You can save on heating in different ways, and this does not always mean creating less comfortable conditions in your house or apartment. Heat-saving film for windows is a polymer material that is applied to glass so that the air temperature in the room is maintained at a given level. You can find such products of different brands on sale, the coating thickness is usually 90-200 microns, the light transmittance remains at 95% or higher. This film has a high ductility index, therefore, in addition to reducing heat loss, it protects PVC windows from mechanical damage to the glass unit.

What is Third Glass?

The third glass (third window) window insulation film is called heat-saving or thermal film. Sellers claim that it reflects heat, keeping it indoors. The temperature inside a room with insulated windows rises by 3-6 or 4-8 degrees.

To insulate windows, you need to stick double-sided tape on the frame around the perimeter. A film is stretched over it from above. To even out the folds, warm it up with a regular hairdryer. After gluing, the film acts as a third glass, and the space between it and the double-glazed window acts as a third window.

Installation of double-glazed windows

In fact, installation is carried out in the reverse order of its removal:

- Install the pads in their old position (you noted that?)

- Place the glass unit on the bottom pads and insert it into the opening (then insert the side pads, if there were any)

- Insert glazing beads starting from the top

The first glazing bead simply inserted into the groove with the shank and pressed along its entire length until it clicks. You can do this with light blows of a rubber hammer, but you can also do it with your hands.

Insert the second and third from the corner of the previous one. You need to simultaneously insert it into the groove and at the same time press it into the corner . Then you can begin to hammer (push) it along its entire length to the opposite end.

The last bead is the most difficult. It must be simultaneously pushed into both corners and at the same time inserted into the groove . Then press it as hard as possible in the center and start hammering.

How to keep warm

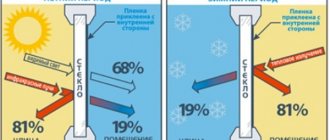

In winter, most of the heat is lost through the windows. There are two ways to transfer thermal energy:

- Convection;

- IR radiation.

Convection cannot be avoided; the thermal conductivity of the window can be reduced. For this purpose, there are double-glazed windows. The more chambers and glasses, the less heat loss due to convection.

More than 99% of infrared radiation passes through glass. Due to it, the room cools down in winter. The amount of heat loss through windows is 25-40%. Of these, IR radiation accounts for 15-30%.

If you have an infrared heater installed, then a considerable part of its heat can escape through the double-glazed windows. Read more about the operating principle and types of infrared heaters in this publication.

Difficulties and errors

When installing polymer films of this category, beginners can make a number of serious mistakes that will affect the comfort of use and durability of the product. To prevent this from happening, experts often share useful tips on online forums :

- After installation, the film is not adjacent to the glazing beads - it is recommended to cut with a small margin, since cutting off excess edges is easier than stretching the product to the required dimensions.

- The film sags even after heat treatment - before purchasing, you need to pay attention to such indicators as specific elongation, as well as the permissible heating temperature.

- The membrane significantly worsens the visual characteristics - the transparency of the product is indicated in the description, and before installation it is necessary to eliminate the risk of dust settling on both the film and the glass.

- The product begins to peel off during use - in the cold season, there is a risk of dew point formation, and therefore you need to choose moisture-resistant double-sided tape.

Provided you carefully follow the step-by-step instructions, taking into account the above recommendations, the membrane will operate for up to 10 years, without the need for repair or replacement.

We bring the third glass to clean water

Manufacturers and sellers of heat-saving film for double-glazed windows claim that it reflects thermal radiation. In fact, this is 100% deception. Now we will prove this to you.

There are high-quality energy-saving films that can reflect part of the IR spectrum. Their cost starts from $15 per linear meter (cheap Chinese manufacturers). European heat-reflecting films cost from $20 per sq.m. depending on the characteristics.

Important

Thermal film third glass can be purchased for $3. Often the kit includes double-sided tape. The difference in cost speaks for itself.

Window insulation with thermal film, which works, occurs by gluing it to the glass. Its task is to reflect infrared radiation. If you stick a third window film on a double-glazed window, there will be no effect.

They sell you a piece of shrink film in the package. You can buy it at a hardware store. The effect will be the same. The cost of such film is from 0.5 dollars per square meter.

Requirements for heat shrink products

The following requirements are imposed on polymer energy-saving products “Third Glass” , in accordance with the current GOST 32563-2013 “Glass with polymer films”:

Mechanical tensile strength of at least 40 mN.- The indicator of heat shrinkage and elasticity must correspond to the characteristics in the quality passport.

- Resistant to temperature changes without the risk of melting.

- Uniformity of composition and thickness.

- Absence of foreign inclusions in the structure.

- Compliance with the actual thermal properties declared by the manufacturer.

- Fire hazard class – not less than G1.

- Environmentally friendly products - when heated, they should not emit substances harmful to human health.

- Service life – from 5 years or more.

According to these regulatory indicators, each manufacturer draws up its own specifications, which are registered with certification bodies. This allows you to test finished products on laboratory benches and obtain an official document indicating the high quality of the product.

Why does the third glass work?

Does third glass heat reflective film work? Yes and no. After insulating the third glass with heat-saving film, the temperature in the room rises. By 1-3 degrees, not by 6 or 8, as fraudulent sellers claim.

Why is this happening? Previously, in villages, oilcloth was nailed onto glass windows in winter. This helped keep the house warm. 3rd glass film works in exactly the same way. Only you attach it inside, and not outside the window. And it lets in more light. Many people still do this:

My husband at the pharmacy (at the end of the building) has been doing this for three years now - he seals all the window openings with thick polyethylene and tape. It's actually warmer. It has its drawbacks - on plastic, then in the spring you can wipe off the remaining tape (on wood, I think, there will be almost none) and the view from the window is like from an aquarium.

When insulated with such a film, an additional chamber is formed, similar to that in a double-glazed window. Heat loss due to convection is reduced. The more chambers, the better the heat is retained.

Losses due to convection are reduced. Infrared thermal radiation continues to leave the room, and this is the main heat loss. It turns out that energy-saving film for insulating windows, third glass, does not save energy so well.

Anti-fog PET film for windows: pros and cons

Thermal-saving material has many advantages:

- Effective protection against cold. Your apartment or house will have a comfortable microclimate both in winter and summer; you won’t need to spend a lot of money on heating or buy a split system or air conditioner.

- Preserving the integrity of glass under minor mechanical impacts. If, however, the window breaks, for example, from a stone, the fragments will hang on the film and will not spill into the room. This reduces the risk of accidental injury.

- The applied coating does not create glare, protects textiles, floor coverings and furniture from fading when exposed to sunlight.

- Relatively low price, due to which you don’t have to spend too much on insulation. Installing such a film is cheaper than installing reinforced double-glazed windows with several cameras.

- Easy installation. On sale you can find self-adhesive window film, the application of which takes a minimum of time.

- A rich list of insulation films available on the market, produced by both Russian and foreign brands. In stores you can purchase products from A-Solar and other companies.

It should be noted that the use of insulating film for insulation is not without its drawbacks. The disadvantages include the following factors:

- It becomes difficult to keep indoor plants on the windowsill. The amount of ultraviolet radiation decreases, so they begin to wither. To solve the problem, you can install phytolamps that provide a 12-hour lighting cycle. The disadvantage of this option is the increase in energy costs, which makes the energy-saving properties of the film meaningless.

- Reduced effectiveness of thermal protection coating in spring and autumn. It prevents the room from heating by the sun's rays, and if the heating has already been turned off or has not yet been turned on, the room will be cold. In some cases, condensation also forms on the windows.

- Some films that create a “thermo” effect are capable of reflecting most radio waves, and cellular communications will work poorly in the room.

Research results

In 2014, a study was conducted at the Ukrainian State Research Institute of Building Structures. A polyethylene film was glued to the frame of the double-glazed window, and its characteristics were checked before and after pasting. Here's the result:

- Tests of the reduced resistance of a window block have shown that the additional use of film installed on the surface of the sash or frame leads to an increase in the heat transfer resistance of the glass unit by 0.2 m2*K/W. When using the film, the reduced heat transfer resistance of the window blocks that were used for testing increased from 0.45 to 0.56 m2*K/W, and the heat transfer resistance of the glass unit from 0.32 to 0.46 m2*K/W.

- The results of calculating the temperature on the surface of the glass unit and the film in the central zone showed that the temperature on the inner surface of the glass unit not covered with film was 5.3 °C, and the temperature on the surface of the film was 10.4 °C.

- During the experiment, no condensation was observed on the surface of the film, while the surface of the glass unit, not covered by the film, was covered with condensation.

- Calculation of heat loss through the building envelope during the heating period showed a decrease in heat loss by 64.6 kW/h, which is 13% as a percentage, for the type of wall structure under consideration.

Based on the results of the study, we can say that insulation with plastic film makes sense. Pasting a window block can reduce heat loss by 30.3%. Exactly the same effect can be achieved using energy-saving film third window, but it will cost more due to the beautiful packaging .

Advice from the experts

Most experts recommend applying this material to windows for warmth only during the winter season: in March or April it is worth removing the film to reduce heat loss. During the period from October to February inclusive, the difference between the temperature outside and inside the house is most significant, so an additional heating surface is most useful. The rest of the time there is no point in leaving the coating on. If carefully removed, the film can be reused in the future.

During installation and operation, it is necessary to protect the material from damage: it is afraid of the impact of piercing objects, especially when deployed. It is advisable to trim the film with a margin; excess can be removed after application, using, for example, a stationery knife.

It is also important to make sure that the glass does not have external defects that could negatively affect the quality of the anti-fog film after installation.

If it is necessary to remove the material, carefully pull it by the corners, this allows you to remove the coating so that there are no traces of glue left on the glass surfaces.

What is REAL heat-saving film

Energy-saving films are glued directly to the glass. They have two tasks:

- Reflect infrared radiation emanating from the room back;

- Let infrared radiation into the room from the outside.

Thermal reflective film usually has a color ranging from yellow to blue. It all depends on the type of spraying. The light transmittance and reflectivity of IR rays depend on the composition of the sprayed substance and its quantity.

A good heat-saving film can return up to 80% of thermal radiation into the room. This is about 20-30% of the total heat loss of the house. For an apartment this will amount to 30-50% of heat loss, since in a multi-storey building heat does not escape through the floor, roof and walls adjacent to neighbors.

Step-by-step instruction

To install the energy-saving polymer film “Third Glass”, it is not at all necessary to turn to professionals, since all the work can be done with your own hands, provided that you follow the technological map :

- Measurements are taken from the glass unit.

- The obtained data is transferred to film.

- The membrane is marked with a marker along the ruler.

- The glass is cleaned of dirt and grease deposits.

- The material is cut to the required size.

- The film is laid on a horizontal surface with the back side up.

- If there is a protective shell, it is completely removed from the product,

- Double-sided tape is applied around the perimeter of the glass.

- The membrane is carefully applied to the glass and smoothed over the entire plane.

- Places with folds and sagging can be effectively removed with a hair dryer.

Note. Considering that, when fixing the membrane, there are no wet processes, operation of the window unit can begin within a few minutes after the film has cooled.

For more information on how to apply film to windows:

Lifehack

To maximize insulation of a house or apartment, you can use overhead heat shields. They are installed on top of conventional metal-plastic or wooden frames. The surface of such a screen is covered with heat-reflecting film. When installed, it seems to add an additional double-glazed window.

You can cover the glass with energy-saving film and ordinary polyethylene, polypropylene or shrink film. This way you will kill two birds with one stone. At the same time, heat loss due to convection and infrared radiation will be reduced.

Necessary tools and equipment

To install polymer films of the “Third Glass” type, a home craftsman will need the following set of tools and consumables :

- A rag and degreaser with an antistatic effect for cleaning the glass surface before installing the film.

- Tape measure for taking measurements of glass units.

- Ruler, construction angle, permanent marker for marking the material before cutting.

- Scissors or a construction knife with a retractable blade for quickly cutting the film.

- High quality double-sided tape for fixing flexible material to glass.

- A construction or hairdressing hair dryer for heating the polymer membrane after installation.

All tools must be in good working order, cleaned of dirt and ready for use. When purchasing consumables, you need to pay special attention to their expiration date.

Reviews of film Third Glass

I have wooden windows and I decided to use thermal film. It's hard to glue alone. It separates along the seam when heated with a hairdryer, and after gluing it reacts to temperature changes - it contracts when heated and comes off. However, the effect is present: after gluing, the temperature rose by 3 degrees, the glass stopped leaking. Like an ambulance.

Alexander, Ukraine

A very curious animal lives in my apartment - a cat, so heat-saving film for windows would definitely attract her attention. To avoid damaging it (the film), I decided to stick it from the street. The apartment became a little warmer, but the condensation, albeit in small quantities, remained. Next year I will stick it on the side of the apartment.

Arthur, RF

In general, everything went according to plan. All that remains is to check how effective this “third glass” is. Therefore, they did not seal the second half and decided to wait until the next day.

The next morning, the other half fogged up, but ours remained clean and transparent:

M., St. Petersburg

The “third glass” turned out to be an ordinary thick, but fairly transparent film of large width. Good double sided tape included. Which need to glue the film to the frame. IMPORTANT: the film should not touch the glass. It turned out to be difficult, because... It is also advisable to glue it without creases and folds, with good tension.

Julia, Kyiv

Selection rules

Colored film for facade and interior decoration

Recommendations for selection:

- You need to make sure that the brand of the material really exists.

- The seller must have a quality certificate. If you use a fake, you won’t be able to stick it properly.

- The packaging must be intact - this is an indicator of proper transportation and storage of the goods.

Summarize

The third window or third glass is a working technology. Not as effective as energy-saving reflective films, but it will help keep the room warm.

There is no need to buy sets and kits, why pay more? You can purchase double-sided tape and shrink film yourself. It will cost 2-3 times less than buying ready-made kits in beautiful packaging.

We hope the article was useful to you. You can ask your questions in the comments. Share with us and our readers your experience of using third glass heat-saving film. Don't forget to share the post with your friends

Do you want to get help from a master, a specialist in this field? Go to the professional search portal. This is a completely free service where you will find a professional who will solve your problem. You do not pay for posting an ad, views, or choosing a contractor. If you are a master of your craft, then register on Pro and receive a flow of clients. Your profit is just one click away!

Thermal insulation of PVC windows with thermal film

PVC windows, which have an additional thermal insulation layer as a heat-saving film, are the most durable. Even if there is a strong blow, the glass will not shatter into small pieces, but will only be deformed. This ensures maximum safety. Insulation of plastic windows is also carried out in some cases.

Although the windows have plastic frames that are additionally insulated with rubber seals, the glass still allows cold air flow into the room. Even owners of double-glazed windows will not be able to obtain ideal thermal insulation. Therefore, in this case, it is most appropriate to use film as a “third glass”.

Installation instructions for thermal film

Instructions:

- Most thermal films have a self-adhesive backing, but some products will stick to the glass due to certain adhesive conditions.

- Before installation, the glass surface must be prepared. Preparation includes thorough window cleaning. After you have washed them, do not forget to dry them. Additionally, use a degreasing solution for treatment.

- After this, the installation procedure for the heat-saving film begins. Apply it carefully; when wrinkles appear, you need to smooth them out using a soft rag. Or you can use a special tool that looks like a car window brush.

- Once you have smoothed out the wrinkles on the surface of the glass, the remaining material must be removed. This can be done using a knife designed for installation.

Average prices for sticker services

Considering that many installation companies offering the installation of window units, as well as their repair, provide services for installing energy-saving film, fierce competition arises between them.

In this regard, prices for this work are approximately the same in all regions of the Russian Federation and depend on the following indicators :

- glazing area;

- dimensions of one translucent structure;

- the need to join the material;

- removal of the object from the city;

- type of instalation;

- presence of additional wishes from the customer;

- internal pricing policy of the installation organization.

If it is necessary to order the installation of “Third Glass”, it is recommended to take into account the following prices :

- Standard installation in an apartment costs from 50 to 100 rubles. for 1 m2.

- Panoramic window with dimensions of more than 2 x 2 m - from 150 rubles. for 1 m2.

- Stained glass glazing of office centers or business class houses - from 150 - 200 rubles. for 1 m2.

- As a rule, most installation organizations, despite the prices, go to the client’s site if the total amount of the estimate exceeds the minimum threshold - from 2.5 to 5 - 6 thousand rubles.

Important. The final price of the estimate is determined after a detailed calculation, based on the features and content of the technical specifications from the client.

Features of using polyurethane foam as insulation

To seal cracks and reduce heat loss, you can use ordinary polyurethane foam. It is extremely easy to use and allows you to obtain the highest quality thermal insulation

You just need to show maximum attention and accuracy during work in order to seal all existing cracks. After the foam has dried, its excess should be cut off with a sharp knife, and the insulation itself should be hidden with something

Polyurethane foam

To mask such thermal insulation, you can use homemade putty. To prepare it, you need to take part of the chalk and 2 times the amount of building plaster. Mix the ingredients, dilute the mixture with water to a semi-liquid state and spread on the foam. Of course, it will not be possible to completely hide traces of insulation, but at least the polyurethane foam will not be so conspicuous.

Thus, to independently insulate windows for the winter, you can use a wide variety of materials. Choose the most suitable and convenient option for you and get started. Good luck with your work and have a warm winter!

Good luck with your work and have a warm winter!

Mineral wool insulation technology

For external insulation of window openings with mineral wool you will need:

- mineral wool,

- plaster,

- adhesive solution,

- reinforcing mesh,

- perforated corners,

- dowels,

- putty knife.

The insulation process should be carried out according to the following scheme:

- Measure the width of the slopes and cut pieces of reinforcing mesh with an overlap of 10 cm.

- Place the mesh on the slopes with an adhesive solution.

- Place a layer of mineral wool on top, having previously coated the surface with glue. Its width should be 1–2 cm greater than the slope.

- To avoid the formation of air space, the slabs should be applied as tightly as possible to the surface of the slope.

- Trim the remaining strips of cotton wool protruding beyond the edge of the slope.

- After complete drying, apply glue to the edges of the insulation and wrap it with the remains of the reinforcing mesh.

- Install perforated corners around the perimeter.

- Wait until it dries completely and apply glue to the screed again using a spatula. The adhesive solution in this case should be slightly thinner than the original one.

- Apply primer and then paint the window façade.

Mineral wool insulation scheme

On the inside, mineral wool is used in combination with PVC slopes or sandwich panels.