Insulating a house with sawdust and lime will help significantly save on costs and increase thermal insulation properties.

Method No. 1

To carry out the work, it is necessary to prepare the following materials:

- sawdust, lime, cement, antiseptic for wood processing;

- container for mixing ingredients;

- shovel, stirrer, and watering can.

The thickness of the insulation layer will depend on the terrain, weather conditions, and operation of the building. If the building is used as a summer house, only in the summer, then the layer of insulation for the attic should be up to 25 centimeters, and for the walls - 15. But if you live permanently in the house, apply a layer of insulation up to 30 centimeters.

To ensure the safety of the house from fire, all wiring must be covered with metal sleeves.

After this, they begin to prepare the insulation mixture. To get the composition right, you need to take 10 parts of sawdust, one of lime, and one of cement or gypsum. All components are mixed and treated with boric acid or any wood antiseptic. Then add about 10 buckets of water (per 10 buckets of sawdust). After kneading, the mixture must be squeezed tightly in your hand, and then make sure that it does not crumble.

Then the composition is applied to areas that need insulation, compacted, and left for two weeks. After this time, check the voids; if there are any, they must be filled with sawdust. If there are no voids, you can proceed with further finishing.

Method number 2

In order to prepare the composition in the second way you will need:

- sawdust, clay, lime, water;

- mixing container;

- shovel, stirrer, and watering can.

To make an insulating mixture, you need to take 10 parts of sawdust, 5 parts of clay, 1 part lime, 7 parts water. The clay is poured with two parts water, it should be completely limp, the solution should resemble thick sour cream and not contain lumps. Then the sawdust is mixed with lime and added to the diluted clay. All components are mixed well, and the rest of the sawdust is gradually added. Then an ordinary stick is placed into the solution; if it remains standing and does not fall, then the mixture is ready for use. If the composition turns out to be liquid, then it must be left for 24 hours so that the moisture evaporates.

What is worth knowing when insulating with sawdust?

The sawdust that remains during wood processing is NOT suitable for insulation in its pure form. The fact is that they must first be subjected to special treatment - coated with an antiseptic, dried well and mixed with slaked lime (it is necessary to protect the material from harmful rodents).

The proportions in this case will be as follows. 1/5 of the total mass will be lime, and the rest will be sawdust. To work, you will need to lay down some kind of shield, made of wood or metal, pour material onto it and mix thoroughly using a shovel. Then the resulting mixture is poured between floor joists, ceiling beams, etc. The thickness of the backfill layer should be approximately 25-30 centimeters .

In addition, we must get rid of the free-flowing properties of sawdust. If this is not done, then over time the material will sag, losing its thermal insulating characteristics. To prevent this, you must do the following: mix sawdust (85%) with lime (10%) and gypsum (5%). Pre-drying is, of course, not required here, but it is worth considering that gypsum hardens quite quickly, which is why the material should be prepared in small “portions” so that it does not harden earlier than necessary. If there is no lime, then lime dough is excellent instead, but you need to use it in half the amount. In turn, gypsum can be easily replaced with cement.

Read about ways to insulate floors in a wooden house here

Types of sawdust

Sawdust is a product of wood processing, and its shape depends on the type of technological operation as a result of which it was formed:

- Small trash. It is formed when cutting wood. The parameters of the dust strongly depend on the characteristics of the saw.

- Chips (3-5 cm in size). It is obtained by drilling and planing.

Depending on the method of wood processing, the fractional composition of sawdust also changes. Fractions usually go on sale in the range of 5-30 mm. Being highly environmentally friendly, sawdust is very inexpensive. In addition, they are lightweight and have excellent sound and heat insulation properties. Sawdust of various species is further used:

- ate;

- pine trees;

- oak;

- ash

What to mix sawdust with

When insulating an attic or floor with sawdust, it is important to choose the right binding component. Basically, clay, gypsum, cement or lime are chosen for this purpose; each substance has specific properties that should be remembered when choosing.

Sawdust cannot be used in its original form; it can cake, forming empty spaces in the insulating layer; rodents and insects often settle there. An additional component disinfects the sawdust layer and makes it more convenient for installation.

Lime

Lime helps prevent the formation of pathogenic microorganisms and protects the insulation from rot and other problems. It is a strong alkali, so insects will never grow in the sawdust layer with lime. It is used to prevent the entry of beetle and rodent larvae, and also as a binder, but in this capacity lime is noticeably inferior to other components. Nevertheless, it is always recommended to add lime to the sawdust layer.

How much cement is needed in wood concrete?

High-quality materials include wood concrete (sawdust concrete), which can be used to form the walls of any room. The composition of wood concrete includes lime, sand, cement and sawdust. Only in a certain ratio. Thanks to this composition of materials, it has a large number of advantages and is popular in the construction of residential premises. Now let’s take a closer look at how much cement to put in wood concrete!

a house made of such material will be very warm

How to insulate a ceiling with sawdust?

Insulation of the ceiling of a private house with sawdust is always done from the outside . Dry sawdust is rarely used in its pure form. They are mixed with other materials to improve not only the thermal insulation properties of the material, but also to protect it from moisture, fungus, mold, rodents and insects. There are antiseptic and fire-retardant substances on sale.

Sawdust is poured onto a plastic film spread under a canopy and treated with an antiseptic , then, after drying, with a fire retardant solution . If the beams and joists of the attic floor were not processed during the construction process, then they should also be processed.

Between the joists, thick cardboard or Izospan with the smooth side facing the insulation. Sawdust is covered in compacted layers. The thickness of the backfill is made at the rate of 150-200 mm , provided that the air temperature does not fall below -20 degrees; a decrease in temperature by 1 degree requires an additional addition of 2-3 cm of sawdust.

Insulation of the ceiling in a private house with sawdust and the height of the layer for harsh conditions reaches 350-400 mm , so it is necessary to increase the existing logs in height with additional boards. It is better to mix sawdust with lime in a ratio of 1:5.

This backfill method is suitable for light wooden floors . If you insulate the ceiling with clay and sawdust, the density of this mixture will be higher, and therefore it is used for durable ceiling structures, where the ceiling is made with tongue-and-groove floorboards or thick overlapping boards with overlapping cracks, as was done in the old days.

Features of using sawdust as insulation, its advantages and disadvantages

Sawdust is a waste product from the forestry industry, but it is an environmentally friendly material and does not emit caustic substances. Since ancient times, sawdust has been one of the oldest materials used as insulation.

Today, new types of insulation are replacing the material under study, but many continue to use it because they know its performance characteristics and its noticeable low cost.

Sawdust can be thrown in loose form into the wall frame

They are used to insulate the walls of small houses, bathhouses and gables in the attic. These waste products from the timber processing industry can be used at any stage of construction. It is not necessary to fill up the wooden dust or put it in bags on the frame; they can be thrown into the finished walls from above and compacted well. To increase the performance characteristics, sawdust is often impregnated with various antiseptic compounds, which prevents the appearance of insects in the insulation.

Sawdust is a flammable and easily ignitable material, so many construction experts recommend pouring this material into the wall using metal plates and partitions that will section the filling zones, thereby creating compartments. An electric cable mounted on walls insulated with sawdust must run in a special metal sleeve or corrugated pipe and have increased protection.

Advantages of sawdust

For many years, sawdust, as insulation, dominated among all types of thermal insulation.

They were used in different forms. Some people poured clean wood scraps, others mixed sawdust with glue or cement, thus creating blocks with which they later laid out the wall. Over the years, this material has been used in various forms to insulate rooms. Sawdust, like any other building material, has its advantages and disadvantages. The first group of characteristics includes:

- Environmental friendliness of the material. The composition does not contain harmful components that could have a negative effect on the human body. If you intend to create blocks from sawdust, then for these purposes you can use clay and lime as additional binding components.

For moisture resistance, silica gel is added to sawdust.

- Low cost. Sawdust is often obtained free of charge at various wood processing enterprises. Costs may only be due to shipping and handling costs.

- Long-term operation. Mankind, through long operational experience, has determined in what form it is best to use this material, therefore, before filling the walls, sawdust is specially moistened and dried several times. In recent years, antiseptics have begun to be added, thereby creating a barrier to the penetration of insects. Bags of silica gel are placed in the filled cells of the walls with sawdust to completely remove moisture from the heat insulator.

- No special preparation required. Wooden waste is filled manually without the use of special tools and equipment. The material is filled in freely, after which compaction is performed.

- Low thermal conductivity. Due to the fine fraction, this raw material has significantly lower thermal conductivity compared to boards or timber due to the absence of solid wood fibers.

Waste and shavings from wood-containing boards are not used as thermal insulation material, since the composition of such products already implies the presence of recycled wood and non-natural binding components.

Disadvantages of sawdust as insulation

Unfortunately, this insulating material has more disadvantages than its analogues, but over a long period of existence, measures have been invented that allow minimizing all negative factors.

The disadvantages of sawdust as insulation include:

- Increased fire hazard. Sawdust is a flammable material, but in order to partially avoid the problem and reduce the risk of fire, additional membranes made of tin or galvanized steel are created in the wall where the sawdust will be poured.

- Attracts living creatures and fungus. Since sawdust is a natural product, it can harbor small rodents, insects and mold. Today, this problem can be easily solved with the help of appropriate drugs that are harmless to the human body.

Soak the sawdust before installation

As you can see, all the main disadvantages of sawdust as an insulating material can be partially covered with the help of special preparations, materials and folk experience in using wood shavings.

Comparison of insulation with sawdust and other materials

We have already talked about the two main advantages of sawdust insulation - such work is inexpensive and mice do not grow in this material. However, they also have other advantages - they allow water vapor to pass through better than any insulation, so their impact on the microclimate of breathable houses is minimal. In addition, even a mixture of sawdust and gypsum is less sensitive to high humidity and falling dew than mineral wool. A mixture with PVA is many times more sensitive to high humidity and dew than mineral wool and is comparable to polystyrene foam, polystyrene foam and polyurethane foam.

Sawdust has another significant advantage, which manifests itself only in Russia, where the building materials market is filled with fakes and counterfeits. By taking free or buying waste from sawing wood at a woodworking plant or sawmill, you can be sure that they will not sell you a fake or counterfeit product, and that the material will not be toxic or poisonous. But this is especially important for bedrooms and children's rooms, so you can put up with the not so many shortcomings of this material.

In all other respects, wood sawing waste is slightly inferior to modern materials. Such insulation requires, albeit not much, but still more effort, because modern materials are supplied in the form of ready-to-use products, but the insulating solution or mixture still needs to be prepared. In addition, in terms of thermal efficiency, a sawdust insulation layer 10 cm thick corresponds to a layer of mineral wool 8 cm thick or a layer of polystyrene foam 6–7 cm thick. In cases where sawdust cannot provide the specified efficiency at a certain layer thickness and it is impossible to make the layer thicker, others are preferable materials. If you can increase the layer, then they are in no way inferior to any other material.

In terms of sensitivity to fire and danger during a fire, sawdust with a binder (with the exception of PVA) is comparable to mineral wool and many times superior to polystyrene foam, polystyrene foam or polyurethane. After all, it is very difficult to set them on fire, but if the house caught fire so much that the heat ignited the insulation, then such a fire will destroy the house with any insulation. But during a strong fire, sawdust does not emit toxic substances, which cannot be said about any other insulation material except mineral wool.

Sawdust concrete

This is a durable material whose composition resembles classic concrete, but fine sawdust and lime are added as fillers. The ratio of components may vary. The choice of option is made taking into account the requirements for the strength of the material. For example, to produce high-density sawdust concrete, you will need:

- 200 kg of cement;

- 200 kg of sawdust;

- 500 kg of sand;

- 50 kg of lime.

The number of components can be reduced/increased, but it is important to maintain the proportions. To influence the ability of wood chips to absorb moisture, they need to be soaked in lime milk, then in liquid glass. At the next stage, the sawdust is dried. This is necessary so that the wood chips do not contain moisture at the time of joining the components.

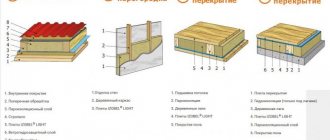

Sawdust floor insulation technology

The way floors were insulated in the old days is still good today. The process is carried out in the following sequence:

- if necessary, the floors are dismantled;

- floor beams are treated with fire retardant compounds;

- skull blocks made from remnants of reclaimed wood are nailed to the floor beams;

- boards are laid on the skull blocks, and since this is a subfloor, low-grade wood can be used; all materials must be treated with fire retardants and antiseptics;

- covering material is spread on the boards, which, unlike polyethylene film, is vapor permeable, and sawdust is poured in a layer about 8–10 cm high;

- to increase the antiseptic properties of the heat insulator and increase waterproofing, they are filled with a weak aqueous solution of lime, lime milk;

- the material is allowed to dry for 24 hours, during which time the insulation layer will sag by 2-3 cm;

- finishing floor is laid.

This method is suitable for thermal insulation of ground floor floors. If it is intended to insulate interfloor ceilings, the thickness of the thermal insulation is approximately tripled, to 20-30 cm.

Option with a mixture of gypsum and lime

The first step is to prepare a mixture of sawdust, gypsum or cement, and lime.

The future insulation is sprayed with an antiseptic, boric acid, using a watering can. The mixture is mixed with approximately five to ten liters of water. Check the humidity yourself - if the mixture compressed into a lump does not crumble, then it is ready.

Next, the resulting mixture is filled with areas that require thermal insulation, thoroughly compacted and left to “ripen.”

After two weeks, the heat insulator is inspected for the presence of voids. If necessary, the process is repeated.

In addition to the homemade mixture, there are also building materials made from sawdust: chipboard, sawdust granules, concrete, wood concrete.

Chipboard floor insulation

Particle boards are wood chips that are mixed with resin during the production process and hot pressed.

The thickness of the floor slabs is calculated to be within 18-20 mm. This technology is usually used for concrete floors. The concrete surface must be completely dry. Warming is carried out as follows:

- First, waterproofing is installed. To do this, the surface of the concrete base is covered with a thick layer of polyethylene film, which protects the insulation material from moisture.

- A pre-prepared and treated chipboard sheet is laid on it, holes are drilled through it in the floor and secured to the floor with self-tapping screws. The drill must have a pobedite tip. The sheets are fixed along the perimeter and along its surface, dividing it visually into squares.

- Chipboard sheets are laid in rows, and, taking into account the possibility of their deformation from humidity or temperature changes, it is recommended to leave gaps between the wall and the rows.

- To process the joints, use a construction mesh, onto which putty is applied, mixed with oil paint, wood mastic or putty prepared by mixing sawdust with PVA glue.

Finally, all irregularities are eliminated by sanding the seams with fine sandpaper.

Plaster mortar - proportions

Plastering is an inseparable stage of surface treatment of walls and ceilings. Along with protective functions, it plays the role of decoration, increases fire resistance and is used as the main insulator. In addition, plaster makes it possible to remove minor imperfections on surfaces and connecting seams. The strength and fundamentality of the plaster layer mainly depends on the correct composition of the mixture.

Types of plastering solutions

Before preparing the plaster mixture, you need to know the microclimate of the room. Thus, for the treatment of external walls, a cement or cement-lime mixture is often used; if the climate is quite dry, then it is recommended to use plaster with the addition of lime for the treatment of external walls. But for moderate microclimates it is most often used for interior spaces.

Depending on the direction, plasters are divided into the following types:

- Cement. It is characterized by a slow increase in strength; the components set within 12 hours after adding water to the mixture. It is characterized by very high strength in comparison with other types of plasters.

- Clay. Used at home for plastering wooden surfaces.

- Limestone. To reduce the setting time and give the greatest strength, the lime plaster mixture is sometimes supplemented with building gypsum.

- Gypsum is also used separately. It must be remembered that complete hardening of the solution occurs after 30 minutes, and after 4 minutes setting occurs.

- In a mixed mortar for plastering surfaces, several binders are used (cement and lime, lime and gypsum, etc.).

- Special plaster. Depending on the application, the desired component is added to the mixture.

Sand is often used as a filler to prepare the solution. River sand is most suitable for making a mixture for plaster. Sea sand is characterized by excess salinity, which affects the strength of the mixture, and sand from ravines is, for the most part, very dirty

Composition and proportions of plaster

To make the mixture you need a binder, filler and water. In some cases, it is necessary to use additives to obtain a mixture of the desired qualities. For example, to obtain a water-repellent mixture, it is necessary to add calcium nitrate to standard parts of cement plaster.

Since plaster is often applied in 3 layers, the structure of the mixture is different for each layer. For spraying, a mixture with a low amount of binder is used, for the production of a primer layer, the amount of binder is slightly increased, and for the finishing layer, the maximum possible amount of binder is used. In this regard, the finishing layer is distinguished by increased strength.

When applying the plaster in one layer, it is advisable to use the average of the listed ratio of binder and filler. Otherwise, the mixture will not be soft enough and may come off the work surface.

In general, solutions for plastering surfaces have different compositions. So how to prepare a solution for plaster?

How to properly perform insulation

To backfill, you need a solution, which is prepared as follows: ten buckets of sawdust, one part of cement and half or one bucket of lime.

After this, an antiseptic is diluted in water and you need to spray this water using a garden watering can. After the mixture is mixed, you should try to squeeze it with your hand. If the lump does not crumble and the water does not flow out, then the mixture is ready. Then the vestibule is filled with sawdust in layers, and the required places in the required amount. The blocks ripen for at least two weeks, and the room must be regularly ventilated. You need to wait a couple of weeks after the filling has taken place and make sure that all the voids are filled and, if necessary, the missing ones are filled up.

Sawdust makes a good plaster: you need to add cement, clay, water and newsprint. This plaster is used for interior work. Also, sheets of the desired size are made from this mixture, they are made in molds, they need to be compacted and given time to ripen. Sheets are used for thermal insulation at discretion.

Areas of application

After applying “warm” plaster based on polystyrene foam granules using the “wet light method” and comparing data on insulation with mineral wool, extruded polystyrene foam and polystyrene foam, the following conclusions emerged.

Warm plaster for interior work

Under the wall, the insulation of which will be done with “warm” plaster, a more powerful foundation is needed, since the solution used is more than ten times heavier than other insulation materials. The same thermal conductivity values can be achieved with a layer of “warm” plaster of 100...200 millimeters, which means it must be applied on both sides.

Criterias of choice

Warm plaster for external use has special requirements:

- environmental friendliness: the components included (lime, gypsum, cement, etc.) do not emit harmful substances;

- compatibility when used with other facing materials;

- biological stability and moisture resistance;

- property of not igniting and not sustaining combustion.

Attention! According to these criteria, warm facade plaster with mineral fillers (vermiculite, perlite, foam glass), belonging to the NG class (non-flammable) and not absorbing moisture, is actively used for exterior finishing. At the same time, heat-insulating finishing material based on expanded polystyrene foam, on the contrary, is flammable and is classified in group G1. For the same reasons, only internal surfaces are finished with solutions containing additives that reduce the thermal conductivity of the finishing layer (sawdust, cellulose pulp).

Conclusion

Of all the options, wood chips are the most environmentally friendly material. It has good thermal conductivity and sound insulation properties, which means it can be used along with technologically advanced analogues. If you correctly approach the improvement of the properties of this material, you can achieve increased fire resistance, moisture resistance, and extend the service life.

This becomes possible thanks to treatment with antiseptics and fire retardants. In addition, proper installation will help reduce the intensity of heat outflow from the room when using sawdust: layer by layer with a tamper.