Thermal insulation of pipelines is a set of measures aimed at preventing the heat exchange of the medium transported through them with the environment. Thermal insulation of pipelines is used not only in heating systems and hot water supply, but also where technology requires transportation of substances with a certain temperature, for example, refrigerants.

The meaning of thermal insulation is the use of means that provide thermal resistance to heat exchange of any kind: contact and carried out through infrared radiation.

The greatest application, expressed in numbers, is the thermal insulation of pipelines of heating networks. Unlike Europe, a centralized heating system dominates throughout the post-Soviet space. In Russia alone, the total length of heating networks is more than 260 thousand kilometers.

Much less often, insulation for heating pipes is used in private households with an autonomous heating system. Only in a few northern regions are private houses connected to the central heating main with heating pipes placed on the street.

For some types of boilers, for example, powerful gas or diesel boilers, the requirements of the set of rules SP 61.13330.2012 “Thermal insulation of equipment and pipelines” are required to be placed separately from the building - in a boiler room several meters away from the heated object. In their case, a fragment of the piping passing through the street necessarily needs insulation.

Pipe laying methods

On the street, insulation of heating pipelines is required both when installed above ground and when laid hidden - underground. The latter method is a channel method - a reinforced concrete trench is first laid in the trench, and pipes are already placed in it. Channelless placement method - directly in the ground. The insulating materials used differ not only in thermal conductivity, but also in steam and water resistance, durability and installation methods.

The need to insulate cold water supply pipes is not so obvious. However, you cannot do without it when the water supply is laid open above ground - the pipes must be protected from freezing and subsequent damage. But inside buildings, water supply pipes also have to be insulated - to prevent moisture condensation on them.

Scope of application

First of all, thermal insulation is used for heating, since there, along with preventing frost, it helps to save an expensive energy resource. It is recommended to insulate pipelines not only outside residential premises, but also inside, as well as in the boiler rooms themselves. After all, this will eliminate the energy consumption for heating non-residential rooms.

There are four main groups of insulating materials for heating communications:

- roll;

- cylindrical cut;

- cylindrical uncut;

- halves of a cylinder (format is better known as "shell").

In any case, it is necessary to calculate the installation of insulating structures for the exact diameter of the pipe. The appearance of a gap significantly reduces the effectiveness of the protection and can even lead to its failure. Important: slag mineral wool is not suitable for heating, or even for water supply or sewerage. The service life of cotton wool insulation is relatively short (it reaches 10 years only if it is completely dry and protected from mechanical factors). Foamed polymers are completely resistant to moisture and significant cooling.

All polymers are characterized by increased flammability, which significantly reduces the scope of their application. If structures made from them will be placed on large pipes, you need to choose products with 3-4 locks. For small and medium-sized pipelines, 2 locks are enough. Polyurethane foam performs better than polystyrene foam, and that is why it is recommended for the most critical pipes. Polyurethane foam insulation materials intended for heating circuits in homes are supplied exclusively as strong shells with a steel shell.

You can use polyurethane foam only with reliable protection from light. Foamed rubber with similar characteristics is recommended not for heating pipes, but for ventilation pipes.

It also works well for protecting the pipes through which the coolant flows. Important: if there is even the slightest chance of rodents, you should use glass wool. They chew through all other substances faster than you can talk about it.

As for water supply, it is necessary to insulate it mainly when pipes are forced to be laid above the freezing line. Important: if the problem is mild, you can simply increase the speed of the water flow. This is done through the use of pumps or receivers. A heating cable is also sometimes used. Cable heating is considered the most reliable and powerful way to protect against the cold.

This is the method recommended for seasonally used cottages. The supply of heat through an electric cable helps to quickly prepare the water supply for use, and when it is no longer needed, it can be stopped.

Thermal insulation itself is most often carried out by using rigid materials, these include:

- expanded polystyrene;

- Styrofoam;

- penoplex.

Both the quality of protection and cost are directly determined by density. Soft insulation is placed in the foam shell to cover possible flaws and voids. Roll insulation of water pipes is made with mineral and glass wool, furniture foam rubber, foil foam. Problems may be associated with the hygroscopicity of the materials used. In addition to protection from harmful environmental factors, you will have to think about how to secure the roll to the pipe.

Professionals note that it is easiest to insulate water pipes using segmental materials. It is this option (sometimes also called casing) that maintains the highest tightness and reliability. Another way to protect your water supply is by spraying polyurethane foam. It initially provides absolute impermeability to water. The consumption of the component used depends on the thickness of the poured layer.

When choosing an option for insulating water pipes, you must take into account the difference between pipes laid underground and above it. The difference remains even when the same type of material is used. Plastic and metal pipes require different insulation. If you need to protect the water supply on the street (under houses, in distribution wells), use any means that will maintain the necessary tightness and will not be destroyed by water.

An aboveground pipeline needs thicker protection than its underground counterpart.

The most difficult section is the one where the pipe rises to the surface. Here either the most powerful insulator is used, or weaker options are laid out in several layers. Covering the main insulating layer from moisture is achieved by wrapping it with plastic film or roofing felt. If both solutions are unacceptable, form a plastic box. In any case, care is taken to reduce to a minimum the number of joints, each of which forms a cold bridge.

The problem can be solved by laying out an insulating coating in the form of two mutually offset layers. But it’s not just the outer parts of the water supply that need to be protected from the cold. The covering of pipes connected to air conditioners also has its own subtleties. The purpose of protection in this case is to maintain the same performance of climate control equipment. When using uncovered pipelines, a considerable part of the energy is consumed through heat transfer. Calculations are made in advance and the location of the air conditioner and all associated pipes are determined. In this case, the required diameter of the insulating layer is calculated.

In most cases, channels serving climate control equipment are protected with synthetic rubber that does not have pores or polyethylene foam. But the hygroscopicity of mineral wool prevents its use in this case. It is much better to use mineral fiber products with a water-repellent layer.

Many pipelines in apartments and private houses are made of polypropylene structures.

The need to insulate them arises when placing:

- in the floor screed of the first floors;

- in floor screeds above unheated rooms;

- near external door and window openings.

It is also necessary to protect polypropylene pipelines entering the water supply and heating risers. They can be covered with basalt cylinders. But this is a rather expensive material, which limits its use. Foam is more versatile.

Another advantage of this material is the ability to use it many times in a row.

Insulating outdoor water pipes using glass wool is significantly complicated by the danger of its dust particles for the skin and respiratory system. Preparing the casings becomes a prerequisite. All metal pipes laid outside must be painted at the preparation stage. As for the insulation of sewage systems, it must be carried out in unheated rooms and in open areas. The only exception to this rule is in areas where in winter the temperature is guaranteed not to drop to negative values.

Of course, in Russia this is only a theoretical assumption, since in reality there are no such areas.

In most cases, sewer pipelines, including those from HDPE, cover:

- mineral wool in various formats;

- expanded polystyrene;

- expanded clay;

- polyurethane foam.

Liquid insulating elements are occasionally used. All such options are considered passive varieties. But sewerage, like other types of pipelines, is often protected using cable heating. Mineral wool should be used with caution to protect sewer systems because it contains formaldehyde resins and can be destroyed under significant mechanical stress. This makes it significantly more difficult to achieve effective thermal insulation.

Cotton insulation is used when it is necessary to cover the free areas of the channels. They cannot be laid in the soil. Wet cotton wool of any type very easily loses its characteristics. And if the pipes are made of metal, they often begin to rust quickly. To install it yourself, you need to use polystyrene foam.

Utility systems often include copper pipes, which have impressive practical properties. But even they need effective thermal protection. In most cases, copper pipelines are covered with foam materials. Such products are suitable not only for air conditioning ducts, but also for all water supply systems and heating lines.

Thermal insulation is also important for heated floors. As calculations show (and practice confirms), floors without insulation in an identical configuration under similar conditions consume 20% more energy. Cork substrates are widely used to stop heat flow. Their advantage is ideal environmental quality and excellent strength. Please note: cork has zero adhesion to cement screeds and blocks.

Installation of cork heat-shielding elements is possible if the ceilings allow it. Cork inevitably raises the floor by 40-50 mm. Therefore, it is unacceptable in rooms with low walls. The most popular method of thermal protection for heated floors is extruded polypropylene. The structure of its plates contains closed cells.

Polypropylene is well processed, it will not be difficult to install it even where the floor configuration is very sophisticated. In addition, the synthetic material does not absorb water and can be used at temperatures up to 130 degrees. Water-heated floors are mainly protected using polystyrene foam. Important: when choosing polymer structures, you need to carefully study their chemical composition. Sometimes it contains toxic components that will be released when heated.

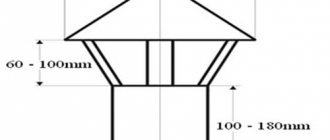

To complete the overview of the areas of application of thermal insulation, it is appropriate to protect chimney pipes placed inside walls.

Help prevent heat loss and damage to the chimney from condensation:

- mineral wool;

- fiber products;

- slag concrete and structures based on it;

- brick break;

- foam glass.

Materials that are easily flammable and can be destroyed by heat are naturally prohibited. Professional builders try to use cinder blocks. This option is quite heavy and requires careful design taking into account the load on the roofing and load-bearing elements.

For independent work, flexible and soft mineral wool is much better suited. Attention: no matter what, where and with what is insulated, it is necessary to take into account the instructions for pipelines and insulating materials.

Glass wool, mineral wool

Insulating materials proven by practice. Meet the requirements of SP 61.13330.2012, SNiP 41-03-2003 and fire safety standards for any installation method. They are fibers with a diameter of 3-15 microns, close to crystals in structure.

Glass wool is made from waste from glass production, mineral wool from silicon-containing slag and silicate waste from metallurgy. The differences in their properties are insignificant. Available in the form of rolls, stitched mats, plates and pressed cylinders.

It is important to be careful with materials and know how to handle them correctly. Any manipulations must be performed in protective overalls, gloves and a respirator.

Installation

The pipe is wrapped or lined with cotton wool, ensuring uniform filling density over the entire surface. Then the insulation, without too much pressure, is fixed using a knitting wire. The material is hygroscopic and easily gets wet, so insulation of external pipelines made of mineral or glass wool requires the installation of a vapor barrier layer made of a material with low vapor permeability: roofing felt or polyethylene film.

A covering layer is placed on top of it to prevent the penetration of precipitation - a casing made of roofing tin, galvanized iron or sheet aluminum.

Type of heat insulator

*

This type of work is carried out using heat insulators in the following forms:

- separate segment;

- cylinder;

- mat;

- half cylinder;

- roll

The pipeline can be thermally insulated using the following types of insulators:

- Mineral wool.

- Shell.

- Polyurethane sealant.

- Pipe insulation.

- Liquid expanded clay.

- Basalt wool.

This is not a complete list of heat-insulating materials. The construction market is subject to constant updating with the advent of new, more modern materials.

Basalt (stone) wool

More dense than glass wool. The fibers are made from the melt of gabbro-basalt rocks. Absolutely non-flammable, can withstand temperatures up to 900° C for a short time. Not all insulating materials, like basalt wool, can be in long-term contact with surfaces heated to 700° C.

Thermal conductivity is comparable to polymers, ranging from 0.032 to 0.048 W/(m K). High performance indicators make it possible to use its thermal insulation properties not only for pipelines, but also for the installation of hot chimneys.

Available in several versions:

- like glass wool, in rolls;

- in the form of mats (stitched rolls);

- in the form of cylindrical elements with one longitudinal slot;

- in the form of pressed fragments of a cylinder, the so-called shells.

The last two versions have different modifications, differing in density and the presence of heat-reflecting film. The cylinder slot and the edges of the shells can be made in the form of a tenon joint.

SP 61.13330.2012 contains instructions that the thermal insulation of pipelines must comply with safety and environmental protection requirements. Basalt wool itself fully complies with this instruction.

Manufacturers often resort to tricks: to improve consumer performance - to make it hydrophobic, more dense, and vapor permeable, they use impregnations based on phenol-formaldehyde resins. Therefore, it cannot be called 100% safe for humans. Before using basalt wool in a residential area, it is advisable to study its hygienic certificate.

Installation

The insulation fibers are stronger than glass wool, so it is almost impossible for its particles to enter the body through the lungs or skin. However, it is still recommended to use gloves and a respirator when working.

Installation of rolled sheets is no different from the method of insulating heating pipes with glass wool. Thermal protection in the form of shells and cylinders is attached to the pipes using mounting tape or a wide bandage. Despite some hydrophobicity of basalt wool, pipes insulated with it also require a waterproof, vapor-permeable shell made of polyethylene or roofing felt, and an additional one made of tin or dense aluminum foil.

Criteria for choosing insulation

There are quite a lot of selection criteria, but they are all determined by significant factors. Let's go through the points so that everyone can choose insulation for a specific situation.

- Price. Yes, the first point is always the price. The question is not so much about the cheapness of the design, but about the specific insulation budget. A specific amount must be allocated that must be met, and only then the remaining parameters come. The cheapest option would be to fill it with expanded clay, but you need to install a separate box under it, which is extremely inconvenient, but cheap.

- Thermal loads. You need to know the temperature of the coolant in the supply line. The insulation must withstand this temperature without any kind of deformation.

- Impact of pests. If you are firmly convinced that you do not have pests, then you don’t have to look back at this point. If they are, you will have to treat the insulation with an antiseptic or use mineral wool. Remember, any modern insulation must be biologically inert. This means that despite any impact, bacteria or fungi will not grow in the insulation.

- Hygroscopicity. Insulation that absorbs water is not the best option. It will have to be covered with additional covers to protect it from moisture. But, if there are no other options, you can also use hygroscopic insulation.

- Shrinkability. Good insulation should not “shrink” over time. In practice, shrinkage means that after a certain period of time the insulation will have to be replaced. The absence of shrinkage extends the service life of the insulation.

- Easy to install. The easier it is to install the insulation, the better. But among other indicators, this one ranks last. If, after you have gone through all the points, there are still a few options left, you can think about ease of installation.

Foamed polyurethane (polyurethane foam, PPU)

Reduces heat loss by more than half compared to glass wool and mineral wool. Its advantages include: low thermal conductivity, excellent waterproofing properties. The service life declared by the manufacturers is 30 years; The operating temperature range is from -40 to +140 °C, the maximum withstandable for a short time is 150 °C.

The main brands of polyurethane foam belong to the flammability group G4 (highly flammable). When the composition is changed by adding fire retardants, they are assigned G3 (normally flammable).

Although polyurethane foam is excellent as an insulating material for heating pipes, keep in mind that SP 61.13330.2012 allows the use of such thermal insulation only in single-family residential buildings, and SP 2.13130.2012 limits their height to two floors.

Might be interesting

Thermal insulation

Insulating the ceiling in a bathhouse - methods, materials, useful...

Thermal insulation

Tables of comparative characteristics of thermal insulation…

Thermal insulation

Why polyurethane foam insulation is the best...

Thermal insulation

Self-adhesive thermal insulation: how to choose and apply?

Thermal insulation coating is produced in the form of shells - semicircular segments with tongue and groove locks at the ends. Ready-made steel pipes insulated with polyurethane foam with a protective sheath of polyethylene are also available for sale.

Installation

The shells are secured to the heating pipe using ties, clamps, plastic or metal bandage. Like many polymers, the material does not tolerate prolonged exposure to sunlight, so an open ground pipeline when using PPU shells requires a covering layer, for example, galvanized steel.

For underground ductless placement, thermal insulation products are laid on waterproof and temperature-resistant mastics or adhesives, and the outside is insulated with a waterproof coating. It is also necessary to take care of the anti-corrosion treatment of the surface of metal pipes - even the glued joint of the shells is not tight enough to prevent the condensation of water vapor from the air.

How to choose insulation

When using insulation, you should try to select a material that is optimally suited for its properties, taking into account the characteristics of the soil in which it will be laid.

In general, types of insulation can be divided into several groups:

- Bulk;

- Roll;

- Slab sheet;

- Foam blocks.

When using the first type, the pipeline laid in a trench can simply be covered with expanded clay. This method of insulating sewer pipes in the ground with your own hands is the simplest and most inexpensive, but is only suitable if the trench is dry. For roll and slab types of insulation, a protective waterproofing box will be required. This is necessary to prevent the formation of ice jams in cold winters.

High-quality insulation of external sewer pipes is due to well-chosen material. The range of thermal insulation materials for sewer pipes on the market is very wide and it is not so easy to make a choice

But what you definitely need to pay attention to is that the insulation is already waterproofed. In this case, you won’t have to worry about additional measures.

Expanded polystyrene (foam plastic, EPS)

It is produced in the form of shells, practically no different in appearance from polyurethane foam - the same dimensions, the same tongue-and-groove locking connection. But the temperature range of use, from -100 to +80 °C, with all this external similarity, makes its use for thermal insulation of heating pipelines impossible or limited.

SNiP 41-01-2003 “Heating, ventilation and air conditioning” states that in the case of a two-pipe heat supply system, the maximum supply temperature can reach 95°C. As for the return heating risers, not everything is so simple: it is believed that the temperature in them does not exceed 50 °C.

Foam insulation is more often used for cold water and sewer pipes. However, it can be used on top of other insulation materials with a higher permissible temperature of use.

The material has a number of disadvantages: it is highly flammable (even with the addition of fire retardants), does not tolerate chemical influences (dissolves in acetone), and crumbles into balls during prolonged exposure to solar radiation.

There are other non-polystyrene foams - formaldehyde, or phenolic for short. In fact, it is a completely different material. It is devoid of these disadvantages and is successfully used as thermal insulation for pipelines, but is not so widespread.

Installation

The shells are secured to the pipe using a bandage or foil tape; they can be glued to the pipe and to each other.

What properties should an insulating material have?

Insulation for pipes, depending on the scope of application (laying underground or external communications), must meet the following requirements:

- Low level of thermal conductivity, which will help maintain the temperature of the coolant in heating and hot water supply pipelines, as well as prevent warm ambient air from heating the pipeline in cooling devices and appliances.

- Materials used for insulation must meet sanitary and fire safety standards and have self-extinguishing properties.

- Insulation cannot be overly hygroscopic, since the amount of air in the structure of a wet material decreases, the amount of which determines its thermal insulation properties.

- Thermal insulation should be easily installed on pipes of any diameter and configuration, with the formation of a minimum number of joints, which eliminates the presence of cold bridges.

- The material must be durable and maintainable, as well as the possibility of its repeated use.

- Possess high resistance to aggressive environments, mechanical strength, and withstand sudden temperature changes.

- Material available at an affordable price.

But you shouldn’t buy cheap insulation, as this can lead to even greater costs if the pipe freezes in winter.

Foamed polyethylene

The temperature range at which the use of high-density polyethylene foam is allowed is from -70 to +70 °C. The upper limit is not compatible with the maximum temperature of the heating pipe, usually accepted in calculations. This means that the material is of little use as thermal insulation for pipelines, but can be used as an insulating layer over a heat-resistant one.

Polyethylene foam insulation has found virtually no alternative use as protection against freezing of water pipes. Very often it is used as a vapor barrier and waterproofing.

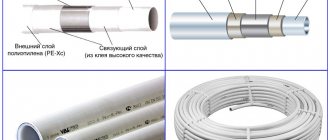

The material is produced in the form of sheets or in the form of a flexible thick-walled pipe. The latter form is more often used, as it is more convenient for insulating water pipes. Standard length is 2 meters. Color varies from white to dark gray. There may be a coating of aluminum foil that reflects IR radiation. The differences relate to internal diameters (from 15 to 114 mm), wall thickness (from 6 to 30 mm).

The application ensures the temperature on the pipe is above the dew point, which means it prevents the formation of condensation.

Installation

A simple way with worse vapor barrier results is to cut the foam material along a small depression along the side surface, open the edges and put it on the pipe. Then wrap it along the entire length with mounting tape.

A more complex solution (and not always feasible) is to turn off the water, completely disassemble the insulated sections of the water supply system and put on solid sections. Then put everything back together. Secure the polyethylene with ties. In this case, only the junction of the segments will become a vulnerable point. It can be glued or also wrapped with tape.

Why is insulation necessary?

There are several reasons why underground water supply should be insulated, all of them are related to the rules for laying communications and financial savings - this is obtained after the insulation work has been carried out. The main reasons for thermal protection of water pipes:

- When laying an underground water supply line, the possibility of draining water from the system is taken into account; for this, the pipeline is laid with a slope of about 20 mm per linear meter towards the source. If the house or cottage is located at a great distance from the well or well from which water is drawn, for example, 50 m, then when laying a pipeline near the house at an average freezing depth of about 1.5 m at the entrance to the source, you will have to bury the pipe at 2.5 m (0.02 x 50 = 1 m). This is not economically feasible and quite difficult to implement technically.

- To collect water from wells, caisson wells are often used, into which pumping equipment is placed and the electric pump is maintained. A standard caisson tank has a depth of immersion underground of about 2 m, while the upper pipe of the casing, according to standards, is located 50 cm above the floor level. Thus, at the exit from the caisson chamber, which is an unheated room, the pipeline is placed at the lower mark of the freezing depth of 1 .5 m, and given that when connecting to the house through the basement a slope is required, the entire section of the water supply will be above the freezing point - accordingly it must be insulated. Read more about plastic caissons.

- Insulating water supply pipes in a private house that run underground allows you to save significant funds that are spent on heating cold water for household needs. It is clear that less cooled water after flowing through an insulated water supply system will require less electricity for heating than cooled water after passing through a non-insulated pipeline.

- It is known that thermal insulation of an underground water supply system from contact with the ground does not heat the pipes, but prevents heat loss, so insulated water supply pipes can also be used effectively in the summer - they prevent the heating of water when the main line is shallow.

- To prevent freezing, they not only insulate water pipes in the ground, but also on its surface at the exit from the well and the entrance to the house, if it is located on stilts; for this, thermal insulation methods and materials similar to underground communications are often used.

Self-regulating electrical cable device

Foam rubber

Foamed synthetic rubber with a closed-cell structure is the most versatile material for preserving heat and cold. Designed for a temperature range from -200 to +150 °C. Meets all environmental safety requirements.

It is used as insulation of cold water pipelines, insulation of heating pipes, and is often found in refrigeration and ventilation systems. Heating pipes laid inside buildings and insulated with rubber do not require the installation of a vapor barrier layer.

Externally similar to foamed polyethylene, it is also available in the form of sheets and flexible thick-walled pipes. Installation is also practically no different, except that such thermal insulation of pipes can be attached with glue.

Reasons for thermal insulation

There are two reasons why all thermal insulation work is carried out:

- Prevention of emergency situations. Frozen water often causes pipes to break. The influence of low temperatures significantly affects the quality of the product material and its overall integrity. The solution to this problem is high-quality insulation of unprotected sections of pipes.

- Reducing energy costs for heating. Many pipeline channels are located on the street: either in contact with the ground or at a short distance from it. The structures reduce the temperature due to high heat transfer to the environment. Lack of proper thermal insulation will entail high financial costs and will also reduce the quality of the material from which the pipeline channels are made.

Thus, thermal insulation of pipelines and equipment is an integral measure.

Installation features

Different types of thermal insulation have different installation technologies:

- Cylinders made of basalt fiber are a composite element, so after their installation it is necessary to secure them with clamps. A protective plastic casing must be placed over the material. Foil basalt cylinders are sealed using aluminum tape and also require additional protection.

- Polyurethane foam is a rigid material that has a “shell” appearance. It is put on the desired pipe and fixed with grooves. Polyvinyl chloride film or aluminum foil is used as a protective material. Such insulation can be installed at any time of the year with minimal humidity. To secure the parts of the “shell” together, a special glue is used, which is used to coat the joints of the grooves. The taped seams are sealed using aluminum tape.

Glass wool and mineral mats are wrapped around the pipe and secured with tape or protective covers.

Anti-corrosion VUS

The highly reinforced anti-corrosion insulation made of tape-polyethylene material deserves special attention. It meets all modern technical and sanitary requirements.

If we compare this type of protection with others, then in this case the technology of applying adhesive tape makes it possible to obtain higher quality coatings. This increases:

- resistance to external mechanical influences;

- adhesion to the surface of the pipe;

- resistance to water absorption;

- duration of use.

The main advantages of these pipes are:

- Resistance to mechanical influence.

- Very low water absorption.

- Adhesion significantly exceeding standard values.

Pipe-rolling assortment with such protection is installed in networks with an operating coolant temperature of -40 to +60 degrees. This protection has not lost its technical performance for half a century.

Anti-corrosion insulation of a highly reinforced type becomes reliable protection for the system and guarantees its trouble-free operation over a long service life.

As for bitumen-polymer processing, it has proven itself to be excellent. For these reasons, it is used when working with different types of soil. This type of protection makes it possible to use the system at ground temperatures from -5 to +30 degrees.

The thickness of the reinforced type treatment is four to six millimeters, and the reinforced type protection is characterized by a thickness of up to nine millimeters.

Video

Insulating a steel pipe using MIG 219

The use of cement-sand options: sand insulation (CI) and cement-sand coating (CSC) is acceptable for steel systems supplying drinking water and in utility pipelines.

Such insulation lasts for at least 30 years and effectively increases the service life of the system. This also reduces the cost of repair work. This is possible due to the fact that internal deposits and fouling of pipes are almost absent.

Steel case with VUS

The steel case with highly reinforced insulation is used in situations where the pipeline passes under the road for cars and under railway tracks.

In such places, pipelines are hidden in a pipe - a case, which in terms of strength should exceed the protected pipelines.

Steel cases take on additional mechanical load and increase the time the line is used. VUS increases the protective capabilities of a steel case, and extruded polyethylene is called one of the best materials for this purpose.

The distinctive characteristics of this material are:

- absolute impermeability of water;

- light weight;

- resistance to the growth of mold, moss and fungus;

- preservation of characteristics at different temperature ranges;

- wear resistance;

- low cost.

Common standard sizes of cases:

- diameter from 21.9 to 102 cm;

- wall thickness from 0.5 to 1.8 cm.

In accordance with the rules, the diameter of the protective case must exceed the main pipe by 20 cm. All products from different manufacturers comply with the regulatory requirements of world standards and can be used in any region of Russia.

Advantages

Very reinforced pipeline insulation is applied to the pipe rolling range in the field of factory production.

This production becomes a guarantee of a high-quality result of the final product, which is characterized by uniform performance and homogeneity.

Almost always, reinforced insulation is a coating of many layers, where the surface layer is a polymer, which has the following characteristics:

- Being in the water for a long time, it does not let it through.

- Biostable, which means it is not destroyed by the influence of mold fungi found in soil organisms.

- Resistance to temperature changes. This type of thermal insulation retains its capabilities even in severe frosts, when the soil completely freezes. Heating also does not change its characteristics. Steel pipelines under such insulation are not exposed to stray debris. And they are the main cause of corrosion formations on steel products located underground.

- Resistant to stretching, tearing, friction and vibration.

- Durable and wear-resistant.

- Low weight of the coating, which does not change the total weight of individual parts of the structure and the system as a whole.

When this period comes to an end, the network needs to be inspected. Places where mechanical damage and wear have occurred can be easily repaired under any conditions. For these purposes, special polymer materials are used: tapes, primers, etc.

Thermal insulation of pipelines and its essence

By using thermal insulation, manufacturers make it easier for themselves to carry out certain technological processes. This solution is widely used in many industries:

- Metallurgical.

- Food.

- Oil refining.

- Chemical.

But insulation receives more attention from energy representatives. In this case, the thermal insulation objects have the form:

- Smoke pipes.

- Heat exchange devices.

- Accumulator tanks where hot water is stored.

- Turbines with gas and steam.

Thermal insulation of pipelines is used on devices that are located in both vertical and horizontal planes. This is a current solution for thermal insulation of equipment, such as tanks in which water is stored along with coolants. A number of stringent requirements are imposed on the effectiveness of insulating coatings.

Inner coating

*

Application of internal insulation for metal pipes is carried out only in factory conditions, in strict compliance with regulatory standards. Internal insulation allows you to maintain all the operational characteristics of the pipeline. Most often, products with this type of insulation are used for laying underground pipelines.

Reinforced internal insulation