Only a true housewife and owner can preserve the warmth of the family hearth - this requires patience, experience, dexterity and love for your home. As for physical heat, it all depends on the materials chosen, a well-thought-out heating system and thermal insulation of the house.

Properly designed communications and installation of thermal insulation will provide the dacha with protection from cold winds and frosts in winter, giving a comfortable atmosphere in the rooms. In addition, good thermal insulation of the cottage will help you save on heating and electricity bills.

If you have seriously decided to extend your dacha season into the winter months, don’t hesitate - insulate your dacha! In order to do this as quickly as possible and with your own hands, there are several simple techniques. These secrets will help you relax in warmth and comfort at your dacha all year round.

However, we note that there are two difficulties in this matter. First, it is important to choose the right materials. Secondly, it is important to check everything before the cold weather sets in. We will talk about these and other nuances in this article.

Why insulate

Insulating your dacha will allow you to save on heating costs in winter.

Modern heating systems are able to create the desired temperature in the room, so why is it necessary to take additional measures. Insulating a country house will allow the owner to solve the following problems:

- high heating costs;

- the appearance of condensation on the walls and ceiling;

- violation of the operating conditions of structures and their destruction.

If during the cold season there is a positive temperature inside the house, but its enclosing structures are not insulated enough, this will lead to many problems, which are easier to prevent than to fix with your own hands.

Important aspects

When the house is already ready, and the amount of insulation turned out to be insufficient, then it is worth following a few tips when creating insulation for garden houses:

- Using bulk and mineral insulation, the thickness of the backfill for temperatures not lower than -20°C should be 10 cm. If the cladding is blown, the figure increases to 15 cm.

- When laying insulation, it must be sufficiently compacted. When clicked, the form should return to its original state. Fine, loose thermal insulation of natural origin is compacted tightly.

- To ensure that the insulation of a garden building for recreation does not result in high costs, you can combine industrial materials with improvised ones. Use good insulation closer to cold sources. When insulating the floor, industrial raw materials will be laid down.

We recommend watching the video: mistakes when insulating a house.

All thermal insulation materials must be dry. At the slightest humidity, the insulation will lose its properties and rot.

After installing a heat-insulating pie, increased humidity may occur in the house, which is provoked by the following conditions:

- Cracks.

- Lack or improper ventilation. Impaired air circulation leads to a lack of air with the subsequent appearance of moisture.

- Poor quality vapor barrier. It does not affect the humidity inside the room so much as it affects the deterioration of the insulation.

Correctly carried out work and timely identification of shortcomings will avoid problems in the future.

Read on our website: drawings and projects of garden houses.

Materials for thermal insulation

The building materials market offers a huge range of types and manufacturers of thermal insulation materials. It’s easy to get lost in this variety. The choice depends on the location of the thermal insulation and the wishes of the home owner. The main heat insulators include:

Main thermal insulators of the house

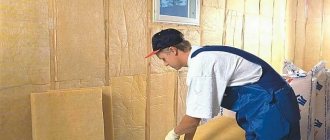

- Mineral wool. Available in the form of mats (rolls) and rigid slabs. The first option is suitable for walls and floors along joists, the second for walls, floors, and roofs. The advantages include non-flammability, high efficiency, durability, resistance to rot and mold. The disadvantage is the ability to absorb moisture. It is important to remember that when working with this material you need to use masks, gloves and protective clothing. Neglecting safety measures will lead to cotton particles getting on the skin and into the lungs, and ultimately to irritation and allergic reactions.

- Styrofoam. The material is made of polystyrene. It is a slab of small balls filled with air. The undeniable advantage was the low cost of the material and availability. There are quite a lot of disadvantages. These include flammability, inability to pass air (the house will need additional ventilation), low strength and instability to simultaneous exposure to moisture and low temperatures. Suitable for do-it-yourself insulation of walls (it is recommended not to use outside), ceilings (better for insulation from below), and attic roofs.

- Extruded polystyrene foam (penoplex). The material is similar to foam, but is an improved version of it. It is low flammable, has increased strength and moisture resistance. Disadvantages include airtightness. Suitable for insulating walls and floors (both between floors and on the ground).

- Expanded clay. Inexpensive material. Compared to the previous three, it is not highly effective. It is small granules of baked clay, free-flowing. Disadvantages include high thermal conductivity and large mass. Suitable for insulating floors (at the same time leveling the surface).

There are also a number of less common materials, these include:

- polyurethane foam;

- ecowool (insulation mats made of flax);

- penoizol (foamed polymer resin);

- isokom (foil material);

- sawdust.

Insulation process

I will talk about the work, dividing it into six parts, so it will be easier for you to understand the nuances of insulation, and you will be able to plan all the actions in the correct sequence. There are no trifles here - the more meticulously you approach the process, the better the result you will get in the end.

Stage No. 1 – windows

You need to start work with this part of the structure. Why? It's simple: if you do not insulate the window openings in advance, then when insulating the walls from the outside or inside you will not be able to make openings, and without this it is very, very difficult to achieve an ideal appearance.

The main recommendations are:

- First of all, you need to assess the condition of the existing window structures; if the wood is severely damaged and restoring it will be problematic, then it is better to order new window units . The ideal solution is plastic double-glazed windows, but if you cannot afford to install them, then it’s okay - if you wish, you can also qualitatively insulate an ordinary wooden window;

Plastic windows are great for a country house

- Frames must have double glazing; single glass is a weak barrier to cold . It is best to use either a double frame design or insert a second frame for the winter, as is still done in rural areas. That is, you need to measure the size of the opening and make a separate structure that will be installed during the cold period; this is the cheapest solution of all possible;

An additional frame is an excellent solution for the winter

- I advise you to disassemble the structure; if there are cracked glasses, they need to be replaced, and also stock up on new beads in advance . The glass is sealed with silicone sealant around the entire perimeter, this will significantly reduce heat loss through the joints. It is also advisable to coat the bead with sealant, after which it is fixed with nails; this option ensures maximum reliability;

To make the joints at the corners perfect, it is better to cut the glazing bead using a miter box

- Another important part of the work is sealing the joint between the frame and the sash or sash . It is best to use a special sealant with a self-adhesive base; it is sold in hardware stores by the meter, so you need to first take all the necessary measurements. A cheaper solution is foam rubber tape for insulating windows; it is also glued around the perimeter, but unlike the first option, its service life is only one season;

The tape securely covers the joint; it is important to secure it around the entire perimeter

- If there are gaps and cracks on the frame and sashes, they need to be sealed with putty, after which the surface is painted . It is important to protect wood from adverse influences, since moisture and temperature changes deform the structure, and over time the material begins to rot;

- It is very important to properly insulate the joint between the frame and the wall; all cracks wider than 5 mm are easiest to fill with polyurethane foam ; it is important that there are no voids inside the structure. As a last resort, you can fill the space with batting, tow and other materials, but this option can be considered as temporary; subsequently it is better to use polyurethane foam;

Foam allows you to quickly and efficiently fill joints

- All joints, especially on the outside, must be covered with either a wooden frame or other materials and additionally protected from moisture using silicone sealant. The fact is that foam does not tolerate ultraviolet radiation well and, under its influence, begins to deteriorate very quickly;

- As a more radical option, you can consider using shutters; they close when necessary and allow you to create an additional barrier to the cold. But it is much easier to install good frames than to build such a structure.

If you urgently need to insulate your windows in winter, then use the option with plastic film - take a piece larger than the size of the window and attach it around the perimeter using a stapler.

Stage No. 2 – door

An ordinary summer house usually has a more or less strong door, the only function of which is to protect against entry. But if you want to use the structure in winter, then the structure should provide excellent protection from the cold.

Let's figure out how to properly insulate this part of the structure:

- The most important thing is that the front door should not go directly into the living space . Be sure to provide a dressing room; if there is none, then fence off a small part of the space. There should be such a barrier between the street and the house; this will significantly reduce heat loss through the door block;

- As for the door material, it is most often wood, although recently metal options are increasingly being used. Here it is important to choose a design with a thicker leaf, and if you have a metal door, then it is advisable that it be filled with mineral wool insulation;

- Let's figure out how you can modify an ordinary wooden door; first of all, you need to seal all the cracks and cracks with a special putty. After this, apply 2 layers of paint or varnish to protect the material from moisture;

All defects are eliminated, because every crack is a place of potential heat loss

- If you need to insulate a structure, the simplest option is to cover the surface with batting or foam rubber . From the outside, the surface is covered with leatherette; to better protect the joints, rollers are made around the perimeter, they seal the junction points;

Rollers around the perimeter - an additional barrier to the cold

- Additional tightness between the door leaf and the frame is ensured by the presence of a special rubber seal . It is glued around the perimeter in a matter of minutes and performs two functions at once: with it, heat loss is significantly reduced, and the door closes more softly. The seal is sold by the meter and has a self-adhesive side for quick installation;

The seal can be bent in the middle and attached to the inner corner of the door frame

- As an option that is suitable for both wooden and metal structures, you can consider using mineral wool or foam plastic on the inside of the canvas. The material can be used to fill the internal cavities, or it can be attached to the outside, it all depends on the characteristics of the door;

Polystyrene foam and mineral wool improve the thermal insulation of the door significantly

As a quick option for improving the thermal insulation of a doorway, I can recommend a curtain made of thick material, a blanket or something similar will do. It’s not very pretty, but it’s very effective, if you don’t believe me, try it.

- As for the connection of the box to the wall, it is filled with polyurethane foam, the excess of which is cut off after drying . Next, you need to close the cracks with a platband or some kind of plank, this will protect the foam and create an additional barrier to the penetration of cold.

Stage No. 3 - ceiling

Do you know that 20 to 25% of heat is lost through a poorly insulated ceiling? This is due to the fact that when heated, the air always rises, and if the structure is not thermally insulated, then it turns out that you are heating the street. Just recently I wrote a detailed review on ceiling insulation, read it and you will understand this part of the work very well.

The ceiling must be insulated efficiently and reliably

Here I will briefly talk about the most popular insulation options:

- The most budget-friendly solution is to use sawdust; in order to protect the material from dampness, it must be mixed with lime . The minimum layer of material is 20 cm, but for effective insulation it is advisable to add 25-30 cm. The greatest advantage is the affordable price, but other indicators leave much to be desired;

- Using clay involves making a solution with sawdust , this increases the strength of the layer and makes this technology more reliable than the one described above. The advantage is the low cost, but the work is quite labor-intensive: you need to dig up the clay, prepare a solution of the correct consistency, after which it needs to be evenly distributed over the surface and leveled, it dries for at least a month;

Preparing a solution from sawdust with clay is a labor-intensive process

- Expanded clay is a good option; this insulation is very popular due to its low cost, light weight and fire safety. The technology for its application is very simple: you need to fill the material on the ceiling with a layer of 20 cm or more. An additional advantage of this material is that it absorbs excess moisture from the air, maintaining optimal humidity in the room;

- Polystyrene foam is a very popular solution today; insulation is affordable and easy to use . The technology for carrying out the work is not at all complicated: you need to prepare the surface by leveling it and laying a waterproofing, vapor-permeable membrane. The sheets are laid in a layer of 100 mm or more, all cracks and joints at the junctions are sealed with polyurethane foam, it serves as a heat insulator and as glue;

The foam should be placed as tightly as possible, but make sure that it does not break

- Mineral wool is another modern, effective option for ceiling insulation . The advantage of this material is its ease of use and high thermal insulation performance, the disadvantage is that the cost will be higher than all the options described above, although it cannot be called very high either. When laying, the main thing is to fill the space tightly; the layer thickness should be at least 100 mm, but it is better if it is 150-200 mm;

When working with mineral wool, be sure to use gloves and a respirator.

- Another option is to use sprayable compounds like penoizol. The advantage of this solution is its simplicity: specialists will do all the work for you, the disadvantage is the high cost.

If your country house design does not have an attic, you will have to insulate the ceiling from the inside. For this type of work, foam plastic or extruded polystyrene foam is best suited; these materials are simply glued to the surface using a special compound, after which all joints are also sealed.

The main thing is to firmly glue the material to the surface.

What is the best way to insulate a ceiling? It's up to you to decide, personally I lean towards mineral wool as it is very effective and easy to use. There is no point in saving on insulating your house.

Stage No. 4 - floor surface

Let's figure out how to insulate a floor in a dacha with your own hands. I will consider the option with a wooden floor, since this is what is found in the vast majority of cases. To keep the structure as warm as possible, you should follow a few simple tips:

- Insulation of floors in a dacha begins with filling the space under the floor with sand, no empty spaces through which frost and wind can travel. One of my friends spent a lot of time and money on expensive insulation, but the floor became warm only after he filled the space underneath with construction sand and waterproofed the surface. Cold and dampness are what an empty underground gives you;

- Next, the logs are laid, the height of which should be 20-25 cm; this is exactly the layer of insulation that we will lay on the surface. The distance between the elements should be such that you can lay the selected material without cutting, this will simplify the work process and improve the final result;

Boards with a thickness of 40 mm or more can also serve as lags.

- Then the surface is covered with insulation; it is best to use mineral wool, as it retains heat well and is easy to use . The work uses inexpensive rolled material 100 mm thick, which is laid in two layers. The insulation should adhere to the structure as tightly as possible, so when cutting, make the elements 3-4 cm larger than the distance between the joists;

This floor insulation is cut using a construction knife, which is very convenient.

Of course, you can use foam plastic or mineral wool in the form of slabs as insulation; in this case, you need to place the elements with offset joints to prevent the appearance of cold bridges. All joints that are not tight enough are filled with polyurethane foam; this should also not be forgotten.

The joints between the insulation sheets must be offset

Before you insulate the floor in your dacha, you must decide on the material and purchase everything you need for the job. Of course, you can use sawdust or expanded clay, but these materials will not give the desired effect unless they are sprinkled in a 40 cm layer. Therefore, rely on the experience of many developers and choose what works.

To ensure the best effect, the surface is covered with a vapor barrier material, after which it is covered with either a floorboard or sheet elements; it all depends on your project, because the floor can be finished with a variety of materials.

Stage No. 5 - wall insulation

It is through this part of the structure that the greatest amount of heat is lost, and this is no wonder, because the walls are the largest part of the structure by area, which opens to the open air, and is not covered by soil or roofing, like the floor and ceiling.

Let's figure out how to insulate a country house with your own hands:

- First of all, it should be pointed out that it is advisable to carry out work outside , this is due to the simplicity of the process, the dew point, which moves outward, and the fact that work inside takes up usable space. I will talk about a comprehensive solution in which the walls will be thermally insulated on both sides; this option provides the best effect at low cost;

- At the initial stage, you need to choose insulation for the walls outside; there are two main options: either polystyrene foam or mineral wool. The first solution is characterized by low cost and light weight, the second – by high efficiency. Most often, foam plastic is used, since not everyone can afford to spend a lot of money on a country house;

Polystyrene foam is an excellent solution for a summer residence

- Work begins with leveling the surface and attaching the frame into which the insulation will be placed . The spacing of the elements should be selected in such a way that the insulation is tightly inserted between them without additional cutting. It is important to align the sheathing evenly, since this determines how level the wall will be later; hangers can be used to secure the structure; this will simplify the work process;

The frame is necessary to create cells for insulation

- Then the entire space is filled with foam plastic, the thickness of which should be 100 mm. Everything is simple here: insert the sheets into the cells as tightly as possible, without gaps or voids. If any have nevertheless formed, then fill them with polyurethane foam to prevent the emergence of places for cold penetration;

Insulation is a simple process, but it requires care and attention to detail.

- For additional reliability, the insulation is additionally fixed with self-tapping screws, onto which special pressure washers are placed (this element is called a rondole). Two fasteners per sheet are sufficient; it is important to fix its position and prevent shifting or sliding over time;

- Next, the surface is covered with a windproof membrane, which will prevent the penetration of moisture into the structure and protect the surface from wind loads. The easiest way to attach it is with a stapler;

- To improve thermal insulation performance and ensure unhindered evaporation of moisture from the surface of the walls, a counter-latt 3-4 cm high is placed on top of the main frame.;

- The finish can vary from siding or wood paneling to more expensive solutions or even plastering (in which case oriented strand board is nailed down first).

Imitation timber is an excellent solution for a country house

I am often asked which insulation to choose for external insulation of a summer house. The advice is simple: if funds allow, then use mineral wool or spray foam, but if there are financial restrictions, then polystyrene foam will be an excellent solution, the main thing is to lay it correctly and fill all the cracks with foam.

Modern industry produces excellent insulation for walls inside a country house - penofol. It is made of foamed polyethylene, on one side of which a reflective surface is glued; it has the property of reflecting heat, thereby helping to save energy resources and increase the temperature in the room.

Penofol is an excellent insulation for walls inside a country house

Let's figure out how to carry out insulation from the inside with your own hands:

- First of all, you need to prepare the surfaces; no special leveling is required, because the material is flexible . The main thing is that the base is clean and dry; covering wet areas with penofol is not the best idea, since mold may subsequently begin to form in these areas;

- Next, pieces of material of the required length are cut, it is better if they extend onto the floor and ceiling, thereby isolating the joints , which are areas with increased heat loss. As for fastening, there are two main options: penofol can be attached to wooden walls using a construction stapler, or you can nail slats on top; this option is good if the surface will subsequently be covered with clapboard;

The slats serve both as a retainer for the insulation and as a frame for fastening the lining

- Do not forget about additional insulation of the seams between penofol - they are glued with special metallic tape . This eliminates cold loss through the seams, which will inevitably occur if you do not take care of it in advance. A country house insulated in this way from the inside will be much warmer, and less energy resources will be spent on heating it.

Adhesive tape with a foil surface is sold in the same place as penofol

Stage No. 6 - thermal insulation of the attic

I put this part of the work last, since an attic can not be found in every building, but due to the limited space for construction, the presence of such a room is advisable, because it significantly increases the usable area. But in order to use this part of the building as a full-fledged living area, it must be very well insulated.

Unlike other rooms, the attic is separated from the outside air only by a roofing system, which is clearly not enough to effectively retain heat.

The workflow in this case looks like this:

The diagram shows the correct sequence of work

- First of all, you need to prepare the space, remove dirt and cobwebs, and also remove from the attic everything that could interfere with the work . Easy access should be provided to all surfaces, then you can begin work on laying materials, below is a drawing showing the structure of the structure;

This insulation option is considered classic

- Next, a vapor-permeable membrane is attached, which will act as a water barrier and will also prevent wind from penetrating into the structure. The material is fastened with a stapler; for reliability, overlaps of 10-15 cm are made on the joints;

- As for the insulation, its layer should be at least 150 (or better, 200) mm, the ideal option is mineral wool , but, as a last resort, polystyrene foam is also suitable, all joints between the sheets of which must be sealed with polyurethane foam. When laying, try to achieve maximum density; the fewer cracks and voids left, the warmer the room will be in winter, remember this;

You can build a frame from a metal profile to support the insulation

- Next, the surface is covered with another material - penofol , it allows you to improve the thermal insulation properties of the surface, as well as reflect heat back into the room, which is especially important in the attic, because this is the upper part of the structure and warm air accumulates here. All recommendations for fastening are described in the section above, so I will not dwell on this aspect in detail;

Alternatively, you can use mineral wool with a reflective layer fixed on it, this will reduce the work process by one step

- Lastly, the finishing is attached; here you should also select materials with good thermal insulation properties. Plywood and wooden lining work well, although if you have insulated the attic well, you can use anything.

How best to insulate

After choosing a heat insulator, you need to decide on the method of insulation. Do-it-yourself insulation of a house for winter living can be done using two methods:

- outside;

- from the inside.

Construction of a country house with thermal insulation

Insulating a country house from the inside is important in the following cases:

- work is carried out in winter, when it is not comfortable to perform operations outdoors;

- you must not touch the façade of the building or disturb its decoration;

- insulation of walls at a sufficiently high height.

It is important to remember that insulating the outside with your own hands is more correct from a technical point of view.

Protecting your home from cold air helps prevent the effects of cold on supporting structures and extend their service life.

Vapor barrier

To understand why a vapor barrier is installed, let’s delve a little into the theory of the process that occurs inside a structure when using insulation, vapor barriers and waterproofing.

There is a term - dew point. What it is?

To put it simply, this is the meeting point between cold air from the street and warm air from inside. This is where vapor condensation begins.

If this place falls on a layer of thermal insulation, it will get wet and lose its properties, become deformed, and decrease in size. Even if it dries out in the summer, its properties are not restored. Moreover, heat leakage in these places increases.

Why is it necessary to lay a vapor barrier layer:

- does not allow the materials and structure of the building to get wet;

- allows you to shift the dew point to the outer part of the wall and save the building from rotting;

- eliminates the formation of mold, which has an extremely negative impact on health. In addition, mold disrupts aesthetic characteristics;

- favorable climatic conditions are created indoors, which primarily concerns humidity;

- promotes economical consumption of electricity for heating needs.

Preparatory work

How to properly insulate the walls of a wooden house from the inside largely depends on the correctly selected materials. If this issue is resolved, then you can move on to preparatory work, which consists of preparing the surface and making the sheathing.

For reference! When preparing the surface, it is necessary to seal the gaps that may have appeared between the beams or logs. To do this, you will need additional materials: tow, felt or polyurethane foam.

Wooden bars are most often used as lathing. Metal sheathing is rarely installed. The metal for the sheathing must be coated with an anti-corrosion compound.

Vertical wood lathing Source uk.aviarydecor.com

Preparation of wooden surfaces

To ensure high-quality application of the insulator, prepare the surface for coating with insulation. Tow/felt/foam is placed in the cracks. After the gap is completely closed, the foam has dried and its excess has been removed, putty is applied to the wall. The putty layer is carefully leveled. The wood is coated with a special compound that protects against mold and mildew. All wooden surfaces are treated with a fire-retardant compound before installing insulation.

See also: Catalog of wooden house projects presented at the Low-Rise Country exhibition.

What to do with the roof

The question of the need to insulate the roof would not make any difference. This isolation must be carried out without failure. Only in this case should the material characteristics and climatic conditions in the region be taken into account.

When the leakage of house roof insulation is reduced by 15%.

And if the attic space is used as a loft, it is simply impossible to do without reliable roof insulation. In the absence of a planned residential building in the attic, it is sufficient to insulate the ceiling of the house or attic.

Conclusion. From the above, we can conclude that those people who value convenience and comfort will not neglect heating at home.

The money saved on electricity, water and gas can be considered well earned and the material will be paid off in the first cold season.

Korovin Sergey Dmitrievich

Master of Architecture, graduated from Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

A country house is a structure that is initially designed only for summer use, therefore, during its construction, insufficient attention is paid to thermal insulation measures. If it is necessary to use it during the cold period, the question arises of how to insulate a country house intended for winter living.

History of dacha construction in Russia

The first wooden buildings for living in summer and autumn appeared at the turn of the eighteenth century. One of them was the hunting lodge of Peter the Great in the suburbs of what was then St. Petersburg, which was promoted by the creators of the national film about midshipmen. Today there is a museum of the same name here, and in the 18th century banquets and evenings were held here after a successful hunt for hares, wild geese, ducks and foxes.

Later, Tsar Peter issued a decree obliging his loyal subjects to own a suburban estate with an adjacent, landscaped plot of land. Another half century later, log buildings became part of the mandatory estates of landowners, as well as peasants with earnings above the average minimum. They lived in them all year round, raised chickens, ran a household and made money by selling dairy products.

In modern Russia, during the turbulent 1990s, citizens were allocated 6 acres. The tiny piece of land almost instantly became a household name and today, when mentioned in conversations between people, it evokes a storm of diverse emotions. Why? Because six hundred square meters is a small area, to put it mildly. Large-scale construction cannot be carried out on it. The maximum is to build a “house” with one or two rooms.

What were country houses built from?

Despite the restrictions voiced in the above paragraph, the Russians built different houses from small one-story buildings to three-story buildings with a usable attic. Taking into account the trend of domestic housing construction in the nineties, today in the Moscow region you can find country houses converted into cottages and villas. Unfortunately, not all structures of that time were built and insulated correctly.

For two reasons, which we briefly mentioned a little higher, modern dachas are, most often, cold, summer houses, unsuitable for living in the winter months. Heat escapes through uninsulated walls, where, if you do research, there are from 10 to 30 cold bridges. The floors and roof also take useful energy and transfer it outside the home, heating the outdoor space.

How were country houses insulated 20 years ago?

The nineties in Russia are famous for the widespread shortage of everything, from food to building materials. At that time, the only thermal insulation product was polystyrene foam. It was impossible to obtain polyurethane foam. Vapor barrier materials like the three-layer super diffusion membrane “Izospan AM” were replaced with whatever they could, and this, mind you, without any exaggeration or manipulation of facts. An example of this is the paragraph below.

Some “craftsmen” paved the space between the walls with unnecessary rags and old things (coats, jackets). Pillows, mattresses, and wall hangings were used. People originally from the USSR, as well as the Commonwealth of Independent States, took advantage of the gifts of nature. Multi-ton layers of snow were not thrown off the roof in order to somehow accumulate heat. And in order not to be an unfounded author, I will give the promised example from practice.

Milk cartons instead of vapor barrier

We often travel to the Moscow region, where we assemble houses from double timber, insulate floors, walls, and roofs with ecowool using thermal frame technology. Every time we come to a construction site, we never cease to be amazed at how the work was carried out before us. What we just didn’t find. They even thought about opening a museum in the image and likeness of the famous TV show with Leonid Yakubovich. But let’s not go deep into lyrical digressions and get to the point.

Last week we found used packages of fermented milk products in the walls. After analyzing the find, we came to the conclusion that the owner of this building was either the director or deputy of a livestock factory or a milk production plant. Logically, he either wrote off or, simply put, stole a ton of other tetra-packs for future use at a construction site outside the city.

Naturally, foil cellophane did not replace the vapor-permeable membrane. A fungal coating formed in the space between the homemade insulated floors. Later, mold formed there, which first provoked an unpleasant odor, then rot and other problems associated with it. For obvious reasons, it was easier to get rid of the building than to convert it into good, quality housing.

The further fate of country houses from the dashing 90s

Not wanting to “mess around” (that’s right) with a foul-smelling building on six acres, the vast majority of homeowners did the following. The structures were repaired hastily. We carried out light disinfection, removed excess odors, changed wallpaper, and in rare cases updated the floors. Once brought into marketable condition, the dacha quickly went under the hammer and was just as quickly resold.

If you dig deeper and delve into the archives of the technical documentation bureau, you will find more than a dozen cases of re-implementation of a suburban building. The number of owners who owned a dacha was estimated at hundreds of people by the time the millennium arrived. But, fortunately, the unstable times for Russia are over and now we are seeing a completely different trend in private housing construction.

Firewood harvesting

Even if you didn’t plan to spend the whole winter at the dacha, you probably dreamed of a couple of romantic weekends in a snow-covered house with hot tea or mulled wine by the fire. This means that in the summer we took care of preparing firewood for the fireplace or stove. If not, you should do this immediately, because the logs still need to be dried and stored in the woodshed under a canopy so that they quickly flare up in the fireplace and produce fire and warmth, and not clouds of smoke.

In order to heat a small house with only a couple of rooms and a kitchen-living room every day using a stove, you will need 8-10 cubic meters of firewood. They should be purchased at least a month before the start of the heating season, dried and stored in a woodpile.

- Choosing firewood for the stove, bathhouse and fireplace

They burn, but don't heat up. They burn and smoke and clog the chimney with soot. They flare up quickly, but they spark and shoot... All these are the consequences of the wrong choice of firewood.

Country construction of the 21st century

Today, when the world is gripped by the coronavirus pandemic, a dacha in the Moscow region is valued like a gold bar. Not all residents of the metropolis of 16 million can afford to buy a plot of land in the Moscow region. Demolishing an old, dilapidated house and building a cottage in its place is not a cheap pleasure. Taking this feature into account, most private owners convert their dachas into spacious, comfortable residences outside Moscow, which buzzes day and night.

Strange and surprising as it may seem, it is not difficult to convert a dilapidated house into a winter cottage with a veranda and a usable terrace. The main thing is to follow the technology. Stop trying on your own without experience, skills, or knowledge. Entrust this task to specialists with higher engineering and technical education. Become the owner of housing that is comfortable according to all the rules and principles with the required number of rooms.

Country houses in the Moscow region

The standard dacha in 2022 is a structure made of double timber, rounded logs, red or sand-lime brick. Warm, comfortable housing with one or two bedrooms, a kitchen of 12-16 square meters, an underground garage, a chalet. Eight out of ten buildings are complemented by a Russian bathhouse with a steam room, a font, and a swimming pool. Cottages owned by Russian entrepreneurs are no longer on six hundred square meters. The surrounding area sometimes amounts to hectares of land.

Particularly discerning Russian businessmen have residences with thousands of square meters of nearby land with small lakes, rivers, coniferous or birch forests. An example of this is a man who bought an entire cooperative in the nineties of the last century and rebuilt it into a personal estate. Such villas, palaces and bungalows are often found in the Rublevo-Uspensky, Novo Riga, Yaroslavl directions from Moscow.

Why is it profitable to buy a country house?

It is a mistake to think that if you did not manage to buy a summer house 20 years ago, doing so now will be extremely problematic, impractical, and unprofitable. The only problem will be finding an old house suitable for living in the winter or making money by renting it out for short-term or, conversely, long-term rental. Vector investments in a dacha deserve a separate article. We will definitely tell you about this, but a little later.

Business on renting out a country house

One-time acquisition costs of one and a half, two, four million rubles can be recouped quite quickly by renting. The level of demand in this segment is constantly growing. People use every opportunity to escape from the noisy metropolis outside the city, to breathe fresh air, walk through the forest, fish in a local river, and be closer to nature. The average income from renting out a country house is from 60 to 100 thousand rubles a month.

Technical characteristics of insulation

All insulation materials have their own technical characteristics, which can affect the ease of installation and their heat-saving properties; to make the right choice, you should familiarize yourself with them.

Types and properties of mineral wool

The class of mineral wools includes glass wool, stone wool, and slag wool. All of them have one common characteristic - they are the finest fibers, which, due to their structure, can guarantee a high level of thermal insulation.

All mineral wools are highly hygroscopic, so it is important to use waterproofing during installation. When working with mineral wool, you must follow safety rules

Properties of polyurethane foam

In its rigid (frozen) form, polyurethane foam has the lowest thermal conductivity of all insulation materials, and it does not require such a large layer as for mineral wool or penoplex.

In addition, this type of insulation is very light, you do not need to use additional devices to attach it, it is simply sprayed onto the surface. This monolithic coating guarantees the absence of cold bridges; the material is environmentally friendly and durable.

Related article:

Recommended material for insulating walls in a country house - ISOVER Warm Walls Strong

Material parameters

| Thickness, mm | 50 | 100 | ||

| Width, mm | 610 | |||

| Length, mm | 1000 | |||

| Quantity per package, m2 | 6.1 | 3.05 | ||

| Quantity per package, m3 | 0.305 | 0.305 | ||

| Quantity per package, pcs | 10 | 5 | ||

Buy now

Video description

We will dwell in more detail on insulating a house with polystyrene foam. Find out how safe polystyrene foam is in our video:

It is impossible to ignite mineral wool even with the flame of a gas burner Source krovlyakryshi.ru

It is easy to compensate for lower thermal insulation properties due to thickness. External insulation is not internal, and a few extra centimeters of insulation mean nothing. It is necessary to insulate with hard mats - rolled materials in vertical structures “move out” over time. And you have to choose between a thickness of 5 cm and 10 cm. For central Russia, provided that mineral wool 10 cm thick is already laid inside the walls, an additional 5 cm of thermal insulation layer is sufficient. Plus the thickness of double-sided wall cladding, interior trim and façade panels.

But if the budget allows, you can lay a layer 10 cm thick.

How to insulate the outside walls of a panel house

A panel house on a wooden frame is not a log house made of logs or timber. In this case, there is no need to talk about the breathing properties (gas permeability) of the walls. Firstly, a continuous layer of vapor barrier is laid on the inside. Secondly, the vapor permeability of plywood or OSB boards with which the frame is sheathed is very low. Therefore, for external insulation you can use those materials that are not used for wooden houses:

- expanded polystyrene;

- EPPS (extruded polystyrene foam);

- sprayed thermal insulation based on two-component or one-component polyurethane foam.

What tools will you need?

To insulate walls, you will need a standard set of tools and materials:

- reinforced mesh for applying plaster;

- primer for the wall. The quantity depends on the scope of work;

- glue for indoor or outdoor work;

- hammer drill, construction mixer;

- hammer, screwdriver;

- spatula, sharp knife.

All these tools should be in the arsenal of a summer resident who decides to insulate the house with his own hands.

Penofol or penoplex

There is no point in comparing these two materials with those discussed above, since their price is superior to both foam plastic and mineral wool. Speaking about them, we note that penofol and penoplex are modern thermal insulation materials that are distinguished by excellent performance characteristics. Especially in this regard, penofol stands out, which experts call combined because it has three layers in its structure:

- waterproofing;

- thermal insulation;

- vapor barrier.

When installing penofol, they resort to the use of a special adhesive composition. But to install penoplex on the surface, special fasteners are used - fungal screws. You should know that penoplex is a panel with a smooth and even surface, which facilitates the process of laying finishing material on top of it.