Home / Installation, repair, maintenance / Insulation / We do it ourselves - insulation of ecowool ceilings

Ecowool is a very beneficial material for ceiling insulation. Its price is low, installation can be done quite quickly. The only obstacle to its independent use is the need for special installation equipment. But, you can insulate the ceiling with ecowool yourself if you use alternative methods of installing this insulation.

Pros and cons of insulating the ceiling with ecowool

Ecowool ceiling insulation is an ideal solution for any attic. However, this material has both advantages and disadvantages that should be taken into account.

Let's start with the advantages of ecowool.

- This insulation is installed without seams, hence the high thermal insulation characteristics. Complete absence of so-called “cold bridges”. When laying it there is no dew point, so there is no condensation.

- Ecowool does not contain carcinogens harmful to humans, so it is completely safe. After installation, the insulation does not cause allergies, which is important for homes with children.

- Ecowool allows your home to breathe.

- This insulation has one very important quality - it can be used several times.

- Ecowool is characterized by excellent adhesion; it easily sticks to the applied surface.

- The described insulation does not cause metal corrosion.

- Ecowool prevents insects from breeding and mold from spreading.

Ecowool, as a thermal insulation material, also has some significant disadvantages. Among them:

- shrinkage;

- installation difficulties;

- need a frame.

The ecowool material itself has a fibrous structure. Over time, it shrinks, volume is lost, and accordingly, the thermal insulation qualities change in a negative direction. When insulating the ceiling, this problem is easy to solve, since the surface is horizontal, and you only need to make the insulation layer a little thicker.

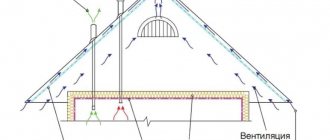

If you organize a high-quality ventilation system on the roof so that excess moisture does not collect, then ecowool will not shrink significantly over the years. It will not be possible to eliminate the voids that appear on vertical surfaces.

As for installation, it will not be possible to carry out high-quality installation of ecowool without special equipment and competent specialists. If you install it on the ceiling manually, then use a drill with a special attachment to loosen the material. During this process, a lot of dust rises into the air, which in most cases causes allergies.

Ecowool has a small percentage of rigidity, like insulation, so it is sprayed or poured onto the surface. In this particular case, it is imperative to use a frame and then a protective cladding.

What kind of material is this

You can’t use who knows what for insulation. Therefore, it is worth understanding what ecowool consists of and what characteristics it has.

Ecowool consists mainly of recycled products, or more precisely, paper. 80 percent ecowool consists of recycled cellulose. The remaining 20 percent is a mixture of antiseptic and fire retardants. They do not allow the material to rot and prevent the possibility of combustion.

In fact, this type of insulation practically does not support combustion, which adds positive points to it. The borax included in the composition is responsible for this feature. Mold and rot are also not a problem for this insulation, since for this purpose, the list of components contains boric acid.

Despite the scary names of the components included, all of them are absolutely safe in terms of human health.

Calculation of ecowool for ceiling insulation

When laying ecowool on the ceiling, you need to know how much is needed per 1 m2. The method by which the insulation layer will be formed will depend on the covering area. Before starting work, the required amount of material is always calculated.

If it is a multi-storey building, then a layer of 100 to 150 mm is required. When working with the ceiling of the first floor, when an attic is planned above, the ecowool layer is increased to 400 mm. This is because heat will accumulate under the roof, and therefore maximum heat loss can be observed. The situation can be improved with the help of this modern material.

To correctly calculate the volume of ecowool, you need to multiply the volume of space by the density of the insulation. If the manual laying method is used, the density level can vary from 30 to 35 kg*m3. When laying mechanically, this figure increases to 40-45 kg*m3.

The process of pouring penoizol

Penofol is foamed polyethylene covered with aluminum foil. Prevents the penetration of cold air, drafts and radon, reflects radiant heat into the room. The material is very light, does not create additional loads, and works very well in combination with mineral wool. Due to its small thickness, it has almost no effect on the height of the room.

Mineral wool contains mainly natural materials: sand, rocks or melts. Available in rolls and sheets of different sizes. It has good heat and sound insulation characteristics and an affordable price. It needs protection from moisture, as when wet it completely loses its thermal insulation properties. It is resistant to temperature changes, restores its shape after load, but cakes over time. The material, unlike glass wool, is almost not scratchy, but still requires protective equipment when working. The main disadvantage is the phenol content, which can easily penetrate human skin.

Basalt wool is made from rock melts. Available in the form of mats and slabs. It is characterized by resistance to loads and high temperatures, hydrophobicity, and elasticity. The material is capable of transmitting water vapor and does not allow it to accumulate inside, does not shrink and can withstand use for up to 70 years without loss of quality. Just like mineral wool, it contains phenolic binders, and the fibers can irritate the skin and mucous membranes.

Ecowool is a bulk material of natural origin, consisting of 80% cellulose with borate additives, which protect it from easy ignition and rotting. Laying work can be carried out wet using a special installation and dry manually. The manual method is extremely simple. It is enough to pour cotton wool between the joists onto previously laid glassine and lightly loosen it. Ecowool increases in volume by 2-3 times. The recommended layer thickness is 30 cm. Thermal conductivity is the same as that of mineral wool, while ecowool is not afraid of moisture and prevents the development of fungi and mold. Serves for more than 100 years.

It is possible to use cheap local materials such as expanded clay, sawdust, hay, pine needles, reeds, clay and slag to insulate the attic floor. Their cost is often equal only to the cost of delivery, but their thermal insulation properties are noticeably lower and they are more difficult to install. Sawdust requires special protective treatment before laying. Otherwise, they can be damaged by rodents, rot and become very flammable. Hay is a tempting place for various small bugs and insects to settle. For a noticeable thermal insulation effect, all bulk insulation materials require a significant thickness - from 30 cm, which leads to a heavy load on the floors.

Good results are achieved by combining sawdust with vermiculite. Both materials are of natural origin, easily absorb moisture and easily release it, maintaining optimal humidity. Vermiculite is made from hydromica and is considered an ideal bulk insulation with environmentally friendly properties. In terms of thermal conductivity, it is comparable to mineral wool. The only drawback of vermiculite is the price.

Laying loose insulation involves filling it between the joists or beams of a specially made sheathing.

Methods of insulating ceilings with ecowool

Ecowool is installed in two ways:

- manual;

- mechanized.

The second method allows you to complete the job faster. Special equipment is used for it, where insulation is supplied automatically into prepared cavities. In this case, you can use not only dry material, but also mixed with water. This technology is available for use only by specially trained people; the average user often uses the manual method.

The manual method is not very effective, but it is the cheapest. It can only be used to insulate floors and ceilings, but not walls. This technology involves creating a non-perfectly even layer that will fill all cavities.

You can get around such difficulties if you use a special blow molding machine during work. When ecowool is supplied under pressure, it easily fills hard-to-reach places. The method is well suited for frame-type houses.

When using the wet method, careful subsequent drying of the laid layer is considered an important condition.

Laying ecowool using this method can only be done using special equipment. The ceiling is covered with a liquid suspension, the fibers are glued together and adhere to the material being laid.

Briefly about the main thing

The very name of ecowool hints that it is an environmentally friendly and harmless insulation material. In fact, one can argue with this statement, as well as with the fact that this is one of the cheapest and most effective thermal insulation materials.

But when compared with expanded polystyrene or mineral wool, it actually has many impressive advantages, in particular - excellent heat capacity, vapor permeability, resistance to harmful biological factors, and a high degree of sound insulation.

Disadvantages can be found in any material, the main thing is that they are not critical and can be leveled out by following the installation technology. In this regard, ecowool is a very worthy insulation material.

Instructions for insulating ceilings with ecowool

Ecowool insulation is more often used in a house with a cold roof. In this case, it is possible to retain heat inside, and, accordingly, save on heating costs. Manual installation is done with your own hands, the main thing is to study the technology well.

It is worth noting that the manual method for ecowool is only available for a small amount of work. The process looks like this.

- First, you will need to lay a vapor barrier on the base. It is fixed with a special stapler used in construction. The material will need to be laid with an overlap of 150 cm.

- The ecowool is in the package; it will need to be poured into a large container to leave some free space. Only 1/3 of the total volume of the container is filled.

- Loosen the material with a drill with a whisk. As a result, the volume of poured raw materials should double.

- A frame with cells is created on the ceiling, into which the prepared material is poured, trying to fill each one as much as possible. You can compact it with plywood.

- If the ceiling to the attic is being processed, then the layer thickness is at least 200 mm; if it is an overlap between floors, you can limit it to 150 mm.

- Be especially careful when filling in the corners. Ecowool will sag after a short period of time, so it is better to fill it with a reserve in the cells.

- To slightly moisten the insulation, water and a spray bottle are usually used. This material contains lignin, which needs to be softened; it is this that then sticks together and produces a dense layer that provides high-quality insulation of the floor.

- The next step is to wait until the layer dries. Only after this can a special vapor-permeable film be laid. It also overlaps.

- You can cover everything with wooden flooring if you plan to use the attic space in the future.

General principles for installing vapor barriers

1. Under-roof membranes

Rules for installing Izospan under-roofing membranes AS, AM, B, C, D:

A). Izospan AS, AM films are mounted on the outside:

– the protection panels are laid directly on the Ecowool layer;

– laying direction – horizontal with an overlap of one panel onto another with a width of 15-20 cm;

– the vapor barrier is fixed with counter-lattice bars;

– it is mandatory to overhang the edge of the lower panel into the drain or from the cut of the ridge system.

b). Izospan B, C, D membranes are mounted on the inside:

– laying of panels can be vertical or horizontal;

– fixation is carried out using sheathing bars or using a point method;

– width of overlap of panels – 10-15 cm;

– places of overlaps and junctions are sealed with Izospan FL, SL tape.

For cold roofs, there is one difference in the installation rules - the film must have some margin when stretched in order to avoid gusts in winter.

2. Vapor barriers in floor structures

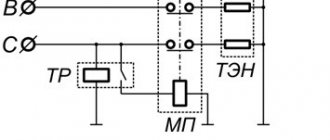

A). On the underside of the ceilings, hydro-vapor barrier is performed with vapor barrier materials Izospan C, D:

– the panels are secured using a stapler to the plank bottom filing of the floors with an overlap of 15-20 cm;

– seams are sealed with Izospan FL, SL insulating tapes;

– the hydro-vapor barrier layer is finally secured with fixing slats;

– the junctions with the walls are fixed with Izospan SL tape and slats.

b). Izospan V material is laid on top. It is mandatory to maintain a gap between it and Ecowool for ventilation and removal of water vapor into the surrounding space.

The panels are fixed with spacer bars, and the subfloor and finishing floor covering are mounted on top of them.

When you place an order for insulation of roofs, walls, floors and attics of buildings in , in a short time you get the opportunity to move into a warm house with reliable steam and waterproofing, which guarantees a long service life between repairs.

Our contact number is 2, you can also use the “Order a call” form on the website pages or use the feedback form in the Contacts section.

Review of reviews of ecowool ceiling insulation

There are many reviews from users on the Internet, some neutral, positive and negative. Some users are dissatisfied with the fact that ecowool shrinks greatly and additional costs are required for laying a new layer.

Others were pleased that this material helped save on heating costs in winter and allowed significant savings on material.

Such a universal solution is becoming more and more in demand; ceiling insulation can be done on your own, the main thing is to follow the technology.

Share the post “Ecowool ceiling insulation” by copying the link: https://kaksdelatsvoimirukami.ru/uteplenie-potolka-ekovatoy/

We insulate the ceiling with mineral wool

As mentioned above, mineral wool is used to insulate wooden floors and ceilings of attic rooms. To prevent the material from becoming saturated with moisture and losing heat resistance, 3 conditions must be met:

- protect the cotton wool from the entry of water vapor from inside the premises;

- ensure ventilation of the outer surface so that the resulting moisture is evaporated from the thickness of the insulation;

- the vapor permeability of the materials used in the “pie” should increase towards a colder room or street, as shown in the diagram.

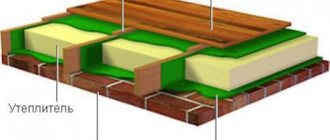

Slab or rolled mineral wool is located in the space between the ceiling beams, as shown in the insulation diagram. When laying thermal insulation with your own hands, follow the following procedure:

- Roll out a vapor barrier film from the bottom of the beams, laying adjacent sheets with an overlap of 100 mm wide. Make an overlap on the walls 10-15 cm wide. Carefully tape the joints with tape.

- Glue the film overlaps to the walls of the structures with silicone sealant. The goal is to cut off room moisture from entering the attic.

- Work is being carried out from the cold roof side. Therefore, first make a rough padding of the ceiling, where the cotton wool will subsequently lie.

- Lay mineral wool boards as shown in the photo. The rolled material is carefully trimmed and placed between the joists; creasing the cotton wool is unacceptable.

- Lay waterproofing sheets on top of the insulation - a diffusion membrane that allows moisture to pass in only one direction - outward. Overlap 10 cm and glue the joints.

- Arbitrarily lay attic floors from edged boards across the joists. It is not necessary to make a continuous flooring.

Sometimes builders lay the first moisture-proofing film on top of the rough ceiling boards, going around each beam. We do not recommend using this approach - a vapor barrier will block the access of air to the log wood, and from below it will remain open for saturation with steam. Then it is clear - the tree will begin to rot.

How to lay mineral wool on the ceiling if the thickness of one layer is not enough. In such cases, a second tier of heat-insulating slabs is made, shifted by 30-50 cm relative to the first row. If the height of the load-bearing beams is not enough to organize ventilation, a frame of sheathing beams is built up, then a 2nd layer of insulation and waterproofing is installed.

The device for additional sheathing is shown on the left when the height of the beams is not enough

The insulation scheme for the attic floor is very similar to the thermal insulation of a wooden floor:

- A counter-lattice is provided on the roof, the diffusion membrane is rolled out from above along the rafters. If there is no external frame, the waterproofing can be attached from the inside, going around each rafter leg and shooting the edges of the sheets with a stapler.

- The insulation is placed between the rafters at random. If the width allows, we lay the slabs in 2 layers with bandaging, otherwise we install a horizontal counter-lattice.

- We nail the vapor barrier to the rafters through slats, where the interior trim from gypsum plasterboard or lining is subsequently attached.

It is extremely undesirable to insulate concrete ceilings with cotton wool from the inside, especially in wet rooms - the kitchen and bathroom. The porous material will harden and lose its properties if effective ventilation is not provided. Another thing is to attach mineral wool in the space behind the suspended ceiling, where water vapor almost does not penetrate.

Which insulation is better?

The quality of insulation of a wooden ceiling structure depends on which insulation is chosen and how well its installation is done.

The effectiveness of thermal insulation is best seen in cold weather. Everything is simple here - if it gets warmer, it means the thermal insulation is working.

Doubts can be dispelled with a little snow. It is left in the attic, if after a while it melts, everything is in order with the protection. When the snow has not yet fallen, you can place ice cream or ice from the freezer in the attic.

Based on the price of the material, then the best option for both external and internal insulation is mineral wool. As for the price tag, more economical options are sawdust and expanded clay, which are only suitable for installation outside.

To make your choice easier, you can use the table.

Among the varieties of mineral wool, basalt wool deserves special attention. It contains the least amount of toxic substances. It also has the widest range of permissible temperatures (+)

Polystyrene foam is also a relatively inexpensive material, but it is not entirely reliable from an environmental point of view.

In addition to using traditional insulation technology, you can use a more progressive and practical solution - installing a heated floor. Such a system can completely replace standard heating or become an effective addition to it.

Thermal insulation using penoizol

An alternative to expanded polystyrene and polyurethane foam is penoizol, which is a “liquid” foam. Due to the fact that it contains special additives, it does not have the disadvantages that are present in its solid counterparts - flammability and the presence of rodents.

Penoizol has a drawback: to apply it, you need to use the services of a team of craftsmen with special equipment. This kind of work is quite expensive. Insulation with penoizol involves laying a vapor barrier and filling the space between the attic beams with a layer of liquid material 20–30 centimeters thick. An additional layer of roofing material is placed on top and a plank floor is laid.

2.2 Floor insulation

Thermal insulation of the floor can be carried out with any material that meets the requirements of thermal conductivity. The best option is insulation with mineral wool, polystyrene foam, or ecowool. When insulating an attic with ecowool, be prepared for the fact that the material will shrink by about 20%.

Installing a vapor barrier over insulation

Let's consider the simplest option for insulating the lag floor of an attic with mineral wool.

On the rough floor covering, a vapor barrier film is laid and secured.

We fasten the film with a stapler so that it fits tightly to the joists and cross boards; We lay insulation between the joists. When using roll or slab thermal insulation, the insulation must be adjusted in size so that it is in close contact with the joists, since the presence of cracks increases the overall thermal conductivity of the insulation; A second layer of vapor barrier film is rolled out and secured on top of the insulation. The film must be solid - the logs are covered together with the insulation; The front covering of the floor is installed from wooden boards.

Flaws

The disadvantages of cellulose wool include:

- an increase in thermal conductivity during operation, which is caused by two reasons: a decrease in volume due to shrinkage (starts from the second year of operation); increasing the humidity of the insulating layer (when wet, it dries, but not to its previous state);

- significant shrinkage on vertical and inclined structures, and therefore manufacturers recommend increasing the layer thickness by 25% compared to the calculated one, or increasing the insulation density to 65 kg/m3. Both options lead to increased consumption of material, and, consequently, to increased costs of repair work;

- weak rigidity, which requires the installation of gratings on the walls and roof of the attic;

- complex technology for performing work not only in the wet state, but also when blowing dry fibers - without special equipment it is practically impossible;

- long drying time when applied “wet” - up to 3 days;

- strong dependence of the quality of ecowool on the feedstock, which is difficult to control even among leading manufacturers.