar way. There is a hole in the lid for the chimney. To connect two containers, a burner tube with a diameter of 100 mm and a height of 35 cm is used. Holes with a diameter of 9 mm in the amount of 50 pieces are made in it. over the entire area of the product.

Related article:

Waste oil furnace: options for making the device yourself

Principle of operation. Device types. Factory assembled models. Making a furnace for testing with your own hands, design options.

By welding, all elements are connected to each other according to the drawing of the waste oil boiler. After installing the device on a flat concrete base, the chimney is installed. Its length is 3.5-4 m. To ensure good traction, the pipe must be inclined. The outer part must be vertical, and it is equipped with a special cover to protect it from snow and rain.

The design and principle of operation of a boiler using waste oil

Homemade heating boiler running on used automobile oil

Drained automobile oils are multicomponent, highly contaminated substances, which also burn poorly. We can say that as a fuel, waste in itself is “not very good”, since oxygen is simply not able to oxidize all the chemical diversity that is contained in it. If you break down the oil into simpler components, it will be much easier to burn them.

The decomposition method has been known to modern science for a long time. Flame separation, or, scientifically speaking, pyrolysis, is used to obtain simple flammable substances from any fuel - oil, coal, firewood, etc. This process is convenient in that no additional costs are required for chemical transformations - for this the heat generated by combustion of fuel is sufficient. The advantage of pyrolysis combustion also lies in the fact that this process supports and regulates itself, and therefore practically does not require outside intervention . All that is needed to start the decomposition process is to evaporate the fuel and heat the vapors to a temperature of 300–400 °C. To do this, you can use two methods.

The processes occurring inside the furnace during processing ensure high temperature and complete combustion of fuel

In the first case, the fuel is set on fire in the tank, after which it begins to actively evaporate. Effective mixing and obtaining a homogeneous gas-air mixture is ensured by the Coriolis force, so accurate calculation of the diameter and height of the combustion chamber is important. Fuel vapor rises through a vertical pipe with numerous holes through which it is saturated with oxygen from the air. At the top of the combustion chamber there is a partition, which is needed to reduce the gas speed and separate the nitrogen oxide afterburning zone. It is here that dangerous chemical compounds react with nitrogen oxides and break down into harmless substances.

The so-called self-burning method undoubtedly has attractive simplicity and reliability, however, a tank of burning oil does not allow us to talk about safety. In order to eliminate this drawback, it will be necessary to complicate the design of the heating unit.

The efficiency of waste combustion is significantly increased when using a specially designed burner

The second method involves the formation of zones of pyrolysis, combustion and afterburning directly in the flame, and this requires a burner of a special configuration. In order for the fuel to be completely oxidized, the injector must provide multi-stage formation of a gas-air mixture. In such a device, the primary movement of the fuel flow is provided by a compressor. Thanks to injection, the injected air carries with it atmospheric air, and the formation of vapors occurs due to the heating of the burner by the flame torch. Almost the same processes can be observed when using a blowtorch. A similar method is implemented in industrial liquid fuel units. Homemade designs use the same principle, but work a little differently. In them, the waste drips into a red-hot container, where it instantly evaporates and burns at high temperature. In this case, we cannot talk about pure pyrolysis, since there is also energy from the decay of molecules in the process of microexplosions.

Oil options for waste oil boilers

Any type of waste oil can be used for these boilers. Not only machine ones are considered suitable, but also shock-absorbing, transformer, transmission, motor, hydraulic, rapeseed, vegetable and other types. The main requirement for fuel is the absence of water, flushing fluids, antifreeze and other undesirable components in its composition. Machine oil is the cheapest and most accessible option. It can be purchased in sufficient quantities at any service station.

Any type of waste oil can be used for boilers

A diesel fuel boiler is characterized by maximum efficiency. Oily substances can be added to it, which will act as a catalyst, which promotes a good combustion process. This could be fuel oil, kerosene, or barbecue lighter.

It is strictly forbidden to use alcohol, gasoline and other flammable substances as fuel for exhaust boilers.

Important! During combustion, fuel must not be added to containers. It is filled only after the fill has completely burned out and the tank has cooled down.

Who is this device suitable for?

The average consumption of waste oil when burned in a boiler with a capacity of 20–30 kW/h is approximately 10 liters of fuel per day , that is, heating an insulated private house with an area of 100–150 m2 during one season will require 1–2 m3 of waste oil.

Therefore, this heating method is suitable only for those who have the opportunity to obtain such a volume of fuel for free or at a low price (up to five rubles per liter).

At this price, the costs will be comparable to the costs of purchasing firewood and coal or network gas necessary to heat an insulated house of such area.

If the cost is 5–10 rubles, then the costs will be more than for wood or coal heating, but comparable to heating a house with electricity or fuel oil; a further increase will deprive boilers during development of their main advantage.

Therefore, a boiler running on machine oil is most suitable for owners of enterprises that have many cars on their books.

Review of Russian-made boilers using waste oil

Domestic waste oil boilers are manufactured mainly in Voronezh, where the manufacturer has all the necessary documents related to the production of products. There are also other small businesses. However, most of them do not have a state certificate for the manufacture of heating equipment. You should pay attention to this when purchasing a boiler.

Powerful boiler STV1 is characterized by high efficiency

The Teploterm GMB 30-50 kW double-circuit waste oil boiler is characterized by high quality workmanship in every detail. Thanks to a multifunctional microprocessor, it is equipped with an automatic control system. The device has many options that simplify the operation of the device, making it safe. Fuel consumption – 3-5.5 l/hour. The cost of the model is 95 thousand rubles.

A popular model is the Gecko 50 pyrolysis boiler. The device can operate not only on waste oil, but also on crude oil, diesel fuel, fuel oil of all brands, kerosene, fats and various types of oil. The boiler is undemanding to the quality and viscosity of the fuel. There is no need for pre-filtration and heating.

The design has small dimensions (46x66x95 cm) and weight 160 kg. The device is characterized by high efficiency, reliability of all elements and connecting units, ease of maintenance and repair. The maximum temperature in the device reaches 95 °C. The fuel consumption is 2-5 l/hour. Power consumption is 100 W. The price of a heating boiler using waste oil is 108 thousand rubles.

The KChM 5K combination boiler has a cast iron reliable body

The Stavfurnace boiler STV1 is characterized by high efficiency. The power of the device is 50 kW. The fuel mixture consumption is 1.5-4.5 l/hour. The body dimensions are 60x100x50 cm. The device is equipped with a reliable modulating burner for a waste oil boiler, which has a high emission rate. The device is equipped with a fuel filter, pump and water tank. Various types of oil, diesel fuel and kerosene can be used as fuel. The price of the boiler is 100 thousand rubles.

The combined apparatus KChM 5K has a cast iron body. It can operate not only on mining, but also on gas and solid fuel. The power of the device is 96 kW. The model is distinguished by high quality parts, safety in operation and durability. You can buy a boiler for 180 thousand rubles.

Expensive domestically produced waste oil boilers

The domestic automatic waste oil boiler Teplamos NT-100 is characterized by an expanded configuration. A double-circuit boiler can be used not only for heating, but also to provide hot water supply in the house. The model is characterized by high quality manufacturing of all components. External parts are powder coated to protect them from corrosion. The body has an internal thermal insulation coating in the form of high-density glass wool.

The Ecoboil-30/36 exhaust boiler can be used to heat a room up to 300 square meters. m

For ease of control, the device is equipped with a remote control, which allows it to operate in automatic mode. It consists of a switch, thermostat, thermohygrometer and emergency thermostat.

The boiler has dimensions 114x75x118 cm and weight 257 kg. The maximum power consumption reaches 99 kW. Fuel consumption ranges from 5-6 l/hour. The price of a waste oil boiler is 268 thousand rubles.

A single-circuit heating device using Ecoboil-30/36 can be used to heat a room of up to 300 square meters. m. It has dimensions of 58x60x110 cm. The power of the device is 28 kW. Fuel consumption can vary from 0.9 to 1.6 l/hour. The boiler operates on any type of oil, regardless of its quality. You can also use kerosene and alcohol for it. The cost of the boiler is 460 thousand rubles.

The Belamos NT 325 water-heating fire-tube boiler, with a power of 150 kW, is capable of heating a room of more than 500 square meters. m. Fuel consumption reaches 1.8-3.3 l/hour. Thanks to the presence of a heat exchanger, it has high efficiency. Equipped with a control unit with a smooth adjustment function and the ability to maintain the set coolant temperature. It can operate on any type of liquid fuel that does not require filtration or heating. The price of the boiler is 500 thousand rubles.

The Teplamos NT 100 double-circuit boiler can be used not only for heating, but also to provide hot water supply in the house

The best known manufacturers and models: characteristics and prices

DanVex B-30

One of the best Finnish-made boilers for heating a private house. In addition to the 35.6 kW version, there are also other versions with a heating capacity of 60-220 kW. It is distinguished by high reliability, a well-thought-out system to simplify maintenance and cleaning (for example, an increased diameter of the firebox and smoke pipes, a vertical chimney, so that soot pours into the ash pan, a door that opens with the burner, so access to the combustion chamber is achieved by pressing the handle).

The boiler is also known for its compact size, functional automation with the ability to connect a GSM module and one of the highest efficiency for this type of boiler - 88%. Fuel consumption at maximum load is 3.3 l/h. The model has all the necessary protective functions and modes, the ability to connect a room thermostat and external temperature sensors.

The only known disadvantages are noisy operation, the absence of a fuel pump, heavy weight (157 kg) and an unreasonably high price. Country of origin: Finland.

NORTEC B70 (WB 40)

Model from a Russian manufacturer with a power of 40 kW. In terms of design and principle of operation, it does not differ from the above-mentioned Finnish analogue, it is equipped with the same heat exchanger made of heat-resistant steel, is less convenient to maintain, inferior in quality of materials and assembly, has larger dimensions and less functional controls.

However, it also has significant advantages in the form of a much lower cost, a full-fledged fuel unit (pump, filters, tank) included with the boiler, and the ability to operate on a large number of fuels (fuel oil, crude oil, heating oil).

EcoBoil-18

Vertical drip type model made in Russia with a power of 15 kW. The distinctive features of the model are its extremely low cost, compact size, reliability and the presence of an oil pump included. In addition to mining, it is capable of burning kerosene. The model is equipped with one of the best automatic control units in the drip oil boiler segment, but the automation is still inferior to standard models that spray fuel.

Also known disadvantages are the need for daily cleaning and domestic build quality. According to installation practice and owner reviews, in all cases the model has been working without problems for more than 7 years.

Cost : 36,800-39,900 rubles.

Furnace KDO-2

Another domestic drip-type model with a power of 28 kW. The boiler has the same design and operating principle as EcoBoil, but has a higher cost with less functional automation. The advantage is the removable pyrolysis bowl (in which the oil evaporates), this makes it easier to clean, and in case of burnout it can be easily replaced.

Cost : 44,500-50,000 rubles.

Finnish boilers for private homes using waste oil

Based on numerous reviews, the waste oil boiler Ecoheat 60S, equipped with a burner, is very popular. The device can be connected to a boiler to produce hot water. The boiler has dimensions of 102x67x79 cm. Fuel consumption does not exceed 5.4 l/hour. The power of the unit is 60 kW.

The boiler body is made of sheet steel and covered with thermal insulation in the form of dense fiberglass. The advantage of the unit is ease of maintenance, which is ensured thanks to the classic shape of the combustion chamber and a double fuel filtration system. You can buy a waste oil boiler for 280 thousand rubles.

Another model worthy of attention is the Danvex B-60 boiler, which operates during mining. It is used to heat a room with an area of 150-200 square meters. m. Device power – 63 kW. The body is made of high-quality heat-resistant steel with a heat-insulating coating. The efficiency of the device is 88%. It can be connected to the boiler. Fuel consumption is 5.6 l/hour.

The Danvex B-60 boiler body is made of high-quality heat-resistant steel with a heat-insulating coating

The model is distinguished by high-quality and professional assembly and stylish design. The unit is easy to operate and maintain. Thanks to the presence of a sealed fuel line, the possibility of oil evaporation and the presence of an unpleasant odor in the room is eliminated. The average price of a boiler is 290 thousand rubles.

A little about safe operation

Heating devices operating during mining are quite dangerous in operation. This must always be remembered.

To avoid trouble, you should strictly follow a few simple rules:

- The room where the heating device is installed must be equipped with effective ventilation.

- The boiler must be equipped with a well-designed and executed chimney that removes combustion products without residue. It must have a damper.

- The passage of the smoke exhaust through the roof is carried out by installing a special casing.

- The boiler must be installed in accordance with fire safety requirements.

- Storing flammable and flammable materials near the heating device is strictly prohibited.

The boiler during testing, like any other heating device, must be treated with care. Carry out all necessary preventive work in a timely manner, then problems with operation and its safety will not arise.

European manufacturers of heating boilers are undergoing testing

Reliable and durable heating equipment is offered by the German company Kroll. Models are characterized by a power of 25-200 kW. Fuel consumption is in the range of 2.1-16.9 l/hour. The boilers are equipped with an inversion combustion chamber, which is located horizontally, and a universal automatic burner. The smoke pipes inside are equipped with stainless steel turbulators, which allows you to regulate the temperature of the flue gases by choosing the pressure level in the firebox. The steel body has a thermally insulating fiberglass casing.

Another German manufacturer Buderus produces low-temperature cast iron heating boilers using waste oil. The devices have a power of 25-100 kW. Most models are equipped with an electronic control system with the option of smoothly adjusting the water temperature in the boiler. Boilers can additionally be combined with water heating tanks to provide hot water supply.

Most Buderus boiler models are equipped with an electronic control system with the option of smoothly adjusting the water temperature

The Spanish company Roca offers a range of heating boilers with a capacity of 58-1744 kW, which can be used to heat a room with an area of 580-17500 square meters. m. The devices are equipped with a reversible combustion chamber. The body is made of sheet steel.

The Italian manufacturer Unical produces boilers with a capacity of 35-1100 kW. The cylindrical firebox with a solid bottom has memory inversion. The device has three gas ducts of the boiler block. Thanks to the short torch, high quality heat transfer is ensured and the level of convection increases.

Large boilers

The only difference between large high-power boilers is that they are made from thicker steel, but the principle of operation is the same as that of devices designed for heating houses.

The lower power limit of these devices is 30 kW, but the upper limit is not limited, so there are heating devices that produce 100 kW or more.

TEPLOCASTO TKS-KA 40 kW

The main difference of this heating device is a three-pass heat exchanger with increased efficiency. Thanks to the third row of smoke pipes located inside the water jacket, the device absorbs more heat.

This increases its efficiency in high power mode, but when operating at low power the risk of condensation in the chimney increases sharply.

This happens due to the lower temperature of the flue gases reaching the chimney, because the additional part of the heat was taken away by the water jacket around the third row of smoke pipes.

However, automatic ignition and operation in start/stop mode compensate for this shortcoming, turning the TEPLOKASTO TKS-KA three-pass boiler into one of the best heating devices of its power (40 kW). Fuel consumption is 1.2–3 l/h, electricity consumption is 0.5–2 kW/h.

The control unit has an automatic start program, according to which the fuel is first warmed up in a bath intended for this purpose, then the air supply is turned on, which entrains oil particles and mixes with them.

When this mixture enters the combustion chamber, it is ignited, constantly monitoring the temperature. If 9 attempts to ignite the mixture are unsuccessful, the device turns off and it can be switched to operating mode only after the causes have been eliminated and the error has been reset.

If during operation of the burner the torch goes out for any reason, then the automatic system is immediately activated , shutting off the fuel supply. Cleaning holes are provided on all sides of the heater to facilitate its maintenance. The volume of the boiler water jacket is 48 liters, the cost is 121 thousand rubles.

POLARUS P12M

This boiler with electric ignition operates in start/stop mode, but a power change mode is also available, the range of which is 10–80 kW.

The device is equipped with a drip nozzle and a low-power air blower (200 W), thanks to which energy consumption does not exceed this value.

Fuel consumption is 1–6 l/h depending on the operating mode. The volume of the water jacket is 35 liters, and the cost of the boiler is 140 thousand rubles.

ZILIM 40

This heating device is equipped with a 40 kW nozzle and is capable of generating thermal energy in the range of 10–40 kW, and the temperature of the exhaust gases, even at minimum mode , is high enough so that condensation does not form in the pipe.

This slightly increases fuel consumption compared to three-pass boilers (3–5%), but extends the service life of the chimney by 1.2–1.5 times with frequent operation in minimum power mode. Fuel consumption 1–4 l/h, electricity consumption 300–1200 W.

Thanks to automatic ignition, the boiler can operate not only at minimum power, but also in start/stop mode, which significantly saves fuel.

If the torch goes out for any reason or ignition fails, the automation activates the ignition device several times , and if there is no positive result, it stops the fuel supply and generates an error signal.

The standard nozzle operates in two power modes (10 and 40 kW), but you can choose a modification with a different burner. The volume of the water jacket is 50 liters, the cost of the boiler with a standard burner is 88 thousand rubles.