In winter, heating a home requires a lot of thermal energy from various sources, which leads to large financial costs. The main wasters of heat are windows.

About 30-40% of it escapes through the glass; it is because of this that the windows need careful sealing. As a rule, all cracks are sealed with silicone or mastic, but this is not always enough. A new way to eliminate a high degree of heat transfer is to insulate windows with a special film.

In appearance it looks like a piece of polyethylene, but the main material is polyester. Thanks to a special production technology, it has a high-molecular structure, which allows it to simultaneously transmit light and retain heat inside the room. It is quite thin, but serves as additional glass, creating an almost invisible thermos effect.

Properties and characteristics:

- The transparent surface allows it to be practically invisible on the window.

- It has practically no specular reflection (the glare is not visible).

- The thickness of the material can be 0.10-0.14 mm and at the same time the indicators can withstand a tensile force within 25 kgf/cm².

- Does not react with household chemicals.

- It is an electrostatic inert material (does not attract dust).

- Prevents the penetration of ultraviolet and infrared radiation into the home.

- The material is completely environmentally friendly.

- It is lightweight and can be subject to thermal shrinkage.

- Produced in various sizes. The most popular are 600×1000 mm, 1200×2000 mm, 1500×2500 mm and 3000×6000 mm.

What is heat-saving film?

Heat-saving (or energy-saving) film is a thin transparent material that consists of several layers.

The film is based on polyethylene terephthalate polymer with a thickness of 80 to 200 microns. A component of the film is a thin metal layer. It is made by sputtering particles of gold, silver, chromium or nickel. The transparency of different types of film varies from 47% to 70%. The price, depending on the constituent materials, starts at 144 rubles and can reach up to 3,000 rubles.

Price

The cost of the material is influenced by several factors, the most important one was mentioned above. The rest are:

- Manufacturer of heat-saving film - German and Polish versions are often more expensive than domestic ones;

- Canvas size - larger materials are cheaper (in terms of size-price ratio).

Countries producing heat-saving films for windows:

- South Korea;

- China;

- Türkiye;

- Ukraine;

- Russia;

- Germany;

- Poland;

- Other.

Most often, the following brands can be embedded in online stores:

- Thermo Tap;

- NANOFILM;

- USB (Ultra SolarBlock);

- ESB technologies (Russia);

- Heat technologies (Poland).

The screenshot below from one online store shows prices for energy-saving (more expensive) window films.

There are, of course, cheaper options. For example, film from the Polish brand “Heat Technologies” can be purchased at a price of 500 rubles per set. There are two types of sets: 1.1 by 6 meters and 2 by 3 meters. The average price per square in this case will be 85 rubles. As a bonus, the set contains a 20 meter roll of tape.

The cost of insulating one window with film

A window measuring 1400 by 1300 mm will require approximately 1.82 squares of film and 5.4 meters of tape. Thus, the cost of thermal insulation with Polish film will be 150 rubles per window.

What types of heat-saving films do manufacturers offer?

Manufacturers offer two types of heat-insulating films:

- films that are glued to the glass surface;

- films that are fixed to the window opening using double-sided tape.

The first type is the most aesthetic and invisible. In this case, the film creates a “third glass”, that is, a thin air layer appears between the window glass and the film, which protects the room from heat loss. The second type of film is effective in the absence of modern double-glazed windows, as it allows you to close the gaps between the glass and the frame.

General information

Self-adhesive insulation for windows - an effective but short-lived solution

Today, many methods of thermal insulation are known. The choice of one method depends on the type of window.

This time you will learn how to make ordinary wooden windows and modern double-glazed windows warmer. In addition, I will talk about how to insulate openings outside the house with your own hands using inexpensive polystyrene foam.

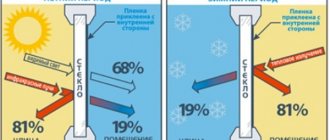

How does heat-saving film work?

The metal layer of the film reflects infrared rays emanating from heating devices, and the heat remains in the room. This layer is practically invisible to the naked eye, so the lighting of the room does not suffer, especially since in winter you cannot do without additional light sources.

In extreme heat, the film has the opposite effect: it acts as an air conditioner, leaving the room cooler than the air outside. An additional advantage of the heat-insulating film is that it strengthens the glass body, making it more durable and does not allow the glass to shatter into pieces upon a strong impact: even if the glass breaks, it remains attached to the film.

Possibility of application of the solution

Polyester is actively used not only for thermal insulation of plastic windows; it is used to create reflective, tinted, sun-protective, and anti-glare surfaces. High quality and technical indicators contribute to the spread of energy-saving films in the following areas:

- for additional insulation of glass facades:

- when arranging greenhouses and greenhouses;

- for the purpose of insulating balconies and loggias;

- during the finishing of transparent roofs and natural solariums.

Thicker variations are often used to retain heat in rooms during construction and renovation.

When is it advisable to install energy-saving films?

With all its positive qualities, thanks to advertising campaigns and the temptation to significantly save on electricity costs spent on heating or air conditioning, heat-reflecting film is not always a panacea. This is due to a number of their features.

If the use of energy-saving film for floor insulation is beyond doubt and is completely justified, then you should use it on windows only after you have weighed the pros and cons. And for this you should know, before you buy a film, which is very expensive, what its physical qualities are and how real the properties of such a “miracle” film declared by the manufacturer are in reality.

To understand the mechanism of action of energy-saving films, let us briefly consider their physical properties.

Thermal reflective film is a transparent polymer material several microns thick, onto which, using “nano” technology, thin layers of rare earth elements (such as gold, silver, platinum, or their oxides, or ceramic components containing such metals) are applied.

The coating process occurs either in a vacuum or in an atmosphere of inert gases (usually argon) by plasma evaporation of the metal, followed by the deposition of its vapor on the base in a layer not exceeding several nanometers.

Several layers are applied to the base in a certain sequence, due to which the reflectivity for certain thermal, light and UV waves changes relative to the transmittance of the window glass. Manufacturers keep the specific content of metals and ceramics used to create the “energy-saving” effect in the strictest confidence.

The only characteristics that you can familiarize yourself with when choosing a particular film are the light transmission coefficient, the heat reflection coefficient and the wavelength range in which this or that film “operates”.

The bulk of solar radiation in the thermal range at the Earth's surface lies in the range of 700-1400 nm. Thus, the “working” range of the energy-saving film should also be within these limits. The second condition that makes it comfortable to use film in a residential area is the light transmission coefficient. If it is high, such a film is practically invisible on the windows and does not affect the overall illumination of the room.

But if the film is tinted in any color, or has a “mirror” coating, then you will have to come to terms with the fact that there will be early twilight and late dawn in your apartment, therefore, you will have to use artificial lighting more and talk about some kind of energy saving there won't be any point.

The third significant factor when deciding to use energy-saving film is the presence of indoor plants in the house.

Energy-saving films not only reflect the flow of thermal energy tending to leave the room, but equally prevent the penetration of UV radiation through windows. And it is vital for the normal functioning of the body (in particular, for the synthesis of D vitamins in the body) and for plant photosynthesis. Lovers of indoor plants will either have to say goodbye to their favorite plants, which will gradually fade away in the absence of UV rays, or immediately after gluing the film, organize artificial lighting for them for 12-14 hours. In this case, there can be no talk of any energy saving.

If you nevertheless decide to stick heat-reflecting film on your windows, then it will be useful for you to know about its positive qualities.

High-quality energy-saving films can reduce heat loss through glass windows in winter by up to 30%.

Thus, a double-glazed plastic window will have the same thermal insulating properties as a triple-glazed one. In the summer, energy-saving film can absorb up to 70% of the thermal energy of the sun's rays and thereby maintain a comfortable temperature in the room without the use of air conditioners. But this is only true for windows oriented in a southerly direction and only for the summer period. In spring and autumn, when the heating is either already turned off or not yet turned on, energy-saving film prevents heat from penetrating into the rooms from outside, and the room becomes cold and damp.

A film glued to glass slightly increases its strength. Some manufacturers claim an increase in the strength characteristics of window glass to 6-8 kg/cm2. Glass becomes more difficult to break. And if this does happen, do not be afraid of the scattering of fragments, which will remain in place, fixed with film.

When using energy-saving film due to the metal content in its composition, it has a good shielding effect. As the manufacturers note, this prevents the possibility of unauthorized removal of information from audio and electromagnetic sources.

For users prone to spy mania, this can be a compelling argument for using film in your apartment.

True, manufacturers modestly keep silent about the fact that the performance of cell phones, which simply stop receiving a signal from the repeater, drops in the same proportion, just like in houses covered with metal siding.

And if, lastly, in order to use a cell phone, you need to go to the window, then in the case of a window covered with energy-saving film, on the contrary, you need to move away from it.

Installation of energy-saving film

Energy-saving films from different manufacturers differ in the method of their installation. They (in most cases) are heat-shrinkable - which, after being fixed to the glass, require treatment with hot air from a hairdryer, or applied to a damp soapy surface, followed by gluing the film sheet to the glass surface as the liquid evaporates. Depending on this, the methods of gluing them to the window are different.

Thermoresistant paper

The shrink film is applied to clean glass, washed with window detergent, thoroughly freed from dust and fibers and degreased with alcohol or gasoline (“Galosh”).

To do this, double-sided tape is glued around the perimeter of the frame on the room side. From a roll of energy-saving film or from a sheet folded in half, a blank is cut out on a horizontal surface, 2 cm on each side larger than the size of the glass on which it will be applied. Then the protective layer of paper is removed from the tape at the top of the window and the top layer of film is glued. You should not pull it too hard.

After this, if you stick the film alone, gradually remove the protective layer of paper from the left and right edges of the glass and, pressing the film from the middle to the edges of the glass, stick it to the freed area of the tape. It is not worth freeing all the tape, since it will be almost impossible to remove the film accidentally stuck to it from the tape and a piece worth 1000-1500 rubles will only have to be thrown away. So, gradually freeing the adhesive tape from the protective paper, the film is glued along the edges of the glass, last of all, the protective paper is removed from the adhesive tape located below, and the film is glued along the entire perimeter of the glass.

After this, use a sharp retractable stationery or construction knife to trim off the excess film that is not stuck to the tape or the tape that is not covered by the film. If this is not done, then dust will stick to it and over time your window will acquire a “mourning” frame.

The final stage of the sticker is treatment with hot air from a hairdryer. Try not to bring the hair dryer close to the surface of the film and do not hold it in one place for a long time. The film must be heated evenly over the entire surface. The completion of gluing will be indicated by a change in the color of the film and its complete transparency.

Wet method of film application

It is also preceded by thorough washing of the window and degreasing it with gasoline or alcohol. The film for gluing must be cut exactly to the size of the glass, without any reserves at the edges. After the film is cut, the window glass must be thoroughly moistened with a soap solution (any uncolored shampoo or detergent).

Moisten the surface of the film and apply it to the surface of the glass, applying the top edge and smoothing it from the center to the edges and stick it over the entire surface of the glass. The film glides well on a damp surface, so you can adjust its position on the glass. After adjustment, use a plastic or rubber window cleaning spatula with an absolutely even edge to squeeze out excess moisture from under the film. This must be done from the center to the edges, from top to bottom.

Particular attention should be paid to expelling air bubbles, since the film will not stick in these places.

For reliability, you can roll the glued film with a small soft rubber roller. As the solution dries, the film will straighten, stretch and stick tightly to the glass.

What not to do: common mistakes

When gluing glass, it is very important to follow the process technology. Any mistake made at the preparation stage or during pasting can significantly worsen the result or completely negate it.

Possible mistakes:

- Incorrect temperature. The permissible temperature range at the time of work is from +5°C to +40°C. This means that it is advisable to glue the film in the warm season. In case of urgent need for pasting in winter, the window sash should be dismantled and moved to a warm room.

- Working in a dusty room. Before starting the process, you should not only wash the windows, but also do a wet cleaning of the entire room. Dust particles settling on the glass prevent the polymer from fixing. In addition, the window will take on a dirty appearance that cannot be removed by washing.

- Incorrect measurement. Undersizing is especially dangerous, since in this case there will be an uncovered gap between the edge of the polymer sheet and the window frame that cannot be corrected. To avoid this, you should cut out pieces of film with a small margin of about 1–2 cm on each side.

- Excessive sheet tension or poor straightening. In the first case, unexpected shrinkage may occur after heating; in the second, ugly wrinkles and folds form.

- Damage to the plastic surface of the frame when cutting off excess. It is recommended to cut the sheet with a sharp knife, but without pressing. When working with a blunt tool, you have to exert force, and the likelihood of scratches on the plastic increases.

Pros and cons of the material

Thermal insulation for windows has been used for a sufficient time; positive qualities can be highlighted based on real customer reviews:

- in winter it is possible to save heat by more than 30%;

- in summer, energy consumption is 25% less, thanks to the saving mode of the air conditioning system;

- easy to glue;

- acoustic and electromagnetic channels in the room are limited;

- some models are capable of retaining more than 90% of heat in winter;

- thanks to the delay of ultraviolet radiation, furniture upholstery does not deteriorate;

- increases the efficiency of PVC construction, retains heat, makes watching TV and working on a personal computer comfortable.

Negative sides:

- stretching after some time;

- if you violate the recommendations for gluing, it will come off;

- instability to mechanical damage. You should not work with sharp, cutting objects near the window. If the integrity is violated, the energy-saving properties are leveled.

Minor damage can be repaired with tape. But product performance will deteriorate.

Variety

The film differs in the type of pasting. The market offers three varieties of this product.

- Self-adhesive film. This product is easy to stick on any window. The main thing is to prevent the formation of bubbles and jammed areas when working with it. To do this, it is better to use a thick fabric and smooth out defects as necessary.

- Thermal film for window insulation. To secure it you will need thermal tape and a hair dryer. The product is attached with thermal tape, so that there is a gap between the film and the glass. Then all this is heated with a hairdryer and the product fits perfectly on the glass.

- Film without adhesive surface. This product is very easy to use. Attaches to window glass with a simple soap solution. Somewhat reminiscent of car tint. Despite its low cost, it is in no way inferior to the above-mentioned heat-saving products. It also retains heat and has a long service life.

Advice! Experts advise window coverings to be carried out exclusively in autumn or winter.

Do-it-yourself insulation of windows with thermal film

Before installing the “Third Glass” film on a plastic window, you should prepare tools such as a stationery knife, scissors and a household hair dryer. These simple tools are available in almost every home. It is easier to install with two people, but you can do the job alone. For detailed video instructions on installing heat-saving film in an apartment, see the end of the article on the website.

Do-it-yourself insulation of plastic windows with thermal film

Instructions for thermal film “Third Glass”

Start insulating roof windows with a small window opening. The surface of the frame should be treated with a degreasing compound and dried. Next, double-sided tape, included in the kit, is attached around the perimeter of the glass unit; The film in the package is folded in half; it should be separated and cut out. Cutting is done in accordance with the size of the window, taking into account the fastening of the thermal film with tape. Check the dimensions of the film by applying it to the window opening being processed; Remove the protective strip from the tape and carefully glue the film to the double-sided tape

Do not pay attention to possible folds, the main thing is that the film is securely attached around the entire perimeter of the frame with double-sided tape; Blow the film with hot air using a construction or household hair dryer; under the influence of temperature, the material will shrink. As a result, the heat-saving film will stretch and become perfectly smooth over the entire area.

Stages of installing heat-saving film on a window

Insulation of plastic windows with heat-saving film

An important advantage of this material is that it increases the strength of the glass unit - the glass will not scatter in different directions into small pieces, which will reduce injuries. The film can be used to insulate wooden and plastic frames; the effect of the material can be compared to installing a double-glazed window. The film reduces the heat transfer of energy from a warm room to a cold one near a double-glazed window.

We will give some more important recommendations based on reviews. When insulating windows for the winter, it is better to install thermal film in October-November. It is recommended to remove it in May, as daylight hours increase. If the film accidentally breaks during installation, do not be upset - the tear can be quickly repaired using ordinary tape.

Changing the seal

It is possible to insulate PVC window blocks by replacing the rubber seals. A seal is placed between the sash and the frame in plastic windows. Its shape and color are individual for each manufacturer, but these parameters only affect the aesthetic qualities of the structure. The main purpose of a soft and flexible seal is to insulate windows. Thanks to this, the plastic doors fit tightly without forming gaps.

Due to cold and constant use, the sealing rubber becomes rough or cracks. You can replace it yourself. After such a simple repair, you need to readjust the fittings.

A special seal will ensure a tight fit of the PVC sashes and eliminate drafts

Thermal insulation of PVC windows with thermal film

PVC windows, which have an additional thermal insulation layer as a heat-saving film, are the most durable. Even if there is a strong blow, the glass will not shatter into small pieces, but will only be deformed. This ensures maximum safety. Insulation of plastic windows is also carried out in some cases.

Although the windows have plastic frames that are additionally insulated with rubber seals, the glass still allows cold air flow into the room. Even owners of double-glazed windows will not be able to obtain ideal thermal insulation. Therefore, in this case, it is most appropriate to use film as a “third glass”.

Installation instructions for thermal film

Instructions:

- Most thermal films have a self-adhesive backing, but some products will stick to the glass due to certain adhesive conditions.

- Before installation, the glass surface must be prepared. Preparation includes thorough window cleaning. After you have washed them, do not forget to dry them. Additionally, use a degreasing solution for treatment.

- After this, the installation procedure for the heat-saving film begins. Apply it carefully; when wrinkles appear, you need to smooth them out using a soft rag. Or you can use a special tool that looks like a car window brush.

- Once you have smoothed out the wrinkles on the surface of the glass, the remaining material must be removed. This can be done using a knife designed for installation.

Rubber or foam insulation

You can get rid of cracks in frames much easier and faster by using special window seals. They can be inserted into a special groove, have a sticky base, or be produced without either. They are made from a variety of materials, but rubber and foam seals are considered the most popular.

Rare shot: Viktoria Isakova showed her grown-up daughter from Yuri Moroz (new photo)

If there is little snow, there will be no harvest: December 16 is Ivan the Silent Day

A student at the Vietnam Police Academy shared how she takes care of her facial skin.

Seals are attached around the perimeter of the window frame or at the junction of the sash. This allows you to close the cracks and prevent cold air from entering the room.

Foam seals are cheaper than rubber ones, but they are suitable for one-time use. The material dries out and begins to leak air. The rubber seal is more expensive, but can be used for several seasons.