Until recently, heat loss through the foundation was not taken into account; it was simply compensated by increasing the heating intensity. However, the constant rise in energy prices forced a change in the approach to the problem of insulation. Nowadays, among thermal insulation methods, the first place in terms of quality and reliability is occupied by insulating the foundations of houses from the outside with penoplex foam.

What is Penoplex

Penoplex is made from polystyrene, which is heated and foamed (extruded) with a mixture of freon and carbon dioxide. After processing, a material with a structure of granules 0.1 - 0.2 mm in size is obtained. Penoplex is used to insulate wooden floors, attics, pipelines, airfield runways, and external foundation walls. Each brand is given properties depending on the conditions of use.

Penoplex is produced in the form of rectangular slabs measuring 60x120 cm, 2 - 10 cm thick. Each slab has a tongue-and-groove locking part. This simplifies the installation of insulation and reduces heat loss at joints.

The following brands are produced for insulating foundations with penoplex:

- Penoplex - 45. The densest insulation that can be laid under monolithic, prefabricated, slab foundations.

- Penoplex - 35 (also known as Penoplex Foundation). Used for insulating monolithic and prefabricated foundations vertically and horizontally.

Rectangular foam boards are connected using tongue-and-groove locks

Advantages and disadvantages

Due to its advantages , penoplex is the optimal option for insulating the foundation of both a private house and a multi-story building:

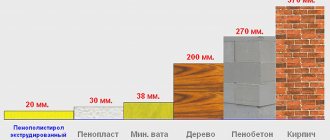

- The lowest thermal conductivity value among thermal insulation materials.

- Withstands loads up to 27t/m² without damage.

- Moisture absorption is no more than 0.6% per month of volume during the service life. Therefore, in addition to insulation, it performs waterproofing functions.

- Consistency of characteristics at temperatures in the range - 50 - + 75⁰C.

- Light weight makes it easier to install insulation and does not overload the foundation.

- Penoplex insulation does not develop mold, mildew, or rot.

- High resistance to aggressive substances contained in groundwater.

- Environmentally friendly material.

- Service life up to 50 years.

The main disadvantage of penoplex is considered to be low fire resistance (class F4). However, contact with open fire is impossible, since after installation the insulation layer is plastered.

Based on the above, we can conclude that penoplex has all the advantages of high-quality insulation.

Specifications

The main difference between the characteristics of Penoplex Foundation thermal insulation and the parameters of other product lines made from extruded polystyrene is increased compressive strength . The material is able to withstand pressure up to 27 tons per 1 square meter of area without loss of performance.

Detailed information is presented in the table:

| Name | Test method | Dimension | Index |

| Density | — | kg/m³ | 29—33 |

| Compressive strength at 10 % linear deformation, not less | GOST EN 826-2011 | MPa (kgf/cm2; t/m2) | 0,27 (2,7; 27) |

| Water absorption in 24 hours, no more | GOST 15588-86 | % by volume | 0,4 |

| Fire resistance category | F3-123 | Group | G4 |

| Thermal conductivity coefficient at ( 25 ± 5 ) °C | GOST 7076-99 | W/(m×°K) | 0,030 |

| Operating temperature range | THAT | °C | —100 … +75 |

The insulation does not contain fire retardants , so it cannot be used in places with elevated temperatures .

Read here about the characteristics of other types of Penoplex.

How to insulate correctly: from the outside or from the inside?

For maximum protection from cold, water, and swelling of the soil, the foundation of the house is insulated from the outside. It is better to carry out the work at the construction stage, so as not to have to do excavations later. The advantages of external insulation include:

- protection of the foundation from freezing;

- prevention of concrete cracking during freezing/thawing;

- protection of waterproofing from mechanical damage;

- increased resistance to temperature changes;

- creating a favorable microclimate in the basements and ground floor;

- shifting the dew point, which prevents the appearance of dampness on the walls due to condensation of moisture vapor contained in the air.

With the internal method, only the room is insulated, and the foundation remains unprotected from the adverse effects of the external environment. Through it, the cold will penetrate the walls of the first floor.

Briefly.

Insulation from the outside maximizes the protection of the foundation from cold and water. Internal insulation does not protect the foundation from external factors, which leads to its gradual resolution.

Penoplex installation rules

Thermal insulation will be of high quality only if you follow the basic rules for its installation:

- Before carrying out work, clean the base, repair holes, cracks or other defects.

- Install two-layer waterproofing using coating and roll materials.

- Join the elements with a comb into the selected quarter, seal the seams with foam.

- If necessary, cut the slabs with a knife or saw.

- Fix the material in the underground part of the structure only with water-based glue or mastic, since drilling holes for dowels is prohibited in order to avoid violating the tightness of the waterproofing.

- If you need to lay 2 layers of heat insulation, install them with offset joints to avoid cold bridges.

Insulation methods

Depending on the tasks, penoplex insulation is performed in three ways:

- The horizontal insulation method is used for thermal insulation of the base of strip and slab foundations. A horizontal layer is also laid along the walls of the house to protect the soil from freezing and to reduce the amount of heaving. Near shallow foundations, penoplex is laid at the level of the sole. In other cases, above the freezing point of the soil.

- The vertical method is used to insulate the outer walls of foundations from the base to the top edge. Penoplex is glued with acrylic glue or special mastic. When insulating plinths, the slabs are additionally secured with dowels.

- The blind area is performed to reduce soil heaving and, accordingly, protect against deformations that occur with temperature changes. Penoplex is laid on the prepared cushion, then poured with concrete.

Proper foundation insulation

Standard sizes of insulation boards

The manufacturer produces Penoplex Foundation thermal insulation with the same length and width, only the sheet thickness is a variable indicator. The most popular product format is 1200 × 600 × 50 mm, but the dimensions are not entirely accurate, in fact there is a difference of 5 mm:

| Length | Width | Thickness |

| 1185 mm | 585 mm | 50;80 mm |

| Number of sheets per package | ||

| 50 mm | 80 mm | |

| 7 PC. | 5 PC. | |

The factory conveyor equipment assembles insulation boards into packages with a standardized thickness - from 350 to 400 mm. The thinner the sheets, the more of them there are in the briquette.

cares about its reputation, therefore it offers consumers only high-quality products from the “Foundation” line. On the official website you can see the quality certificate -

.

How to properly insulate a foundation with Penoplex

Any thrifty owner has the tools and consumables for insulating the foundation with penoplex with his own hands. If insulation is not done at the foundation installation stage, then labor costs on an old building will increase significantly due to excavation work. In both cases, the thermal insulation of the foundation is carried out in conjunction with the installation of waterproofing and drainage systems.

Scheme of foundation insulation with penoplex

Excavation of the foundation

During excavation, cracks may form on the foundation due to uneven subsidence of the building. Therefore, you must first make a calculation of the load redistribution. To access the foundation walls, a trench is dug along the perimeter of the building, up to the depth of the cushion, and at least 1 m wide, so that it is convenient to install insulation. It is not recommended to use earth-moving equipment, as there is a high probability of damage to the walls.

In areas with high groundwater levels or high rainfall, a drainage system is installed at the level of the base of the foundation. Having retreated half a meter from it, a trench of small depth is dug along the perimeter. A sand cushion up to 10 cm thick is placed at the bottom, a layer of crushed stone 5–10 cm thick is poured on top. Then it is covered with geotextile so that the edges extend out of the trench. Pipes are laid along the canvas, on the walls of which holes are drilled, with a slope of at least 2 cm/1 m. A layer of crushed stone 10 cm thick is poured on top. The pipes are covered with the remaining edges of the geotextile.

At the initial stage, a trench is dug along the perimeter of the foundation

Preparing the surface of foundation walls

Adhered soil and broken pieces of concrete are removed from the walls of the foundation and plinth. Cleaning is carried out with a stiff brush, the dirt is washed off with a stream of water. After many years of being underground, the surface of the walls was unlikely to remain perfectly smooth. Therefore, before applying waterproofing, leveling is performed with plaster:

- Beacons are attached along the surface from the base and 0.5 m above the ground at a distance of 1.5 m between them.

- The plaster mixture is made from cement and sand in a ratio of 1/4. When mixing, make sure that the solution is thick enough, otherwise the liquid will drain from the walls.

- Using a construction trowel, the mortar is applied to the walls.

- After filling the space between the beacons with a 2-meter rule, excess solution is removed using wave-like movements. The remaining depressions are filled with mortar and leveled using the rule.

- When the first one dries, apply a leveling layer.

Application area

In practice, Penoplex Foundation is recommended to be used when it is necessary to insulate a loaded structure, which does not impose increased requirements in terms of fire safety.

These can be different foundations, insulated floors, plinths, as well as basements and even garden paths. Bricks, concrete, gas silicate blocks, foam blocks, as well as other types of flat surfaces can be used as base materials. That is, the material is quite suitable for insulating foam blocks, as well as insulating aerated concrete.

Such slabs should be used mainly for external insulation. They will be able to counteract soil heaving during frosts, and will also act as part of the drainage system, helping to remove moisture from the foundation.

However, it cannot be said that in terms of internal use there are any strict restrictions. Therefore, penoplex can be used inside. For example, to insulate the basement.

Where is the material used?

Expanded polystyrene penoplex Foundation is usually used for the following purposes and objects:

- Vertically loaded insulation for foundations

. The slabs are mounted without using additional fastenings using dowels. Laying is carried out on a layer of bitumen or roll waterproofing. Sand and soil on top. The upper part of the penoplex will protrude above the ground level by about 40-50 cm; - Shallow foundations

. Penoplex formwork for the foundation is effective. The material should be cut and laid on the base on top of the drainage (a base of sand and gravel that has been compacted). Make it 30-40 cm lower than the future blind area. And the second half is glued to the walls in a vertical plane. As in the first case, the top of the slab should protrude at least 40 cm; - Objects with rare visits

. In this case, penoplex is mounted under the foundation, and thinner sheets are also attached from the outside; - Unheated structures

. To increase their service life and also effectively remove moisture, penoplex is attached from the bottom. Here it is recommended to take slabs whose thickness ranges from 50 to 100 mm; - Columnar foundations and individual supports

. Penoplex should be cut into pieces that will be larger in area than the cross-section of the structures. And then install a drainage mixture of sand and gravel on top; - Strip foundation

. Here, thermal insulation is carried out according to a similar scheme. That is, you need to cut the insulator into appropriate strips; - Insulation of blind areas and garden paths.

As you can see, there are more than enough application options. You just need to decide what exactly the Penoplex Foundation can be useful to you for.

One of the advantages is easy installation

"Penoplex Foundation", the dimensions of which were mentioned above, is distinguished by the fact that it can be easily installed independently. The material can be used inside and outside, as well as comprehensively. As practice shows, external thermal insulation is still the most effective. It is carried out in several stages.

The first step is to dig a trench along the perimeter of the base, the depth of which will be below the sand cushion. Its width should equal the depth of soil freezing

It is important to take into account a margin of 5 cm. Sand will act as a continuation of the pillow, which is poured under the base and compacted well