In physics, thermal conductivity is the ability of molecules to transfer energy from heated areas of a substance to cold ones. The coefficient is denoted by the Greek letter λ ( lambda ) and is expressed in W/(m·K) or Watt/(meter·degree Kelvin).

The lower the number, the greater thermal protection the building and finishing materials have. We’ll tell you what the value depends on, where the warm air goes, and also give a complete table of values by group.

We will take the main data for the article from two regulatory documents: SNiP 23-02-2003 and SP 50.13330.2012 “Thermal protection of buildings”.

What does heat conductivity depend on?

Thermal conductivity directly depends on the following factors:

- Density _ The closer the molecules of a substance are to each other, the faster the energy exchange occurs. This means that an increase in density leads to a decrease in thermal protection.

- Structure . Porous materials contain capsules with air, which significantly inhibits the process of heat evaporation. Porous means warmer.

- Humidity . λ value of water at a temperature of + 20 °C is 23 times greater than that of air. Therefore, wet brick cools faster.

Based on the humidity level, we will calculate the operating conditions necessary to refine the search for thermal conductivity values in the table.

Warm designs

To increase thermal thermal resistance, modern materials should be used in which thermal conductivity rates are as low as possible. The number of such materials is now increasing. The following became popular:

- Wooden structures. They are considered an environmentally friendly material, which is why many people prefer to build using this particular component. Any type of cultivated wood can be used: log house, log, timber. More often they use pine, spruce or cedar, whose conductivity indicators are quite low compared to other materials. It is necessary to provide protection from atmospheric influences and pests. The material is covered with an additional layer that protects against negative factors.

- Ceramic blocks.

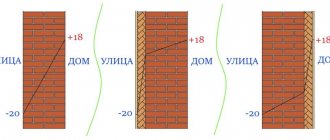

Example of protection against external air

- Sandwich panels. Recently, this material has become increasingly popular. Main advantages: low cost, high resistance to cold. The material has many air cells, sometimes a “foam” structure is made. For example, some types of panels have vertical air channels, which provide good protection from the cold. Other components are made porous so that the large amount of trapped air helps cope with the incoming cold.

- Expanded clay concrete materials. Their use will also reliably protect your home from the cold.

- Foam blocks. The structure is made porous, but this is achieved not by simply wedging in air layers, but by performing a chemical reaction. Sometimes a porous material is added to the cement, which is covered on top with a hardened solution.

terms of Use

Determining the operating conditions will help to obtain an objective value of thermal conductivity (parameters “ A” and “ B” ). To do this you need to go through 3 simple steps.

Stage 1 . Let's find the humidity conditions of the room based on the table:

| Mode | Indoor air humidity, %, at temperature, °C | ||

| Up to +12 °C | From +12 to +24 °C | More than +24 °C | |

| Dry | Before 60 % | Before 50 % | Before 40 % |

| Normal | From 60 to 75 % | From 50 to 60 % | From 40 to 50 % |

| Wet | Over 75 % | From 60 to 75 % | From 50 to 60 % |

| Wet | — | Over 75 % | Over 60 % |

Stage 2 . Let's determine the humidity zone depending on the region. Characteristics are indicated by numbers from 1 to 3 . They can be seen in the subtitle picture or seen on a more detailed map at the link:

.

Stage 3 . Let's correlate the parameters obtained in the first two stages and get the required letter of operating conditions :

| Humidity conditions of building premises (stage 1) | Operating conditions A and B in the humidity zone (according to stage 2 map) | ||

| Dry | Normal | Wet | |

| Dry | A | A | B |

| Normal | A | B | B |

| Damp or Wet | B | B | B |

Example : let the humidity in our room at room temperature from + 12 to + 24 °C not rise above 50 %, then the mode is dry . The house is located in Tver - humidity zone 2 normal ). Then the operating conditions are obtained with the designation “ A ”. We will pay attention to them.

What you need to know about the thermal conductivity of foam plastic

The ability of a material to transfer heat, conduct or retain heat flows is usually assessed by the thermal conductivity coefficient. If you look at its dimension - W/m∙C o , it becomes clear that this is a specific value, that is, determined for the following conditions:

- The absence of moisture on the surface of the slab, that is, the thermal conductivity coefficient of polystyrene foam from the reference book, is a value determined in ideally dry conditions, which practically do not exist in nature, except perhaps in the desert or Antarctica;

- The value of the thermal conductivity coefficient is given for a foam thickness of 1 meter, which is very convenient for theory, but somehow not impressive for practical calculations;

- The results of measuring thermal conductivity and heat transfer were carried out for normal conditions at a temperature of 20 o C.

According to a simplified method, when calculating the thermal resistance of a layer of foam insulation, you need to multiply the thickness of the material by the thermal conductivity coefficient, then multiply or divide by several coefficients used to take into account the actual operating conditions of the thermal insulation. For example, strong watering of the material, or the presence of cold bridges, or the method of installation on the walls of the building.

How the thermal conductivity of polystyrene foam differs from other materials can be seen in the comparison table below.

It's actually not that simple. To determine the thermal conductivity value, you can create it yourself or use a ready-made program for calculating insulation parameters. For a small object this is usually done. A private owner or self-builder may not be interested in the thermal conductivity of the walls at all, but rather lay insulation from foam plastic material with a margin of 50 mm, which will be quite enough for the harshest winters.

Large construction companies that insulate walls covering an area of tens of thousands of square meters prefer to act more pragmatically. The calculation of the insulation thickness is used to draw up an estimate, and the actual thermal conductivity values are obtained on a full-scale object. To do this, glue several sheets of foam plastic of different thicknesses onto a section of the wall and measure the actual thermal resistance of the insulation. As a result, it is possible to calculate the optimal thickness of the foam with an accuracy of several millimeters; instead of approximately 100 mm of insulation, you can lay the exact value of 80 mm and save a considerable amount of money.

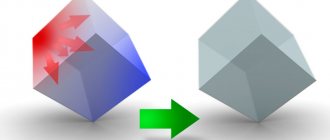

How beneficial the use of polystyrene foam is in comparison with standard materials can be assessed from the diagram below.

Thermal insulation materials

Further, we will indicate the basic thermal conductivity as λ0 , the same value with the designation λ ( A ) is a parameter for normal operating conditions, and λ ( B

) is a marker of high humidity.

Density - ρ0 , vapor permeability - μ .

We replaced W/(m·K) with W/(m·°C) since these reference frames are identical for determining the level of energy transfer. The degree value is the same for both scales. A degree here is a unit of temperature difference (gradient, increment).

Thermal insulation materials are the main barrier to cold air. The coefficient table for them is as follows:

| № | Material | ρ0, kg/m³ | λ0, W/(m °С) | λ (A), W/(m °C) | λ (B), W/(m °C) | μ, mg/(m h Pa) |

| 1 | Expanded polystyrene boards | Before 10 | 0,049 | 0,052 | 0,059 | 0,05 |

| 2 | Same | 10-12 | 0,041 | 0,044 | 0,050 | 0,05 |

| 3 | « | 12-14 | 0,040 | 0,043 | 0,049 | 0,05 |

| 4 | « | 14-15 | 0,039 | 0,042 | 0,048 | 0,05 |

| 5 | « | 15-17 | 0,038 | 0,041 | 0,047 | 0,05 |

| 6 | « | 17-20 | 0,037 | 0,040 | 0,046 | 0,05 |

| 7 | « | 20-25 | 0,036 | 0,038 | 0,044 | 0,05 |

| 8 | « | 25-30 | 0,036 | 0,038 | 0,044 | 0,05 |

| 9 | « | 30-35 | 0,037 | 0,040 | 0,046 | 0,05 |

| 10 | « | 35-38 | 0,037 | 0,040 | 0,046 | 0,05 |

| 11 | Expanded polystyrene boards with graphite additives | 15-20 | 0,033 | 0,035 | 0,040 | 0,05 |

| 12 | Same | 20-25 | 0,032 | 0,034 | 0,039 | 0,05 |

| 13 | Extruded polystyrene foam | 25-33 | 0,029 | 0,030 | 0,031 | 0,005 |

| 14 | Same | 35-45 | 0,030 | 0,031 | 0,032 | 0,005 |

| 15 | Polyurethane foam | 80 | 0,041 | 0,042 | 0,05 | 0,05 |

| 16 | Same | 60 | 0,035 | 0,036 | 0,041 | 0,05 |

| 17 | « | 40 | 0,029 | 0,031 | 0,04 | 0,05 |

| 18 | Plates made of resolnophenol-formaldehyde foam | 80 | 0,044 | 0,051 | 0,071 | 0,23 |

| 19 | Same | 50 | 0,041 | 0,045 | 0,064 | 0,23 |

| 20 | Perlite plastic concrete | 200 | 0,041 | 0,052 | 0,06 | 0,008 |

| 21 | Same | 100 | 0,035 | 0,041 | 0,05 | 0,008 |

| 22 | Perlite phosphogel products | 300 | 0,076 | 0,08 | 0,12 | 0,2 |

| 23 | Same | 200 | 0,064 | 0,07 | 0,09 | 0,23 |

| 24 | Thermal insulation products made of foamed synthetic rubber | 60-95 | 0,034 | 0,04 | 0,054 | 0,003 |

| 25 | Mineral wool slabs made of stone fiber (mineral wool) | 180 | 0,038 | 0,045 | 0,048 | 0,3 |

| 26 | Same | 40-175 | 0,037 | 0,043 | 0,046 | 0,31 |

| 27 | « | 80-125 | 0,036 | 0,042 | 0,045 | 0,32 |

| 28 | « | 40-60 | 0,035 | 0,041 | 0,044 | 0,35 |

| 29 | « | 25-50 | 0,036 | 0,042 | 0,045 | 0,37 |

| 30 | Glass staple fiber slabs | 85 | 0,044 | 0,046 | 0,05 | 0,5 |

| 31 | Same | 75 | 0,04 | 0,042 | 0,047 | 0,5 |

| 32 | « | 60 | 0,038 | 0,04 | 0,045 | 0,51 |

| 33 | « | 45 | 0,039 | 0,041 | 0,045 | 0,51 |

| 34 | « | 35 | 0,039 | 0,041 | 0,046 | 0,52 |

| 35 | « | 30 | 0,04 | 0,042 | 0,046 | 0,52 |

| 36 | « | 20 | 0,04 | 0,043 | 0,048 | 0,53 |

| 37 | « | 17 | 0,044 | 0,047 | 0,053 | 0,54 |

| 38 | « | 15 | 0,046 | 0,049 | 0,055 | 0,55 |

| 39 | Wood-fiber and particle boards | 1000 | 0,15 | 0,23 | 0,29 | 0,12 |

| 40 | Same | 800 | 0,13 | 0,19 | 0,23 | 0,12 |

| 41 | « | 600 | 0,11 | 0,13 | 0,16 | 0,13 |

| 42 | « | 400 | 0,08 | 0,11 | 0,13 | 0,19 |

| 43 | Wood-fiber and particle boards | 200 | 0,06 | 0,07 | 0,08 | 0,24 |

| 44 | Fiberboard and wood concrete slabs based on Portland cement | 500 | 0,095 | 0,15 | 0,19 | 0,11 |

| 45 | Same | 450 | 0,09 | 0,135 | 0,17 | 0,11 |

| 46 | « | 400 | 0,08 | 0,13 | 0,16 | 0,26 |

| 47 | Reed slabs | 300 | 0,07 | 0,09 | 0,14 | 0,45 |

| 48 | Same | 200 | 0,06 | 0,07 | 0,09 | 0,49 |

| 49 | Peat thermal insulation slabs | 300 | 0,064 | 0,07 | 0,08 | 0,19 |

| 50 | Same | 200 | 0,052 | 0,06 | 0,064 | 0,49 |

| 51 | Tow | 150 | 0,05 | 0,06 | 0,07 | 0,49 |

| 52 | Gypsum slabs | 1350 | 0,35 | 0,50 | 0,56 | 0,098 |

| 53 | Same | 1100 | 0,23 | 0,35 | 0,41 | 0,11 |

| 54 | Gypsum cladding sheets (dry plaster) | 1050 | 0,15 | 0,34 | 0,36 | 0,075 |

| 55 | Same | 800 | 0,15 | 0,19 | 0,21 | 0,075 |

| 56 | Products made from expanded perlite with a bitumen binder | 300 | 0,087 | 0,09 | 0,099 | 0,04 |

| 57 | Same | 250 | 0,082 | 0,085 | 0,099 | 0,04 |

| 58 | « | 225 | 0,079 | 0,082 | 0,094 | 0,04 |

| 59 | « | 200 | 0,076 | 0,078 | 0,09 | 0,04 |

Disadvantages of the high thermal conductivity of copper and its alloys

Copper has a much higher value than aluminum or brass. But meanwhile, this material has a number of disadvantages that are associated with its positive aspects. The high thermal conductivity of this metal forces the creation of special conditions for its processing. That is, copper billets must be heated more accurately than steel. In addition, there is often pre- or auxiliary heating before starting treatment. We must not forget that pipes made of copper imply that careful thermal insulation will be carried out. This is especially true for those cases when the heating supply system is assembled from these pipes. This significantly increases the cost of installation work. Certain difficulties arise when using gas welding. To get the job done, a more powerful tool is required. Sometimes, to process copper with a thickness of 8 - 10 mm, it may be necessary to use two or even three torches. In this case, one of them welds the copper pipe, and the rest are busy heating it. In addition, working with copper requires more consumables.

Working with copper requires the use of specialized tools. For example, when cutting parts made of bronze or brass with a thickness of 150 mm, you will need a cutter that can work with steel with a large amount of chrome. If it is used for processing copper, then the maximum thickness will not exceed 50 mm.

Backfills

Bulk materials are used in construction for arranging foundations and serve as components for cement-concrete mixtures. Their thermal conductivity coefficients are shown in the table:

| № | Material | ρ0, kg/m³ | λ0, W/(m °С) | λ (A), W/(m °C) | λ, W/(m °С) | μ, mg/(m h Pa) |

| 1 | Expanded clay gravel | 600 | 0,14 | 0,17 | 0,19 | 0,23 |

| 2 | Same | 500 | 0,14 | 0,15 | 0,165 | 0,23 |

| 3 | « | 450 | 0,13 | 0,14 | 0,155 | 0,235 |

| 4 | Expanded clay gravel | 400 | 0,12 | 0,13 | 0,145 | 0,24 |

| 5 | Same | 350 | 0,115 | 0,125 | 0,14 | 0,245 |

| 6 | « | 300 | 0,108 | 0,12 | 0,13 | 0,25 |

| 7 | « | 250 | 0,099 | 0,11 | 0,12 | 0,26 |

| 8 | « | 200 | 0,090 | 0,10 | 0,11 | 0,27 |

| 9 | Shungizite gravel ( GOST 9757 ) | 700 | 0,16 | 0,18 | 0,21 | 0,21 |

| 10 | Same | 600 | 0,13 | 0,16 | 0,19 | 0,22 |

| 11 | « | 500 | 0,12 | 0,15 | 0,175 | 0,22 |

| 12 | « | 450 | 0,11 | 0,14 | 0,16 | 0,22 |

| 13 | « | 400 | 0,11 | 0,13 | 0,15 | 0,23 |

| 14 | Slag pumice and agloporite crushed stone ( GOST 9757 ) | 800 | 0,18 | 0,21 | 0,26 | 0,22 |

| 15 | Same | 700 | 0,16 | 0,19 | 0,23 | 0,23 |

| 16 | « | 600 | 0,15 | 0,18 | 0,21 | 0,24 |

| 17 | « | 500 | 0,14 | 0,16 | 0,19 | 0,25 |

| 18 | « | 450 | 0,13 | 0,15 | 0,17 | 0,255 |

| 19 | « | 400 | 0,122 | 0,14 | 0,16 | 0,26 |

| 20 | Porous gravel with a vitrified shell of blast furnace and ferroalloy slag ( GOST 25820 ) | 700 | 0,14 | 0,17 | 0,19 | 0,22 |

| 21 | Same | 600 | 0,13 | 0,16 | 0,18 | 0,235 |

| 22 | « | 500 | 0,12 | 0,14 | 0,15 | 0,24 |

| 23 | « | 400 | 0,10 | 0,13 | 0,14 | 0,245 |

| 24 | Crushed stone and sand from expanded perlite ( GOST 10832 ) | 500 | 0,09 | 0,1 | 0,11 | 0,26 |

| 25 | Same | 400 | 0,076 | 0,087 | 0,095 | 0,3 |

| 26 | « | 350 | 0,07 | 0,081 | 0,085 | 0,3 |

| 27 | « | 300 | 0,064 | 0,076 | 0,08 | 0,34 |

| 28 | Expanded vermiculite ( GOST 12865 ) | 200 | 0,065 | 0,08 | 0,095 | 0,23 |

| 29 | Same | 150 | 0,060 | 0,074 | 0,098 | 0,26 |

| 30 | « | 100 | 0,055 | 0,067 | 0,08 | 0,3 |

| 31 | Sand for construction work ( GOST 8736 ) | 1600 | 0,35 | 0,47 | 0,58 | 0,17 |

Building materials for external walls

Walls today are built from different materials, but the most popular remain: wood, brick and building blocks. The main differences are in the density and thermal conductivity of building materials. Comparative analysis allows us to find a middle ground in the relationship between these parameters. The greater the density, the greater the load-bearing capacity of the material, and therefore of the entire structure. But thermal resistance becomes less, that is, energy costs increase. Usually at lower densities there is porosity.

Thermal conductivity coefficient and its density.

Concrete

Concrete products with the addition of cement serve as the basis for the construction of houses. Let us describe their thermal conductivity in the table:

| № | Material | ρ0, kg/m³ | λ0, W/(m °С) | λ (A), W/(m °C) | λ (B), W/(m °C) | μ, mg/(m h Pa) |

| 1 | Tufobeton | 1800 | 0,64 | 0,87 | 0,99 | 0,09 |

| 2 | Same | 1600 | 0,52 | 0,7 | 0,81 | 0,11 |

| 3 | « | 1400 | 0,41 | 0,52 | 0,58 | 0,11 |

| 4 | « | 1200 | 0,32 | 0,41 | 0,47 | 0,12 |

| 5 | Concrete on lithoid pumice | 1600 | 0,52 | 0,62 | 0,68 | 0,075 |

| 6 | Same | 1400 | 0,42 | 0,49 | 0,54 | 0,083 |

| 7 | « | 1200 | 0,30 | 0,4 | 0,43 | 0,098 |

| 8 | « | 1000 | 0,22 | 0,3 | 0,34 | 0,11 |

| 9 | « | 800 | 0,19 | 0,22 | 0,26 | 0,12 |

| 10 | Concrete on volcanic slag | 1600 | 0,52 | 0,64 | 0,7 | 0,075 |

| 11 | Same | 1400 | 0,41 | 0,52 | 0,58 | 0,083 |

| 12 | « | 1200 | 0,33 | 0,41 | 0,47 | 0,09 |

| 13 | « | 1000 | 0,24 | 0,29 | 0,35 | 0,098 |

| 14 | « | 800 | 0,20 | 0,23 | 0,29 | 0,11 |

| Concrete on artificial porous aggregates | ||||||

| 1 | Expanded clay concrete on expanded clay sand | 1800 | 0,66 | 0,80 | 0,92 | 0,09 |

| 2 | Same | 1600 | 0,58 | 0,67 | 0,79 | 0,09 |

| 3 | « | 1400 | 0,47 | 0,56 | 0,65 | 0,098 |

| 4 | « | 1200 | 0,36 | 0,44 | 0,52 | 0,11 |

| 5 | « | 1000 | 0,27 | 0,33 | 0,41 | 0,14 |

| 6 | « | 800 | 0,21 | 0,24 | 0,31 | 0,19 |

| 7 | « | 600 | 0,16 | 0,2 | 0,26 | 0,26 |

| 8 | « | 500 | 0,14 | 0,17 | 0,23 | 0,3 |

| 9 | Expanded clay concrete on quartz sand with moderate (up to 12%) porosity | 1200 | 0,41 | 0,52 | 0,58 | 0,075 |

| 10 | Same | 1000 | 0,33 | 0,41 | 0,47 | 0,075 |

| 11 | « | 800 | 0,23 | 0,29 | 0,35 | 0,075 |

| 12 | Expanded clay concrete on perlite sand | 1000 | 0,28 | 0,35 | 0,41 | 0,15 |

| 13 | Same | 800 | 0,22 | 0,29 | 0,35 | 0,17 |

| 14 | Sandless expanded clay concrete | 700 | 0,135 | 0,145 | 0,155 | 0,145 |

| 15 | Same | 600 | 0,130 | 0,140 | 0,150 | 0,155 |

| 16 | « | 500 | 0,120 | 0,130 | 0,140 | 0,165 |

| 17 | « | 400 | 0,105 | 0,115 | 0,125 | 0,175 |

| 18 | « | 300 | 0,095 | 0,105 | 0,110 | 0,195 |

| 19 | Shungizite concrete | 1400 | 0,49 | 0,56 | 0,64 | 0,098 |

| 20 | Same | 1200 | 0,36 | 0,44 | 0,5 | 0,11 |

| 21 | « | 1000 | 0,27 | 0,33 | 0,38 | 0,14 |

| 22 | Perlite concrete | 1200 | 0,29 | 0,44 | 0,5 | 0,15 |

| 23 | Same | 1000 | 0,22 | 0,33 | 0,38 | 0,19 |

| 24 | « | 800 | 0,16 | 0,27 | 0,33 | 0,26 |

| 25 | Perlite concrete | 600 | 0,12 | 0,19 | 0,23 | 0,3 |

| 26 | Concrete on slag-pumice crushed stone | 1800 | 0,52 | 0,63 | 0,76 | 0,075 |

| 27 | Same | 1600 | 0,41 | 0,52 | 0,63 | 0,09 |

| 28 | « | 1400 | 0,35 | 0,44 | 0,52 | 0,098 |

| 29 | « | 1200 | 0,29 | 0,37 | 0,44 | 0,11 |

| 30 | « | 1000 | 0,23 | 0,31 | 0,37 | 0,11 |

| 31 | Concrete on vitrified slag gravel | 1800 | 0,46 | 0,56 | 0,67 | 0,08 |

| 32 | Same | 1600 | 0,37 | 0,46 | 0,55 | 0,085 |

| 33 | « | 1400 | 0,31 | 0,38 | 0,46 | 0,09 |

| 34 | « | 1200 | 0,26 | 0,32 | 0,39 | 0,10 |

| 35 | « | 1000 | 0,21 | 0,27 | 0,33 | 0,11 |

| 36 | Fine-grained concrete based on granulated blast furnace and ferroalloy (silicomanganese and ferromanganese) slags | 1800 | 0,58 | 0,7 | 0,81 | 0,083 |

| 37 | Same | 1600 | 0,47 | 0,58 | 0,64 | 0,09 |

| 38 | « | 1400 | 0,41 | 0,52 | 0,58 | 0,098 |

| 39 | « | 1200 | 0,36 | 0,49 | 0,52 | 0,11 |

| 40 | Agloporite concrete and concrete based on fuel slag aggregates | 1800 | 0,7 | 0,85 | 0,93 | 0,075 |

| 41 | Same | 1600 | 0,58 | 0,72 | 0,78 | 0,083 |

| 42 | « | 1400 | 0,47 | 0,59 | 0,65 | 0,09 |

| 43 | « | 1200 | 0,35 | 0,48 | 0,54 | 0,11 |

| 44 | « | 1000 | 0,29 | 0,38 | 0,44 | 0,14 |

| 45 | Concrete based on ash fired and unfired gravel | 1400 | 0,47 | 0,52 | 0,58 | 0,09 |

| 46 | Same | 1200 | 0,35 | 0,41 | 0,47 | 0,11 |

| 47 | « | 1000 | 0,24 | 0,3 | 0,35 | 0,12 |

| 48 | Vermiculite concrete | 800 | 0,21 | 0,23 | 0,26 | — |

| 49 | Same | 600 | 0,14 | 0,16 | 0,17 | 0,15 |

| 50 | « | 400 | 0,09 | 0,11 | 0,13 | 0,19 |

| 51 | « | 300 | 0,08 | 0,09 | 0,11 | 0,23 |

| Concrete is especially lightweight with porous aggregates and cellular | ||||||

| 1 | Polystyrene concrete based on Portland cement ( GOST R 51263 ) | 600 | 0,145 | 0,175 | 0,20 | 0,068 |

| 2 | Same | 500 | 0,125 | 0,14 | 0,16 | 0,075 |

| 3 | « | 400 | 0,105 | 0,12 | 0,135 | 0,085 |

| 4 | « | 350 | 0,095 | 0,11 | 0,12 | 0,09 |

| 5 | « | 300 | 0,085 | 0,09 | 0,11 | 0,10 |

| 6 | « | 250 | 0,075 | 0,085 | 0,09 | 0,11 |

| 7 | « | 200 | 0,065 | 0,07 | 0,08 | 0,12 |

| 8 | « | 150 | 0,055 | 0,057 | 0,06 | 0,135 |

| 9 | Polystyrene concrete modified with Portland slag cement | 500 | 0,12 | 0,13 | 0,14 | 0,075 |

| 10 | Same | 400 | 0,09 | 0,10 | 0,11 | 0,08 |

| 11 | « | 300 | 0,08 | 0,08 | 0,09 | 0,10 |

| 12 | « | 250 | 0,07 | 0,07 | 0,08 | 0,11 |

| 13 | « | 200 | 0,06 | 0,06 | 0,07 | 0,12 |

| 14 | Gas and foam concrete with cement binder | 1000 | 0,29 | 0,38 | 0,43 | 0,11 |

| 15 | Same | 800 | 0,21 | 0,33 | 0,37 | 0,14 |

| 16 | « | 600 | 0,14 | 0,22 | 0,26 | 0,17 |

| 17 | « | 400 | 0,11 | 0,14 | 0,15 | 0,23 |

| 18 | Gas and foam concrete with limestone binder | 1000 | 0,31 | 0,48 | 0,55 | 0,13 |

| 19 | Same | 800 | 0,23 | 0,39 | 0,45 | 0,16 |

| 20 | « | 600 | 0,15 | 0,28 | 0,34 | 0,18 |

| 21 | « | 500 | 0,13 | 0,22 | 0,28 | 0,235 |

| 22 | Gas and foam ash concrete with cement binder | 1200 | 0,37 | 0,60 | 0,66 | 0,085 |

| 23 | Same | 1000 | 0,32 | 0,52 | 0,58 | 0,098 |

| 24 | « | 800 | 0,23 | 0,41 | 0,47 | 0,12 |

Valid values

When performing a thermal engineering calculation of an external wall, the region in which the house will be located is also taken into account:

- For southern regions with warm winters and slight temperature changes, walls of small thickness can be erected from materials with an average degree of thermal conductivity - single and double fired ceramic and clay, brick, high-density foam and aerated concrete. The wall thickness for such regions can be no more than 20 cm.

- At the same time, for the northern regions it is more expedient and economically profitable to build enclosing wall structures of medium and large thickness from materials with high thermal resistance - rounded logs, gas- and foam concrete of medium density. For such conditions, wall structures up to 50–60 cm thick are erected.

- For regions with a temperate climate and winters alternating in temperature, walls made of materials with high and medium thermal resistance are suitable - gas and foam concrete, timber, rounded logs of medium diameter. In such conditions, the thickness of the wall enclosing structures, taking into account insulation, is no more than 40–45 cm.

Brick

Brick is a popular material both for the construction of houses and for the installation of enclosing structures. Its thermal conductivity characteristics are available in the table:

| № | Material | ρ0, kg/m³ | λ0, W/(m °С) | λ (A), W/(m °C) | λ (B), W/(m °C) | μ, mg/(m h Pa) |

| 1 | Clay ordinary on cement-sand mortar | 1800 | 0,56 | 0,7 | 0,81 | 0,11 |

| 2 | Clay ordinary on cement-slag mortar | 1700 | 0,52 | 0,64 | 0,76 | 0,12 |

| 3 | Clay ordinary on cement-perlite mortar | 1600 | 0,47 | 0,58 | 0,7 | 0,15 |

| 4 | Silicate on cement-sand mortar | 1800 | 0,7 | 0,76 | 0,87 | 0,11 |

| 5 | Trepelny on cement-sand mortar | 1200 | 0,35 | 0,47 | 0,52 | 0,19 |

| 6 | Same | 1000 | 0,29 | 0,41 | 0,47 | 0,23 |

| 7 | Slag on cement-sand mortar | 1500 | 0,52 | 0,64 | 0,7 | 0,11 |

| Hollow brick brickwork | ||||||

| 1 | Ceramic hollow core with a density of 1400 kg/m³ (gross) on cement-sand mortar | 1600 | 0,47 | 0,58 | 0,64 | 0,14 |

| 2 | Ceramic hollow core with a density of 1300 kg/m³ (gross) on cement-sand mortar | 1400 | 0,41 | 0,52 | 0,58 | 0,16 |

| 3 | Ceramic hollow core with a density of 1000 kg/m³ (gross) on cement-sand mortar | 1200 | 0,35 | 0,47 | 0,52 | 0,17 |

| 4 | Silicate 11-hollow on cement-sand mortar | 1500 | 0,64 | 0,7 | 0,81 | 0,13 |

| 5 | Silicate 14-hollow on cement-sand mortar | 1400 | 0,52 | 0,64 | 0,76 | 0,14 |

Properties of different block types

Red ceramic

This type of building materials is popular and affordable. Consists of clay and other additives. These building materials are used to build a load-bearing structure, to line or insulate the walls of an old house, to build fences and lay the foundation. The product is characterized by high strength and durability. The thermal conductivity of ceramic bricks depends on the type. The best option for insulating a house is to use hollow bricks. The greater the degree of hollowness, the less the product is able to conduct heat. A brick wall can be laid in one or two rows. In addition, the building material has the following properties:

- strength;

- frost resistance;

- fire resistance;

- soundproofing.

Clinker

This type of red ceramic building material is most often used for facing work and laying sidewalks. This is due to its high thermal conductivity. It reaches 1.16 W/m°C. A reduction in this indicator can be achieved with hollow samples. When building a house from such blocks, it is necessary to use additional insulation methods. The high density of the product gives it additional moisture and frost resistance. Facing bricks are widely used for decorative finishing of houses outside and inside.

Characteristics of fireclay

Since this type of building material is characterized by a high ability to conduct heat, it is often used in the construction of fireplaces and stoves. This explains its name “kiln brick”. In this case, the thermal conductivity of fireclay bricks plays a decisive role in the choice of materials for construction. Such properties help save energy for heating the room. In addition, fireclay brick has the following properties:

- fire resistance;

- resistance to temperature changes;

- high thermal conductivity;

- a light weight;

- resistance to alkalis and a number of acids;

- strength;

- aesthetics.

This type of building material is valued for its durability, environmental friendliness and soundproofing. But the thermal conductivity of this type of brick is not high, so rooms made from it require additional insulation. Silicate blocks are made from a mixture of sand and lime with the addition of binding components, which are pressed and subsequently fired. The most common product is the M100 brand. There are ordinary and facing silicate bricks. Each of them has its own scope of application. In addition, the material is capable of absorbing moisture, which does not allow its use in places with high humidity and during the construction of a foundation.

Construction materials

Structural materials are intended for cladding and forming reinforced concrete structures. Thermal conductivity can be determined from the table:

| № | Material | ρ0, kg/m³ | λ0, W/(m °С) | λ (A), W/(m °C) | λ (B), W/(m °C) | μ, mg/(m h Pa) |

| 1 | Reinforced concrete | 2500 | 1,69 | 1,92 | 2,04 | 0,03 |

| 2 | Concrete on gravel or crushed stone from natural stone | 2400 | 1,51 | 1,74 | 1,86 | 0,03 |

| 3 | Cement-sand mortar | 1800 | 0,58 | 0,76 | 0,93 | 0,09 |

| 4 | Complex mortar (sand, lime, cement) | 1700 | 0,52 | 0,7 | 0,87 | 0,098 |

| 5 | Lime-sand mortar | 1600 | 0,47 | 0,7 | 0,81 | 0,12 |

| Natural stone cladding | ||||||

| 1 | Granite, gneiss and basalt | 2800 | 3,49 | 3,49 | 3,49 | 0,008 |

| 2 | Marble | 2800 | 2,91 | 2,91 | 2,91 | 0,008 |

| 3 | Limestone | 2000 | 0,93 | 1,16 | 1,28 | 0,06 |

| 4 | Same | 1800 | 0,7 | 0,93 | 1,05 | 0,075 |

| 5 | « | 1600 | 0,58 | 0,73 | 0,81 | 0,09 |

| 6 | « | 1400 | 0,49 | 0,56 | 0,58 | 0,11 |

| 7 | Tuff | 2000 | 0,76 | 0,93 | 1,05 | 0,075 |

| 8 | Same | 1800 | 0,56 | 0,7 | 0,81 | 0,083 |

| 9 | « | 1600 | 0,41 | 0,52 | 0,64 | 0,09 |

| 10 | « | 1400 | 0,33 | 0,43 | 0,52 | 0,098 |

| 11 | « | 1200 | 0,27 | 0,35 | 0,41 | 0,11 |

| 12 | « | 1000 | 0,21 | 0,24 | 0,29 | 0,11 |

Methods of transferring thermal energy

When considering the question of what the thermal conductivity of materials is, it is worth mentioning possible methods of heat transfer. Thermal energy can be transferred between different bodies through the following processes:

- conductivity - this process occurs without the transfer of matter;

- convection - heat transfer is directly related to the movement of matter itself;

- radiation - heat transfer is carried out due to electromagnetic radiation, that is, with the help of photons.

For heat to be transferred through the processes of conduction or convection, direct contact between different bodies is necessary, with the difference that in the process of conduction there is no macroscopic movement of matter, but in the process of convection this movement is present. Note that microscopic motion occurs in all heat transfer processes.

For ordinary temperatures of a few tens of degrees Celsius, it can be said that convection and conduction account for the bulk of the heat transferred, and the amount of energy transferred by radiation is negligible. However, radiation begins to play a major role in the process of heat transfer at temperatures of several hundred and thousand Kelvin, since the amount of energy Q transferred in this way increases in proportion to the 4th power of absolute temperature, that is, ∼ T4. For example, our sun loses most of its energy through radiation.

Roofing materials, waterproofing, cladding and rolls for floors

When the walls of the house are built, it is the turn of the roof. Roofing materials help protect the room from cold and rain. Waterproofing is needed to prevent moisture from penetrating the insulation. Let's consider the tabular parameters of thermal conductivity:

| № | Material | ρ0, kg/m³ | λ0, W/(m °С) | λ (A), W/(m °C) | λ (B), W/(m °C) | μ, mg/(m h Pa) |

| 1 | Asbestos-cement flat sheets | 1800 | 0,35 | 0,47 | 0,52 | 0,03 |

| 2 | Same | 1600 | 0,23 | 0,35 | 0,41 | 0,03 |

| 3 | Petroleum bitumens for construction and roofing | 1400 | 0,27 | 0,27 | 0,27 | 0,008 |

| 4 | Same | 1200 | 0,22 | 0,22 | 0,22 | 0,008 |

| 5 | « | 1000 | 0,17 | 0,17 | 0,17 | 0,008 |

| 6 | Asphalt concrete | 2100 | 1,05 | 1,05 | 1,05 | 0,008 |

| 7 | Ruberoid, glassine, roofing felt | 600 | 0,17 | 0,17 | 0,17 | — |

| 8 | Polyethylene foam | 26 | 0,048 | 0,049 | 0,050 | 0,001 |

| 9 | Same | 30 | 0,049 | 0,050 | 0,050 | 0,001 |

| 10 | Polyvinyl chloride linoleum on a heat-insulating base | 1800 | 0,38 | 0,38 | 0,38 | 0,002 |

| 11 | Same | 1600 | 0,33 | 0,33 | 0,33 | 0,002 |

| 12 | Fabric-based polyvinyl chloride linoleum | 1800 | 0,35 | 0,35 | 0,35 | 0,002 |

| 13 | Same | 1600 | 0,29 | 0,29 | 0,29 | 0,002 |

| 14 | « | 1400 | 0,2 | 0,23 | 0,23 | 0,002 |

Thermal resistance

Any wall, door, window serves to protect against external natural influences. They are able to protect the home from the cold to varying degrees, since their conductivity coefficient is different. For each fence, the coefficient must be calculated differently. Calculations are carried out in the same way for internal partitions, walls, doors, and unheated parts of the house.

If there are parts of the building that are not heated, it is necessary to insulate the walls between them and other rooms as well as external ones. Air is a poor heat transfer agent because the particles there are located at a considerable distance from each other. It turns out that if you isolate some air masses hermetically, you get good insulation from the cold. To clarify the data, the reduced resistance is calculated. The data shows how well the home is insulated and whether there is a need for additional insulation.

Modern materials

In old houses there were always two frames, so that there was a certain amount of air mass between them. Now double-glazed windows are made using the same principle, but the air between the glasses is completely pumped out so that there are no particles that conduct heat at all. The thermal resistance in them significantly exceeds that of old windows. Entrance doors are made according to the same principle. They are trying to make a small corridor, a dressing room that will keep the house warm.

If you install additional rubber seals in several layers in your home, this will improve the thermal insulation properties. Modern entrance doors are made multi-layered; several different layers of insulating material are placed there. The structure becomes practically airtight; additional insulation is often not required. The heat transfer resistance of walls is usually not so good, so additional materials are used for insulation.

Wood, metals and glass

Wood enjoys well-deserved popularity among Russian builders. It is used to make lining, plywood and even parquet boards. Metal is necessary for the construction of the roof and reinforcement frame, and glass takes its place in the frames of the window openings. Thermal conductivity is presented in table form:

| № | Material | ρ0, kg/m³ | λ0, W/(m °С) | λ (A), W/(m °C) | λ (B), W/(m °C) | μ, mg/(m h Pa) |

| 1 | Pine and spruce across the grain | 500 | 0,09 | 0,14 | 0,18 | 0,06 |

| 2 | Pine and spruce along the grain | 500 | 0,18 | 0,29 | 0,35 | 0,32 |

| 3 | Oak across the grain | 700 | 0,1 | 0,18 | 0,23 | 0,05 |

| 4 | Oak along the grain | 700 | 0,23 | 0,35 | 0,41 | 0,3 |

| 5 | Plywood | 600 | 0,12 | 0,15 | 0,18 | 0,02 |

| 6 | Cardboard facing | 1000 | 0,18 | 0,21 | 0,23 | 0,06 |

| 7 | Multilayer construction cardboard | 650 | 0,13 | 0,15 | 0,18 | 0,083 |

| Metals and glass | ||||||

| 1 | Reinforcing rod steel | 7850 | 58 | 58 | 58 | 0 |

| 2 | Cast iron | 7200 | 50 | 50 | 50 | 0 |

| 3 | Aluminum | 2600 | 221 | 221 | 221 | 0 |

| 4 | Copper | 8500 | 407 | 407 | 407 | 0 |

| 5 | Window glass | 2500 | 0,76 | 0,76 | 0,76 | 0 |

What is "dew point"

At the final stage of the calculations, you will need to correctly position the insulation and the boxes of window blocks in the thickness of the walls. This is necessary to shift the dew point outward, otherwise it will not be possible to get rid of moisture on the glass and internal walls at the beginning of the heating season.

The dew point is the temperature barrier at which water begins to condense from the warm air in a room with high relative humidity. To increase the service life of power structures, the dew point must be moved beyond the outer surface of the wall so that the brick. Wood and concrete were not destroyed by moisture.

In addition, a shift in the dew point inside the insulation layer will lead to an increase in energy consumption for heating the home already in the third season of operation. The thermal insulator will get wet, and its thermal resistance will decrease.

Incorrect installation of window blocks leads to a similar situation - the slopes will be consistently wet all winter. Therefore, SNiP standards recommend shifting the internal plane of the window unit:

- flush with the internal wall in log houses, brick cottages with 1.5 brick masonry

- the distance from the outer plane of the wall is from 12.5 cm with a significant thickness of the masonry

The choice of structural, cladding, and thermal insulation materials should be carried out comprehensively. The vapor permeability of individual layers of the wall should decrease from the inside to the outside. The principle of this method becomes clearer with a simple example:

- if you veneer the facades of a cottage made of aerated concrete blocks with ceramic bricks or clinker without a ventilation gap

- humid air from the premises will freely overcome the wall material and will be stopped by the cladding

- the blocks will begin to collapse in an aggressive environment, the lifespan of the building will decrease

In addition, water freezing inside the blocks will expand, further destroying the masonry, weakening the strength frame of the cottage. The problem is solved by replacing ceramics with siding, wooden cladding, or creating a ventilation gap through which moisture can be removed by air masses.

Join the discussion! We would be interested to know your point of view, leave your opinion

Main characteristics of insulation

Let us first provide the characteristics of the most popular thermal insulation materials, which you should first pay attention to when choosing. Comparison of thermal conductivity insulation should be made only on the basis of the purpose of the materials and room conditions (humidity, presence of open fire, etc.). We have further arranged in order of importance the main characteristics of insulation

We have further arranged in order of importance the main characteristics of insulation.

Comparison of building materials

Thermal conductivity. The lower this indicator, the less thermal insulation layer is required, which means that insulation costs will also be reduced.

Moisture permeability. The lower permeability of the material to moisture vapor reduces the negative impact on the insulation during operation.

Fire safety. Thermal insulation should not burn or emit toxic gases, especially when insulating a boiler room or chimney.

Durability. The longer the service life, the cheaper it will cost you during operation, since it will not require frequent replacement.

Environmentally friendly. The material must be safe for humans and the environment.

How to do calculations using an online calculator

To get the required values, you should enter into the online calculator the region in which the building will be operated, the selected material and the expected thickness of the walls.

The service contains information for each individual climate zone:

- t air;

- average temperature during the heating season;

- duration of the heating season;

- air humidity.

Indoor temperature and humidity are the same for each region

Information that is the same for all regions:

- indoor air temperature and humidity;

- heat transfer coefficients of internal and external surfaces;

- temperature difference.

In order for the house to be warm and to maintain a healthy microclimate, when performing construction work it is necessary to carry out a calculation of the thermal conductivity of the wall materials. This is easy to do yourself or using an online calculator on the Internet. For more information on how to use the calculator, watch this video:

To guarantee an accurate determination of the wall thickness, you can contact a construction company. Its specialists will perform all the necessary calculations in accordance with the requirements of regulatory documents.