A modern residential building is a complex complex whose task is to provide for the everyday needs of its residents and inhabitants. The comfort of the inhabitants and the level of amenities depend on the level of technical equipment of a residential building. One of the leading roles in this regard is played by the heating system, which should not only provide heating of the interior during the cold season, but also guarantee the operation of the hot water supply system. For a country house, in the absence of a central gas supply, issues with heating and hot water supply can be solved by a double-circuit solid fuel boiler.

Let's take a closer look at what this technique is.

Operating principle and features of a solid fuel boiler

Unlike a traditional wood or coal stove, the unit is modernized and optimized for the realities of each home - the required heating and water heating for domestic needs. Boilers differ in combustion principle:

- Pyrolysis. In addition to the main action - burning fuel, the system collects the released gas - usually CO - and mixes it with oxygen, and then ignites it. As a result of the combustion of the mixture, a certain amount of temperature is again released, which is used to heat the medium.

- Upper combustion chamber. The principle does not work from the bottom up, but, on the contrary, allowing the process to go slowly and with greater impact.

The design of heat exchangers for the units is different. In the first option, it is located horizontally above the combustion chambers, in the second, the vertical heat exchanger completely surrounds the firebox. As a rule, containers are made in the form of coils.

Famous manufacturers and best models

When choosing a device model, it is recommended to first consider the products of the most well-known companies that develop and manufacture heating equipment.

Karakan 16TPEV-3 16 kW

Inexpensive but reliable device with an open combustion chamber. The unit is capable of operating on all types of fuel: wood, coal, briquettes. Features of the model are a deep firebox and the presence of a hob. The efficiency is 75%. The unit is suitable for heating a room up to 160 square meters. m. Mechanical type control. The heating circuit operates in energy-independent mode. The primary heat exchanger is made of steel. To heat water for domestic needs, a built-in heating element with a power of 9 kW is provided.

Karakan 16TPEV-3 16 kW is a boiler with an open combustion chamber.

Dragon TA-GV-15

A 15 kW installation is suitable for heating a house or cottage with a total area of up to 150 square meters. m. The model is easy to use and highly efficient. The efficiency of the installation is 88%. The large volume of the firebox allows the device to operate on one load of fuel for up to 6-10 hours.

The pyrolysis type boiler is equipped with an open combustion chamber and an improved fuel afterburning system. The heat exchanger is made of heat-resistant steel. Mechanical type control is used. No electrical connection required. It is possible to additionally install a burner for liquid fuel. The disadvantage of the Dragon TA-GV-15 is the high cost of the product.

Wirbel ECO-CKB 20

The combined energy-independent heat generator has a power of 20 kW. Open type working chamber. For the preparation of domestic hot water, a built-in storage tank with a volume of 65 liters is provided. The heat exchanger is made of furnace steel. Firewood, coal, and pellets can be used as fuel. Additional installation of gas and liquid burners is possible. Disadvantages - high cost, difficulty in maintenance due to the low prevalence of the model.

Wirbel ECO-CKB 20 is a combination boiler.

Trajan T-15-2KT

A double-circuit solid fuel boiler from a Russian manufacturer has a power of 15 kW. Despite its small size, it has a spacious combustion chamber with a volume of 80 liters. The pyrolysis type device allows you to achieve high efficiency, reaching 85%, and reduce fuel costs. Coal and wood can be used as fuel. Trayan T-15-2KT is a non-volatile heat generator and does not require connection to the electrical network. The heat exchanger is made of steel.

Principle of operation

Double-circuit boilers are universal appliances. They can heat houses and provide prepared hot water

, heated to a certain temperature. Their design is quite complex, there are many additional components and modules, because the finished design should be as compact and functional as possible. This is precisely what distinguishes double-circuit boilers, both gas and solid fuel.

The most complex structure is gas equipment, which, in addition to the burner and heat exchanger, contains gas units, security systems, piping, various sensors and fans. All this makes the equipment difficult to maintain and repair. As for double-circuit solid fuel boilers, they are much simpler. In them we will find:

Construction of a solid fuel boiler with two circuits: heating and hot water.

- Burner – classic or pyrolysis;

- Double heat exchanger;

- Additional pipes for water supply and intake.

A wood or wood gas burner produces heat that warms the coolant circulating through the heat exchanger. This heat exchanger contains tubes responsible for heating the incoming water from the water supply. Since direct contact with hot metal is excluded here, this scheme allows you to get rid of scale

– the temperature here is insufficient for its formation.

Some boilers are designed differently - the flame passes through the middle of a cylindrical heat exchanger, which first heats the heating circuit. The hot water supply circuit in such units is located on top of the heating circuit. This approach ensures that there is no overheating of water in the DHW preparation system.

Thus, there are no three-way valves or other complex components here, which is already a definite plus. As soon as you open the tap, hot water immediately begins to flow from it. Moreover, it is too hot, since adjusting the temperature in the DHW circuit in a double-circuit solid fuel boiler is very problematic - especially if it does not have a combustion control system.

You can count on a more or less stable water temperature in the hot water supply circuit only in pellet models. But gas and liquid models cope best with this.

Long-burning solid fuel double-circuit boilers are equipped with spacious combustion chambers that can accommodate a large amount of solid fuel. Some models can work up to 12 hours from one bookmark

. The record holders are pellet devices that operate on compressed wood pellets - they can be equipped with extremely capacious bunkers that ensure continuous combustion for 7-10 days.

The operating principle of this type of heating equipment

A lot has already been said in various materials about what the operating principle of long-burning solid fuel heating equipment is based on. The achieved effect is due to a fundamentally different method of fuel combustion in the combustion chamber. Due to the multi-stage combustion process, complete burnout of the fuel mass loaded into the boiler is ensured. In this case, wood gas is released in large quantities, which does the main work of heating the coolant.

For reference: the units operate on the basis of pyrolysis, the process of generating volatile flammable compounds obtained from wood as a result of exothermic reactions. During the smoldering process of fuel, wood (pyrolysis) gas is formed, which, when interacting with hot air, ignites. This technique is also called gas generators.

* The operating principle of boiler equipment is relatively clear; let’s figure out how a double-circuit autonomous solid fuel boiler works at home. Let's look at its main functions. The presence of two circuits in the system provides heating in the house and hot water supply. Boiler water circulates in the first circuit, which disperses throughout the pipeline, supplying heat to the heating radiators. The second circuit is designed to remove waste coolant back to the boiler for subsequent heating. The detector sensors installed on both circuits react sensitively to the slightest change in the set coolant temperature, giving signals to the control panel. Accordingly, the automation activates a mechanical device that regulates the air flow in the combustion chamber of the heating device.

Types of boilers based on combustion principle

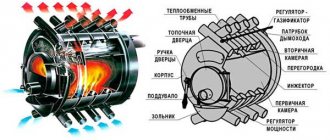

The combustion principle significantly affects the efficiency and efficiency of the device. In solid fuel systems, the most common fireboxes are gas-generator and top-burning.

Gas generators

Pyrolysis or gas generator boilers have two combustion chambers. In the first: the fuel, due to the low supply of oxygen, smolders and releases flammable gases, which are then burned in the second chamber.

This system provides very high efficiency due to maximum combustion of all fuel. Waste in the form of ash is quite insignificant here.

Top burning

Top combustion boilers have one firebox. Often such a cauldron can be recognized by its cigar-shaped shape. The firebox can take up about half its length. The principle of combustion in it is realized by supplying oxygen from above. Thus, only the upper part of the bookmark burns, and the lower part, due to the lack of oxygen, cannot burn. As it burns out, the air is supplied lower and lower, until the entire load is completely burned. This method allows you to use fuel economically and regulate combustion.

What is the difference

Both systems allow you to increase combustion duration. The first is due to the afterburning of the resulting gases, the second is due to limiting the uncontrolled combustion of the entire stash.

These systems differ in design and combustion process. The gas generator has two furnaces, and, accordingly, two stages of combustion: the actual filling and the resulting combustible gases. The top combustion furnace has one chamber and one long and economical combustion process.

How to choose a long-burning stove

Long-burning heating devices are supported by their undoubted advantages - economy, environmental friendliness, compactness, ease of operation, high efficiency (up to 70-85%), long service life, accessibility.

Power

The main criterion when choosing a heating device with a long combustion cycle using solid (wood) fuel is its power. It must correspond to the volume of the heated room. There is no point in installing a high-power stove in a small room, since part of the heating material will burn irrationally. In addition, a large device will take up a lot of space, and the room temperature will be too high. On the contrary, a low-power stove in large rooms will work at the limit of its capabilities, which will quickly cause it to fail.

Fuel

When choosing, you should decide on the type of fuel that is supposed to be used - firewood, pellets, coal, fuel briquettes, etc. You should know that the moisture content of wood fuel is of great importance, since water vapor diluting the gases interferes with combustion, reduces the power of the device and promotes the formation of condensation. In some cases, excessive moisture in the burned material can lead to spontaneous extinguishing of the furnace. Firewood for long-burning fireboxes, for example, should have a moisture content no higher than 20-35%.

Remember, the use of fuel not specified in the operating instructions and the use of heating material that does not correspond to the size and design of the firebox is strictly prohibited!

Material

The metal or alloy from which the long-burning furnace is made is also an important selection criteria. The thicker the material of the device body, the slower the device cools and the longer its service life. Some models of long-burning stoves made of cast iron last up to 50 years (!) and, moreover, are not subject to corrosion.

Elements of many modern stoves - firebox, hob, trim, door - are made from different materials (cast iron, vermiculite, steel, stainless steel, heat-resistant glass, etc.), which allows to increase service life, improve design, improve ease of use and long lasting time to maintain appearance.

Design

The appearance of the heating device often plays no less important role than other factors. A stove for a living space should have a modern design and fit harmoniously into the interior. There are many imported models on the market, from which you can choose a ready-made stove for any home. Canadian, German, Polish, French long-burning stoves and fireboxes made in Serbia are very popular. Russian stoves with a long combustion cycle are also presented in an equally extensive range.

Homemade products

For a service or utility room (greenhouse, garage, warehouse), you can make it yourself or order it from craftsmen a long-burning heating device from a gas cylinder such as Slobozhanka, Bubafonya, etc. Sometimes metal barrels are used for the artisanal production of such devices. Although such devices do not have an elegant and original design, they can provide effective heating with minimal manufacturing costs.

Functionality

In some cases, additional features play a decisive role when choosing a heating device. This may be the presence of a hob, the possibility of using a heat exchanger, a thermal accumulator, the presence of a high-quality automation system, etc.

Features of a double-circuit solid fuel boiler

Long-burning solid fuel double-circuit boilers combine at least two advantages: firstly, they provide both heating and hot water supply, and secondly, they allow you to significantly increase the intervals between visits to the boiler room.

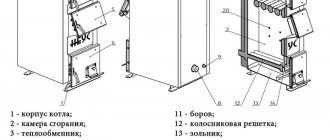

Design

The design of such units is distinguished by the presence of two circuits.

The main elements of the device are the same as conventional ones:

- firebox;

- ash pan;

- heat exchanger;

- automation and control devices.

To ensure long burning, an automatic fuel loading system can be used, which includes a hopper for pellets or other bulk fuel, as well as a screw or pneumatic mechanism for supplying fuel to the burner.

Operating principle

The operation of boilers is based on a fairly simple principle: fuel, when burned, transfers energy to a heat exchanger, which, in turn, through a system of pipes, radiators, boiler and other devices, heats rooms and provides hot water for various domestic needs.

Boiler houses that heat not a private house, but entire cities work on the same principle. Thus, your own boiler is a mini-boiler room.

How is it different from a boiler with one circuit?

The number of circuits directly affects the number of possible functions. Each circuit is, in fact, a separate pipe that performs its task. If it is alone, then it performs one task, as a rule, heating the room. In most single-circuit systems, it is highly undesirable to withdraw water from circulation for other needs.

If there are two pipes, then the second one can provide hot water for the kitchen or shower. There are boilers with three pipes, in which case another circuit can be used, for example, for a heated floor system, which is an additional advantage during the heating season.

In the private sector, the most common multifunctional boilers are 2-circuit ones.

Advantages

A stove heating system often meant having several fireboxes in a house, one for every one or two rooms. In this sense, a modern boiler can be called a central heating system. Compared to single-circuit ones, the advantage is that they perform more functions.

Advantages:

- Work on available fuel.

- Relative efficiency, both due to a decrease in the amount of fuel and an increase in efficiency.

- Long service life. Despite the low warranty period, with proper installation and use, the main system can work for decades.

- Wide selection of models in different price categories. The simplest systems can cost up to 25 thousand rubles.

- Possibility of working without electricity and gas. In some models, an electric burner is used for kindling, in some a container with flammable liquid is connected, in some these options are interchangeable.

- Simplicity and ease of use. The main maintenance work consists of loading fuel and cleaning the ash pan. In long-burning systems, the maintenance frequency can be up to once a week.

- Possibility to use a variety of materials as fuel: firewood, coal, wood chips, pellets, peat.

- Possibility of a high degree of automation. Today, even the presence of a GSM notification module is not exotic.

Flaws

To paraphrase the classic, we can say: comfort requires sacrifice. The main sacrifice is an increase in costs with an increase in functionality. The more complex the system, the more expensive it is. In some cases, the payback period of an expensive unit is lower than that of a cheap one. This “golden mean” is the goal of any prudent owner.

The disadvantages include:

- The need to manually reload fuel. Even long-burning systems require periodic “feeding”.

- The need for cleaning and preventative maintenance. Even devices with self-cleaning ash pans require maintenance.

- Organization of additional premises for fuel storage. For example, a pellet boiler consumes up to one and a half tons of pellets per month for a room of 100 m², which requires 1.5-2 m³ for storage. It is easy to multiply this figure by the number of months of the heating season.

Advantages and feasibility of installation in a residential building

Installing a solid fuel boiler is an effective and simple way to organize heating for a cottage or summer house. This option is especially convenient for buildings that are not connected to the gas supply system. Electrical installations, although convenient and reliable, are expensive to maintain due to high tariffs. It is more profitable to use them as a backup option.

Solid fuel devices are cheaper to maintain. They are able to work on wood, coal, and waste from the wood processing industry.

The use of such boilers is a justified and economically feasible solution if the house is located in a non-gasified area. In this case, long-burning double-circuit units will be the best choice for installation in a cottage or country house.

Such devices have a number of important advantages:

- low fuel costs;

- ease of installation, maintenance and repair;

- reliability and long service life of equipment;

- high energy efficiency;

- the ability to work in autonomous mode without connecting to the mains.

Installing a solid fuel boiler is justified.

Comparison with electric and gas

Solid fuel boilers have the undoubted advantage of being independent from utilities. This equipment has proven itself in areas where there are interruptions in the supply of gas and electricity.

Flaws

The main disadvantage of a long-burning solid fuel boiler is the need for space to store firewood, coal, peat or pellets. It is recommended to allocate a dry room for this purpose, where the raw materials will be guaranteed to be protected from moisture. Outdoor storage is only permitted if the fuel is under cover. Additionally, fuel can be covered with a tarpaulin.

Taking this into account, solid fuel boilers are best suited for heating the premises of a private house, and in apartments of multi-storey buildings this equipment becomes inconvenient and unsafe. Boilers running on gas and electricity are ideal for use in multi-apartment residential buildings.

The disadvantages of solid fuel heaters also include the need to constantly maintain fuel combustion, regularly adding new portions of raw materials. For long-term heating of water, again, it is better to use gas, diesel and electric boilers.

Question of price

If we compare the cost of different types of heating equipment, the cheapest and most affordable will be a solid fuel boiler. Its operating costs are low, especially considering the relatively high prices for gas and diesel fuel.

A pellet solid fuel boiler is the most economical, since wood pellets are becoming cheaper every year. The production of this raw material is carried out from production waste and costs the manufacturer a few pennies.

Sometimes heating equipment requires not only heat, but also hot water. And if there is no gas in the house, natural or liquefied, a double-circuit solid fuel boiler should be adapted for these purposes. It is highly desirable that this be a long-burning model that does not require too frequent addition of fuel. There are a huge number of such boilers on sale, so you should learn how to choose them. This is why we have prepared this review.

How to increase productivity

When purchasing and installing a solid fuel boiler, a prudent owner thinks about how to increase its service life. And this is correct, since in such a unit there are a number of techniques, following which you can obtain maximum efficiency.

The first advice given by experts is to professionally select the type of fuel to increase productivity. The second piece of advice also applies to fuel; it must be of good quality; for example, you should not throw raw wood or coal into the firebox. The third piece of advice is to optimize the heating system in the house as much as possible by using modern options, for example, with manifold distribution of coolant. The fourth tip is to provide reliable thermal insulation in the house.

If all the advice is followed by the owner, then the solid fuel boiler will be able to compete with gas and electric units.

Nuances of operation

Be sure to read the accompanying documentation. The efficiency and performance of equipment can be influenced by a number of factors that at first glance seem insignificant.

It is worth noting that most manufacturers strictly recommend that installation be carried out by specialists, since in some cases, deviation from this requirement can lead to loss of warranty, and in the worst case, to serious breakdowns and accidents.

After installation, regularly inspect the perimeter of the harness for leaks.

Equipment is often sensitive to fuel quality. Cast iron boilers are the most unpretentious, while steel boilers can burn out when using high-temperature fuels

Therefore, it is important to follow the manufacturer’s recommendations when choosing fuel

Any boiler, even one equipped with various types of self-cleaning systems, requires regular maintenance and cleaning of both ash and soot.

How to increase productivity

The economic and actual efficiency of the boiler depends not only on its initial characteristics.

To improve your performance, take the following measures:

- Use high-quality and dry fuel. Wet firewood will take up some of the energy for drying, and household waste will lead to contamination of the heat exchanger and chimney.

- Take the time to clean regularly.

- Ensure a stable flow of air into the room where the boiler is located: there is no fire without oxygen.

- Reduce heat loss from heated rooms. You can especially identify problem areas using a thermal imager.

- Install auxiliary equipment: for example, a heat accumulator.

Additional equipment and its installation lead to increased costs; not only a buffer tank will be required, but also a circulation pump, but it is worth it. The heat capacity of water is quite high: 1 liter of water, cooled by 1 degree, can heat 1 m³ of air by 4 degrees.

The principle of operation of the battery is quite simple: the pump takes cold water from the tank, drives it through the boiler heat exchanger and returns it back. This happens until all the water is heated. After all the fuel has burned out, the tank is completely filled with hot water. Thermal insulation of the tank allows you to keep the water hot from several hours to a day, so the resulting heat can be used for a fairly long period of time.

Video

Detailed explanation of the operation of the boiler and buffer tank, features of installation of shut-off valves:

Service Security

Heat generators running on solid fuel are safer than gas and electric devices. There is no danger of the flame coming off in the burner and no risk of short circuit in the wiring. Solid fuel boilers do not require connection to the electrical network and can operate autonomously.

The automation and control systems provided by the manufacturer block the access of air to the furnace if the permissible operating parameters of the equipment are violated. After this, the combustion process stops on its own.

Solid fuel boilers are safer than gas boilers.

When operating the equipment, the following safety requirements must be met:

- do not cut off the air supply to the working chamber;

- use only the types of fuel specified by the manufacturer;

- do not light a boiler with an empty heating system;

- provide ventilation in the room where the device is installed;

- Do not operate the unit if the smoke exhaust is faulty or there is insufficient draft;

- remove flammable items away;

- close the firebox door during operation;

- Do not carry out repairs or maintenance after igniting the fuel.

Recommendations for selection

The choice should be based on fuel availability as well as practical and aesthetic considerations. The first include the need for hot water supply and heating of a certain area, the availability of premises for storing fuel of proper quality, that is, all the critically necessary parameters. The second ones are optional, but increase the comfort of use.

Define:

- what types of fuel are available;

- frequency of use of the boiler;

- how many circuits are needed;

- what area will be heated;

- how often the firebox can be loaded;

- how much fuel the storage facility can hold at one time;

- price range of possibilities (both acquisition and installation).

Determining these parameters will help formulate a rather narrow request, within which additional requirements can be entered.

For example, such as:

- availability of automation;

- GSM notification module;

- emergency shutdown systems;

- overheat protection;

- frost protection.

After the circle has been drawn, study the advice of experts and feedback from buyers of the selected models. Who better than a dissatisfied customer to reveal the whole truth.

Be sure to pay attention to the terms of warranty and service, as well as the availability of the most popular spare parts

How to calculate power

Boiler power is measured in kilowatts, usually 1 kW is enough to heat 10 m² of house area. If the premises are not insulated or are located in harsh climatic zones, the reserve should be 20-30% of the minimum.

It should be noted that you should not purchase a boiler with a large supply, since a constantly low load can lead to its failure. This mainly applies to foreign models equipped with automatic transmission.

If the ceiling height in the house is more than 2.7 meters, additional calculations are required. This is done quite simply: calculate the coefficient of the difference between the minimum ceiling and the real one, and multiply it by the power, based on the area of the room.

For example, if the ceiling is 3.0 m and the room area is 100 m²: 3 m / 2.7 m * 10 kW = 11 kW.

It is also necessary to take into account climatic features.

Climate zone coefficients:

- 1.5-2 for northern regions;

- 1.0—1.2 for the middle band;

- 0.7-0.9 for the southern regions.

If there is a second circuit, 20-25% is added, and it is also necessary to add a reserve for peak cold temperatures - 10%.

Prices for the Wiessmann Vitoligno 100-S boiler

Wiessmann Vitoligno 100-S

Thus, the power of 11 kW must be increased first by 25% and then by another 10%: (11 kW * 25%) * 10% = 15 kW.

For an accurate calculation, it is necessary to take the amount of possible heat loss from the building, as well as the safety factor. The product of these two indicators will be the estimated power of the boiler. You can determine real heat loss with the help of a thermal imager: for this it is advisable to contact a specialized organization.

Important factors that can affect heat loss include the presence of windows and their total area, number of floors, as well as the thickness and material of the masonry.

On sellers' websites there is a power calculation calculator that can be used to confirm calculations.

What to look for when choosing

Before choosing a boiler model, decide for yourself the following questions:

- Boiler for permanent residence, cottage or heating reserve.

- Type of solid fuel by availability and cost.

- Number of circuits (heating, water heating, heated floor)

- Minimum required thermal energy power (1 kW per 10 m2 of heated area + 20-25% reserve, number of liters of hot water per minute).

- The heat exchanger is cast iron or steel (cast iron retains heat longer, is resistant to inevitable corrosion and lasts a long time, steel heats up faster, but can burn out).

- What is the efficiency (high - pyrolysis combustion boiler, low - classic).

- How often are you ready to load fuel?

- Is dependence on electricity necessary (automated ignition and fuel supply).

- Fuel storage capacity and storage quality.

- The budget that you are willing to spend on the purchase and installation of equipment.

Boilers with a burning duration of one load of fuel up to 7 days

Types of fuel

Long-burning boilers differ from conventional boilers in that they can operate on one wood load for more than a day.

Depending on the type of fuel used, boilers are divided into several categories.

Powered by wood and coal

Wood-burning types are marked with the letter S and have an efficiency of 70-80%. Once every 3 days, the chamber of wood-burning boilers must be cleaned of accumulated ash. Any coniferous or hardwood wood can be loaded into the firebox. The greater the density and calorie content of the raw material, the longer it will burn. The moisture content of the firewood should not exceed 20%, otherwise the fire will not be able to be maintained.

Coal - marked with the letter U, the efficiency level reaches 90%. This high rate is achieved due to the fact that the combustion chamber is equipped with heat-resistant elements to avoid heat leakage. Coal of any class and fraction is suitable for use, except in cases where the boiler is automated. Then you need to follow the manufacturer's recommendations.

Pyrolysis and pellet

Pyrolysis units have a special structure that allows for the best combustion of fuel at high temperatures. They work on thoroughly dried wood. Pellet units are designed to burn fuel pellets. The advantage of pellets is their low ash content and high calorie content.

Finally, there are universal models - all types of raw materials are suitable for their combustion. The combustion chamber can be loaded manually or automatically.

User reviews

Anatoly, 48 years old, Voronezh:

“I am the owner of a summer house. There is no gas in our area and there is no prospect of it in the near future. I had to install a solid fuel boiler. I chose the universal Karakan model, equipped with a second circuit for heating water. I burn with wood. I've been using the unit for almost 2 years. There are no problems yet."

Vasily, 30 years old, Ryazan:

“I have been using the Trayan T-15 device for more than a year. Reliable and easy to maintain unit. Large firebox, can be heated with wood up to 55 cm long. Installed it myself. Works good".

Nikolay, 61 years old, Penza:

“I bought a Dragon TA-15 six months ago. The model is not cheap, but it is worth the money. I use pellets, it turns out cheaper than firewood. I like the built-in hot water tank. During operation, I have not identified any problems yet.”

Water circuit - what is it and why is it needed?

The water circuit is a well-known heating system using radiators . It is necessary in houses with a not very good layout, it reduces heat loss from the window, and evenly heats the room.

Traditional boilers without a water circuit heat locally, and if there are more than two rooms in the house that are not in contact with the boiler room, a water circuit is simply necessary, because in its absence, remote rooms will not warm up sufficiently.

Heat loss in them will be very high, and temperatures often do not even reach optimal for living and long-term stay.

In addition, in houses with stove heating, corners often freeze . A water circuit will avoid this problem.

Heat exchanger

The reliability of the boiler is important - this is influenced by the material of the heat exchanger. Cast iron is durable, can last up to 20 years, but can be damaged by mechanical shocks and sudden temperature changes. Steel is resistant to such loads, but a steel heat exchanger will last about 6 years. Cast iron is recommended for private houses.

In addition, plate and tubular heat exchangers are distinguished:

- Plate ones are most common, they are characterized by their low cost and high heat transfer area. The disadvantage is the requirements for water purity. The circuit must include a water treatment system.

- Tubular ones have a small heat transfer area per unit weight, which is compensated by their massive construction and copper construction, which significantly increases the price.