Thermal insulation of floors in the country has its own characteristics. Here you can use inexpensive practical materials, the main thing is to reliably protect them from moisture and rodents. Insulation is most often carried out in two ways - on the subfloor or on top of the finishing coating (plank floor). Both options have simple technology, so everyone can insulate the floor in their dacha on their own.

Insulate the floor in the country house

Thermal insulation is an important stage of arrangement

Nowadays, an insulated floor for a dacha is no longer a luxury; the owners of modern country houses want to be able to relax there not only in the summer, but also, say, comfortably celebrate the New Year.

Contrary to popular belief, it is not so difficult to make insulated floors in a dacha with your own hands; the main thing is to choose the insulation correctly, so that later repairs to the dacha floors do not become a regular occurrence and do not turn into a kind of hobby.

The market leaders in this case are the following materials:

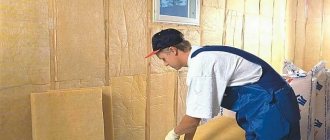

Mineral wool has many advantages; it is widely used for insulating walls and ceilings in almost any type of residential or commercial buildings. Available in the form of soft cotton rolls and dense mats. This material does not burn, does not melt and has good heat and sound insulation characteristics. But it also has serious disadvantages. The price of environmentally friendly, water-repellent mats is quite high, and cheaper options will quickly become unusable. In particular, budget options for mineral wool can get wet and lose their quality. Plus, they dry out and begin to crumble, forming microscopic and very harmful dust. Since the floor is constantly in motion, this dust will spread.

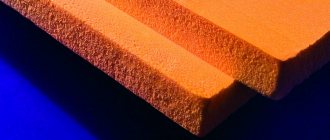

- Extruded polystyrene foam or, in the budget version, ordinary polystyrene foam, can be called perhaps the most common type of insulation. It belongs to environmentally neutral materials, retains heat perfectly, does not get wet and has decent soundproofing qualities.

- One of the disadvantages is that it does not allow air to pass through, in other words, it does not breathe and when exposed to open fire it can melt and burn. But this is more relevant for wooden structures. If country houses are insulated from block containers, then polystyrene foam is the best option.

Expanded clay is currently considered one of the market leaders. This is a completely environmentally friendly, harmless bulk material. It is natural clay, fired and foamed in special ovens. The result is granules made of solid porous material that are not afraid of moisture.

Polyurethane foam

It is obtained from polyol and isocyanate components and can be either soft or hard.

It has a cellular structure filled with gas. The advantages include:

- light weight;

- not afraid of steam and water;

- does not cause allergies;

- considered the best among insulation materials.

Installation is carried out using special equipment by applying foam directly to the floor surface. Because of this, good adhesion to any material is ensured. Does not require additional layers of steam and hydro insulation.

How to choose floor insulation

Professional builders have been arguing for a long time about the best thermal insulation material for a dacha floor, but in most cases, owners of their own homes care not only about the efficiency of the insulation, but also about its cost, and it is desirable that it be as low as possible. A warm floor in a country house can be made using inexpensive bulk materials, thermal insulation mats or slabs, and if funds allow, you can organize polyurethane foam spraying and forget about drafts forever. There are plenty of insulation products on the market, but almost always the choice is based on financial capabilities.

There are a number of requirements for floor insulation:

- Light weight so as not to create additional load on the foundation.

- Waterproofness - the insulation should not allow or minimally allow water to pass through, not dampen and provide additional waterproofing (ideally).

- Durability - agree, no one wants to undertake such large-scale work to change insulation every 3-5 years.

- Fire safety - insulation should not be easily flammable or support combustion.

- Ecological cleanliness.

If your financial situation allows, you can purchase modern insulation materials that can be easily and quickly installed without the help of specialists. There is a solution for budget-conscious owners - traditional insulation schemes using cheap materials, but you will have to tinker with their installation. Let's consider all the options.

Inexpensive insulation materials

If you want to save money on construction without sacrificing quality, there are several thermal insulation materials that reliably protect against the cold and are inexpensive. For example, our ancestors used dry sawdust to insulate floors. They can be purchased at a minimal price or even obtained free of charge from a woodworking industry. However, in this case, you will have to strengthen the waterproofing, because sawdust easily absorbs moisture, and when it gets damp, it stops retaining heat.

A more practical option is sawdust pellets - this is a product of modern production, the raw materials for which are wood processing waste. Sawdust is pressed under pressure into small hard granules, which do not easily succumb to moisture and last longer. The granules are treated with fire retardants (agents that prevent them from easily catching fire) and antiseptics. This material is mainly used for thermal insulation of floors on the ground. In addition, chemical-free pellets are an excellent, economical fuel for stoves and boilers. They are also used as cat litter, which speaks in favor of their environmental friendliness and safety.

Expanded clay has excellent thermal insulation qualities and is a favorite insulation material for budget-conscious builders. These are clay granules foamed under the influence of high temperature, which practically do not absorb moisture and can give the house warmth for many years and even decades.

The only drawback of expanded clay is its fragility, so care should be taken during transportation. For high-quality thermal insulation of the floor in the middle latitudes of Russia, it is recommended to pour a layer of expanded clay about 30 cm thick

Another inexpensive insulation material is mineral wool in rolls without a corrugated shell or foil layer. However, it, like sawdust, requires enhanced waterproofing. The same applies to rolled materials based on fiberglass, stone wool, and slag wool.

Foam boards are also inexpensive, but they are very fond of being damaged by rodents, which sooner or later appear in any private home. In addition, the foam should be protected from fire - and although it does not burn on its own, when melted it emits acrid smoke, which can lead to suffocation.

Expensive modern materials

If you want to carry out high-quality insulation of floors in your country house and are not short on funds, you have a lot of options open to you, each better than the other.

The most popular modern insulation materials:

Reviews

People leave reviews about insulation, saying that without thermal insulation it is impossible to achieve comfort in the house.

Pavel, 60 years old, Moscow region

“I insulated the dacha myself, using penoplex for this purpose. It’s easy to work with the material; I laid everything myself, secured it, and the house became warmer and more comfortable. I bought it at the market, now there is a huge selection.”

Marianna, 45 years old, Stary Oskol

“My husband insulated the house with glass wool. He had to work hard. He chose this material for its performance qualities - it does not burn, is resistant to pests and mold. The family is happy. The price of cotton wool is low. We have a huge dacha, but it was relatively inexpensive.”

“I chose mineral wool. The material worked well, so I went to the market already knowing what I would buy. Working with stone wool is easy and no special clothing is required.”

Choosing insulation for your dacha is not difficult. And if you have construction skills, you can handle the flooring quickly. If they are absent, then it is better to contact specialists.

Source

Insulation on wooden floors

If the floors in the dacha are very strong and smooth, and there is no desire to open them, you can perform insulation directly on the boards. The disadvantage of this method is that the ceiling height will decrease by about 8-10 cm.

Tools and materials

To work you will need:

- grinding attachment;

- jigsaw;

- building level;

- primer;

- wood putty;

- bars 50x50 mm;

- sheet material, for example chipboard;

- vapor barrier film;

- insulation;

- self-tapping screws;

- screwdriver;

- construction tape.

The bars will serve as lags, so they must be smooth, without defects, and well dried. Since the work process will take very little time, the bars should be pre-treated with antiseptic impregnation and dried.

Floor preparation

Step 1. Carefully remove the baseboards and clean the floor from dust. Check the horizontality of the surface with a level gauge.

Step 2. If there are protrusions on the floor, the surface is treated with a sanding attachment. The gaps between the boards and recesses are filled with putty.

Puttying a wooden floor

Step 3. Cover the working surface with two layers of primer mixture and allow the floor to dry.

Step 4. The beams are laid out on the floor in parallel rows with a step of 30 cm. From the outer beams to the walls the distance is 2-3 cm. Using a level and wooden wedges, the beams are aligned exactly horizontally and screwed to the base with self-tapping screws.

Laying and fastening lags

Step 5. The space between the beams is filled with insulation. Mineral wool and polystyrene foam are best suited for this. The resulting seams need to be blown out with foam.

Laying insulation in the space between the joists

Step 6. Cover the top of the insulation with a vapor barrier membrane, carefully straightening the material and securing the seams between the strips with tape.

Mineral wool is covered with a membrane

Step 7. For convenience, the sheet material is cut into squares and the flooring begins. Starting from the second row, the sheets are laid with the joints offset by 20-25 cm. The seams should be minimal, so fit the squares as tightly as possible.

Laying sheet material on joists

Step 8. If you plan to lay boards over chipboard, no additional treatment is needed for the subfloor. For thinner finishes, it is necessary to fill the joints and sand the entire floor with a sanding attachment. After this, remove the dust, apply a primer and wait until the floor dries.

The described options are the most practical for a summer residence; If you follow the technology, you won’t have to change the thermal insulation layer for at least 10 years.

An insulated floor in a country house will last at least 10 years

Comparative table of floor insulation

Types of materials used in floor assembly

For the construction of floors from natural building materials in the countryside, the following options are most often used:

- Sheet type building material. This variety includes plywood, chipboard and OSB;

- Uncut board;

- Lumber from laminated veneer lumber;

- The boards are folded.

The first two types of material are used in the construction of a rough foundation. In the future, a top decorative covering will be laid on the subfloor of the basement or first floor, which can be formed from boards, laminated veneer lumber or seamed lumber. The decorative coating is subsequently painted or varnished, as shown in the photo.

To ensure that the floors are not only beautiful, but also durable, it is important to choose high-quality wood of the right species. You can find out which wood species is best suited for floor assembly by watching the detailed video review attached to the article.

Ways to protect your dacha floor from moisture

The problem when installing a floor in a country house on a strip foundation is often its protection from dampness coming from the ground. The durability of the floor largely depends on good ventilation of the subfloor. Therefore, taking care of it begins with a project that necessarily provides for the arrangement of vents in the strip foundation. Vents are holes located oppositely. They are opened in the warm season and closed for the winter if the country house is intended to be used in winter.

In areas where the groundwater level is high, simple subfloor ventilation may not be enough. Evaporation rising from the ground saturates the logs and leads to their rotting. Plastic film will help correct the situation. It needs to be spread under the entire area of the house and covered with a layer of regular sand.

By taking these precautions, you can significantly increase the durability of your entire floor structure.

By definition, a columnar or screw foundation allows for free passage of air. The logs on such a foundation will never rot, but the lack of strapping and warm filling around the entire perimeter leads to the need for more serious insulation of the floor.

Installation of a wooden floor on joists with tongue and groove boards

If a wooden floor is installed on joists and the plank flooring is made with tongue and groove boards, then you can make the floor with your own hands as follows. To install a finished floor on joists, it is better to use boards connected to each other in a quarter, on an insert strip or in a tongue and groove; these types of connections ensure a tight fit of the floor boards. The tongue and groove board differs in its sidewall: one sidewall has a groove, the other has a ridge. To fasten a tongue-and-groove board to a wooden joist, nails are driven at an angle into the corner of the ridge and the head is slightly recessed so as not to disturb the tightness of the boards.

When laying each subsequent board, for greater joint density, the laid board is knocked down from the side with a small hammer through a wooden block. You should not hit the board with a hammer, especially from the joint side, so as not to damage it. Use a wooden block. The block is placed against the board and the block is struck with a hammer. So the board fits tightly into the ridge with a groove.

Loose penoizol

Penoizol is made from resin and resembles snow flakes in appearance and is easily crushed with your fingers. Thermal conductivity - 0.028-0.038 W/m² C

Disadvantages: low mechanical strength.

Penoizol is an easily deformable material. Not suitable for floor screed, installed only between joists, with a floorboard installed on top, to avoid mechanical stress.

Installing a concrete floor at the dacha

The specifics of insulating floors in a country house with a concrete base allow for several methods of insulation. The first is reminiscent of working with a wooden floor, and the second is only suitable for a concrete base. So, insulating the floor using film and layers of heat-insulating material in a dacha can be done with your own hands. The film is laid in one layer, its footage is easy to calculate. In this case, preliminary work is necessary - sealing cracks and chips using cement screed and putty.

After the surface has dried, a wooden frame is set up on it. The distance between the beams is at your discretion, but it is better that it is no more than 80 cm. A film is laid on this base and secured with a stapler. The space between the beams is filled with heat-insulating material.

The second option for the floor in the country house is a little more interesting. First, the floor is leveled using putty or screed. Next, you can lay a layer of roofing felt for additional insulation. Insulation is laid on it - always in the form of slabs. They are glued together to form a single layer. Filling with screed secures them completely. After drying, the flooring is laid depending on your preferences.

Continuation of instructions

The above section is necessary because the dacha is located in different areas. Some are lucky to be on land, while others are forced to settle for “wet” places. Further scope of work on insulating the floor at the dacha with your own hands:

- The insulating layer is spread as a continuous sheet, extending 10-15 cm onto the walls. It turns out to be a kind of pallet. If it is a rolled material, then it is laid overlapping, connecting the strips to each other using tape. To make further work more convenient, the insulating coating can be stapled in some places to the joists and walls.

- The “boxes” formed between the joists are now filled with selected heat-insulating material, and there should be a ventilation gap (about 2 cm) between its surface and the edge of the joists. If this is not possible, it is necessary to form a counter-lattice. To do this, a batten is nailed in increments of 40 cm along the logs “in a cross” in their direction.

- Now you should lay a layer of waterproofing (glassine or diffuse membrane) in order to protect against moisture rushing down. At the same time, if a counter-lattice was constructed, then the insulating layer should be located under it.

- The final step is to secure the floorboards according to the marks. After this, the plinths are put back and the excess insulation is trimmed along its edge.

The issue of choosing insulation must be resolved at the construction stage. But insulation of floors in a dacha in a finished house can also be done using the instructions provided.

Concrete floors

In modern construction, wooden floors are used very rarely; they have long been replaced by concrete floors. The main advantage of a concrete floor is its low cost, ease of installation, high strength and durability, as well as environmental friendliness and fire resistance.

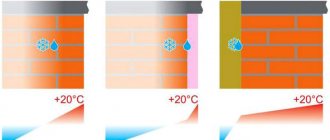

But there is one big “BUT”: the concrete floor has high thermal conductivity, which is why even on the hottest days it feels cold. Therefore, it is necessary to cover the concrete floor with special insulation. You can use the same materials as for a wooden floor along the joists.

A well-dried concrete floor must also be covered with a waterproofing film before laying the thermal insulation layer. The technology for laying thermal insulation with joists is the same as for a wooden floor. It should be noted that when insulating using joists, the floor height will increase by 10-15 cm.

Another good way to insulate concrete floors is to use particle boards. This material is in no way inferior to mineral insulation and is quite often used for insulation in private homes and country buildings. Organic insulation materials include wood shavings, moss and sawdust. You can also add straw, small dry grass, reeds, hay, sedge or peat chips.

To protect the chipboard from moisture, the concrete is covered with polyethylene film with high waterproofing. Then chipboards are laid. In this case, the slabs do not need to be laid close to the walls, maintaining a distance of about 1.5 cm. This is necessary so that the slabs do not warp due to strong changes in temperature and humidity.

The plates are firmly fixed with dowels. After fixing the slabs, all joints must be reinforced with construction mesh and covered with putty, which is mixed 1:1 with oil paint. Then a plinth is installed around the perimeter. Linoleum or carpet is laid on the finished structure.

You can insulate the floor in your house with your own hands using “warm” linoleum. This material consists of two layers - a warm base and polyvinyl chloride, resistant to chemical and mechanical damage. The backing of such linoleum is made on the basis of natural felt or synthetic non-woven material. Its thickness is about 3-4 mm.

When laying insulated linoleum, it is cut so that there is a small distance between it and the wall, otherwise after a few days it will warp due to its increase in size as it is trampled down.

Concrete floors can also be insulated using technical cork, which is practical and durable. It is made from cork oak bark, which is glued together with the resin contained in the cork mass. This material is 100% environmentally friendly, does not allow water to pass through, has high heat resistance and does not burn. But there is also a significant drawback - high cost.

Isolon is also considered one of the best and most effective heat insulators. It is very easy to insulate a floor with its help - you need to roll it out on a well-dried concrete floor, and then start laying the floor covering.

Insulating the floor in your dacha is a necessary measure by which you will make your home even more comfortable. It’s so nice to sit down on a warm floor with the whole family when the weather outside is “non-flying” and play, for example, Monopoly or Twister.

Wood sawdust

Only fine sawdust obtained from modern woodworking machines is suitable as insulation. Despite the very low cost, it is extremely rare, since sawdust is highly hygroscopic and is rarely used in its pure form, and more often as a mixture with other bulk insulation materials.

It is good to carry out insulation with sawdust because of its size; it is easy for it to penetrate even small cracks and hard-to-reach places. The environmental friendliness of sawdust also plays an important role. The disadvantages of this method are compensated by good sound absorption and low weight. It is especially popular to use sawdust mixed with other building materials.

For example, a mixture of sawdust, cellulose glue and a fire retardant-antiseptic produces insulation called pellets, sawdust granules, combining the properties of not only insulation but also an antiseptic. Such granules hardly burn.

A mixture of sawdust with sand, cement and water, after drying, will give sawdust concrete. Its properties will be similar to cinder concrete, but it is afraid of water.

Despite the improvement in the quality of sawdust in mixtures with other components, they are most often used in their pure form as insulation.

How to insulate a dacha floor with your own hands without removing the old one

Warm floors in a country house are a prerequisite for comfortable living in the winter. The funds invested in insulation are compensated by a reduction in heating costs and the absence of colds in the family.

Almost all technologies require the dismantling of the top covering and the installation of mineral fiber or polystyrene foam thermal insulation between the joists of the floor frame. What to do if the need for floor insulation occurs during the heating season? The traditional sequence of thermal insulation work with removal of the coating can create many problems for the owners living in the house.

On construction forums, owners of problem dachas offer their options, from which you can choose the most acceptable one.

To insulate floors using joists, our experts recommend

| Rockwool Light Butts | Baswool Light 35 | URSA GEO M-11 |

Methods for insulating a floor without pre-installation

In temperate climates, oriented strand board (OSB) flooring is practiced. The structure of the coating is characterized by low thermal conductivity. For decoration, several layers of colored varnish are applied to the surface. Naturally, the base must be fairly level. As waterproofing, you can use a fairly dense polymer film, sealed at the seams by heat welding.

In regions with difficult climatic conditions, high-density hydrophobized mineral wool panels are recommended for floor insulation. In the budget version - extruded polystyrene foam 30 mm thick. The insulation can be covered with any sufficiently strong and moisture-resistant panels; linoleum, laminate or material with identical properties can be used as the front covering.

Floor insulation in mineral wool version

- Panel stone wool, the thermal conductivity of which is sufficient for the implementation of the most complex projects, is characterized by stable working properties, chemical inertness, and a long service life.

- The material is environmentally friendly, therefore it has no restrictions on the internal insulation of residential premises. It is possible to use semi-rigid panels to insulate concrete screeds under floor tiles.

- Moisture-repellent impregnation of mineral wool panels works quite effectively, but the presence of a damp basement determines the need to use film or mastic waterproofing.

More affordable polystyrene foam and expanded polystyrene retain their insulating properties even in damp environments. To seal the system, it is enough to seal the seams and joints with moisture-resistant putty or glue them with construction tape.

When choosing insulation, this disadvantage should be taken into account first.

To insulate floors under screed, our experts recommend

| Penoplex Geo | URSA XPS N-III-L | Ravatherm XPS Standart G4 |

Expert recommendations

Indeed, the proposed schemes are workable and can be used in a budget option for floor insulation. It should be noted that manufacturers of cheap facing materials continue to use old technologies using phenol-containing components. Savings are possible, but it is better to refrain from purchasing cheap panels and insulation at the selection stage.

How thick should modern floor insulation be? It is difficult to recommend volumetric coverings, since raising the floor by only 80 mm significantly affects the reduction in the volume of the room. The low thermal conductivity of both insulation materials allows the use of slabs with a thickness of 20-30 mm. Even taking into account the panel cladding, the floor height will increase by only 40-45 mm.

Wood floor insulation

Wooden floors often deteriorate. If you purchased a house or inherited it, you need to meticulously inspect its condition. It happens that a house, quite suitable in terms of decoration and layout, turns out to be resting on half-rotten beams. Perhaps the builders did not saturate them with a solution that improves the properties of wood, and over time it became damp. If the floor is unusable, you need to dismantle it. All boards must be torn off from the base in the form of a ceiling of beams. This is labor-intensive work, but it must be done.

It is better to lay the floor in the dacha from new boards. It is better to fasten them with self-tapping screws rather than nails. They are easier to handle and dismantle. In addition, their fastening will not be a test for the tree, since the hole can be shot with a power tool. The boards should fit tightly together to prevent air from leaking from the basement or crawlspace. By the way, it can be filled with a metal mesh to prevent the movement of rodents if they get started.

A layer of insulation will provide a warm floor in the country house. Install wooden logs around the perimeter of the floor - beams, between which the insulation will be laid. The distance between them can be from 40 cm to a meter. A vapor barrier film is laid on them, which is fastened with a furniture stapler. It is better to seal any gaps or breaks. Secure the film at all folds so that it adheres to the joists and floor. Both polystyrene foam and expanded polystyrene are suitable for insulating floors in a dacha. Mineral wool is recommended as a filler for seams and joints. Insulation blocks are easy to cut, crumble and cover, so anyone can handle this job. The layer can be from 5 to 20 cm, depending on whether you plan to live indoors in winter.

The top layer will already become the finishing coating; it can be laid from chipboard, wooden panels, plywood

Here it is important to level the base so that all the boards are on the same plane. Between them, gaps are acceptable, and even necessary, that will allow the material to expand and contract depending on humidity, in its natural mode

Fastening here should be done carefully so that there are no protruding screw heads or other irregularities on the surface. Such a floor in the country house will retain the heat that will be produced by a fireplace or convector, and will also maintain the temperature inside slightly higher than that outside, even during your absence.

Expanded clay

Sometimes the floor is insulated with expanded clay - a porous aggregate of artificial origin. This material has proven itself well. There are important conditions - when laying, expanded clay must evenly fill the space. In contrast, foam and wool are produced in the form of blocks, which are simply laid on a previously prepared surface.

The next stage is the installation of the screed, which becomes the basis for the facing floor covering. As a rule, the construction mixture is purchased ready-made, and it only needs to be diluted in a certain proportion. As soon as the solution has dried, you can begin the final stage - installation of the front floor covering. This could be carpet, parquet, or other building materials.

Wood flooring installation process

In the process of constructing a wooden floor covering, whether in a country house or in a brick cottage, there is nothing complicated: the work can be done with your own hands. However, in order to obtain a beautiful, strong and durable coating as a result of the work, it is necessary to take into account many nuances when performing it, and also to study well the theory of floor laying.

In a brick house, cottage or small wooden building, you can arrange the floors with your own hands in different ways. Let's look at the two most popular options:

- A floor covering created on a rough layer and with an additional layer of insulation (sound insulation), located on a base of soil or on overlapping beams;

- The floor is made of wood, built on a concrete base with an insulating layer.

In country houses, the first option is more often used. Moreover, this method creates floors on the first floor or basement, and it can also be used when arranging floor coverings on different floors of the building.

In the second option, the flooring design is built completely differently and can be modified and modified to reduce costs. More often, this method is used to make floors in brick cottages and apartments; it makes sense to lay floors in the kitchen on a concrete base.

Justification for carrying out the work

Insulating a floor on the ground with sawdust

Some gardening enthusiasts work at their summer cottage not only in the summer, but also in the fall. And they usually start work in early spring. However, a country house, as a rule, is not insulated, which can cause discomfort in cool weather.

In the absence of insulation of the house, heating the room is problematic and expensive, especially if many communications in the country house are missing. Attempts to heat the dacha end with the heat from the heating devices escaping through the floor and ceiling.

You can carry out floor insulation work in your dacha with your own hands. To reduce the cost of purchasing materials, as well as to reduce labor costs, you can insulate only one or two rooms. However, insulating the entire room will be much more comfortable for spending time in spring and autumn.

When planning insulation activities, it is necessary to schedule the work for the summer period, this will improve their quality.