Engineering systems › Heating › What kind of facility do you have?

EuroHolod provides heating for production premises with turnkey installation. For questions related to heating, call +7(495) 745-01-41.

To receive a commercial offer

, write a request to e-mail [email protected] or send a quick request

During the cold season, autonomous heating of the production premises provides the company's employees with comfortable working conditions. Normalization of temperature conditions also has a beneficial effect on the safety of buildings, machines and equipment. Heating systems, although they have the same task, have technological differences. Some use hot water boilers to heat industrial premises, while others use compact heaters. Let's consider the specifics of industrial heating and the effectiveness of using various systems.

Requirements for heating industrial premises

At low temperatures, heating of production premises, as required by labor protection, should be carried out in cases where the time workers spend there exceeds 2 hours. The only exceptions are premises in which permanent presence of people is not necessary (for example, rarely visited warehouses). Also, structures are not heated, being inside of which is equivalent to carrying out work outside the building. However, even here it is necessary to provide for the presence of special devices for heating workers.

Occupational safety imposes a number of sanitary and hygienic requirements for heating industrial premises:

- heating indoor air to a comfortable temperature;

- the ability to regulate the temperature due to the amount of heat generated;

- inadmissibility of air pollution with harmful gases and unpleasant odors (especially for stove heating of industrial premises);

- the desirability of combining the heating process with ventilation;

- ensuring fire and explosion safety;

- reliability of the heating system during operation and ease of repair.

Radiant or convective heating

In traditional heating systems, it is considered normal when the air temperature near the ceiling is significantly higher than near the floor. This is due to objective physical laws - the density of heated air is less, which is why it rises. As a result of these processes, an uneven temperature distribution along the height is formed. And the most unpleasant thing is that the warm layers remain inaccessible to humans.

In addition, unused thermal energy is lost through the ceiling structures. That is why when designing air, steam or water heating, the height of the premises must be taken into account. Depending on this value, the power of the heating equipment is selected. The higher the ceilings, the higher the capacity you need to buy a boiler.

Radiant heating systems in industrial buildings with high ceilings look much more preferable. IR rays are directed to the lower zones and transfer thermal energy to the surface rather than to the air. Thanks to this, there is no need to purchase expensive powerful equipment. Heat losses are also reduced, since heated air does not accumulate near the ceiling.

The air temperature in the building itself is slightly lower than generally accepted, but the working staff do not experience any discomfort. The high temperature of working surfaces (table, machine, tool, etc.), even in relatively cold rooms, has a beneficial effect on the productivity of enterprise employees. Radiant heat generators do not require a coolant and transfer the generated energy directly to the object.

Heating calculation

To carry out a thermal calculation, before planning any industrial heating, you need to use the standard method.

Qt (kW/hour) =V*∆T *K/860

Where:

- Qt – heat load on the heated space;

- V – internal area of the room requiring heating (W*D*H);

- ∆ T – the value of the difference between the external and desired internal temperature;

- K – heat loss coefficient;

- 860 – recalculation per kW/hour.

The heat loss coefficient, which is included in the calculation of the heating system for industrial premises, varies depending on the type of building and the level of its thermal insulation. The less thermal insulation, the higher the coefficient value.

Use of automation in the heating system of workshops

Most companies strive to automate work and system management. However, certain problems arise along the way, since the heating network is quite large and has a complex structure.

Which functions can be set to automatic mode:

- Notification of accidents and other emergencies

- Maintaining the same temperature according to the set value

- During an emergency, the system will automatically switch on a new operating mode

- If this is not possible, a complete power outage will occur.

Of course, the main priority at the enterprise is the precise and efficient operation of the automatic heating system. There is no need to skimp on equipment and materials. In addition, when choosing a contractor and other project participants, it is necessary to carefully check their experience and qualifications. Otherwise, the consequences may be unpredictable and very sad.

Steam heating of industrial buildings

Heating the production premises using steam allows you to maintain a high temperature of the environment (up to 100 degrees). When organizing the heating process, you do not need to take into account the number of floors. You can bring the temperature to the required value in a short time. This applies to both heating and cooling. All equipment, including communications, does not take up much space.

The steam heating method is optimal if the production premises need to be heated or reduced in temperature periodically. The method is more effective than the water method.

The following disadvantages are identified:

- there is a lot of noise during operation;

- it is difficult to regulate steam flow;

- The steam method is not recommended for use in rooms with aerosols, flammable gases, or heavy dust.

Heating options for spacious non-residential buildings

To heat large areas, three main types of systems are usually used:

- water;

- air;

- radiant.

Water heating refers to systems using radiators. They are beneficial due to the wide selection of heating devices. But at the same time, many premises owners are not satisfied with the irrational use of space, high costs and energy consumption, and high thermal inertia. The systems are not suitable for many retail outlets and warehouses, because... radiators take up space near the walls, where it is convenient to place shelving. Air and radiant heating are more popular, so we will consider their arrangement in detail.

Water heating of industrial facilities

Water heating is appropriate if you have your own boiler room nearby or if there is a central water supply. The main component in this case will be an industrial heating boiler, which can run on gas, electricity or solid fuel.

Water will be supplied under high pressure and temperature. Usually, it cannot be used to efficiently heat large workshops, which is why the method is called “on-duty”. But there are a number of advantages:

- air circulates calmly throughout the room;

- heat spreads evenly;

- a person can work actively in conditions with water heating, it is absolutely safe.

The heated air enters the room, where it mixes with the environment and the temperature is balanced. Sometimes you need to reduce energy costs. To do this, using filters, the air is purified and reused for heating industrial buildings.

Design

There are many different ways to heat a production facility, with different heat sources and methods of supply. The main sources are hot water boilers, but heat can be generated in many other ways, such as using ground heat. There are also many solutions for supplying heat to a room; in principle, heat transfer is carried out in three ways: convection, radiation and thermal conductivity; all heating devices transfer heat in all three ways. The main difference is the percentage of heat transfer in one way or another, for example, radiators heat the room mainly by radiation, but there is also heat transfer from the surface of the radiator to the air and convective currents around the heated surface.

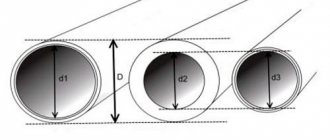

Design of water radiator heating in the workshop

The most traditional and often found in the workshop is water heating based on radiators or registers made of smooth pipes. In workshops with high humidity, in workshops with the release of various oils, in paint shops and other rooms with active release of pollutants, even if there is exhaust ventilation in the workshop, registers are still designed from smooth pipes. In relatively clean workshops, warehouses, and hangars, conventional radiators can be used. The advantages of this scheme are simplicity and reliability, the system is simple, access to all elements of the system is simple and cleaning or repair does not cause any difficulties. Among the disadvantages, it can be noted that in workshops with high ceilings the system is not very effective, since all the heat rises upward.

Design of air heating in the workshop

Air heating is most often used to heat the workshop using fan heaters, less often using an air-conditioning unit or roof top. The advantage of air heating based on a fan heater is a more uniform temperature distribution, since the fan has a high flow rate, thanks to which it actively mixes all the air in the room. Another advantage is lower capital costs, because the fan heater has a fairly high performance and, accordingly, fewer of them are needed to supply the required heat. Since the quantity is smaller, the hydraulic circuit is simpler and not so highly branched.

Designing an infrared heating system in a workshop

Infrared heating systems are often designed in workshops where there is no need to heat the entire volume of the room, but there are personnel working in certain permanent places. Specialists from our design institute for climate systems recommend installing infrared panels above workplaces, the coolant of which can be gas, water or electricity. The main feature is that the panel does not heat the air, but the surface over which it is installed, while the workplace is heated and the staff can work calmly. In this way, the entire workshop can be heated; in each specific case, it is necessary to calculate operating and capital costs.

Air heating

Most enterprises during the existence of the Soviet Union used a convection heating system for industrial buildings. The difficulty in using this method is that warm air, according to the laws of physics, rises, while the part of the room located near the floor remains less heated.

Today, more efficient heating is provided by an air heating system for industrial premises.

Operating principle

Hot air, which is preheated in the heat generator through air ducts, is transferred to the heated part of the building. Distribution heads are used to distribute thermal energy throughout the space. In some cases, fans are installed, which can be replaced by portable equipment, including a heat gun.

Advantages

It is worth noting that such heating can be combined with various supply ventilation and air conditioning systems. This is what makes it possible to heat huge complexes, something that could not be achieved before.

This method is widely used in heating warehouse complexes, as well as indoor sports facilities. In addition, this method in most cases is the only possible one, since it has the highest level of fire safety.

Flaws

Naturally, there were some negative properties. For example, installing air heating will cost the owners of an enterprise a pretty penny.

Not only do the fans necessary for normal operation cost quite a lot, but they also consume huge amounts of electricity, since their productivity reaches about several thousand cubic meters per hour.

Calculation of thermal power by room volume

To roughly calculate the thermal power required to heat a warehouse, you can use the method that is usually used by company managers who advise clients. The formula below applies:

- V – internal volume of the room, presented in cubic meters

- W is the total thermal power per room, expressed in kilowatts (kW). It is equally valid for ALL types of boilers.

To determine the volume of the room, you need to use another formula:

- V – actually, internal volume

- S – area expressed in square meters

- h – ceiling height, expressed in meters

So, using formulas, we can determine that a warehouse with a ceiling height of 5 m and an area of, for example, 200 sq.m. for normal heating it will require about 40 kW of thermal energy.

For a more accurate calculation of warehouse heating, the so-called thermal insulation coefficient of the room or thermal dissipation coefficient (K), which corrects for insulation, must be taken into account:

- 1.3 – for heating a warehouse with poor thermal insulation, or with a large glazing area,

- 1 – for standard thermal insulation,

- 0.8 – for heating well-insulated warehouses with small area glazing.

Infrared heating

Not every company is ready to spend a lot of money on an air heating system, so many prefer to use another method. Infrared industrial heating is becoming increasingly popular every day.

Principle of operation

An infrared burner operates on the principle of flameless combustion of air located on the porous part of the ceramic surface. The ceramic surface is distinguished by the fact that it is capable of emitting a whole spectrum of waves that are concentrated in the infrared region.

The peculiarity of these waves is their high degree of permeability, that is, they can freely pass through air currents in order to transfer their energy to a certain place. The stream of infrared radiation is directed to a predetermined area through various reflectors.

Therefore, heating industrial premises using such a burner allows for maximum comfort. In addition, this heating method makes it possible to heat both individual work areas and entire buildings.

Main advantages

At the moment, the use of infrared heaters is considered the most modern and progressive method of heating industrial buildings due to the following positive characteristics:

- quick heating of the room;

- low energy intensity;

- high efficiency;

- compact equipment and easy installation.

By performing the correct calculation, you can install a powerful, economical and independent heating system for your enterprise that does not require constant maintenance.

Scope of application

It is worth noting that such equipment is used, among other things, for heating poultry houses, greenhouses, cafe terraces, auditoriums, shopping and sports halls, as well as various bitumen coatings for technological purposes.

The full effect of using an infrared burner can be felt in those rooms that have large volumes of cold air. The compactness and mobility of such equipment makes it possible to maintain the temperature at a certain level depending on the technological need and time of day.

Safety

Many people are concerned about the issue of safety, since they associate the word “radiation” with radiation and harmful effects on human health. In fact, the operation of infrared heaters is completely safe for both humans and equipment located in the room.

How to organize production heating

If the height of the premises does not exceed 6 m, then the heating ceiling is installed immediately. Most often, such buildings have concrete floors, so wooden sheathing will be required. Also, do not forget about thermal insulation. For this purpose, you can use any construction insulation (for example, expanded polystyrene with a thickness of 100–150 mm).

The owner should also take care of the quality of the enclosing structures. The presence of numerous cracks, crevices and voids, constant drafts, etc. will lead to significant heat loss, as a result of which either the heating ceiling system will not cope with the task, or heating the production will be extremely expensive due to increased energy consumption.

What to do if the ceiling height is higher than permissible? In this case there is also a solution.

This may be equipment for a rough ceiling in the form of a suspended structure. Some of our customers lowered the ceiling from 12 to 5 meters using cable braces.

h1 - 6.9 m. h2 - 5.0 m. 1 - Ceiling slabs. 2 — Cable stretchers. 3 - Wooden sheathing. 4 - Expanded polystyrene 100 mm. 5 - Folgoizolon. 6 — High-power film electric heaters.

And a heating ceiling was installed on the resulting structure with wooden lathing.

If reducing the ceiling height is unacceptable, then you can use high-temperature infrared heaters; they work well at a height of up to 10 m.

Average energy consumption of film electric heaters

The allocated power of the electrical network is of great importance when heating production. For heating alone, about 12 kW is needed for every 100 m², so it is important to correctly calculate the energy consumption.

What is the average energy consumption in a particular production facility if a heated ceiling is installed there?

The energy consumption of any heating system, including film electric heaters, directly depends on the level of thermal insulation of the building envelope. With minimal heat loss, the system only maintains the set parameters, that is, it turns on less often and for a shorter time. Industrial buildings are most often made of concrete or brick and are not insulated in any way. With high heat losses, heating production will require 30–40 W/m² of heated area per hour. For smaller heat losses, for example heating a frame house, no more than 12–18 W/m² of heated area is required, because in it the level of insulation of enclosing structures is an order of magnitude higher than that of industrial premises.

SNiP standards for heating industrial premises

Before you start designing a particular system, and think about which industrial heating boiler to choose, you need to study the following rules and follow them. It is imperative to take into account heat loss, because not only the air in the room heats up, but also equipment and objects. The maximum temperature of the coolant (water, steam) is 90 degrees, and the pressure is 1 MPa.

When drawing up a heating project, staircases are not taken into account. The use of boilers and other gas-powered equipment is permitted only if oxidation products are removed closed and there is no danger of an explosion or fire in the workplace.

Each of the listed heating methods has its own disadvantages and advantages. It is necessary to choose the optimal method based on the technological processes that are carried out in a particular workshop. Workers cannot be indoors if the air temperature there is below 10 degrees. Warehouses usually store finished products. To maintain its quality, you need to maintain an optimal microclimate.

We are a professional engineering design and installation company. On our website you can receive a commercial offer and find the necessary information.

EuroHolod provides heating for production premises with turnkey installation. For questions related to heating, call +7(495) 745-01-41.

To receive a commercial offer

, write a request to e-mail [email protected] or send a quick request

See below

- Heating systems. Heat supply for buildings

- What is your object?

Nuances of design and installation of industrial heating systems

Heating systems in factory workshops have different characteristics, so choosing the optimal equipment must be taken seriously. What parameters are used: area of premises, number of employees, weather conditions, specifics of production. Moreover, they look at the budget and expected costs for the heating system, ways to save money and convenience.

Note!

Before installing the heating network, it is important to carry out a detailed calculation. When installed inside industrial buildings, the situation becomes more complicated, since each individual case will have its own specifics. In addition to the above, the building has openings (windows, doors, grilles) that significantly affect the movement of heat. This point must be taken into account when designing.

To ensure complete control over the procedures, as well as to avoid errors, specialists are guided by SNiP on heating systems. It describes in detail all the rules for calculating values and procedures with detailed descriptions of requirements. The system is determined by calculating the volume of heat loss and selecting a sufficiently powerful device.

Be sure to remember that installation and installation work cannot contradict either the requirements of the project or building codes.

Attention is also paid to the system of metal or plastic pipes (air ducts), since they perform the function of transporting air and gas masses. They must be installed in each room according to the location of the rooms. The shape and dimensions of the elements must be precisely selected, since when connecting the parts, special adapters will be needed to connect the channels and pipes. Their quality affects the performance of the entire air duct.

As soon as the type of heating system for the workshop is determined, installation of the system begins: pipes are installed and routed, electrical cables are laid so that gas-air mixtures move smoothly. Specialists perform all the necessary procedures to create a tight connection. They begin checking the performance of the system at low capacities, gradually increasing it. You must constantly remember the safety rules, deviation from which is strictly prohibited.

Industrial heatingcolor

Industrial heating is a system of measures aimed at creating favorable conditions for production activities. The main task of industrial heating is to maintain a comfortable temperature in the workplace, which, as a rule, helps to increase labor productivity. Maintaining an optimal temperature is also necessary to protect equipment from sudden changes in heat, which can lead to failure of machines and equipment, which leads to unnecessary financial costs for their repair or replacement. The management, which has set the task of organizing industrial heating, faces complex issues that need to be resolved in the most optimal way. The problem immediately arises of how to achieve this goal while spending a minimum amount of money. First of all, the entrepreneur must take into account the climatic features of the area where industrial heating is required. For the regions of Moscow or St. Petersburg, these will be the same conditions with the typical climate for this area; for Tyumen or Yakutia, completely different conditions due to severe frosts and winds in winter. All these features are taken into account in the color>questionnaire for calculating heat losses in production presented on the website.

Heating systems producedcolor>

Industrial heating systems are technical means that make it possible to create acceptable climatic conditions in workplaces for production activities. The most common heating systems today are infrared, air and water. The last two belong to central systems that provide heat from heating plants. With an air-based industrial heating system in a workshop area, air ducts are installed through which warm air is supplied from a heat generator located outside the production facility. The efficiency factor (COP) of this heating method reaches about 50%. Water, unlike air, has its advantages and disadvantages. Since the heat capacity of water is significantly higher than the heat capacity of air, its consumption for heating the same room will be much less, and therefore the coolant delivery system is much less than that of air. At the same time, the water heating system has great inertia due to the fact that heating water takes much longer than air. This significantly increases the time required to warm the room to the desired temperature. The main disadvantage of these industrial heating systems for enterprises is the presence of a significant amount of additional equipment (heat generators), bulky supply systems that ensure the delivery of heat to the heated object, large heat losses along the route, and low efficiency.

Infrared heating systemscolor> are devoid of all the disadvantages inherent in the above methods. There is an opportunity to significantly free up the workspace from unnecessary bulky heat management of production areas that take up a lot of space and to deploy on it the production of additional products manufactured by the enterprise. At the same time, the efficiency of this heating system is about 70 - 90%, depending on the method of using infrared heating, which also provides serious savings in money and ultimately allows you to reduce the cost of the final product. The absence of expensive supply systems and heat losses along the route also reduces operating costs for industrial heating, which in turn makes it possible to additionally provide heat to new jobs. The customer, as a rule, chooses which industrial heating system to use at a given enterprise. But at the same time, it is necessary to take into account all the features inherent in one or another method of coolant delivery and its efficiency, depending on the current conditions and prices on the market.