Rating of the most economical and reliable electric heating boilers for a private home. Models are presented with durable heating elements, properly functioning safety automation and effective temperature control. Such boilers do not require complicated installation. There is no need to install a chimney, supply and exhaust ventilation or allocate a room for them. Modern models of heating element modifications have a built-in security system and other necessary elements and components, so to create a simple heating system you do not need bulky boiler piping. Below we will consider the methodology for calculating boiler power by area of the house, calculate energy consumption indicators in seasonal terms and give several ways to save energy.

To choose an electric heating boiler, you need to select the correct power and inspect the electrical wiring. The cross-section of the power cable must correspond to the load. Models up to 3.5 kW are connected directly to the apartment outlet. More powerful electric heating boilers operate through automatic protection devices, which are responsible for controlling the current strength.

The installation of electric boilers with a power of up to 10 kW does not need to be coordinated with Energonadzor. This is done only when connecting a multi-tariff meter in order to save electricity on the price difference between the day and night tariffs. For boilers with a power of more than 6 kW, it is necessary to organize a three-phase connection (380 V).

Advantages and disadvantages

Developers are improving models of three-phase boilers. Among the devices, you can find wall-mounted and floor-mounted types. Models are equipped with multi-stage adjustment devices, automatic air exhaust, and temperature control.

The device is compact, suitable for small spaces. The device has a good design and can fit well into the decoration of the room.

If we compare an electric device with a gas heater, economically, the first option is less profitable, but has advantages:

- In terms of space occupied, an electric boiler is superior to some heaters. Installation can be carried out anywhere. The only condition is the presence of an electrical network.

- To remove decomposition products, it is not necessary to install a chimney or ventilation. It is possible to save some of the budget funds.

- The device does not emit combustion products, carbon monoxide and unpleasant odors are excluded. The boiler is an environmentally friendly equipment.

- When the electric boiler is in operation, it is almost silent.

- The device does not have an open flame, and there is no need to comply with fire safety measures.

A three-phase boiler has increased efficiency - up to 96%.

Disadvantages - requires current conversion to 380 V. Requires high-quality electrical wiring in the house. Electricity is more expensive than gas. Economically less profitable. Due to power surges, breakdowns and complete failure may occur.

Proper placement and installation

Well, we got to the main thing. Our advice has given you a rough picture of the equipment you need. And now a little about the installation.

| Boiler installation |

The electric boiler is placed in a room where there is no access to explosive compounds, conductive dust and acidic vapors. It is necessary to control air humidity, it should not exceed 80%, and the temperature inside should not exceed +25 degrees.

For placement, it is important to maintain a distance of 5 centimeters between the body and the walls. In front of the boiler, 70 centimeters of free access to the equipment is left. In this case, the distance to the ceiling is left at least 80 centimeters. For a hanging boiler, the distance to the floor is left from 50 centimeters. The same distance is left to the nearest pipes.

The wires protect against accidental ingress of water and condensation from the ceiling. To protect the cable, use a cable channel or corrugation made of non-flammable material.

The floor-standing boiler is installed on a stand, which is sold complete. For a wall-mounted boiler, anchors and dowels are used. The wall is marked and holes are made in a horizontal plane with a drill. Minimal misalignment affects the performance of the boiler. Dowels are hammered into the holes and anchors are screwed in. Next, hang the boiler.

The device is connected directly from the network; for this, a cable is led from the current distribution box to the boiler. To protect the cable from damage and not spoil the interior of the house, it is laid in a hidden way.

To prevent power surges from damaging appliances, a voltage stabilizer is connected to the boiler. The ground wire leads directly to the boiler.

After connecting the elements, check to see if there are any exposed contacts or if the insulation is damaged. Inspect couplings, joints on pipes, taps. Then the system is started: the valves of the equipment are opened and current is supplied.

Types of electric boilers

There are many models of electric boilers on the market. Peculiarities:

- Different number of connected circuits. Three-phase boilers can be single-circuit or double-circuit. Single-circuit boilers have a high output power.

- By heater type. Heating elements equipment, electrode, induction.

- By type of coolant. Antifreeze may be used.

- According to the type of electrical network used. Operate from 220, 380 volts. The number of phases varies - with one, three.

- According to the method of heating the coolant - flow-through, storage devices.

To create increased power, greater productivity is needed. An electric boiler with a power of 12 kW or more requires connection to a 380 volt network. It is necessary to go to the appropriate authorities and obtain permission to lay a separate line.

In electric boilers with three phases, when there is a shortage of coolant in the system, it boils.

High-quality boilers for houses up to 60 square meters. m.

1

Teplodom i-TRM SILVER StS 6 6 kW single-circuit

Rating:5.0

- Thermal power: 6 kW

- Mains voltage: single-phase/three-phase

- Power levels: 3

- Heated area: 60 sq.m

- Coolant temperature: 5 – 80 °C

- Functions: auto-diagnostics, frost protection, pump blocking protection

Average price: RUB 20,300

The electric boiler with microprocessor control has an intuitive user interface and provides adjustment of the coolant temperature within the range of +5℃ ... +80℃. The smart system ensures alternating operation of the heating elements in order to ensure their uniform depreciation. Seven-voltage switches open and close the network silently, so there will be no clicks characteristic of relay ECUs.

When connecting an external water meter with a pulse output, the boiler will turn off without operator intervention if the flow in the heating circuit stops for some reason.

Peculiarities:

- durable heating element made of stainless steel;

- the ability to participate in a cascade connection paired with other boilers;

- presence of an input for an external thermostat and weather-compensating automation;

- maintaining operability at extreme voltage values.

With a 3-phase connection, the boiler has another advantage - it automatically selects the priority phase to even out the load on the electrical network.

2

EVAN EPO 6 6 kW single-circuit

Rating:4.9

- Thermal power: 6 kW

- Mains voltage: single phase

- Efficiency: 99%

- Heated area: 60 sq.m

- Coolant temperature: 30 – 85 °C

- Functions: power-on indication, overheat protection

Average price: RUB 12,550

An inexpensive electric heating boiler can be integrated into a heating system with natural circulation or a built-in pump. Tap water or antifreeze can be used as a coolant. The temperature in the range of +30℃…+85℃ is smoothly regulated using a built-in thermostat.

Peculiarities:

- electric heater made of high-quality stainless steel;

- emergency thermal switch that turns off the boiler when the coolant temperature reaches 92;

- possibility of connecting an external thermostat;

Unlike the previous model, EVAN EPO 6 does not have such rich functionality, but the price of the unit is much lower.

3

Teplodom iTRM-6 SILVER 6 kW single-circuit

Rating:4.8

- Thermal power: 6 kW

- Mains voltage: single-phase/three-phase

- Heated area: 60 sq.m

- Maximum current 3F: 16 A

- Coolant temperature: 30 – 80 °C

- Functions: autodiagnostics, frost protection, power-on indication, overheating protection, thermometer

Average price: RUB 13,900

The Teplodom electric boiler is equipped with a rich set of useful functions, and has a huge price advantage among similar models. The triac electronics used in this unit operate silently and are resistant to surge voltage surges. Steel heating elements have a special chemical coating that extends their service life. The frost protection system, emergency shutdown and self-diagnosis allow the device to remain operational for a long time.

Peculiarities:

- presence of an input for weather-compensating automation;

- advanced digital, LED and sound indication;

- intelligent power modulation with phase selection.

This electric boiler is suitable for a private home or cottage as a main or backup heat source. The boiler can be connected to 220 V or 380 V electrical networks.

Operating principle of electric boilers

Principle of operation:

- Coolant is supplied to the electric boiler through pipes.

- Inside, under the influence of an electric heater, the water is heated.

- The hot coolant is sent through pipes to the heating radiators.

Methods for heating the coolant:

- Heating element heaters. Act as boilers. The quantity depends on the device model. A boiler operating on heating elements is reliable, affordable, and has a high efficiency.

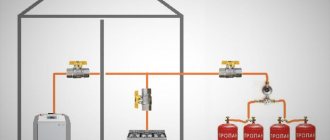

heating element device

To increase the efficiency of the device, you need to install a programmer. The device allows you to set the optimal room temperature automatically. Settings are made depending on room and outdoor temperature indicators. The economic efficiency of the device is 30%. You can install it yourself.

- Heating device on electrodes. The coolant is heated by alternating current. The device is reliably protected from short circuits, accidental leaks, and overheating.

Differences between PETN and electrode devices

- Induction boiler. Electromagnetic induction is used.

Induction

Boilers 100-150 sq. m

1

Protherm Slope RAY 14 KE /14 14 kW single-circuit

Rating:5.0

- Thermal power: 7 – 14 kW

- Mains voltage: three-phase

- Power levels: 2

- Maximum current 3F: 25 A

- Coolant temperature: 25 – 85 °C

- Functions: autodiagnostics, frost protection, power-on indication, overheating protection, thermometer, pressure gauge

Average price: RUB 50,882

A wall-mounted electric boiler is used for heating and organizing hot water supply when a boiler is connected. Users can configure up to four power levels. It is possible to connect a remote control and a weather-dependent automation unit. Thanks to the LED indication and liquid crystal display, it is convenient to monitor the temperature and control the operating status of all components.

Peculiarities:

- automatic protection against overvoltage, freezing, water hammer;

- built-in expansion tank and pump unit with float air vent;

The efficiency of this unit is 99.5%. This is a convenient and economical boiler option for installation in an apartment, private house or country house.

2

Vaillant eloBLOCK VE 14 14 kW single-circuit

Rating:4.9

- Thermal power: 7 – 14 kW

- Mains voltage: three-phase

- Power levels: 2

- Maximum current 3F: 25 A

- Coolant temperature: 25 – 85 °C

- Functions: autodiagnostics, frost protection, pump blocking protection, power-on indication, overheating protection, thermometer, pressure gauge

Average price: RUB 56,304

The electric boiler from the German brand is equipped with rich energy-saving functionality. The microprocessor control unit provides automatic temperature control, protection against overloads in the electrical network, freezing of the boiler and boiler. Power supply is supplied from a three-phase alternating current network with a voltage of 380V.

Peculiarities:

- possibility of connecting an indirect heating water heater;

- compatibility with Warm Floors systems;

- effective pump anti-blocking system;

- presence of a BUS bus for connecting weather-compensated automation.

The boiler has a modern design. Despite the powerful electronic filling, it has the simplest possible control panel and can be an excellent alternative to gas heating.

3

EVAN S2 12 12 kW single-circuit

Rating:4.8

- Thermal power: 12 kW

- Mains voltage: three-phase

- Heated area: 120 sq.m

- Efficiency: 99%

- Coolant temperature: 30 – 85 °C

- Functions: power-on indication, overheat protection

Average price: RUB 22,440

The boiler with Czech electric heaters made of stainless steel is famous for its durability and easy operation. The coolant temperature is controlled by a thermostat and is smoothly adjusted in the range of +30℃…+85℃. Precisely maintaining the desired room temperature using an external thermostat allows you to save electricity. When using an additional remote control module, you can control the operation of the unit from a distance.

Peculiarities:

- the design of the heating element on a threaded connection simplifies the replacement procedure;

- The emergency sensor turns off the unit at a temperature of +92±3℃.

Unlike the previous model, this device does not have a circulation pump, but there is a block for connecting it. The unit performs its functions at a pressure in the circuit within the range of 0.12 - 0.15 MPa.

4

EVAN Next 12

Rating: 4.6

- power: 6 – 12 kW

- heating area: – 120 sq.m

- number of circuits (if any): single-circuit

- Efficiency: – 99%

Average price: 12,350 rub.

EVAN Next 12 is a single-circuit boiler with a heating element. The power of the heating system is from 6 to 12 kW. Heats up to 120 square meters. Efficiency is high - 99%. Mechanically controlled. The boiler is installed on the wall. There are two power levels. Three-phase mains voltage. The product is protected from overheating. Weighs 8 kg. The manufacturer promises 10 years of operation.

Advantages:

- low noise level;

- compactness;

- low price;

- Ease of Management.

Design

The design of a three-phase boiler includes the following elements:

- Depending on the type of device, it may have 1-2 heating elements.

- The design includes one heat exchanger.

- Expansion tank.

Heating tank

- Circulation pump.

- An air vent is installed to circulate air flow.

- Safety valve.

- The device is filled with electronics and automation.

Condensing boilers

A few words should be mentioned about condensing-type boilers, which can be floor-mounted or wall-mounted. Their main difference from classical models is their high efficiency, which exceeds 100%.

The main disadvantage of such equipment is the high initial costs. For their operation, high-power radiators are required. Warm floors work best with them. Heating must be designed in such a way that the coolant flows to the return with a temperature not exceeding 35-40 degrees.

If we talk about the initial costs, they can reach 3-5 thousand dollars. However, the savings are more than significant. It will be possible to heat a house with an area of 150-200 square meters for a modest 40-50 USD.

Types of three-phase heaters

An electric boiler is common in heating private homes. Double-circuit boilers are popular. Available in two types:

- Electrode type of heaters. The advantage is a high heating rate.

- With induction heating method. Electrical energy consumption is reduced and the family budget is saved. Cons: heavy weight, price higher than many types of heaters.

Equipment production is carried out at low capacity. To increase this, craftsmen use a cascade method of installing heaters. Install 3 heaters with separate connection phases.

There are devices equipped with heating elements, but they are not as popular as induction and electrode boilers. The reason is constant cleaning of heaters and periodic replacement.

Structure and main differences

A gas boiler consists of three main modules - a burner, a heat exchanger, and automatic control. The burner is located in the combustion chamber, above it there is a heat exchanger in which the coolant is heated. The entire process is controlled by automation. It ensures safety and changes the operating modes of the equipment.

Boiler with a closed combustion chamber (turbocharged)

Types of heat exchangers

A double-circuit boiler is distinguished by the fact that it can heat both water for heating and water supply. This must be done separately, because special heat exchangers are needed. There are two types:

- Double heat exchanger. It consists of two separate modules - primary and plate. In the primary, the coolant from the heating system is heated, in the secondary - plate - water for domestic needs. The primary heat exchanger is a tube with fins, the secondary is a set of plates. They are located in different parts of the boiler - primary at the top, plate at the bottom, but they are connected to each other so they can be read as a single part.

- Bithermal heat exchanger. It consists of two metal tubes of different diameters inserted into one another. In the inner tube, water is heated for hot water supply, in the outer tube - for the heating system.

The structure of a double-circuit gas boiler

A system with a dual heat exchanger is more reliable. Since heating is a closed system and the coolant circulates in a circle, little scale is formed. When heating water for hot water supply, the situation is the opposite - running water heats up, which means there is a lot of scale. This part of the heat exchanger periodically requires repair or replacement. If in a dual heat exchanger it is possible to replace only the part that heats water for domestic needs, then in a bithermal heat exchanger there is no separation; you have to change the entire device, and this is much more expensive. There is one more point: a double-circuit gas boiler with a double heat exchanger works normally for heating, but with a bithermic the situation is different - it does not work at all.

Heat exchanger material

The choice of a double-circuit gas boiler can also be influenced by the material from which the heat exchanger is made. It could be:

- Stainless steel. A good option in terms of durability, but it has rather low heat transfer, which reduces the efficiency of the boiler. However, the price of such a heat exchanger is high.

- Cink Steel. This is the cheapest type of heat exchanger, but also the most short-lived.

- Copper. An excellent option for heat transfer (boilers have high efficiency) and durability, but the price is high. But this scares few people - it outweighs the opportunity to pay less for gas during operation. It is for this reason that most good double-circuit gas boilers are equipped with a copper heat exchanger.

This is what the primary heat exchanger looks like in gas wall-mounted boilers

Choosing a double-circuit gas boiler based on this parameter is not so difficult. Copper seems to be the best option. Not without its drawbacks - high chemical activity and low melting point - but they have long learned to compensate for them. The boiler automation ensures that there is no overheating. Chemical activity is neutralized by using chemically neutral materials in the heating system - using polymer pipes - polypropylene or cross-linked polyethylene.

Types of burners for gas boilers

In wall-mounted double-circuit gas boilers, atmospheric gas burners are installed. According to the method of controlling the flame, they are:

- Single stage. The burner either burns or it doesn’t. There are no intermediate provisions. To maintain the required heating mode, the burner either lights up or goes out. Not the best working algorithm.

- Two-stage. There are two operating modes - at 100% power and at 50-60%. The automation itself regulates the required power. Such burners are more economical and allow you to maintain the temperature more accurately. By reducing the number of on/off switches.

Double-circuit gas boiler with modulating burner is the most economical

If we talk about the optimal choice, then these are modulating burners. They not only allow you to maintain the heating temperature accurately, but also heat the water exactly to the specified parameters. If you want to choose an economical double-circuit gas boiler, it must have a modulating burner.

Automation

Automation is a must in gas boilers - it ensures safety and switches operating modes. There are three main parameters that are constantly monitored:

- presence of draft in the chimney;

- gas pressure;

- flame control.

These are key points that simply need to be monitored. If at least one of these parameters is not normal, the boiler does not turn on. In addition, there is an extensive list of additional functions:

- Maintaining a stable temperature. There are two types of automation: one controls the temperature of the coolant, the second controls the air in the room. More comfortable conditions are created by controlling the air - the weather changes, but regardless of this, the set mode is maintained in the room.

This is the remote control from which all parameters are set

These are the functions that are common, but there are also specific ones: the ability to connect (and control) solar panels, underfloor heating systems. There is weather-compensating automatic control. In this case, there are remote sensors that are installed on the street. Based on their data, the operation of the boiler is adjusted.

Ferroli Diva gas boiler control panel

All these functions are embedded in the microprocessor, which controls everything. Of all the automation systems, the average user only encounters a remote thermostat, which can be installed in any room and based on the readings of which the temperature can be adjusted (another additional feature). Basically, all interaction with the boiler and its automation is limited to a small panel. All necessary information is displayed on the screen. There are also buttons with which you change modes and set the temperature.

Operating rules

Electric boilers are safer than their analogues; however, safety precautions must be observed when working with boiler equipment. Especially when connected to the mains.

It is worth highlighting the main requirements:

- The electrical circuit is connected directly to the meter. To protect devices from overloads, do not forget to install circuit breakers in the electrical network. In the event of a short circuit, the device will be safely switched off without damage.

- Grounding installation is required. The manufacturer indicates the item in the warranty card. Failure to comply will result in termination, waiver of liability in the event of breakdown of the electrical appliance.

When operating the device, it is necessary to monitor the condition and performance of the group responsible for the safety of the three-phase boiler:

- Safety valve.

- Pressure gauge.

Pressure gauge

- Air vent.

Combustion chamber type

The gas burner is located in the combustion chamber. There are two types - open (atmospheric) and closed (with a turbine, forced). A double-circuit gas boiler with an open combustion chamber can only be installed in rooms with good ventilation. During operation, the oxygen necessary for combustion is taken from the room, and combustion products are discharged into the chimney with good draft. Therefore, a good air flow and a properly functioning exhaust ventilation duct are necessary.

Gas boilers come with open and closed combustion chambers

Gas boilers with a closed combustion chamber are distinguished by the fact that at the chamber outlet there is a coaxial chimney (pipe within a pipe) equipped with a fan. The chimney is taken out into the street, or into the wall near the boiler. Through one pipe, air is taken in from the street, through the second, combustion products are removed, their movement is ensured by a fan-turbine.

Which combustion chamber is better? A boiler with a closed combustion chamber operates more stably - air enters directly into the combustion zone. But there is also a disadvantage to this: with a side wind, the air flow can be so strong that it blows out the burner and the boiler turns off. The second disadvantage of this solution is freezing and the formation of ice in winter. Well, the third drawback is that such a boiler only works when there is electricity - without a turbine it turns off. Well, there is another small minus - the turbine is not silent. It’s almost inaudible, but it’s “almost.” Apparently for these reasons, if possible (a working ventilation duct), boilers with an open combustion chamber are installed. After all, ensuring a constant flow of air is much easier.

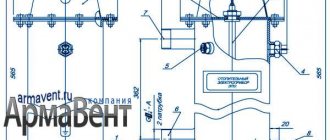

Piping, first start-up of a three-phase boiler

Before installing an electric boiler, it is necessary to carry out calculations of the schematic piping. Compared to 220 volt, the circuit is more complex; permits are required. It is better to entrust the connection to a 380-volt electrical network to a specialist.

If you will be making the connection yourself, first read the instructions that come with the device. The process requires care. You need to connect the wiring correctly.

Mistakes made when laying 380 volt wiring can lead to consequences.

The main parameter is power

One of the main characteristics that people pay special attention to when choosing a gas heating boiler is its power. The higher this value in the technical documentation, the larger the area the equipment can heat.

The market is very extensive and offers models whose power ranges from a few units to hundreds of kW.

Advice. In order not to make a mistake when choosing equipment, it is recommended to contact a specialist. A qualified technician will quickly select the power based on specific operating conditions.

If you determine the required boiler power yourself, you must proceed from the ratio: 1 kW for every 10 sq. m. In this case, the room should be well insulated, and the height should be less than 3 m. If there is no possibility or desire to insulate the walls of the house, it is recommended to increase the calculated power indicator by 20-30%.

Another pitfall that you will have to face and take into account is the gas pressure in the pipelines. In the technical documentation, manufacturers indicate power, taking into account its nominal value. In reality, the pressure may be lower, especially in remote areas. Consequently, the useful power will be less.

Choosing a brand of electric boiler

Purchasing three-phase boiler equipment does not present any difficulties.

The device must meet your requirements and the structural features of the building. Pay attention to the available functionality and the manufacturer's warranty.

Devices made in Germany, the Czech Republic, Spain, and Switzerland are popular. German and Swiss manufacturers pay attention to the quality of the product, which is reflected in the price.

Electric boiler from a German manufacturer

Czech electric three-phase boilers have no less functionality and performance. Cheaper than German analogues.

Russian manufacturers are also engaged in the production of boiler equipment, inferior to foreign partners, but not much. Equipment available. According to customer reviews, Russian-made products are of high quality and reliable.

Selecting the optimal number of circuits

Most models intended for installation in private houses and cottages can be divided into two types according to the number of circuits:

The first ones function extremely simply and are intended exclusively for heating systems. If it is necessary to provide hot water supply in the house, models are purchased that can serve two or more circuits at once.

Advice. When it is necessary to additionally provide hot water to other systems in the house, for example, heated floors, multi-circuit equipment is purchased or modern automation is installed.

Double-circuit gas boilers, which are most widespread, can be divided into two types:

- With built-in boiler

- Flow-through

Boilers with a built-in boiler have one advantage - next to them there is a tank with a capacity of more than 100 liters, in which heated water constantly accumulates. The operation of such equipment allows you to save on fuel, and in the event of a gas shutdown, you can consume the heated liquid for some time. The disadvantages include the need for free space (preferably a separate boiler room) and high starting material costs.

If the need for heated water is small, you can safely use flow-through models. In them, the liquid is heated directly at the moment when it circulates through the circuit.

Calculation of heating costs

If we compare solid fuel, gas and electric boilers, appliances that run on electricity are the most cost-effective. To calculate monthly seasonal costs for heating a room, you need to consider:

- To produce 1 kW of thermal energy, it is necessary to spend 1.03 kW of electrical energy. The indicators will be correct if the efficiency of the device is 100%.

- Find the area of the house, divide by 10. Multiply by the indicator.

- We multiply the resulting number by the cost of one kW, then by 24 and by the number of days.

For example: heating a house of 100 square meters, with an electricity cost of 3.2 rubles per kW, will cost about 26,000 rubles. Price may vary. The temperature outside the window is not a constant value; the boiler requires an increase in heating power, a decrease.

PS (post scriptum)

Buying a double-circuit electric boiler for heating an apartment in the future does not bring any benefit to its potential owner. If you buy heaters for the heating system and hot water supply separately, it will be much cheaper and more convenient. It’s generally better to forget about water heated floors powered by an electric boiler. There is an alternative - electric heated floors, of which there are several types. The possibility of a coolant leak is eliminated, and even if a breakdown occurs, only some part of the heated floor will cease to function. The newest infrared mats are not susceptible to damage at all.

Steel and cast iron boilers

Boilers with a steel heat exchanger have a long flue gas path. In this regard, they better transfer heat to the heat exchanger. In addition to this, the walls of the smoke duct are easy to clean. To achieve a high level of efficiency, cast iron boilers have a heat exchanger surface with many fins located close to each other. The design of such a boiler does not have a long flue gas path, so cleaning such a boiler is a complex and time-consuming process.

Use of materials is permitted only if there is an indexed link to the page with the material.

Warmth in the house is a prerequisite for comfortable living. In the absence of centralized heat supply systems, boilers are installed to heat water. From an economic point of view, a gas boiler is the most profitable, but central gas supply is not available everywhere. If it is impossible to use gas equipment, an electric boiler will be the best choice.

Heating elements are installed mainly in storage boilers used to heat water for the hot water supply system. But there are also models of boilers with heating elements designed for heating a home. Boilers with heating elements are unreliable. If there is a water supply failure, the automation does not always have time to operate, and the heating element may burn out.

Electrode system

The electrode water heating system is more economical, reliable and safe. Due to direct contact with the heated medium, heat loss is reduced and energy is saved. If there is no liquid inside the housing, the contact between the heating elements disappears and heating stops without the participation of sensors, that is, the boiler cannot burn due to the lack of coolant.

The only but significant drawback, which appears after several years of operation, is the accumulation of scale on the electrodes. This significantly reduces the efficiency of the equipment.

Induction coils

A modern boiler, in which the liquid is heated by electrical induction, is the most effective solution. Since the heating element does not have direct contact with water, scale formation on them is excluded.

Therefore, the induction boiler operates throughout its entire service life without reducing its efficiency. The disadvantages of a boiler with an induction coil include its high cost, so this type of heating equipment is less often used for home improvement.

(no votes yet)

Conclusions and useful video on the topic

We recommend that you familiarize yourself with a selection of reviews and practical tips on the use of electric boilers of various designs for heating and hot water supply at home.

Nuances of electric heating - boilers and other electric heating devices, calculation of equipment power and costs for the heating season:

Although double-circuit electric boilers seem very comfortable to use, before you go shopping, calculate your electricity costs for the cold season or contact a heating engineer.

Perhaps they will advise you on a more economical system with a single-circuit boiler with an indirect heating boiler, or they will design a combined heating system, where the “gluttony” of the electrical appliance will be compensated for by additional energy sources.

Please write comments in the block below. Tell us what was the decisive argument for you in choosing a double-circuit boiler model. Share useful information that will be useful to site visitors, ask questions.

What to look for when purchasing?

When you have figured out what type of device you want to buy, it’s time to think about its size and technical parameters.

Most often, electric boilers are installed in the kitchen, but you can also equip a mini-boiler room, which will allow you to hide unattractive communications and additional equipment (storage tank, indirect heating boiler, etc.).

Selecting a device by installation method

Regardless of the type of construction, all double-circuit boilers can be divided into two large groups - wall-mounted and floor-mounted. The dimensions and choice of model directly depend on the area that you need to heat, and also on the amount of free space for the device itself.

A wall-mounted boiler differs from a floor-mounted boiler in its small size - if necessary, it can be hidden in a wall cabinet or cabinet, but even an undisguised device does not look bulky and harmonizes perfectly with other household appliances

Attachment units are designed for heating relatively small areas - up to 100 m2, therefore they are most often installed in apartments or small country houses. They are attached to special brackets to any vertical surface that can withstand such a load.

Floor-standing boilers are rather bulky devices, but they can provide a house with an area of up to 200 m2 with heat and an uninterrupted supply of water, and storage tanks can either be built into the device itself (which significantly increases its dimensions) or mounted separately

If the cottage area exceeds 200 m2, you can equip a boiler room with several electric boilers or use additional heating sources - solid fuel equipment or solar panels.

Calculation of required power

The simplest way is to divide the heated area by 10. It is believed that when heating 10 m2, 1 kW will be spent, but the resulting figure will be very arbitrary, because such a calculation makes sense only for rooms with a height of no more than 3 meters.

In addition, heat costs largely depend on the presence of insulation, the quality of windows and their sizes, the climatic features of the area and the materials used in the construction of the house.

If the house has high ceilings, you must first determine the volume of the room (multiply the area by the height). Then calculate the required power on the basis that 1 m3 will require 35 W.

When purchasing, consider models whose power is 15-20% higher than your calculated values - it is better to set the boiler to a weaker mode than to freeze in the cold winter with the equipment working at its limit

To the obtained result you need to add a “margin”:

- 10% - with a large glazing area (panoramic windows, veranda, etc.).

- 15% - in the absence of house insulation.

- 10-15% - for areas with cold winters.

- 20% - for additional load when DHW operates in flow-through heating mode.

When calculating the required power for boilers with built-in storage, you need to rely on the data specified by the manufacturer in the technical documentation.

The method of feeding it also depends on the technical parameters of the boiler. Appliances up to 10 kW can be connected to a regular 220 V network, and more powerful boilers can be connected to a three-phase network (moreover, this may require permission from local power grids if a 380 V line is not supplied to the house).

Other important nuances

Based on the principle of heating water, double-circuit electric boilers can be divided into flow-through and storage. The first is a good option for a small house and family; it can easily serve 1-2 water points in addition to heating. But despite its compactness and ease of use, the 2-in-1 device has a significant drawback - a high load on the electrical network.

But the storage unit takes up much more space due to the additional tank in which the supply of hot water is stored. The advantage of this type of equipment is that it can supply water in large quantities and allows you to save up to 10% on electricity, since it does not waste energy on constant heating, but only maintains its temperature.

Thanks to the insulating casing, the heat loss of water in the tank per hour will be no more than 0.5 degrees. The technical data sheet of a device intended for connection to a hot water supply system must indicate its throughput - minimum and maximum temperature, volume of water and the required time for heating it.

Modern electric boilers allow you to control the device and control the heating temperature in the room using smartphones or a smart home system

Additionally, the boiler can be equipped with:

- Automation unit for remote control from a remote control or via a network.

- Frost protection, which will allow you to maintain a minimum temperature in the system, which is important for country houses and country houses where there are no permanent residents.

- Sensors that monitor weather changes turn the device on when temperatures drop and turn it off during sunny hours.

- Equipment that lowers the water temperature for connection to the “warm floor” system.

- Sensors with the ability to program the microclimate in the entire room or individual rooms at your discretion.

Of course, “bonuses” from the manufacturer increase the cost of the device, but with their help it is much more comfortable to operate the boiler.