Different types of heating elements

Electric heating devices are often used to heat rooms. One of the varieties of such heating heating elements is tubular electric heaters. What is this widespread device? A heating element is a device for medium-temperature heating of a coolant. Structurally, it is a thin-walled metal tube with a spiral placed inside, which is made of a high-resistance material - nichrome. The ends of the spiral come out in the form of a contact rod, are sealed and are used for connection to the electrical network.

The tube itself is made of steel, carbon or stainless steel. After placing the spiral inside and centering it, the tube is filled with a special coolant - periclase and sealed. Being under high pressure, periclase fixes the spiral along the axis and after that the heating element is bent and given the required shape, depending on the model.

Regardless of how exactly the heating elements will be used - in a solid fuel heating boiler or in an infrared heater - there are certain rules for installing and operating heaters of this type. At the same time, electric heating elements can be used for a variety of purposes: for heating a garage, heating a house, for installation in heating boilers or radiators. Let's take a closer look at how to use heating elements for heating.

Tubular electric heater design

What is heating element and its pros and cons

Heating elements are electrical devices that, when immersed in a container of liquid, heat it up. These include heating elements for a heating radiator and a regular water boiler. As a rule, these devices are installed in radiators either as the main source of heat in houses with an autonomous heating system, or as an additional means that increases heat transfer and automates the entire process.

Typically, a heating element for a cast iron radiator is installed if:

- A transition to autonomous heating is required.

- The centralized heating system “does not exhaust” and the room is cold, then it is used as an additional source of heat.

- Installing a heating element in a cast iron battery as an emergency heater. It is able to save the heating circuit from freezing in the event of a power outage. It is enough to turn off the heating taps and plug in the electric heater.

These devices have their advantages and disadvantages. The first include:

- Quite high operating efficiency and cost-effectiveness. This is due to the fact that the transition of electricity into thermal energy occurs with virtually no losses.

- Easy to install and can be ridden by any beginner using the instructions included with each unit.

- They serve flawlessly for many years, provided they are installed correctly.

- Heating elements for heating radiators are compact and practically invisible.

- They are safe because they are equipped with control sensors.

- The cost of the device is low, but a thermostat, which is not included in the kit, can cost a pretty penny, depending on its design.

- Electric heating elements for cast iron batteries can not only regulate the heating of the coolant, but also save energy resources.

Among the disadvantages of the device:

- High electricity consumption if the heating element in the heating radiator is used as the main and only source of heat.

- These devices should not be used in homes with unstable power supply.

If you use a heating element for a cast iron battery with a thermostat in a house where people rarely live, then the anti-freeze mode will save the heating system from bursting pipes. It is able to maintain a minimum temperature of the coolant, which does not consume much electricity, but at the same time prevents it from freezing.

Radiator electric heating at home

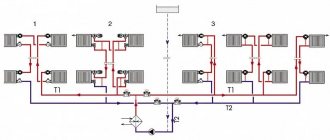

Installation diagram of the heating element in the radiator

Before installing a heating element into the heating system, you need radiator parameters. The main one is the diameter of the connecting pipe. Currently, manufacturers produce products in two sizes - 1/2 and 3/4 inches. Then a comparative analysis of the heating parameters is carried out before and after installing the heating element.

Connecting the heating element to the existing heating

If it will be used as an additional method of heating water, you need to take into account the change in hydraulic pressure when passing through the radiator. Since the flow diameter of the system this month will be smaller, it is recommended to install a pump of higher power.

When connecting a radiator to the system, installing a heating element for heating the house will not be possible. To do this, you must either change the connection diagram to the top, or install a heating element on the top of the battery, which is not recommended by experts.

They are often installed in old cast iron batteries. Before performing work, you must first check the direction of the thread of the pipe (right or left) and also measure its diameter. Then you should follow this scheme:

- Coolant drain. It is prohibited to install a heating element into a heating radiator if there is water in it;

- Checking the battery level. Even at a slight angle of inclination, the likelihood of air pockets significantly increases;

- Installing the heating element into the pipe. To seal the holes, you must use the gaskets supplied with the heating element or make them yourself;

- Installation of a unit with a thermostat, if included.

An example of installing a heating element in a cast iron radiator

After this, you need to fill the system with water. Using the installed Mayevsky crane, possible air pockets are removed. Before switching on, to ensure safety, a tester is used to check any possible heating coil-battery circuit. If there is one, you need to dismantle the heating element and install it again, improving the sealing.

Radiator electric heating

When organizing heating using heating elements made by yourself, installation of a pipeline is not necessary. A heating element must be installed on each radiator. At the same time, it is possible to install models of different power depending on the thermal conditions in a specific room of the house. The advantages of such a system are as follows:

- Saving on the purchase of materials and reducing the labor intensity of installation work;

- If you use a heating element with a thermostat for heating and a temperature sensor connected to it, the degree of heating of the room will be adjusted automatically;

- Minimum system heating inertia.

But all these positive qualities can be offset by the total cost of service. Therefore, before heating with electric heaters, you need to calculate not only the cost of purchasing materials and components, but also the subsequent costs of electricity. Only after this should a heating system of this type be introduced.

It is recommended to purchase factory radiators with installed heating elements. Their operating efficiency is higher than that of homemade ones, since special oil is used as a coolant. Even when the heating element is turned off, it will give off heat to the room for some time.

The design of the heating element and its operating principle

The design of the electric heating element is quite primitive. It is a metal cylinder, inside of which there is a spiral of copper or strong steel wire in a special insulator. Since the heating element for heating radiators has a thermostat, it is used not only as a heating element, but also to adjust the temperature of the coolant.

The cylinder with a spiral is protected by a housing equipped with control sensors. Their task is to ensure that the device does not overheat. The galvanization process to which it is subjected gives additional reliability to the device. Chrome and nickel plating enhance the strength of the heating element and create an additional protective barrier that protects people from contact with electricity.

In addition to heating functions and thermoregulation, modern electric heating elements for cast iron batteries are equipped with additional “responsibilities”:

- The “anti-freeze” mode is capable of maintaining a constant coolant temperature of +10°C, which is enough to prevent the water in the pipes from freezing. Having heated the liquid to the desired level, the heating element turns off and starts working again when it cools down.

- If the autonomous heating of a private house is equipped with cast iron batteries with heating elements, then the “Turbo” mode will suit perfectly. With it, the device turns on at full power, which ensures almost instantaneous heating of the system and heating of the air in the room. The subsequent operation of the heating element is to maintain the selected temperature of the coolant in the network, which ensures energy savings during heating.

Some consumers believe that the best coolant for radiators with heating elements is technical oil, since it heats up faster and cools down more slowly. This does not mean that it is not advisable to use it in a water heating system.

Composite heating elements

Tubular heating elements

Tubular elements typically consist of a thin nichrome coil or heat-resistant alloy wire that is contained in a metal tube (stainless alloys such as Incoloy or copper) and powder insulated (magnesium oxide).

To maintain constant humidity in the hygroscopic insulator, the ends are equipped with an insulating material, such as ceramic or silicone rubber or a combination of both. The pipe is pulled through a die to compress the powder and maximize heat transfer. They can be straight (as in a toaster), or curved to enclose the heated space (for example, in electric ovens and coffee makers).

Polymer heating elements

Resistance heaters can be made from conductive rubber PTC materials, where the resistance decreases as the temperature increases. Such a heater will generate high power to heat water when it is cold and constantly maintain the desired temperature.

Due to the decreasing specific resistance of the heater, such a heating element will never be able to produce more heat than necessary. When heated to a certain temperature, PTC materials act as an electrical insulator and do not allow current to pass through, after which they naturally stop heating. The temperature can be selected during the manufacturing process, with typical temperatures being between 0 and 80 °C (32 and 176 °F).

Thus, heating elements made of polymer materials are self-regulating. This means that it independently maintains a constant temperature without the need for electronic regulation. Self-limitation means that the heater is not able to exceed a certain temperature and does not require the use of overheating protection.

How to choose the right heating element for a cast iron radiator

For a heating element to truly become an effective assistant, you need to select it according to the following parameters:

- First of all, you should focus on the power of the heating device. To select the power of a heating element for a cast iron battery, you need to calculate what it should be. If we focus on SNiP indicators, then 1 kW of power will be required to heat 10 m2, but this is not the only indicator that should be taken into account.

- Of considerable importance is what metal it is made of and how the heating radiator works. There is a difference between heating elements for cast iron batteries and aluminum or bimetallic ones. For the former, heating elements of a different shape and with a larger plug diameter are produced.

When purchasing a heater, you need to clarify what type of radiators it is suitable for.

- To choose the correct heating element length, you need to focus on the number of sections in the radiator . As a rule, the optimal length of the device is 10 cm shorter than the battery. This will allow it to heat the coolant in the device evenly and quickly.

- You can install a heating element in a heating radiator with a thermostat if it will be used as an additional heat source. When its function is to heat a house or apartment, additional external electronics will be required to automate the heating process. This makes the device itself somewhat more expensive, but helps save on energy resources during its operation.

- The pressure in the central heating batteries should also be taken into account. If it tends to increase, then you should periodically bleed the air using a Mayevsky tap.

Tubular electric heaters for vulcanizers

In the automotive industry, vulcanization is actively used and its process, of course, requires heating elements. The shape of the heating elements used can be oval or round. Number of elements – one, two.

The heating elements are connected to the vulcanizer using connectors. The use of two round-shaped heating elements makes it possible to reduce the vulcanization time due to faster heating of the rubber to the required vulcanization temperature.

A thermal fuse is installed in each heating element to protect the elements themselves and the raw rubber at the heating site. Vulcanizers with heating elements of this shape can be mounted on horizontal and vertical surfaces.

Two oval-shaped heating elements, allowing you to change the geometric surface, provide more accurate force transmission regardless of the tire profile. To facilitate the maintenance of vulcanizers and quick change of heating elements, both heating elements are equipped with electrical and pneumatic connectors.

Power calculations

To choose the optimal heating element for a cast iron battery, you will have to make some calculations.

- The power of the device is determined by the amount of heat that the room needs. So, to heat 1 m2 you will need 100 W, which means that for a room of 20 m2 you need 2000 W. Since cast iron batteries are used as heaters, the required amount of heat must be divided by the thermal power of one section of the battery, for example, 180 W. It turns out that this room will require 11 cast iron sections. The length of the heating element and its power must correspond to the size and needs of the radiator.

- Another parameter that should be calculated is the volume of coolant in the structure. This is important, since even a powerful device will not be effective if there is not enough liquid in the battery. Therefore, when purchasing a heating element, it is so important to consider what type of battery it is needed for. The volume of aluminum radiators is only 0.2 l, while in a cast iron battery it can be from 0.6 to 1.5 l, depending on the model and manufacturer.

Approximately 1 kW of heating element power per 15 liters of coolant is taken. Based on this and taking into account the number of radiator sections, it is easy to determine what power the device needs and how many of them should be in the heater.

About methods of connecting heating elements

Let’s immediately make a reservation that heating elements for water heaters can be installed in devices either one at a time or several at a time. It is quite obvious that the more heaters, the higher the power of the boiler itself will be. But the fact is that the power indicator also depends on how the individual elements are connected - such a connection can be either single-phase or three-phase. But in city apartments, as you know, the network is single-phase, so we will consider it. So, this network provides three ways to connect the heating element:

- parallel;

- sequentially;

- combined.

Let's take a look at each of the methods mentioned.

Water heater connection diagram

Previously, we talked about how to properly connect a water heater; in addition to this article, we advise you to read this information and read about it here

Method one. Parallel connection

This connection method is carried out in accordance with the following requirements.

- The voltage both in the electrical network and in all individual elements must be the same.

- To determine the total power of an electric water heater, it is necessary to sum up the powers of all existing elements.

- If for some reason one of the heating elements fails, then the entire circuit will still function. In this case, the only thing that needs to be done is to replace the failed heating element.

Note! To determine the total power of the network, you need to divide the voltage by the total resistance of the network. And the total resistance, in turn, is determined by the traditional formula used when connecting individual resistances in parallel

Method two. Serial connection

The next method, which consists of a serial connection, operates according to the following principles.

- If one of the heating elements fails, the functioning of the entire network will be interrupted.

- In order to determine the total resistance, it will be necessary to add up all the resistances present in the network.

- Finally, the total voltage cannot in any way exceed the total voltage of all heating elements.

Note! To determine the total power of the network, you need to divide the voltage by the total resistance of the network. And the total resistance, in turn, is determined by the traditional formula used when connecting individual resistances in series

Method three. Combined connection

According to this diagram, different connection methods must be used in several sections of the circuit. Often, a combined technique is advisable in cases where it is not possible to purchase heating elements for water heaters of the required power. Therefore, the required value is achieved by combining parallel and serial connections.

Steps and rules for installing a heating element in a battery with your own hands

How to install a heating element in a cast iron battery will not cause problems even for a beginner. The only thing you need to do is follow the instructions and follow some safety rules:

- First of all, you need to stop the water supply to the cast iron radiator and drain it from the system.

- The lower plug is removed and the heating element is installed in the radiator instead.

- After tightening the plug, the electronics are installed and water is reintroduced into the system to check the tightness of the structure.

Basic safety requirements:

- Heating elements cannot be used if there is no high-quality ventilation in the room. Like any electrical appliances, they burn air, which needs to be taken into account, especially in small enclosed spaces.

- There should be no easily flammable elements near the device connected to the network.

- Before installing and connecting the heating element into a cast iron battery with your own hands, you need to make sure the quality of the electrical wiring and its ability to withstand additional load.

- Under no circumstances should you dry clothes or shoes on a radiator with a heating element.

Otherwise, this is an excellent way to additionally heat an apartment in conditions of unstable heat supply. If you need to heat your house with cast iron batteries with heating elements, then you need to make very accurate calculations regarding their power and quantity. Often, it is better to place the heating element directly into the boiler to increase the heat transfer of the entire heating circuit.

Modern electric heating elements are heating elements equipped with precise and sensitive electronics that help create the necessary microclimate in the room.

Today there are a large number of electric tubular electric heaters for heating on the market. The models differ in appearance, power, and degree of protection of the outer shell. But the principle of their operation has not changed practically since the middle of the 20th century.

Inside a metal tube with good thermal conductivity characteristics there is a wire (nichrome), twisted in a spiral and a coolant (periclase). Current is supplied to this element and the wire heats up.

It is used as the main component in many household appliances:

- washing machine;

- Dishwasher;

- boiler;

- electric kettle and many others.

This system gives the owner a number of opportunities:

- Maintaining a comfortable temperature at any time of the year. This is especially convenient in the fall before the start of the heating season or in the spring after turning off the central heating;

- Organization of autonomous heating using a ready-made central heating system;

- Use for emergency heating of liquid in case of accidents during cold periods;

- Saving money on air heating due to high efficiency.

However, heating by direct convection has also not been canceled, so the heating tube is actively used in convectors, heat curtains or guns, and so on.

TOP 10: Nibe BU – 500.8

Application

This type of heat accumulator is used for heating boilers with different heat sources, be it a heat pump or a boiler, a solar collector or another, and also, as an alternative supplier, effective when the centralized supply is turned off.

Important: when operating with boilers using solid fuel, overheating of heat accumulators is eliminated, the efficiency increases and the service life of the boiler equipment is extended. Additionally, it is possible to reduce the frequency of loading it with fuel

Peculiarities

For this heat accumulator model they are as follows:

- attractive design;

- effective polystyrene foam thermal insulation up to 140 mm thick. It was easy to remove it in order to reduce the size of the device if it was impossible to pass through doorways. It is similar in appearance to molded panels, the outer side of which is covered with white PVC;

- allows connection of more than one electric heater;

- use as an alternative source, in the absence of centralized heating;

- the ability to consume cheap energy (night tariff) when working with two-tariff meters and electric boilers;

- the presence of additional coils for individual modifications installed in the lower part. Thanks to them, you can connect additional heat sources;

- there are flanges for connecting heating elements and a thermometer;

- the ability to distribute the coolant along the entire height of the device, thanks to the vertical bar available at the inlet of the heat storage tank (on the left);

- suitability for organizing the most complex heating systems, including those for which the heat load is quite large.

Technical indicators

- Type – floor;

- Tank capacity - 500 liters;

- The maximum pressure in the external tank is 6 bar;

- Maximum heating temperature - 95 Cº;

- Device weight – 106 kg;

- Diameter – 750 mm;

- Height – 1757 mm.

Buy

Types of heating elements with thermostat

You need to understand that when current is applied to the coil inside the tube, it immediately begins to heat up and cannot turn off on its own. The thermostat monitors the media parameters, turning off the power when the required temperature is reached.

This saves electricity costs and extends the life of the heating element. In this case, there is no connection between the type of heating element and the manufacturer of the thermostat; these two components are packaged together based on economic feasibility.

Three types of heating elements are used for heating.

Tubular electric heater

The most common type, which is found almost everywhere where it is necessary to heat a liquid or the surrounding space.

Peculiarities

The outer tube can be coated with a special composition to resist corrosion and have a bizarre shape. It is possible to select a heating element to suit any request.

Specifications:

- tube diameter from 6 to 20 millimeters;

- length ranges from 0.2 meters to 6;

- metal workmanship:

- steel;

- stainless steel;

- titanium;

- almost any configuration, power and performance, selected by the buyer individually.

- high efficiency (about 98%);

- use without additional projects and permits;

- affordable price.

Advantages and disadvantages

The advantages include:

There was also some negativity:

- high cost of heating when using a heating element as the main heater;

- relatively short lifespan;

- the formation of an electromagnetic field that negatively affects human health.

Finned heating element electric heaters

Another type that is used to heat air or gas.

Peculiarities

Metal ribs are attached to a smooth tube, which are located perpendicular to the surface of the heating element. The easiest way to make such a design feature is from a metal strip, which is attached to the base with special nuts.

A heating tube of this shape allows you to remove more heat from the surface; it is often used with a fan that forces air passing through the heating elements.

Advantages and disadvantages

The pros and cons of the device are the same as in the previous version, except that the price is slightly higher. But the efficiency of fins in heating air pays for the costs.

Rules for choosing a heating element with a thermostat

The diversity on the market makes it difficult for the buyer to choose, so you need to decide in advance on the characteristics, appearance, and connection method.

A few features of the devices that you should pay attention to when purchasing:

- The diameter of a specialized hole in the radiator. Not every model will fit the heating device. This parameter needs to be known in advance;

- Thermostat quality. Ideally, a small control device should have a turbo mode for emergency heating and an economy mode, which prevents the system from defrosting. But a simple sensor with a temperature scale will do the job just fine;

- Heating element power. It is a generally accepted fact that 1 kilowatt is required per 10 square meters of room. If oil or antifreeze is used as a coolant, then a coefficient of 1.5 is applied, that is, for the same size of heated space, the heating element must have a power of at least 1.5 kilowatts;

- Metal tube. Titanium is an ideal and durable option, but extremely expensive. Regular or stainless steel is most often used. It’s not worth purchasing a Chinese heating element, because the thickness of the metal will cause it to burn out in a short time;

- Type. Based on the required power and heating method, you need to decide on the variety. The features of each are described above;

- Additional options. Shutting off when overheating will avoid many troubles. After all, even in a radiator filled with liquid, there are air pockets that cause the tube to heat up much faster.

TOP 7: HAJDU AQ PT 1000 C

Description

The buffer design, in addition to storing excess heat generated by a solid fuel boiler or any other alternative energy source, can redirect it to a heat accumulator.

Their advantage is that they supply practically free heat all year round, even with little lighting. Even in cloudy weather, the heating system can receive tens of kilowatts of energy from them.

Design

Inside the Hajdu AQ PT 1000 C tank there is a heat exchanger in the form of a spiral. Its area is 4.2 square meters. The coolant heated by the sun's rays, flowing through the coil, gives off its heat, which is directed to the heating system for heating.

The dimensions of the device allow it to function in tandem with a solid fuel boiler, whose power is 25-35 kW.

Important: the system that ensures the accumulation of heat by a buffer capacity is only capable of functioning in a heating system with a forced cycle, and is not suitable for a gravity system. The designers of the Hoidu brand did not limit themselves to the described function of the device, i.e.

the ability to accumulate heat. Therefore, they provided a technological hole that makes it possible to install 2, 3, 6, 9 - kilowatt heating elements. The importance of this solution is the ability to increase the time between downloads. This was appreciated by those living in country cottages and dachas

The designers of the Hoidu brand did not limit themselves to the described function of the device, i.e. the ability to accumulate heat. Therefore, they provided a technological hole that makes it possible to install 2, 3, 6, 9 - kilowatt heating elements

The importance of this solution is the ability to increase the time between downloads. This was appreciated by those living in country cottages and dachas

We recommend:

- Portable phone chargers: advantages, features, price - TOP 7

- Thermal accumulators: purpose, features, price - TOP-6

- TOP 6: inexpensive solar collectors for heating and heating swimming pools, prices and where to buy

Now they can load cheap heat, i.e. load the energy storage device at a discounted rate. There is no need to insert an electric boiler into the heating system, because the heating elements heat the storage tank directly, releasing the heat accumulated during the night into the system during the day.

Inner surface

On the inside, the walls do not have an enamel coating, like boilers with indirectly heated water heaters, so heat accumulators are not recommended for use in hot water supply.

Buy

| Where can I buy | Price in rubles |

| https://avangardteplo.ru/products/name/teplonakopitelj_hajdu_aq_pt_1000_c?_openstat=bWFya2V0LnlhbmRleC5ydTv/ | 40030 |

| https://xn—-7sbcqc4aneonsmco5krb.xn--p1ai/products/bufer-emkost-hajdu-aq-pt-1000-c | on call |

| https://vsegdateplo.ru/vodonagrevateli/teploakkumulyatory/hajdu/hajdu-aq-pt-1000-c-bez-izolyatsii / | 42725 |

| https://nasos-kotel.ru/bufernyy-nakopitel-hajdu-aq-pt-1000-c/ | 40030 |

| https://mrklimat.ru/teploakkumulyatory/teploakkumulyator-hajdu-aq-pt-1000-c.html | 40030 |

Installation features

Installation is not difficult at all. The heating element is mounted in heating radiators as follows:

- the equipment is turned on outside the radiator for a short time to check its functionality;

- water is drained from the system;

- a hole opens for the heating element, it is placed there and secured;

- the system is filled with water, after which voltage is applied to the tubular heater.

It is worth paying attention to the following nuances:

- If the product documents indicate the need for grounding, then this is necessary for long-term operation. Otherwise, the service life will be significantly shorter;

- You cannot wet a heated heating element with water; an explosion and destruction of the outer shell are practically guaranteed. Therefore, the water level must be monitored before power is supplied.

The air convector and other devices are simply connected to a grounded network. The only limitation is the wire of the required cross-section.

A hole for the heating element opens and it is placed there and secured.

Operating rules

A few simple rules for operation and maintenance will extend the life of the heating element and make its operation more efficient. Here they are:

- If water is used as a coolant, it must be distilled. This will protect you from scale;

- Frequent switching on and off leads to a decrease in service life, so the thermostat must be adjusted accordingly. The minimum difference in water temperature should be at least 5 degrees;

- It is mandatory to use an emergency power cut-off system. This way you can protect other household appliances in the event of a serious breakdown in the heating element;

- It is necessary to deal with voltage surges using a stabilizer or an uninterruptible power supply;

- The appearance of static electricity on the surface of the radiator indicates depressurization of the tube. The heating element must be turned off and removed, otherwise a short circuit is possible, and this means a higher level of problems or material costs.

Failed heating element

Possible faults

According to experts, the service life of heating elements in boilers is approximately 5 years. Most often, the most common cause of equipment failure is hard water. To extend the service life of the device, regular preventive maintenance is needed, which consists of cleaning the anode and the heating element itself from any scale that has appeared.

The main sign that the heating element is broken is a lack of heating and automatic protection is triggered. There are several options for checking an element for its functionality:

- Using a simple light bulb. To do this, you need to assemble a serial network, which consists of a light bulb and a heating element connected to electricity. If the light is on, then everything is fine with the heating element and there is no need to replace it.

- Using a tester, you need to determine the resistance of the heating element. If the resistance is zero, then the heating element must be changed.

Replacement of elements must be done with devices that fully correspond to the boiler capacity. The steps in this case are as follows:

- First you need to turn off the power and water supply. Afterwards, the liquid is drained from the storage container and the top cover of the device is removed.

- Then you need to check the input terminals using a phase meter for the absence of current.

- The bolts that directly secure the heating element are unscrewed, then the wiring cable is removed.

- It is imperative to determine the condition of the contacts of the new heating element. They must be dry.

- Then, simultaneously with the heating element, the anode, which is intended for protection, is also replaced.

- When installing a new element, only high quality seals are used without any defects.

- Installation is performed in the same way, but in reverse order.

- At the end, the storage tank must be filled with water, and the remaining air must be drained from the tap, which is designed to supply hot water. Afterwards, all that remains is to connect the water heater to the electrical network and check its functionality.

average cost

Offers taken from online stores in Moscow:

- TEN1500W made in Slovakia. Includes thermostat, branded fittings, power 1.5 kilowatts. Cost 1930 rubles;

- Heating element with thermostat, made in Russia:

- power 4 kW – 1500 rubles;

- power 3 kW – 1350 rubles;

- power 1.5 kW – 990 rubles;

Devices made in China can be found for 500–600 rubles, but their quality is highly questionable. And a heating element with a price of 1000 rubles (or so) can be of high quality, provided it is produced in the Russian Federation.

TEN1500W made in Slovakia

Blitz tips

Here are a few recommendations from professionals that will help extend the life of your heating element or avoid mistakes when installing it. So:

- A good place to install a heating element in a radiator is the bottom. This way you can avoid possible air pockets, and therefore overheating;

- When purchasing a heating element, pay attention to the manufacturer’s recommendations for additional sealing;

- When securing the wires to the terminals, you must not apply too much force , otherwise the nut will burst or the tube’s tightness will be compromised;

- When using tap water as a coolant, the heating tube must be removed every 3 months and the deposits must be cleaned off non-mechanically.

A heating element is an electric liquid heater in the form of a metal tube, inside of which there is a spiral. There are many designs and varieties. Heaters are manufactured for both large and small industries.

These heaters are widely installed, for example, in electric boilers and electric boilers, and therefore are also produced by well-known manufacturers.

But in any market you can find heating elements intended for installation in heating radiators. These devices are often manufactured in Poland, Ukraine, and China. They can be equipped with built-in temperature sensors, i.e. work in semi-automatic mode, monitoring the degree of heating.

Based on such electric heaters, you can easily create a heating device with your own hands. This is what home craftsmen use, constructing the simplest heating and, as they think, “saving” a fair amount of money.

But is it really profitable to use heating elements? Where and in what situations are these electric water heaters usually used? How to install and use heating elements...

How big is the benefit from heating elements?

If you have an old battery, then why not use a heating element to turn it into a heating system for a small utility room - a chicken coop, a workshop, a garage...

There are even myths that heating with heaters is beneficial. But “dreams are shattered by harsh reality” - heating with electricity is the most expensive. Since the most expensive energy carrier is used.

Metal materials used for heating

- Nichrome: the vast majority consists of nichrome 79/21 (79% nickel, 21% chromium), for example Fastov heating elements, are produced in the form of wire, tape or strip. It is a first-class material because it has a relatively high resistance and forms a layer of chromium oxide when heated for the first time. The material under this layer does not oxidize and is protected from destruction and burnout.

- Metal Resistance: The metal resistance of heating elements can be in the form of wire or tape, straight or spiral. They are used in general heating devices such as heating elements, toasters, hair dryers, furnaces for industrial heating, floor heating, roof heating (to prevent icicles from forming), trail heating (to melt snow and ice), dryers, etc.

The most common materials used for the manufacture of heating elements in Fastov at Elektronagrevatel ODO:

- Nichrome - wire and strips;

- Cupronickel (copper-nickel) - alloys for heating at low temperatures.