Exists two types of heating systems according to the principle of interaction with the atmosphere:

- open : the system has contact with the atmosphere, usually a tank filled with water and connected to the pipes of the heating system, it plays the role of an expansion tank. With an open system, constant contact of the coolant with atmospheric oxygen leads to increased corrosion of pipelines and radiators. The formation of various contaminants reduces the overall efficiency of the heating system.

- closed : has no contact with the atmosphere. The expansion tank is made in the form of a steel container, inside of which there is a rubber bulb or membrane under air pressure. When the coolant expands, the bulb contracts and releases additional volume. The volume of the expansion tank is selected according to the volume of the coolant. For a rough calculation, 10% of the total internal volume of the coolant is taken.

This article will primarily focus on a closed system.

General information about the heating system

Heating boiler connection diagrams are distinguished by the method of coolant circulation.

Based on this feature, the systems are as follows:

- Gravitational . This is a natural circulation when the process of replacing heated liquid with cold masses takes place, which rises upward. The coolant returns to the boiler by gravity, under the influence of gravity. Such systems have a great advantage - they are non-volatile, so they will continue to work even in the absence of electricity.

- Forced . Here you need the help of electric circulation pumps. With this scheme for connecting the heating system to the boiler, the radiators in all rooms are heated quickly and evenly. This method is optimal when installing a heating system in a large house.

On a note. Installation of heating devices and pipelines is done in such a way as to minimize heat loss through the external enclosing structures. Heat losses in pipelines passing through unheated rooms should not exceed 10 percent of the heat consumption for heating.

According to the method of connecting pipes to radiators, the schemes are as follows:

- single-pipe, when heating devices are connected in series;

- two-pipe - parallel connection of radiators;

- bifilar - a series connection of first the first halves of the devices, then, for the coolant flow in the opposite direction, connect all their second halves.

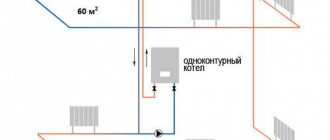

Single-pipe wiring method

Single-pipe water heating wiring is the following main line wiring system: water heating devices are installed sequentially one after another and thus form a long pipe - the diagram will help you understand what it looks like.

The coolant in such a system is antifreeze or water - the liquid alternately enters the radiators, which are the final link in the chain, and gives off its heat, which is then used for water heating of the house.

Thus, the system scheme consists of supplying water from the boiler to the radiator using pipes.

The disadvantage of this device is that the water reaches the closing radiator already cold.

With such a device, the single-pipe option is quite effective.

A single-pipe water heating circuit is best suited for a two-story house, because... in a house with one floor, problems may arise with the placement of the accelerating manifold, which is necessary for the quality operation of the structure.

An accelerating manifold is necessary to speed up the flow of heat from the pipes to the radiators, as well as to maintain the desired temperature and reduce noise during system operation.

Video:

At the same time, the efficiency of work depends on how high the collector will be located - which is why its installation for a two-story house will be much more efficient.

For a two-story house, all these problems disappear: the collector will work quietly and effectively maintain heat in the rooms.

The manifold of a single-pipe heating system looks like a continuation of the pipes, but at the very top of the heating system an expansion tank is connected to it.

Single-pipe wiring is inexpensive, and this is one of the main advantages in its favor. The low price is maintained due to the fact that single-pipe wiring does not require a large number of pipes.

Another advantage of this design is that it can be laid even in difficult places, for example, under doorways.

However, single-pipe water heating wiring also has disadvantages: in order to replace failed elements, you will have to completely turn it off, and uneven heating - the quality of heating depends on the distance of the battery to the boiler.

However, as has already been written, if the design is somewhat modernized and installed correctly, it will be free from such shortcomings.

Installation of the system can be done in several stages, they differ depending on the scheme.

The most profitable option is to install all elements of the system (boiler, distribution, heating main) completely inside the house, when it starts at the supply point and ends at the boiler.

Pipe connections in a single-pipe system can be of two types: diagonal and lower through.

The first type of connection is chosen most often, because it is as effective as possible.

In addition, an expansion tank must be installed in the house (most often it is placed in the attic of a two-story house), which must be connected to the wiring, water supply and sewerage systems.

The diagram will help you do everything right.

A two-story building has its own installation features.

In this case, a single-pipe circuit should include radiators on each floor, and the number of sections in them and their total number should be approximately the same so that the temperature is comfortable in all rooms of a two-story house.

This option is not very beautiful, but it is easy to implement and quite effective.

Study the diagrams of how to install single-pipe wiring for a two-story house, then it will be easier for you to decide which option is suitable for your building.

What pipes are needed to connect a heating boiler?

The choice of pipes is a very important stage in preparation for the installation of heating equipment.

For efficient operation of a heating system with a circulation pump, the pipes must withstand the following indicators:

- pressure - 1-2.5 kgf/sq. cm.;

- supply liquid temperature 70-75 °C;

- return temperature - 55°C.

These are parameters that are maintained during normal operation of the system, without emergency situations.

If the pump stops for some reason, the situation will develop as follows:

- for a gas, electric and diesel boiler, the thermostat will shut off the fuel supply and the operation of the water circuit will remain safe;

- For a boiler operating on solid fuel, the thermostat will close the ash pan, but combustion (smoldering) of the fuel will continue for up to half an hour, which means that the temperature of the coolant may increase.

In this situation, the performance characteristics of plastic and metal-plastic pipes that will be used for a gas, electric and diesel boiler must have operating parameters of at least 80 °C.

As for the solid fuel unit, at least 1-2 meters of the water circuit coming from the boiler must be made of steel, copper pipes or stainless steel. Steel pipes, resistant to temperature changes and hydraulic pressure, are unfortunately susceptible to corrosion, have considerable weight and an insufficiently smooth inner surface. Installation must be done by welding. The outside of the pipes is coated with paint, and such maintenance must be done regularly. Copper and stainless steel pipes do not have such problems. The only drawback is the rather high price of these products.

With natural circulation, the heating process of the coolant occurs slowly. The temperature of the liquid leaving the boiler sometimes exceeds 90°C. Therefore, the pipeline between the boiler and the expansion tank is always made of metal.

Not even the best plastic can withstand abnormal temperatures. Leakage and plastic softening are guaranteed at 130°C. Polypropylene pipes burst due to overheating.

Important. The internal diameter of the supply pipe cannot be less than 32 mm. This is necessary in order to ensure minimum hydraulic pressure during gravity heating.

In recent years, attempts have increasingly been made to hide the pipeline from view. The wiring is done not only externally, but also hidden in the walls, under the finished floor, inside plasterboard boxes. In heating systems, it is permissible to combine different types of pipes.

Preparation of material and welding of parts

The process of argon metal welding.

To install heating devices in the form of registers, it is necessary to prepare pipe and consumables:

- smooth steel pipes with a diameter from 76 to 159 mm;

- pipes with a diameter of 32 mm for jumpers;

- inlet and outlet pipes for welding, threaded or flanged type with a diameter of 35 mm;

- threaded fitting for connecting an air vent (Mayevsky valve);

- plugs for pipe diameters;

- floor supports made from corners or brackets for mounting to the wall.

For the manufacture of such heat exchangers, pipes with diameters of 76, 89, 108 and 159 mm are most often used. Products with profile, rectangular or square sections are also used.

Tools you will need:

- welding machine;

- gas key;

- grinder (grinder);

- hammer, electrodes;

- roulette, level;

- welder protective equipment.

Heating register device.

The joining surfaces of the parts are cleaned and degreased before welding to avoid defects in the seams. The ends of the pipes must be perpendicular to their axes. Large-diameter pipes are processed using milling machines or gas-acid cutting.

The pipes are cut into pieces of calculated sizes, the ends are cleaned with a grinder. On horizontal pipes, holes for jumpers are marked and cut out; the pipes must fit into the hole.

Jumpers inserted into the holes are welded to horizontally laid pipes in accordance with the dimensions. Plugs are welded to the ends of the register elements. The inlet and outlet pipes are welded into pre-cut holes at two ends (diagonally).

At one of the upper ends a threaded pipe is welded for installing a Mayevsky tap. All seams are cleaned with a sander to give an aesthetic appearance. Racks are welded to the structure (if the device is installed on the floor).

To check the register for leaks, the lower outlet for the coolant outlet is closed with a plug. The structure is filled with water and inspected for leaks. When they are detected, the water is drained and the problem areas are boiled again. The seams are cleaned again and the register is painted.

Equipment with a closed system with forced circulation

When the heating system does not communicate with the surrounding air and operates under pressure, such circuits are only closed.

In this case, the following equipment is required to piping the boiler:

- a 100-200 watt pump, which should be installed for supply;

- membrane-type expansion tank to provide the coolant with additional volume during expansion;

- safety valve for releasing coolant if the permissible pressure is exceeded;

- an automatic air vent that will help the emerging air plug to leave the system on its own so that the coolant circulates freely throughout the circuit;

- pressure gauge - to control pressure.

These are required elements. The following options may also be included in the scheme:

- filter for gas unit;

- filter at the inlet of the heat exchanger to protect against debris;

- heat accumulator, which is advantageous to pair with solid fuel or electric boilers to save energy resources.

Why do you need a heat accumulator?

The heat accumulator is a tank that is connected to the boiler and water circuit. Its body is reliably covered with a heat insulator and allows it to accumulate warm water for the circuit, and then heat the room for about a day when the boiler is turned off.

How does a heat accumulator work:

- The heating unit is loaded with fuel and ignited.

- The circulation pump pumps coolant through the heat exchanger. Cold water from the bottom of the tank rushes into the boiler, and already heated water arrives at the top. Since the density of the cold and hot liquid is different, it will not mix. This will gradually fill the tank with hot water.

- If the calculations are done correctly, when the fuel burns out, the container will be filled with hot water at the required temperature. Good thermal insulation will keep the coolant hot for a long time.

- When the boiler is not functioning, the heating system continues to perform its task. The circulation pump of the heating circuit circulates the coolant through the system. Water is drawn from the top “hot zone” of the tank.

- The water returns to the return line already cooled, so the heat accumulator will gradually release the accumulated heat.

In real conditions, water is drawn into the heating system continuously. The heat accumulator accumulates “excess”, currently unclaimed heat.

A battery with a volume of 3 tons, with a supply of water at a temperature of 40-80°C, will be able to heat a house with an area of 80 sq.m. for a day. These parameters correspond to 170-175 kW hour. heat.

A regular boiler needs to be heated up to five times a day. If a heat accumulator is installed, the frequency of adding fuel to the combustion chamber will be reduced by five times. The heated water in the tank will gradually release heat energy to the radiators. A solid fuel boiler will work much more economically. This scheme for connecting a heating boiler in a private house allows you to heat the room for a long time without reducing the boiler power.

It is very beneficial to pair a heat accumulator with an electric boiler when saving energy resources is especially important.

On a note. The night tariff with a two-tariff meter is much lower than the day tariff: 2-4 times. If you turn on the electric boiler only at night, so that during the day the heat accumulator only gives off heat, you can significantly save on electricity.

Installation

Even the simplest piping, which is done by hand, requires a competent choice of pipes. Products as simple and beloved by many people as polypropylene pipes also need to be used correctly. The ease of operation should not be misleading, although you only need to use a soldering iron. It is allowed to use PN25 pipes, which are reinforced from the inside with aluminum foil.

To connect to a heated floor, you can tie the boiler with pipes of category PN10. Their walls are very thin and are designed to pump water heated to +45 degrees under a pressure of 1000 kPa. Polymer pipelines can be used in both open and hidden installation schemes, but thermal expansion must be taken into account. The connection of fittings to pipes is done either by creating a thread or using cold (hot) welding. Thread cutting simplifies the matter, but the cost of such a solution immediately increases.

Before welding begins, the foil must be cleaned, otherwise the strength of the connection can be forgotten. Glass fiber does not require such treatment when used for reinforcement. Cold welding using specialized glue is now almost out of use, since it does not guarantee a reliable joint. If two small heating boilers or more are installed in the system, piping with parallel oriented passages is allowed. As practice shows, this can be more economical than using a single boiler of the same amount of power.

To prevent water from moving through temporarily disconnected circuits, it is very important to ensure that they are closed with separating valves and other shut-off valves. In some cases, the equipment is mounted on a foundation pad (clay, 0.1 m high), on top of which sheet iron or asbestos is placed

The main requirement is to install the boiler at a lower level than installing the batteries. You need to resort to copper pipes only if you plan to heat a house with very high temperatures and pressures. In all other cases, there is no point in these expensive components.

How to choose strapping elements

When choosing a pump, you need to pay attention to the thermal load on the circuit. Here it is important to calculate the difference between the supply and return water temperatures.

The formula is as follows:

- Q=0.86xR/Dt,

- where Q is the pump performance indicator (cubic meters per hour),

- R - boiler power,

- Dt is the temperature difference.

For example, with a boiler power of 20 kW and a heating system temperature of 80/60oC, a pump is needed with the following performance characteristics:

- 0.86x20(80-60)=0.86 m3/h.

A pump with stepwise power adjustment performs well. It will be able to provide such a level of performance that the radiators throughout the circuit are evenly heated.

A parameter such as coolant pressure, which is measured in meters of water column, can be ignored. In a heating system, the number of floors in the building or the floor on which the circulation pump is located does not matter. The minimum pump value is 2 meters. Devices with this parameter cope well with the movement of coolant in the water circuit of an apartment building with high hydraulic resistance. When piping a heating boiler, these points need to be remembered.

What to pay attention to when installing a membrane tank:

- First of all, it is important to choose the volume of the tank. It should be 1/10 of the volume of coolant in the water circuit. There is an easy way to calculate this. If the heating system has aluminum or bimetallic radiators, then 1 kilowatt of boiler power requires 15 liters of coolant.

- The tank can withstand temperatures up to +120 C.

- The operating pressure of the device often does not exceed 1.5 bar. Sometimes there is a need to increase it. To do this, pump air into the tank using a bicycle pump.

How to select security group elements:

- The valve has an upper limit of permissible pressure of 2.5 bar.

- A pressure gauge must be selected with a pressure of 4 atmospheres.

How to arrange the strapping elements:

- The circulation pump is placed in front of the combustion chamber (in front of the heat exchanger), where the temperature is lower.

- The valve and pressure gauge are mounted at the outlet of the heat exchanger, in the place where the pressure begins to increase.

- The expansion tank is mounted in any part of the circuit, but not next to the pump (pressure fluctuations will lead to wear of the tank).

Safety regulations

Always follow safety precautions when using wood burning stoves

Never leave stoves burning for a long time without control, do not forget to clean the ash chamber in a timely manner and add firewood to the firebox. Pay attention to the chimney channel valves. keep them in the open position until you start to light the stove Use only in the cold season, its use in summer is not advisable

Significant overheating can lead to breakdown, and then the stove will have to be repaired

and seriously. High temperatures can cause destruction of the furnace walls. That is why you should avoid excessively high temperatures and using the unit in the warm season

Significant overheating can lead to breakdown, and then the stove will have to be repaired. and seriously. High temperatures can cause destruction of the furnace walls. That is why you should avoid excessively high temperatures and using the unit in the warm season.

Mini boiler rooms

Nowadays, boiler models are produced equipped with an expansion tank, pump, valve and pressure gauge. These can be heating elements, electric, diesel, gas units with forced draft. These units can be called mini-boiler rooms. Thus, safety valves in the electric heating circuit of a private house with a pump are mounted directly on the heat exchanger together with the heating element. This design allows you to quickly discharge excess coolant if it boils when the pump is stopped.

The connection diagram of the boiler to the heating system in this case is not complicated. You only need to install two ball valves, which can be used to shut off the boiler if necessary. Repairing the unit or any preventive maintenance will not cause difficulties.

Equipment with open gravity system

With an open gravity system, the entire load falls on the open expansion tank.

It performs the following functions:

- takes away excess amount of coolant;

- compensates for increased pressure;

- removes air and hot steam when the coolant boils.

The volume of the tank should not be less than 10 percent of the coolant volume. More is possible. Install it at the top point of the circuit, where the accelerating manifold ends. From the tank, the filling goes back to the heat exchanger, with a slope that ensures that air pockets are removed and the coolant moves by gravity.

Cold water is usually poured through an open expansion tank to compensate for evaporation.

Hot water supply system connection diagram

Often an additional hot water supply system is connected to the heating boiler.

Different methods can be used here:

- With a two-pipe dead-end circuit, heating devices are connected between bottlings. The big disadvantage is that nearby radiators will be hotter, and those farther away will be colder, so this system requires balancing.

- When connecting a double-circuit gas boiler, a separate heat exchanger is needed to organize DHW. Here the scheme is simple: cold water goes through the heat exchanger and is sent further to the plumbing fixtures.

- If a double-circuit boiler is connected to the heating system using a forced circulation circuit, then the radiators are installed in a parallel manner so as not to cut the coolant supply pipe.

- When using a scheme with a single-circuit boiler to obtain hot water in a private house, you need to connect an indirect heating boiler. In this case, the coolant will transfer its thermal energy to the boiler heat exchanger. In summer, the heating circuit is switched off.

- The classic gravity heating system is based on the height difference between the heat exchanger and radiators.

- If a heat accumulator is attached to a solid fuel boiler, the temperature of the radiators is regulated by a three-way valve with a thermostat.

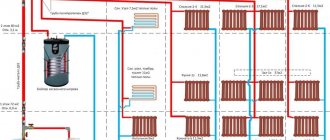

Option for implementing a heating system for a double-circuit boiler:

- the small circuit into which the circulation pump is built is closed by a heat exchanger with a hydraulic arrow;

- the next position is manifold wiring to independent circuits: 2 radiators and 4 underfloor heating circuits.