Even metal-plastic structures eventually cease to be a reliable barrier to cold air and drafts.

There can be many reasons for windows blowing, ranging from dishonesty of installers to violation of operating rules. Let's figure out how plastic windows are insulated, whether this can be done without replacement, and other nuances.

Preparing for work

Before you insulate plastic windows with your own hands, you need to carry out a complete diagnosis.

To do this, critical areas that allow wind to pass through are identified. It can come from different places, but it mainly comes from the window sill, window sashes and areas with worn out insulation. To understand where the wind is blowing from, you just need to raise your hand to different parts of the window. If this method does not help, then you can light a candle and sweep it across the entire structure, since fire is most sensitive to air currents. Rain can also help with diagnosis. Places where a lot of moisture has accumulated and lingered are the most problematic. If moisture was noticed in the middle of the window, this may indicate that there is a small crack in the glass.

The seal can be easily checked using a sheet. It must be inserted into the opening and the window closed. If the sheet is easily pulled around the corner, it means that the seal does not fit tightly to the frame.

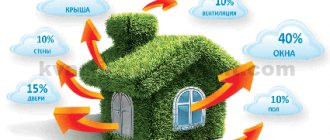

Before insulating plastic windows with your own hands, you need to understand the purpose of the work. Naturally, this is done to save heat, but not every compromise can be made. You need to decide whether it is worth abandoning the aesthetic appearance of the window structure for the sake of savings or limiting access to the light flux.

Additionally, cost must be taken into account. Some materials are inexpensive. For example, sealant can be bought for several hundred rubles. Better and more durable solutions may require larger financial investments and the help of a qualified specialist. But don't be afraid of the high cost. High-quality insulation done once will please the owner for a long time.

It’s easy to do all the work yourself, but you can also resort to the help of specialists. It is quite possible to insulate the frame, window sill and replace the insulation on your own.

Before installing the insulation, do not forget to check the frame for chips and dents

It is worth remembering that windows have a warranty period. If during this period defects begin to appear on the windows, the company must eliminate all defects at its own expense.

It is necessary to insulate windows immediately before the onset of winter. This time is the most favorable for work. It is also necessary to take into account the specifics of materials. For example, a sealant can only be used in a certain temperature range, otherwise there is a risk that it will lose its properties.

Identifying problem areas

Before you begin insulation, you need to find and identify all the places that need thermal insulation . Particular attention should be paid to the joints, as well as the junction of the walls and the frame. You should also check the slopes and window sill. To identify areas where cold air enters, you can use a regular lighter. It should be passed over all possible places of blowing.

Damage to thermal insulation can cause condensation to form on the glass.

Condensation, frost or drafts may also indicate an area that requires insulation. Depending on the cause of the thermal insulation failure, you need to think about how to fix it.

Blowing from a plastic window, find and eliminate

Where can it blow from plastic windows?

To understand why it blows from a PVC window, you need to inspect the components, and for this you need to know the design principle of the window unit.

Construction of a window unit - main elements Construction of a plastic window and door - list of elements

The most common places for blowing:

- window glazing bead (glass unit holder);

- rubber compressor;

- window fittings (for example, blowing from under the hinges, into the handle);

- the perimeter of the window frame - the junction of the slopes, window sill, walls.

How to determine where it is blowing from a plastic window?

The presence of a defect in one of the components of the window unit leads to blowing from plastic windows. There are three ways to determine the exact location of heat loss from metal-plastic windows:

tactile hand. To identify a gap, just run your palm over the surface of the window block;

lighter. The search procedure is similar to the previous one, but the light is more sensitive to drafts and can detect even the weakest blowing.

paper. An ordinary sheet of paper is pressed against the window (put into the open window and clamped by completely closing the sash), if you pull the corner of the sheet and it easily pulls out, then the seal is not pressed enough (this may indicate that the window is operating in summer mode, the old seal is in this mode does not press well to the frame).

Why does it blow from plastic windows - reasons for heat loss

installation error. This is the most common reason associated with ignorance or non-compliance with the correct technology for installing a plastic window. 15 years ago, this service was so in demand that everyone who had at least some idea about installing window units became installers. Naturally, few people installed PVC windows according to GOST;

window distortion due to shrinkage of the house. A pressing problem for residents of new buildings and wooden houses;

an attempt to save money. One of the weighty arguments in competition is always price, especially during an economic crisis. The price reduction often occurred at the expense of quality: saving on foam, on insulation, ignoring the need to protect the heat insulator, using low-quality components when assembling windows - all this over time led to the fact that the consumer is forced to change or additionally insulate PVC windows;

physical wear of window components, in particular sealing rubber bands, or weakening of the pressing force of the sashes;

violation of the operating rules for plastic windows, which include the need to wash the window seal and treat it with glycerin. This care prevents the seal from losing its elasticity and cracking.

What to do if it's blowing from a plastic window

Of course, eliminate the source of the draft. From a practical point of view, there are two simple options - call a specialist to repair and adjust (expensive) windows or do it yourself (cheap).

The desire to seal all the cracks yourself using improvised means is nullified because: firstly, it is not aesthetically pleasing, and secondly, there are no guarantees.

When is it advisable to hire professionals:

The plastic window was recently installed. The installer company is responsible to the consumer for the reliable operation of the windows (if the warranty covers this period);

the window opening is located at a considerable height (in a multi-story building). It is better to entrust any high-altitude work to professionals (industrial mountaineering services). If the window is located on the second floor or higher, the work will be associated with increased risk;

if there is a manufacturing defect. For example, obvious manufacturing or installation defects that appeared during the warranty period;

if necessary, replace parts. It is better to install “original” fittings if it is necessary to replace individual elements of the window unit;

work is carried out in winter. Knowledge of installation technology and how to insulate plastic windows for the winter allows installers to complete the work quickly, without significantly cooling the living space.

However, often, the cost of hiring specialists is equal to the cost of installing a new window, and this fact makes it more profitable to do the insulation work yourself.

Application of Swedish technology

The essence of Swedish window insulation is to glue an additional rubber seal between the sashes. A “glazed window effect” is achieved, which contributes to a significant increase in thermal insulation.

This method is considered the most expensive, as it involves window repairs.

Even the smallest gaps can become the main cause of heat loss. You can carry out window insulation work yourself. If difficult situations arise, when the house is still cold, you need to contact the installers to correct the defects.

External window insulation

Proper insulation of plastic windows involves external and internal work. The first include:

- finishing of external slopes;

- insulation of ebb tides.

Each type of work requires its own approach, so it is important to consider them separately

External slopes

Most often, during the installation of windows, the external slopes are not finished, so they are the first point that should be taken care of when insulating a plastic window. Without this event, you can do whatever you want from within, but it will not have any effect. Insulating plastic windows on the street side makes it possible to move the dew point. This way, moisture condensation will not occur on the inside of the glass. This often leads to the appearance of mold, which not only spoils the appearance, but is also harmful to health. Another factor that requires finishing of slopes is polyurethane foam. If it is not protected from ultraviolet radiation and precipitation, it will begin to crumble, which will only intensify drafts.

To carry out the work you will need insulation, glue and tools. It is best to use extruded polystyrene foam as insulation for slopes. It has minimal thermal conductivity and is easy to install. This insulation also perfectly resists moisture and is not susceptible to rotting. To secure it to the wall you will need dowels in the shape of umbrellas, as well as special glue.

Note! If you want to use stone wool to insulate a slope, you need to take care of its high-quality waterproofing. If this is not done, then it will pick up moisture and lose its insulating properties, which will not solve the problem in any way.. First of all, you need to thoroughly clean the window slopes of debris

If there are sagging marks left on them from the old plaster, then they should also be knocked off with a hammer or a hammer drill with a chisel. If there are cracks or other damage, they must be repaired using tile adhesive or a similar solution. After this, the surface is coated with a deeply penetrating acrylic primer. If the first layer is absorbed too quickly, then you can apply another one and wait until it dries completely. Using a construction knife, the insulation is cut to the required size. An adhesive base is applied to it and it is placed in place. At the same time, it should fit snugly against the window frame.

The first step is to thoroughly clean the window slopes of debris. If there are sagging marks left on them from the old plaster, then they should also be knocked off with a hammer or a hammer drill with a chisel. If there are cracks or other damage, they must be repaired using tile adhesive or a similar solution. After this, the surface is coated with a deeply penetrating acrylic primer. If the first layer is absorbed too quickly, then you can apply another one and wait until it dries completely. Using a construction knife, the insulation is cut to the required size. An adhesive base is applied to it and it is placed in place. At the same time, it should fit tightly to the window frame.

Using a hammer drill, several holes are drilled in the insulation and the wall. A small amount of foam is blown into them and plastic umbrellas are clogged, which will additionally press the insulation to the wall surface. All remaining gaps that may exist between the insulation and the plastic window are sealed with glue. The insulation is covered with a small layer of glue. After this, a reinforcing mesh is mounted on it, which increases the strength of the slopes. Using a spatula, the mesh is pressed against the insulation so that the glue spreads evenly onto its surface. After grouting and drying, you can begin finishing work. You can watch a video about insulating window slopes below.

Working with tides

Insulating the ebb of a plastic window is not a difficult task, so it can be easily done and will not require large funds.

It is important to carefully inspect the space and eliminate all the gaps that exist between the wall and the window. A metal strip is mounted on the ebb, which covers part of the opening and prevents it from getting wet.

Under the bar you can place a small piece of insulation, which is firmly glued to the surface. All cracks are additionally filled with sealant.

Adjusting the clamping mechanism

During operation, the window is exposed to mechanical and climatic factors. As a result, loss of sealing rubber volume may occur. What causes air to get inside the house. To solve this issue, it is not at all necessary to resort to replacing the gasket, unless, of course, it is completely in unusable condition. You just need to adjust the clamping mechanism.

To begin, find the protruding cylinder - the axle - in the cut places of the metal plug. Then move the hooks to the required position or adjust the trunnions. To change the position of the hooks, loosen the bolts. When moving to the street side, the pressure increases, and in the opposite direction decreases.

How to insulate a plastic window from the street: basic steps

If you are using sealant. trim off the remains and level the surface.

Treat the slopes with a primer with special antibacterial additives.

If plastering is required, apply it using a square, after thoroughly cleaning the surface.

You need to cut a slab from expanded polystyrene to the size of the slope. Then attach it to the surface using mounting adhesive and dowels, and place the corner.

A fiberglass mesh is installed on top.

Fix the structure by coating it with glue. Once the slope is dry, coat it with water-based paint.

For internal insulation it is necessary

- Trim the foam and apply primer. After this stage, the surface is processed and the procedure is repeated;

- Plaster;

- Attach a sheet of foam plastic of the required size to the mounting adhesive;

- After drying and installing the corner, the structure is covered with putty;

- The last step will be to secure the casing.

You can cover a slope not only with plaster: plasterboard is increasingly used as a final finishing touch.

How to insulate windows from the outside

Adjust the sashes: each owner can do this simple work independently. It is necessary to tighten the necessary elements so that there are no gaps between the window and the window frame. Tighten the screws and check the mobility of the structure.

Often additional insulation is also needed for double glazed windows. A special coating is applied to the surface - an energy-saving film. All work must be carried out only in dry weather.

How to insulate the window sill of a plastic window

Improper installation of this part can lead to serious consequences: deep and wide cracks, strong drafts. Over time, the heat-retaining material dries out and defects may occur. You need to put polyurethane foam into the gap: such processing will not require much time. However, such a quick solution cannot replace repair work, which should be carried out in the summer or spring.

You can secure a sheet of plastic under the window sill by placing sealant in the resulting cavity. Leave a small gap: the seven or eight centimeters you marked will improve air circulation.

Some tips for those who decide to protect their apartment from the cold

Buy construction foam. When choosing, give preference to European brands - the quality of the material will ensure reliable insulation.

Remove any remaining old coating and thoroughly clean the resulting cavity.

Fill the gap, observing the position of the dispenser and noting any small cracks. A silicone-based product can deal with them better and more effectively.

To understand how to insulate plastic windows for the winter with your own hands, watch the training video

If your profile begins to leak cold, do not rush to contact professionals. Most of the necessary work can be done independently, spending a minimum of money on preparation. Turning to specialists should be a last resort: strict adherence to the rules and sequence of key actions will help you return warmth and comfort to your home in a short time.

What materials are suitable for thermal insulation?

In order for all the activities carried out to have a positive result, it is necessary to select the right materials. The following is used as a heat insulator for slopes:

- Mineral wool (basalt, slag or glass wool).

- Styrofoam.

- Extruded polystyrene foam.

- Polyurethane foam.

- Sandwich panels.

- Fiberglass, one side of which is covered with a layer of foil.

In the process of selecting the required material, the dimensions of the window opening and the places where the insulation will be installed are taken into account. Mineral wool, for example, performs its functions with a thickness of at least 10 cm, which is not always convenient for insulating a window from the outside.

In addition, cotton insulation requires the use of a water barrier on both sides. This is due to the fact that after getting wet the material loses its insulating properties.

An affordable and popular option is to use polystyrene foam and extruded polystyrene foam (penoplex). Moreover, the latter material is preferable because it has a higher density with a smaller thickness. It is important to protect the polymer insulation from the sun in a timely manner. When exposed to ultraviolet light, foam becomes brittle.

If polyurethane foam was used during the installation process, then there is no hope for complete thermal insulation. Of course, if the voids are densely filled, some of the heat will still be retained in the room, but if the house is located in a region with low winter temperatures, then you will have to take care of additional insulation.

A good option that solves two problems at once would be sandwich panels. The top layer is a decorative material, the bottom layer is insulation. At the same time, it is possible to choose an option for your home if the facade is already lined, but the slopes had to be insulated later. In addition, some creators of such panels offer options with different insulation materials.

A new option for insulating slopes is fiberglass with a foil base. It is difficult to install such material with your own hands, so you need to take the help of professionals. But you will be 100% sure of the result. The insulator perfectly protects against moisture and penetration of cold air currents.

How to change the seal

Special rubber bands are used as a seal on plastic double-glazed windows, improving sound and thermal insulation. They are available in different quality on sale. Rubber bands marked EPDM optimally combine affordable price and good quality, which is why they are most often purchased. Products with the VMQ brand are of high quality, but are too expensive. There is no need to buy TPE sealant, as it quickly deteriorates when exposed to weather.

Important!

There is also a seal with an adhesive layer on sale, which is attached to the window using the principle of adhesive tape. It is not a complete replacement for a conventional seal, so it is not advisable to buy it.

Seal replacement procedure:

- The seal that has served its useful life is removed by prying it by the middle. The freed space in the grooves is thoroughly washed with laundry soap or other detergent. Then thoroughly dry and degrease with alcohol.

- To make the fit tighter, the corners of the profile are glued with construction adhesive, PVA or silicone. After applying the composition, wait until it dries completely.

- After this, the rubber seal is prepared for installation. If material marked EPDM is used, it is measured along the length of the perimeter of the opening, since it bends easily. The remaining materials are cut to the length of the side of the opening with a small margin.

- Then the elastic is inserted into the grooves, being careful not to deform the material. It is more convenient to do this operation together using improvised tools.

To extend its service life, the rubber band should be washed and coated with silicone grease several times a year. After five years of operation, the seal is replaced with a new one.

Average prices

The price of insulation for PVC window blocks is determined based on a linear meter or a finished set. It depends on the brand, type of material, length and color of the product.

Average prices for popular insulation materials:

- EPDM Montblanc, 16 RUR. for 1 p.m.

- Ultima TPE 4952 LM, 150 rub. for 5.5 p.m.

- EPDM Century black, 18 RUR. p.m.

- KBE TPE, black, 18 rub. p.m.

- Schlegel polyethylene, polyurethane foam, 45 rub. per p.m.

- Hotrock Smart basalt mats, RUB 270/pack.

- Foam plastic PSB-S 25, 2000*1000*25 mm, 210 rub./sheet

- Penoplex 1185*585*50mm, 500 RUR/sheet.

- Foam insulation VASmann thermofoam, RUB 300/cylinder.

How to insulate plastic windows with your own hands

When to insulate windows for the winter

Repairs and insulation must be carried out before the onset of cold weather. This is due to the following requirements:

more comfortable working conditions;

material requirements. Some building materials, such as dry mixes and sealants, can only be used in a certain temperature range. Otherwise, they lose their characteristics;

optimal humidity;

no draft;

the ability to simultaneously perform internal and external insulation;

reducing the risk of catching a cold among apartment residents.

Insulating window openings for the winter

To insulate a window opening, you can use different materials and methods:

polyurethane foam. As the foam expands, it fills all the voids around the perimeter of the window opening, preventing air movement. Due to the fact that foam is 90% air, it is an ideal insulation material. However, the foam needs protection from ultraviolet radiation, high and low temperatures. This means that it is not advisable to use it by itself;

mineral wool. An excellent thermal insulation material for insulating window sills and internal slopes. Cotton wool has a more limited range of uses when insulating windows;

polystyrene foam/expanded polystyrene. Used for insulating slopes of plastic windows;

Note. Rigid insulation is used when the thickness of the installation seam is no more than 3 mm; in other cases, it is better to give preference to mineral wool.

silicone sealant. A reliable way to eliminate air leaks between plastic window elements;

dry mixtures for finishing slopes, used if necessary to insulate the window from the outside;

construction tape. Glues on top of the sealant or instead of it;

Advice. It is not recommended to use ordinary masking or window tape; after sticking it, unattractive marks remain on the plastic of the window frame that are difficult to remove without damaging the front covering.

Insulation of a window block

- seal;

- construction tape;

- sealant;

- heat-saving film for windows (energy-saving);

- mechanical methods of insulation, for example, tightening (adjusting) fittings.

After the question of how to insulate has been resolved, we will deal with the question of how to insulate a double-glazed window, frame, plastic, aluminum profile, etc.

Cold check in 1 minute

The old windows are safely thrown away and your new ones are sparkling. Warm, reliable, beautiful. Such where the manufacturer is obliged to adhere to quality standards and take into account all weather conditions - wind protection, frost resistance and heat. It seems that all the stories about the cold can be forgotten, at least for 5-7 years. But experts advise doing a very simple test for cracks and drafts regularly.

To do this you need:

- Walk along the joints with a lighter or a lit match. The deflected fire will quickly reveal cracks invisible to the eye;

- Wet your finger and run it around the perimeter of the window. Sharp cold on the skin will serve as an excellent indicator of even a small draft.

Important! Pay attention to the frame from the inside. Frost, ice or condensation should not be present.

Causes of drafts

You should also have basic information about the causes of drafts. Having basic knowledge, you can avoid such unpleasant situations in the future.

- Making mistakes during window installation. One of the most common problems associated with the low qualifications of the installer. If a draft occurs immediately after installation, then you need to contact this installation company again and demand that the defects be corrected. If you install plastic windows yourself, you need to check the correct installation and correct any errors.

- Shrinkage of the soil under the house and, as a result, skewing of windows. A rare problem that occurs among residents of new houses.

- Poor quality materials and manufacturing defects. An attempt to save on the price of double-glazed windows can cause poor window sealing, but even owners of expensive windows are not insured against defective parts. If the terms of purchase allow, take advantage of the opportunity to return the entire set or only the defective parts.

- Physical wear and tear on the locking parts of the window and seal. A very common problem for window owners who have been using them for a long time without replacing them.

- Violation of the rules of use and care. Over time, the sealant may lose its properties. To prevent this from happening prematurely, it is necessary to wash it and treat it with emollients. For example, glycerin.

If you evaluate in detail all the causes of drafts and heat leaks, you can divide them into two categories based on the possibility of eliminating them - with the help of window installation specialists and solving problems yourself.

It is best to use the services of professionals to solve the following problems:

- If problems with the window are identified during the warranty period. At this time, the installer company bears full responsibility for its operation. Independent intervention in the design features may result in denial of further warranty service.

- External work at height is required. In such conditions, the likelihood of injury greatly increases, and it is better to entrust such work to professional workers.

- Detection of manufacturing defects during the warranty period.

- Replacement of some structural parts, requiring certain tools and skills to work with them.

If the work is done from the inside, then most of it can be done independently.

Trust the professionals

Many years of experience have made it possible to make sure that any third-party intervention in the window system can lead to serious damage. Window maintenance should be entrusted to professionals - such as craftsmen.

Why us?

- Our staff includes only experienced craftsmen who have passed professional selection. Average experience is more than 3 years.

- We are confident in the quality of the services we offer and provide an official one-year guarantee.

- Our prices will pleasantly surprise you, because we work without intermediary markups.

- Our specialists are ready to leave immediately to carry out urgent work.

- We are ready to travel to any point in the Moscow region.

We are not saying that “Healthy Window” is the best window company in Moscow and the Moscow region, our clients say that for us!

Return to page navigation

Internal insulation of windows

The process of how to insulate windows with your own hands also includes the interior finishing of some components. These include:

- internal slopes;

- insulation;

- windowsill.

Insulation will require special patience and care.

Internal slopes

The process of how to insulate the slopes of plastic windows from the inside is very similar to what was described above. Internal slopes require careful processing to achieve a pleasant appearance. It must match the chosen interior. The first step is to cut off the protruding foam, and also add it in those places where cracks have formed. The old finishing that was near the old windows is completely removed. The surface of the slopes is treated with a deep penetration primer and left until completely dry. The next step is to install drywall, plastic panels or putty and plaster.

Note! After finishing, the slopes can be painted using water-based paint or finished with decorative plaster, which is better than using plastic panels.

Windowsill

The window sill is an integral part of the window. For plastic windows, PVC window sills are used, which can be of various sizes and designs. But the correct installation must unite them. First of all, you need to find out where the heat loss is going. The gap can be between the window and the window sill, as well as the window sill and the concrete part. In the first case, it is necessary to seal the gap with sealant. For a white profile, you can purchase white sealant, and for other colors, transparent is perfect if the required color is not available.

If it blows from under the window sill, then certain mistakes were made during its installation. In cases where complete dismantling of the window sill is impossible, there is an option using foam to try to blow out problem areas. After the procedure, it is advisable to place something heavy on the windowsill so that the foam does not deform it and lift it up. If you have the opportunity to remove the window sill, you can additionally foam the junction of the window and the wall. A small layer of insulation is also placed under the window sill.

Advice! Insulation can be done using a special film. The process of such insulation is shown in the video below.

Why is it necessary to insulate slopes?

Often, after replacing windows, they are limited to only decorative finishing of the slopes, which is wrong and can lead to problems in the near future, because:

- The seams between the wall and the glass unit are filled with polyurethane foam. But this material is not sufficiently resistant to high humidity, ultraviolet radiation and low temperatures. Very quickly, unprotected polyurethane foam will begin to deteriorate under the influence of weather conditions, which will lead to heat loss through voids in the seams.

- Numerous cracks on untreated surfaces of slopes are a common cause of heat leakage from a room.

- Moisture can accumulate in the voids between the wall and decorative panels, which means condensation may form.

Expert recommendations

The insulation procedure is characterized by its peculiarities. Knowing the subtleties, you can avoid many problems. To ensure the highest quality work, adhere to the following rules:

- If there is no insulation of the required size, you can use separate pieces. They are placed tightly to each other.

- Ideal adhesion can be achieved through a combination of glue and reinforcing mesh.

- Preparatory work includes getting rid of cracks and defects. If the hole is larger than 3 mm, sealant must be used.

- Of all insulation materials, extruded polystyrene foam has the maximum thermal insulation function. This will be a plus when performing outdoor work.

- You need to choose thermal insulation based on the dimensions of the gaps. If the free space exceeds 4 cm, use polystyrene foam or polystyrene foam. If the gap is 2-3 cm - fiberglass, less than 2 cm - polyurethane foam, mineral wool.

You cannot take foam with a density of less than 30 kg/cubic meter. m. If you prefer mineral wool, the density should exceed 75 kg/cu.m. m. Otherwise, the insulation will not withstand the load and will quickly become unusable.

Sources

- https://domsdelat.ru/okna_i_dveri/uteplenie-okon-snaruzhi-svoimi-rukami-prichiny-poteri-tepla-metody-utepleniya-otlivov-i-otkosov-instrukciya.html

- https://ebtim.com/montazh/uteplenie-otkosov-okon-snaruzhi.html

- https://balkon4life.ru/osteklenie/okna/tyoplye-otkosy/.html

- https://1pofasadu.ru/uteplenie/otkosov-snaruzhi-svoimi-rukami.html

- https://uteplix.com/obyekty/okna/uteplenie-otkosov.html

- https://okna-dom.net/utepleniye-otkosov-plastikovykh-okon/

- https://vdome.club/remont/okna-dveri/teplye-otkosy-dlya-plastikovyh-okon-kak-sdelat-svoimi-rukami.html