Thermostats are small in size, but very practical devices for controlling heat transfer in everyday life. Depending on the actual need, temperature regulators for radiators increase or reduce the volume of coolant. Agree, this is useful both for the well-being of the owners of the house/apartment and for their wallets.

For those wishing to purchase thermostats to equip radiators, we suggest that you familiarize yourself with a detailed description of the types of heat transfer control devices. We have presented and compared their control methods, operating principles, cost, and installation specifics. Our recommendations will help you choose the optimal variety.

We supplemented the information presented for consideration, collected and systematized for future buyers of heat regulators, with visual photo collections, diagrams, regulatory tables, and videos.

Automatic heat control system (SART)

TeleSystems LLC proposes the implementation of an automatic control system for heat consumption (SART) in order to ensure the rational use of thermal energy and create comfortable conditions for living and working.

Each of us has noticed more than once that during periods of warming, the radiators in the building remain as hot for a long time as in cold weather. Unfortunately, the centralized heating system in our country is characterized by inertia: correction of the coolant temperature at the heat source is carried out with a noticeable lag. Moreover, the centralized system is always focused on the average consumer, as a result of which in buildings located closer to the heat source, overestimated coolant parameters are always observed. In an effort to provide ourselves with comfortable living and working conditions, we open the windows, and the heat we pay for goes outside. And therefore, here lies the source of energy savings.

You can save on heat consumption by installing an automatic coolant temperature control system (CART) in the individual heating station of the building. It is designed to regulate heat consumption by increasing or decreasing the flow of coolant into the building, depending on its real needs at the moment.

Installation Rules

Thermostats are installed at the inlet or outlet of the radiator. Installation is standard - on linen winding or FUM tape. The process itself is also standard. The thermostat has a thread for which the appropriate fittings are selected. Or taps are used to cut internal threads on a metal pipe.

When choosing an installation location, consider the following:

- Recommended height. This item is indicated in the technical documentation for the device. Each device is calibrated at the factory to control temperature at a certain altitude. As a rule, this is the upper radiator manifold, approximately 60-80 cm.

- If the radiators only have a bottom saddle connection, there are three options: look for a device that can be installed at the bottom, install a model with a remote sensor, or reconfigure the thermal head. The procedure is simple; the description must be in the passport. You will need to have a thermometer and at certain moments turn the head in one direction, then in the other direction.

What thermostat is on your radiator?MechanicalElectronic

- An important point that those who want to install a thermostat for a heating radiator in apartment buildings should remember. If you have a single-pipe installation, they can only be installed if there is a bypass - a section of pipe that stands in front of the battery and connects the two pipes to each other. If you have a similar wiring (there may not be a pipe on the right), a bypass is required. The thermostat should be installed immediately behind the radiator. Otherwise, you will regulate the entire riser, and the neighbors will not like this. For such a violation, a very substantial fine can be issued. Therefore, it is better to install a bypass.

- In two-story buildings, the recommended location of the thermostat is on the second floors. This is where the warm air is directed, and the first floor invariably turns out colder.

- Thermostats with sensors are installed in rooms where air movement is not obstructed. The indicator is placed strictly horizontally so that it shows a reliable picture. It should be taken into account during installation that the thermostat valves are equipped with an external thread on one end, and oriented inward on the other.

- It is not allowed to place automatic thermostats behind thick fabric drapery or behind a decorative screen. If you do this, the system will begin to measure the heating inside the cavity that appears, and not in the room itself. The solution to the problem is either the use of a remote sensor, or placing the regulator on horizontal sections of the system, as close as possible to the entrance to the radiator.

If the heating system is not created from scratch, before installing the thermostat, all water should be drained from it before installation work begins. When the heating season ends, the thermostat is opened to avoid the accumulation of sediment inside the mechanism.

The main tasks of SART:

- Elimination of the supply of coolant to the facility with overestimated (“overheating”) and underestimated parameters, while the regulation of the coolant parameters depending on the outside air temperature occurs with minimal inertia - SART performs the correction instantly.

- Regulating the temperature of the coolant in the return pipeline of the heating network to eliminate the application of penalties by energy supply organizations for exceeding this temperature. SART allows you to limit the coolant intake from the network and re-enter it from the return pipeline into the heating system. And so on until his temperature reaches normal.

- Saving thermal energy by lowering the coolant temperature at night, as well as on weekends and holidays. For example, if a workshop operates in three shifts without days off, then this mode is not applicable, but if there is no staff in the workshop at night and on weekends (holidays), then it is possible to reduce the temperature of the coolant during this time.

- Maintaining a given temperature regime in the building using sensors located in control rooms. This will not save money, but will provide comfortable living and working conditions. The difficulty lies in selecting a control room for installing the sensor, taking into account that the temperature in it will affect the climate in the entire building. It is used, as a rule, for objects with a clearly defined control room, where it is necessary to ensure the greatest comfort with a variable schedule: cinemas, swimming pools, etc.

Also, the system developed by our specialists provides the technical ability to issue signals to a unified dispatch center when the regulated parameters go beyond the control limits. This significantly increases its reliability and minimizes the likelihood of system and equipment failure.

Benefits from implementing SART

The cost of creating a SART (design, installation and delivery to the ESO) by specialists of TeleSystems LLC, according to the price list, starts from 250 thousand rubles.

Our calculated average values of possible savings in thermal energy consumption using all algorithms of the SART module:

- application of weather control

16%, application of scheduled regulation

Total: total savings are about 38%.

In addition to savings and comfortable living conditions, the implementation of SART ensures balancing of the heating system, increases the service life of heating system equipment, increases the attractiveness of the house and ensures compliance with legislative requirements for energy saving.

Composition of the regulatory system

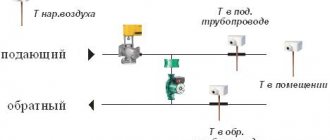

SART is a system of temperature sensors, a control valve, pumps, a controller and communication equipment (if remote control of the system is required). Using installed sensors, the temperature outside and inside the house, as well as the temperature in the supply and return pipelines, is analyzed. This data is transmitted to the control cabinet controller. The controller analyzes the sensor readings and issues a command to the control valve in accordance with a given schedule.

The control unit allows:

- set the temperature control mode for each day of the week, taking into account working and non-working hours;

- automatically maintain the specified mode for regulating the coolant supply;

- adjust the temperature regime and calendar when shifting working days and weekends;

- programmatically set the configuration of the heat control system from a set of standard schemes.

- facility supply line schedules;

- object return line schedules;

- hourly graphs of the regulator operating mode;

- normalized room temperature;

- standardized temperature at the boiler outlet;

- characteristics of valves and hydraulics; pump operating modes.

An automatic heat control system is installed on existing pipelines.

The cost of SART and its payback period are determined after the Customer fills out the questionnaire and processes it by the specialists of TeleSystems LLC. According to the experience of our company, residents’ investments pay off in 1 to 1.5 heating periods, while the service life of the equipment, if used correctly, is at least 15 years.

Our specialists have many years of experience in installing SART. We use reliable equipment from well-known manufacturers such as Danfoss, Wilo, Grundfoss, etc. Contact us and we will help you choose the best option for you. Preliminary examination is free.

Additionally, we recommend installing a module for commercial metering of consumed thermal energy in the heating station. Its installation will allow you to pay for real heat consumption, rather than calculated, and thus reduce heating costs.

Based on the experience of installing heat metering modules, the average savings during the heating season are:

- in residential brick buildings (taking into account the termination of payment for excess losses) - up to 40%;

- at social facilities (schools, kindergartens, hospitals, sanatoriums, etc.) - up to 40%;

- in residential panel buildings – up to 35%;

- in office buildings and administrative buildings – up to 25%;

- in industrial buildings (production workshops, warm warehouses, etc.) - up to 20%.

An integrated approach to energy saving

– Conducting energy surveys: from express surveys to in-depth energy surveys, from audits of products and technological processes to audits of a group of enterprises.

– Formation of energy saving programs both for an individual enterprise and for a region based on the results of energy surveys.

– Implementation of energy saving programs: from installing energy meters to renovating buildings.

A special place in the company’s product line is occupied by a number of complex products aimed at automating the accounting and management of energy resources based on the “Bee.Net” software developed by the company’s specialists.

© TeleSystems LLC Address: 620028, Ekaterinburg, st. Melnikova, 20 Tel./fax

Operating principle of the temperature controller

The thermostat for heating radiators consists of a thermostatic head and a valve, the latter playing the role of a so-called actuator. The head, in turn, consists of a cylinder filled with a working substance that is sensitive to temperature fluctuations. Actually, thanks to this, the thermostat performs its function.

When the temperature rises, the volume of the working fluid increases, and if it decreases, then vice versa. During this, the pressure rod, which is connected to the cylinder, moves. The thermostatic head is installed on the valve. When expansion/compression occurs, the rod releases or compresses the locking cone located under the spring (this cone is necessary to close/open the hole through which the coolant is supplied).

The regulator can operate on a liquid or gaseous working substance; according to this parameter, in fact, all devices are divided into two large groups. Gas-filled thermostats are more sensitive to temperature changes, but liquid thermostats respond more accurately to pressure surges in the device, so the temperature can be adjusted with maximum accuracy.

Note! The principle of operation of the regulator is the same for all heating systems - both single- and double-pipe. The only difference is the resistance of the valves: in the first case it is significantly lower than in the second

Choosing a heat control system with maximum efficiency

In accordance with the requirements of regulatory documentation and Federal Law No. 261 “On Energy Saving...”, the installation of automatic weather control systems should become the norm, both for new construction projects and for existing buildings, since this is the main tool for heat supply management. Today, such systems, contrary to popular belief, are quite accessible to most consumers. They are functional, highly reliable and allow you to optimize the process of thermal energy consumption. The payback period for the installation of equipment is within one year.

The automatic heat control system (SART) allows you to reduce thermal energy consumption due to the following factors:

- Elimination of excess thermal energy (overheating) entering the building;

- Decrease in air temperature at night;

- Decrease in air temperature on holidays.

Integrated indicators of thermal energy savings from the use of SART installed in an individual heating point (IHP) of a building are presented in Fig. No. 1.

Fig.1 Total savings reach 27% or more*

*according to NPP Elekom LLC

The main elements of classical SART are shown in general form in Fig. No. 2.

Fig.2 Basic elements of SART in ITP*

*auxiliary elements are not shown

Purpose of the weather controller:

- Measurement of outside air and coolant temperatures;

- Control of the KZR valve depending on the established regulation programs (schedules);

- Data exchange with the server.

Purpose of the mixing pump:

- Ensuring constant coolant flow in the heating system;

- Ensuring variable coolant mixing.

Purpose of the KZR valve:

control of the supply of coolant from the heating network.

Purpose of temperature sensors: measuring coolant and outside air temperatures.

- Differential pressure regulator. The regulator is designed to maintain a constant pressure drop of the coolant and eliminates the negative impact of an unstable pressure drop of the heating network on the operation of the SART. The absence of a differential pressure regulator can lead to unstable operation of the system, reducing the economic effect and service life of the equipment.

- Room temperature sensor. The sensor is designed to monitor indoor air temperature.

- Data collection and control server. The server is designed for remote monitoring of equipment performance and correction of heating schedules based on readings from indoor air temperature sensors.

The principle of operation of the classical SART scheme is qualitative regulation, complemented by quantitative regulation. Qualitative regulation is a change in the temperature of the coolant entering the heating system of the building, and quantitative regulation is a change in the amount of coolant coming from the heating network. This process occurs in such a way that the amount of coolant supplied from the heating network changes, but the amount of coolant circulating in the heating system remains constant. Thus, the hydraulic mode of the building’s heating system is maintained and the temperature of the coolant entering the heating devices changes. Keeping the hydraulic mode constant is a necessary condition for uniform heating of the building and efficient operation of the heating system.

Physically, the control process occurs like this: the weather controller, in accordance with the individual control programs embedded in it and depending on the current temperatures of the outside air and coolant, supplies control actions to the KZR valve. When in motion, the shut-off element of the KZR valve reduces or increases the flow of network water from the heating network through the supply pipeline to the mixing unit. At the same time, due to the pump in the mixing unit, a proportional selection of coolant is carried out from the return pipeline and mixed into the supply pipeline, which, while maintaining the hydraulics of the heating system (the amount of coolant in the heating system), leads to the required changes in the temperature of the coolant entering the heating radiators. The process of reducing the temperature of the incoming coolant reduces the amount of thermal energy that is taken per unit time from the heating radiators, which leads to savings.

SART diagrams in ITP of buildings from different manufacturers may differ slightly, but in all schemes the main elements are: weather controller, pump, KZR valve, temperature sensors.

I would like to note that in conditions of the economic crisis, an increasing number of potential customers are becoming price sensitive. Consumers are beginning to look for alternative options with the least amount of equipment and cost. Sometimes along the way there is a mistaken desire to save money by installing a mixing pump. This approach is not justified for SART installed in ITP buildings.

What happens if you don't install a pump? And the following will happen: as a result of the operation of the KZR valve, the hydraulic pressure drop and, accordingly, the amount of coolant in the heating system will constantly change, which will inevitably lead to uneven heating of the building, inefficient operation of heating devices and the risk of stopping the coolant circulation. In addition, at negative outside temperatures, the heating system may “defrost”.

It’s also not worth saving on the quality of the weather controller, because... Modern controllers allow you to select a valve control schedule that, while maintaining comfortable conditions inside the facility, allows you to obtain significant amounts of thermal energy savings. This includes such effective heat management programs as: eliminating overheating; reducing consumption at night and on non-working days; elimination of overestimation of return water temperature; protection against “defrosting” of the heating system; correction of heating schedules based on indoor air temperature.

To summarize the above, I would like to note the importance of a professional approach to the selection of equipment for a weather automatic control system for heat consumption in a building’s ITP and once again emphasize that the minimum sufficient basic elements of such a system are: a pump, a valve, a weather controller and temperature sensors.

23 years of work experience, ISO 9001 quality system, licenses and certificates for the production and repair of measuring instruments, SRO approvals (design, installation, energy audit), accreditation certificate in the field of ensuring uniformity of measurements and recommendations from clients, including government agencies, municipal administrations, large industrial enterprises allow the ELECOM company to implement high-tech solutions for energy saving and increasing energy efficiency with an optimal price/quality ratio.

Recommended radiator thermostat settings for different rooms.

The comfortable temperature for different rooms differs; the table shows the recommended thermostatic head settings for each of them.

| Position on regulator | Room temperature | Mode or type of room |

| * | 7℃ | Frost protection |

| 1 | 15℃ | Staircases and halls |

| 2 | 18℃ | Bedrooms |

| 3 | 21℃ | Living rooms |

| 4 | 24℃ | Bathrooms |

| 5 | 27℃ | Maximum temperature setting |

Weather-compensated automation with shut-off valve and circulation pump.

And finally, the last type of automation for maintaining the temperature in apartments of residential buildings, depending on the temperature outside, is weather-dependent automation with a shut-off and control valve and a circulation pump.

Let's look at the principle of operation of this automatic temperature control system in an apartment, or rather, in an entire apartment building.

Here, temperature control in the heating system occurs by changing the valve capacity and, as in the previous scheme, mixing returned (return) network water from a residential building using a circulation pump, now installed on the return pipeline of the heating system. In principle, where the network or circulation pump will be installed is generally unimportant; it’s just that for a two-way valve such a scheme is still preferable due to its design features.

During the regulation process, the controller also periodically polls the coolant temperature sensors in the heating system of the house, indoor air sensors (if installed) and an outdoor air sensor. After processing the received information, the controller generates an output control signal to open or close the actuator of the two-way valve, and the value of opening or closing the flow area of the control valve changes accordingly. In the absence of an indoor air sensor, the main priority of regulation is also to maintain the temperature in the apartments according to the temperature schedule.

There is only one drawback of control schemes with valves - loss of electricity. For more information about the advantages and disadvantages of weather-dependent automation, see the article on weather control with a control elevator. The advantage of weather control schemes with valves over a control elevator is usually called the depth of regulation, although in our opinion such an advantage is controversial and can easily turn into a disadvantage if, for example, the ITP has a thermal energy metering unit, and its measurement limits are worse than the operating limits of automatic weather control. After installing automatic weather control without agreement with the energy supply organization, such a heating system can legally be recognized as non-commercial, which means that instead of saving, you will again receive payment for heat according to the standard.

- insufficient pressure at the inlet to the ITP, less than 0.07 mPa

- excessive resistance of the internal heating system of the house, more than 5 m.w.c.

- installation of automatic control valves on heating devices and risers, for example

- use of an independent heating system through heat exchangers.

I would also like to warn residents who are especially concerned about saving money that weather-compensated automation circuits with mixing valves cannot be used without a pump or with the pump turned off . In the operating mode with the pump turned off, the pumping of coolant through the heating devices sharply decreases; the difference in temperatures between the temperatures in the heating devices of different apartments sometimes reaches 45 degrees, instead of the twelve recommended for the economical mode of operation of weather-compensated automation. And most importantly, due to the lack of mixing in cold weather, the temperature in the heating devices of the first apartments along the route can reach 115 degrees or more, which will inevitably lead to the failure of modern polypropylene pipes , as well as burns from accidental touching of the heating devices - this is at a minimum. At the same time, the residents of the last apartments along the coolant path will sit in the cold.

This is the savings, and everything will be OK according to the instruments. And most importantly, if the check valve on the jumper between the direct and return pipelines fails, not only your home, but the entire area may be left without heat. The coolant will not go to the apartments, but will return back to the boiler room.

We examined possible options for schematic solutions for implementing weather-dependent automation in the control framework of multi-storey residential buildings. In any case, the decision to choose one or another weather-dependent temperature control scheme in the apartments of a residential building, and most importantly the selection of equipment, should be entrusted to specialists. You, as residents, should have your say only when choosing a design organization and the type of equipment - domestic or imported. The price depends on this.

All about the prices for design work, purchased equipment and installation and adjustment of automatic weather control in apartments of residential buildings on the next page.

Criterias of choice

When selecting a thermostat model, most users focus on price. Mechanical models are several times cheaper than electronic ones, but at the same time less convenient to operate. The most convenient are electronic devices with programming capabilities.

With their help, you can set the temperature for different time periods. Such thermostats are able to turn off the heating for the period when no one is in the apartment, and bring the temperature to comfortable values at the required time. You can also program day and night modes for heating the room.

Thermostats also differ in internal content:

- Devices with bellows filled with liquid are inexpensive, but their response to temperature changes in the environment is somewhat slower.

- Gas-filled thermal heads are very sensitive to any temperature fluctuations. They will “notice” if the air in the room becomes warmer because the sun is shining through the window and will close the valve, stopping the supply of media.

This criterion is important to consider when purchasing a specific model.

It is also important to take into account the following differences between gas and liquid thermostats:

- Gas-powered devices have a long service life. At the same time, the gas reacts smoothly to temperature changes, which does not cause excessive sudden loads on the device. Liquid ones operate quickly, which has a greater impact on the wear of working parts, but allows you to quickly respond to a drop or rise in temperature.

- In liquid thermostats, the sensor can be remote or built-in. If it is built-in, then the device is placed in a horizontal position to reduce the influence of convection currents from the radiator and pipes.

- It is advisable to install remote-type sensors when the device is covered with thick curtains that affect heat transfer, the thermostat is located vertically, the radiator is installed in a deep wall niche or too close to the window sill.

In order to install a heat saving system in your home, you need:

Application

Survey

Visit of a specialist to the site and commercial offer - free of charge

Agreement

We carry out major and current repairs

Project

We develop an individual project. Approval from supervisory authorities

Installation

In any season. Quality assurance. Right on time.

Commissioning

We carry out commissioning work. Setting the optimal heat consumption mode at home.

in the period from 2013 to 2022, existing heating units were retrofitted with weather-dependent automatic heating and maintaining the set hot water temperature. The heating and hot water systems are equipped with 2-circuit ART-05 regulators, control valves with electric drives and circulation pumps.

Apartment buildings, administrative and industrial buildings, as well as institutions of the Department of Culture of the Vladimir Region were retrofitted with weather-dependent automation.

The average monthly result of heat savings with proportional heating control was 20%. At the same time, the problem of uniform heating of heating devices throughout the house and the absence of overheating was solved.

By agreement with the customer, it is possible to establish a daily schedule for regulating the temperature of heating and hot water for additional savings and comfort for residents of the apartment building.

Various operating modes and modifications

DHW regulators have two different modifications. The first of them makes it possible to use the device only as a hot water temperature regulator, while the second, in addition to the main function, makes it possible to protect against emptying of the system. The first modification is correspondingly simpler and consists only of a control valve, its actuator and a control device. At a given temperature, all moving parts of the device remain stationary, and when it is exceeded, the volume of the cylinder of the control device changes and the shutter of the actuator device moves. In contrast, the 'protective' modification is additionally equipped with a universal direct-acting pressure regulator - URRD, which protects against pressure drops. With this scheme, the pressure in the return pipeline is less than in the local heating system. Due to this, during a drop in pressure, the balance of the acting forces is disturbed and the valve closes. When the pressure normalizes, the automatic regulator itself will switch to the state of maintaining the required temperature.

Needle valve

This device is usually installed in the heating system in front of the pressure gauge. The valve smoothly and effectively changes the flow of coolant, gradually blocking it. The design feature of this device is that the width of the passage in it is half as much.

For example, when installing inch pipes and the same cross-section of a needle valve, its capacity will be only ½ inch. As a result, each device built into the system reduces this parameter. Several products installed in series, for example in a single-pipe design, result in the latter devices being lukewarm or cold.

Since the passage is greatly narrowed, a needle device is not recommended to be installed when solving the problem of how to regulate the temperature of the battery, since its heat transfer is greatly reduced.

You can increase it as follows:

- removing the valve;

- doubling the number of sections;

- by installing a device that has twice as many couplings.

Operating principle and device

The DHW regulator operates on the principles of mixing two streams of water of different temperatures from the supply and return pipelines, with the formation of a third stream with the required temperature, directly sent to the consumer's hot water supply system. The device itself consists of a body and a working part, the main component of which is a bellows-sealed cylinder, usually filled with benzene or paraffin and maintaining the desired temperature balance. It is a heat-sensitive element of the system; its expansion or contraction leads to a change in the amount of mixed hot water, and, accordingly, an increase in cold water. The regulator is automatic and non-volatile; it does not require additional human control.

Summarizing

You can regulate heating radiators using several types of devices, but experts believe that the best solution is to use special control valves. Such products are manual taps and automated products - thermostats, and only in some cases can a three-way valve with a thermal head be used.

In high-rise apartments with centralized heating, it is better to give preference to control taps or a three-way valve. As for individual heating systems, the problem of how to reduce the temperature of the coolant in a heating radiator is solved using thermostats.

If the apartment owner still prefers automatic adjustment of radiators, then a filter should be installed before the thermostat - it will trap most of the various impurities.

Thermostat cost

The cheapest thermostats are mechanical with manual adjustment. They allow you to set the temperature in the range from 5 to 30 ° C, do not have a display, and are turned on and off with one button.

More advanced models have digital backlighting and a clear display with manual control. These thermostats allow you to set multiple day programs and are also available in a wireless version.

You can buy top-end thermostats with a range of features. They are equipped with a combined sensor. They have several modes and preset programs. They can be connected to a smartphone via Wi-Fi, GSM module.

Heating temperature regulators model range and prices

Let’s say right away that there are a lot of manufacturers and we do not intend to consider each of them. Let's talk only about the most popular models.

Teplolux MCS 300

- Remote control and control of underfloor heating via the Internet

- Control from one mobile device all heated floors in an apartment, country house or country house. Replace classic wall thermostats with MCS 300 - and control your comfort from your smartphone screen.

- separate operating mode for each thermostat

- programming events for each room during the day, days of the week

The Computherm Q7 model, also an electronic type, with a temperature range of +5 – +35 C, costs about 1400-1800 rubles.

Price 1400-1800 rubles.

Temperature controller – Veria Control T45

A more expensive regulator is the Veria Control T45, its range is the same as the previous model.

Price 4300-4400 rubles.

Mechanical heating temperature controller Terneo RTP

Mechanical regulators are cheaper. For example, the Terneo RTP model with a temperature range of +10 – +40 C.

Price 1050-1100 rubles.

Although there are more expensive mechanical devices. So, Legrand Etika 672630 costs as much as 7750-10600 rubles.

As you can see, you always have to pay more for quality, and our case is no exception. But we note that mechanical models are still simpler and, accordingly, cheaper. Now let’s find out how to properly install the heating temperature regulator.

Do you want to learn more about thermostats for radiators?

Our installation instructions and a large overview of models with their technical characteristics Read more here

Installation of the device

The equipment installation process is simple, but if you don’t want to carry it out yourself, you can always turn to professionals.

Correct position of the device

Instructions:

- Disconnect the battery from the system. To do this, close the ball valve or shut-off valve. Then drain the water from the battery and vent the radiator.

- Remove the adapter. Before doing this, lay a lot of rags on the floor to absorb the liquid. Secure the valve body with an adjustable wrench, and use the second to remove the nut from the adapter pipe. Next, remove the adapter from the device body.

Installation location

- Installing the adapter. Screw on the union nut and collar. In this case, first clean the thread and wrap it with locking tape. You should wrap it clockwise, doing it 3-5 times, then smooth the tape. Assemble the adapter, heatsink and corner nuts together.

- Mount the new collar. Install the collar and blind nut on the pipe. All actions are performed with a screwdriver.

- Installation of thermostat. Secure the device in the directions of the arrows. Tighten the nut between the regulator and the valve, fixing it with an adjustable wrench. At the same time, tighten the nut. Do all actions carefully. After installation, make sure the fastening is secure.

- Fill the battery with water.

Fixing the thermostat

Applications of three-way valves

One way to regulate heating radiators is to use a three-way valve. True, it is rarely used. Despite the fact that it is designed to solve other problems, such an application is possible.

Install a three-way valve at the junction of the bypass with the supply pipe going to the heating battery. To stabilize the temperature of the working environment, it must be equipped with a thermostatic head.

When the temperature near the head of the three-way valve becomes higher than the set parameter, the flow of liquid moving to the radiator is blocked - it is sent to the bypass. After the coolant cools down, the valve begins to operate in the opposite direction, and the battery heats up again. This connection method is usually implemented in single-pipe heat supply systems, with vertical wiring.

Control method

Adjustment of operation is carried out in two ways: mechanical, as, for example, in the model of equipment, and also electronic, as in.

In the first case, the water temperature is adjusted using a screw regulator, and in the second - through a push-button keyboard. Note that with electronic control, all set parameters are reflected on the LCD display, which is located on the front panel, which is very convenient for monitoring work. In the event of a breakdown, a special code is displayed on the screen, the decoding of which is most often found in the instructions. So, if a problem occurs, the technician will fix it very quickly.