In panel houses for summer residence, the “lightest” version, timber with a cross section of 10x10 cm is used for the load-bearing frame of the walls. If polystyrene foam is used as a filler for the cavities, then you don’t have to worry about additional thermal insulation - EPS with a thickness of 10 cm is similar in thermal conductivity to a gas silicate block D500-D600 width 375-400 mm. The question of how to insulate a panel house for winter living arises only if mineral wool is laid inside the wall - such a thickness is not enough for Russian frosts. Even frame walls made of 150x100 timber with mineral wool inside will require additional insulation. But in addition to the walls, there is also a floor, ceiling and attic, which also cannot be ignored if the house is transferred to year-round living.

This is what the internal insulation of frame-panel walls looks like Source otdelka-expert.ru

How to insulate the outside walls of a panel house

A panel house on a wooden frame is not a log house made of logs or timber. In this case, there is no need to talk about the breathing properties (gas permeability) of the walls. Firstly, a continuous layer of vapor barrier is laid on the inside. Secondly, the vapor permeability of plywood or OSB boards with which the frame is sheathed is very low. Therefore, for external insulation you can use those materials that are not used for wooden houses:

- expanded polystyrene;

- EPPS (extruded polystyrene foam);

- sprayed thermal insulation based on two-component or one-component polyurethane foam.

Finnish house

For the first time, such houses appeared on the territory of the former USSR after the Second World War as an option for prefabricated housing for temporary residence. The structure was a wooden frame-panel structure. The frame of such a house is sheathed on the inside with plywood, and on the outside, along the vertical bars of the sheathing, with wooden “siding”. The insulation inside the frame is 3 layers of soft fiberboard 18mm thick, installed “in space” in several layers with air layers. No vapor barrier. It is clear that such houses were cold and drafty. Trying to make them warmer, the owners lined the walls with brick. True, this helped insignificantly. A more effective method of modernization - replacing the insulation inside the frame - was tested in practice by our reader, Valentin. He shared his experience of insulating his parents’ house:

“I decided to carry out the modernization from inside the house. Opening the walls showed that the wooden parts of the frame were in excellent condition - everything was dry, intact, and strong. And this despite the fact that the house was built back in 1958. I threw out the old insulation, installed 10cm stone wool in its place, covered it with a vapor-proof film, and nailed down old plywood. The walls were additionally lined with gypsum board. The house has become noticeably warmer, however, in order to meet today’s requirements for the thermal resistance of walls, it would be necessary to sacrifice the area of the house and add another 50 mm of insulation to the walls.” (You can read more about the reconstruction of the Soviet “framework” here).

Video description

We will dwell in more detail on insulating a house with polystyrene foam. Find out how safe polystyrene foam is in our video:

It is impossible to ignite mineral wool even with the flame of a gas burner Source krovlyakryshi.ru

It is easy to compensate for lower thermal insulation properties due to thickness. External insulation is not internal, and a few extra centimeters of insulation mean nothing. It is necessary to insulate with hard mats - rolled materials in vertical structures “move out” over time. And you have to choose between a thickness of 5 cm and 10 cm. For central Russia, provided that mineral wool 10 cm thick is already laid inside the walls, an additional 5 cm of thermal insulation layer is sufficient. Plus the thickness of double-sided wall cladding, interior trim and façade panels.

But if the budget allows, you can lay a layer 10 cm thick.

General principles

The internal placement of the insulation layer implies that:

- the insulation is installed between the supporting elements of the frame without additional sheathing;

- work processes are carried out from the inside without unnecessary difficulties in any weather conditions;

- the material is well protected from adverse external influences;

- reconstruction is combined with decorative finishing of rooms.

The insulation is installed between the supporting elements of the frame.

The approximate distribution of heat losses through different parts of the structure should be taken into account (maximum in %):

- walls and corner connections - 15;

- windows and entrance group - 20;

- floor and plinth (basement) - 15;

- roof - 30.

This list confirms the feasibility of improving the insulation parameters of the facility.

To increase the effectiveness of the event, the project should be supplemented with systems modernization:

- heating;

- ventilation;

- conditioning.

The list of materials and construction tools will help you correctly draw up a purchase plan and financing scheme.

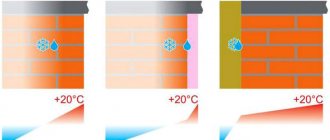

Based on the correct calculation of the “dew point”, drawings along with additional documents can be prepared independently. It is not necessary to follow design standards. However, even a simple freehand drawing with dimensions will prevent mistakes.

How to insulate walls outside

How to insulate a frame house for winter living:

- “foreign” objects must be removed from the surface of the external walls - ebbs, cornices, canopies, brackets for mounting lighting fixtures and attachments;

- remove the old finish - dismantle the trim, clean the paintwork;

- make markings for the sheathing , taking into account the width of the insulation mats;

- treat all wooden elements of the sheathing with an antiseptic;

- install a timber sheathing with a height equal to the thickness of the insulation;

The vertical lathing for external insulation of the pediment and walls does not have to coincide with each other. The main thing is that the step matches the width of the mats Source ekoplat.ru

- fix the insulation between the sheathing;

- lay a continuous layer, with overlapping sheets, of a superdiffusion waterproofing membrane , secure it to the sheathing;

- fill the counter-lattice beam , which should provide a ventilation gap and serve as a place for attaching facade panels (the height of the beam must be at least 6 cm - this is the minimum size of the ventilation gap);

- cover the facade with siding, block house or any other finishing materials for a ventilated facade.

Important! Even before insulation, it is necessary to replace the windows with a “winter” version. It is also necessary to insulate the entrance area - arrange a small vestibule and install a second entrance door.

Additional insulation of a panel house can be carried out along a horizontal lathing, and the counter-lattice can be made vertical to create a ventilated gap and fasten the sheathing.

Material selection

In the process of arranging a house under construction, you will have to find answers to a number of questions. Before determining what material to cover a frame house with, it is important to choose the optimal insulation.

Thermal insulation must meet certain requirements. This is necessary so that the building serves for a long time and faithfully, and also does not threaten the health and life of the residents.

We are talking about such moments:

- absence of harmful components and toxic smoke when burning;

- temperature resistance and fire resistance;

- reduced heat loss;

- strength and resistance to deformation;

- the ability to maintain shape and properties over a long service life;

- reasonable price, since frame houses are a budget solution.

Spending a lot of money on insulation by choosing frame-panel technology is somehow illogical. There are also inexpensive insulators that provide the required level of protection from the cold during winter living.

But objectively, in this case it is better to take polystyrene foam or mineral wool.

Expanded polystyrene

It's also penoplex. The material is lightweight, and therefore will not create a load on the foundation and walls.

You can also highlight the following advantages:

- good thermal insulation characteristics;

- ability to withstand repeated freezing and thawing cycles;

- resistance to changes in the structure of the material;

- resistance to temperature changes;

- water does not penetrate the cells and does not freeze inside.

But penoplex has its drawbacks.

The main disadvantages include the following points:

- ability to ignite quickly;

- sheets become deformed due to mechanical shocks;

- low breathability.

It is important to understand that the house has a ventilation system. Therefore, the building will not become like a thermos.

Regarding ignition, the issue is controversial. The material will be under a layer of exterior and interior finishing. Plus, effective fire protection treatment is carried out.

Expanded polystyrene, as well as its derivatives, can only be used for external thermal insulation.

Mineral wool

This material is highly popular in the insulating materials market. But there are several reasons:

- can be used for internal and external insulation;

- does not absorb harmful components at all;

- does not emit hazardous substances;

- does not burn or smolder;

- with low weight it has excellent thermal insulation and sound insulation properties;

- Rolls of cotton wool can be placed in corners, arches, and also curved surfaces.

But here we are not talking about perfect material.

The disadvantages here are the following:

mandatory waterproofing is required, since cotton wool deteriorates when wet;

if wet, the insulating properties disappear completely;

It is important that the material is correctly fixed, does not register anywhere and does not move away from the wall.

That is, if the process is not organized correctly, it may be necessary to quickly replace the insulation in a frame house. It does not matter whether it is carried out internally or externally. You will have to dismantle the casing and then start all over again. Too expensive. Therefore, everything needs to be done as efficiently as possible, and also in accordance with technology.

Base insulation

Full insulation of a panel house from the outside will require work on the thermal insulation of the base for a strip base or a fence for a pile foundation.

Insulation of the base of a strip foundation

According to experts, a house through the foundation loses up to 10-15% of the total heat loss due to the fairly high thermal conductivity of reinforced concrete or building blocks (depending on what the base is made of). And this phenomenon must also be fought.

This is what the general diagram of heat loss through the enclosing surfaces looks like Source valet.ru

In this case, it is better to choose EPS for insulation. It is difficult to protect mineral wool near the ground from moisture as part of a “wet” facade (especially a curtain wall). Extruded polystyrene foam has a very low water absorption coefficient, and can even successfully perform waterproofing functions.

How to insulate a panel house for winter living using “wet facade” technology :

- prepare the surface of the base - clean it from dirt, if necessary level it with cement mortar, treat it with a primer for deep penetration concrete;

- attach the slab to the adhesive solution and additionally fix it with mechanical fasteners;

- apply a layer of adhesive solution , reinforce it with a mesh, pressing it into the solution, level the surface;

- cover the base with tiles made of artificial or natural stone.

If the finishing is carried out with basement siding or fiber cement panels, then the insulation has the following scheme :

- prepare the surface;

- install brackets for the sheathing;

- slabs are secured using glue plus mechanical fasteners;

- the seams are blown with foam;

- install a vertical sheathing made of galvanized profile on the brackets;

- cover the sheathing with panels;

- cover the base with ebb on top.

Basement insulation with EPS slabs and stone paneling Source homesto.ru

How to insulate a floor

Thermal insulation of the floor is already a technology for insulating a panel house from the inside. From the point of view of heating engineering, the insulated floor of a wooden house is a single-layer structure that simultaneously performs load-bearing and thermal insulation functions. There are different options for arranging a heated floor in a panel house, but they all come down to thin-layer cladding of a load-bearing wooden frame, inside of which heat-insulating materials are placed. And in order to protect the insulation from exposure to moisture and water vapor, it must be protected by continuous layers of vapor and waterproofing.

There are certain differences in the insulation of the floors of an apartment building and a private house. In an apartment building, the floor insulation must be protected from the penetration of water vapor from below, from the side of another heated apartment. And here the vapor barrier is spread over the ceiling (from below relative to the insulation).

In a panel house, the partial pressure of water vapor in the warm air inside the room is higher than in the cold air from the side of the pile or strip foundation. Therefore, a vapor-impermeable barrier should be on the floor covering side.

One of the possible schemes for installing an insulated floor. Regardless of the materials of the floor covering and subfloor filing, the order of layers does not change Source abisgroup.ru

There are different options for arranging an insulated wooden floor, but the principle is common to all, and the diagram looks like this :

- boards ;

- continuous layer of waterproofing membrane ;

- insulation;

- continuous layer of vapor barrier ;

- finishing floor .

Important! Moisture from the insulation should be ventilated into the underground, and from there through the vents to the street.

Thermal insulation of the attic room

Insulation of a panel house with an attic requires thermal insulation of the second floor. This can be done in two ways:

- Perform insulation along the contour of the attic room itself;

- Insulate the roof.

In any case, the entire plane of the truss structure from the roofing side, in front of the continuous decking or sheathing, is covered with waterproofing material (membrane). If the roof covering is metal, a technical gap must be left between it and the waterproofing layer to remove moisture from under the roof and allow condensation to drain onto the drip line.