Insulating a bathhouse from the inside is the easiest way to create a “thermos” that will retain heat as efficiently as possible. This will also allow you to warm up the room faster, rather than waiting for hours to steam. However, in this case, the thermal insulation of the walls must be heat-resistant, resistant to moisture and not emit harmful substances when heated.

We'll tell you how to insulate a bathhouse from the inside, which insulation is best suited for a bathhouse, and how to properly install it on the walls and ceiling.

Is it necessary to insulate a bathhouse and steam room?

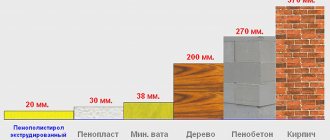

Brick baths always need insulation due to the high heat capacity of the structural material from which the walls are made. Simply put, walls take a long time to heat up, so a thermal insulation layer is necessary. Thanks to it, the temperature in the room rises at lightning speed and then very slowly drops. And in general, much less resources are spent on heating.

The heat capacity of wood is lower than that of stone. So you can do without insulation if the wooden wall is thicker than 150 mm. But then the bathhouse will take longer to heat up, retain heat worse, and spend more resources on maintenance and heating.

Therefore, the insulation of a bathhouse and steam room depends not only on the material of the walls, but also on the desire to make these rooms as durable and energy efficient as possible. In addition, thermal insulation can be completed without the help of professional workers in just a few hours. And it will subsequently save time and money for decades.

However, there are other important benefits. For example, due to the fact that LOGICPIR insulation does not allow moisture to enter the walls, it helps to maintain not only warmth in the room, but also an environmentally healthy environment. This material prevents the appearance of mold and mildew, which means it reduces the likelihood of developing asthma, allergies and other lung diseases. After all, their main enemy is high humidity.

“Pie” insulation technology

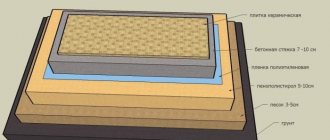

It is called so because, upon completion of the work, the wall is covered with several layers at once: thermal insulation, vapor barrier, cladding. You should start from top to bottom.

First of all, attach the bars to the load-bearing surfaces - at a distance from each other 1 cm less than the width of the mineral wool. Having created the frame in this way, you mount basalt slabs on it by surprise - carefully, without crushing the edge, ensuring a tight fit. Do not forget that gaps are places where moisture accumulates and “cold bridges” form.

Cover the resulting structure with a vapor barrier, so that its foil side faces the inside of the room, and be sure to seal all joints and seams with special tape. Then you perform the sheathing - directly on the wood of the still protruding base, at a distance of 5-10 cm from the previous layer. This way you will create a buffer zone in which the condensate will drain without coming into contact with the lining and without subjecting it to rot. And to finish, close the “Pie” with the lining.

Why we recommend using LOGICPIR insulation

What is the best way to insulate walls in a bathhouse and steam room? We recommend LOGICPIR insulation. This is a polymer material with a porous internal structure, lined with aluminum foil on both sides. At high temperatures, catalysts and additives form closed cells filled with low thermal conductivity gas.

In addition, this rigid insulation is very easy to process, cut and install. At the same time, it does not generate dust, does not prick, and does not irritate the mucous membranes of the person doing the installation. And it performs two functions at once: insulation and vapor barrier.

Mineral materials

We are talking about mineral insulation, which contains basalt. Durable cotton wool material that can retain its shape. It has good insulating qualities and requires quick and easy installation. Able to withstand temperatures up to 1000 ºС, while its characteristics are not destroyed. Does not attract rodents.

But such mineral material has its drawbacks. You will have to come to terms with the fact that the cotton wool is sagging. It must be of high quality - counterfeits have a bad effect on human health. A frame base is required, otherwise the process of subsidence will occur much faster. It is best to fix the wool over the sheathing.

High thermal insulation characteristics

Two features make LOGICPIR insulation most effective:

- record low thermal conductivity coefficient of 0.022 W/m•K;

- high reflection coefficient - from 95 to 98%.

The material belongs to the class of reflective thermal insulation - it fully complies with the requirements of GOST R for reflective thermal insulation. That is, it allows you to retain radiant heat from the stove, save its energy, effectively reduce heat loss in the room, and at the same time does not absorb moisture at all.

Ceiling insulation

It is carried out from top to bottom: it is simply more convenient to carry out work in this way, because it is easier to descend systematically than to take on one surface, skip another, and then return to it. It is this order that makes it possible to ensure the same microclimate at every point of the building - there will be no hot or cold zones. True, for this it is necessary to lay the materials overlapping, so that later it is easier to fasten them together.

Craftsmen thermally insulate the ceiling according to the following scheme:

- cover its surface overlapping with roll materials of your choice;

- the bars are mounted, forming a frame;

- place foil on top, covering all connections;

- glue the joints with aluminum tape (several times), evaluate the tightness;

- carry out installation;

- lined with clapboard finished to look like wood.

Vapor barrier properties

LOGICPIR insulation is laminated with vapor-proof foil - this eliminates the need for a separate vapor barrier layer. This will be confirmed by all professionals who know that only aluminum foil can be considered a full-fledged heat-resistant vapor barrier.

When gluing the joints of the plates with foil tape, a continuous and sealed vapor-tight layer is obtained, which reliably protects the entire structure from moisture. The foil does not allow moisture to pass through and reflects heat, like a mirror: it returns up to 95% of the energy of infrared rays from the sauna stove into the room.

Thanks to this, the bathhouse heats up faster, and the insulation layer becomes a reliable barrier between air with high and low temperatures. LOGICPIR retains heat in the room, like a warm fur coat.

What dangers await you if the steam room is not insulated correctly?

Sooner or later, the flaws of improper work will come out. There are only two main ones:

- Wrong choice of materials. As a result, you can get an unpleasant odor released by the material when heated, poor heat retention and, as a result, high heat and energy consumption.

- Violation of the tightness of the room. It is observed when the vapor barrier of walls and ceilings is incorrect. In this case, there will be a leak of steam, a decrease in heat and an increase in thermal energy consumption. Under the influence of hot air, deformation of finishing materials and internal structures of the building will occur. Steam turning into water will become a source of dampness, and subsequently an unpleasant odor and mold.

How to properly install LOGICPIR insulation

We have already found out what is the best way to insulate a bathhouse, now we will tell you how to install the insulation correctly. You will need:

- insulation LOGICPIR Bathhouse 30-50 mm thick;

- adhesive foam LOGICPIR;

- LOGICPIR foil tape 50 mm wide;

- PVC tape 220 mm wide and epoxy glue (if necessary);

- fasteners for fixing insulation and wooden slats.

A pleasant bonus of LOGICPIR insulation is ease of installation. The owner of the bathhouse can easily cope with the installation himself, without hiring qualified workers. The whole process takes several hours and consists of 5 stages.

- Clear the bases of debris and level them. They should be strong, dry and even. In addition, there should be no wane on the wooden base.

- If the bases are stone, attach the insulation boards to the walls using special LOGICPIR foam adhesive. In order not to disturb the thermal circuit, places that are difficult to access for installation should also be insulated with foam adhesive. If the bases are wooden, it is better to install the insulation on self-tapping screws, and it is important to seal the installation locations of the fasteners with pieces of tape.

- Glue or attach the insulation with self-tapping screws along all bases with a continuous thermal insulation layer.

- Tape the joints of the slabs with aluminum tape to create a continuous and sealed vapor-tight layer that will reliably protect the structure from moisture and mold.

- If necessary, glue elastic PVC waterproofing tape with epoxy glue along the entire perimeter of the junction of the insulation with the floor. This will prevent water from getting into the gaps where the floor meets the wall.

As a result, you will get an easy-to-install, energy-efficient, fireproof and durable system. LOGICPIR insulation makes it easy to achieve the effect of a “real Russian bath” in a room.

Working with drywall

When we insulate the walls of a bathhouse from the inside with our own hands, one of the final stages of this process is laying the rough sheathing. An excellent material for these purposes is drywall. When working with this material, you need to take into account several rules:

- The UD type guide profile is attached along the perimeter of the ceiling or wall. The pitch of such fastening should not exceed 600 millimeters. This profile is fixed to timber or logs with self-tapping screws, and to a concrete or brick wall - with screws and plastic dowels.

- The axes of the CD profile are marked and then hangers are attached along these axes at a distance of 600-800 millimeters from each other.

- Installation and fastening of CD profiles is carried out with metal screws, the length of which is 9 millimeters. Then the protruding edges of the hangers are bent.

- We attach our drywall to the entire resulting structure, under which the insulation is located.

Where to order or buy

Insulation services are provided by companies whose main specialization is the construction of turnkey bathhouses. Our specialists perform high-quality work, which guarantees safe use.

Performers with skills in the construction industry can perform thermal insulation themselves. To implement the project yourself, you will need materials, first of all, insulation. The companies collected in the corresponding section of our website specialize in the sale of thermal insulation materials.

Useful video

Of course, this is an advertisement from TechnoNIKOL, but they didn’t lie anywhere in the instructions; the pie is shown clearly and correctly:

***

Insulate yourself better and subscribe to our Telegram channel to stay up to date with all the site news!

We recommend that you read other articles that provide information on the construction and arrangement of a bathhouse:

- application and features of the production of impregnated wood;

- a list of the best antiseptics for baths and saunas;

- bath furniture;

- bath windows;

- bath painting options;

- bathhouse roofs.